primary mover hydraulic pump in stock

We provide a variety of high-quality single and double-acting 12V hydraulic pumps. Choose from a selection of poly or steel reservoir sizing options. Our pumps are ideal for application with Dump Trailers and more. Browse our shop today and find the right hydraulic pump for your hydraulic circuit needs!

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RVs, boat lifts, some liftgates, tow trucks, wreckers, car haulers, agriculture equipment, snow plow equipment, and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to ourDeluxe Kit. Select theDeluxe Kitoption to include a hydraulic hose and fittings kit with your purchase.

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RV"s, boat lifts, some liftgates, tow trucks, wreckers, car haulers, car lifts, agriculture equipment, snow plow equipment and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to ourDeluxe Kit. Select theDeluxe Kitoption to include a hydraulic hose and fittings kit with your purchase.

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RVs, boat lifts, some liftgates, tow trucks, wreckers, car haulers, agriculture equipment, snow plow equipment, and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to ourDeluxe Kit. Select theDeluxe Kitoption to include a hydraulic hose and fittings kit with your purchase.

Now you can hydraulically raise and lower your original landing gear. Our new pre-assembled control box containing our pump, motor, hoses and fittings, attaches easily to your trailer"s frame.

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RV"s, boat lifts, some liftgates, tow trucks, wreckers, car haulers, agriculture equipment, snow plow equipment and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to our Deluxe Kit. Select the Deluxe Kit option to include a hydraulic hose and fittings kit with your purchase.

We offer the ultimate dump bed kits available in the dump trailer & pickup market. Our dump bed kits come complete with the Power Hoist scissor lift system and hydraulic pump backed by a 3-year manufacturer warranty. Shop for dump bed kits and hydraulic accessories in our online store today!

Do your Auxiliary Trailer Batteries need some love? Save 25% on an 8 Amp Panel Mount Battery Charger & Tester today thru Valentine"s Day with purchase of any of our Single or Double-Acting Hydraulic Pumps. Redeemable only athttp://PrimaryMover.com. Discount Code: VDAY25

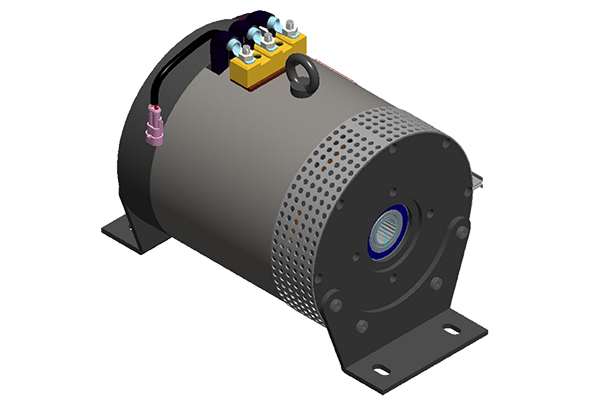

In application areas as diverse as industrial, mobile, marine, machine tools, agricultural equipment and offshore installations, machinery that needs to generate high forces in a compact package will typically rely on hydraulic drive systems. At the heart of that power transmission system is the hydraulic pump, in turn driven by a prime mover which might be a motor (electric, hydraulic or air) or an engine.

Correct coupling of the hydraulic pump to the prime mover is key to the performance of the entire drive system. Improper pump installation can lead to premature pump failure, increased maintenance costs and reduced productivity. And correct pump shaft alignment is required to prevent unnecessary wear and damage to the pump shaft seal and bearing.

Hydraulic pump adapters are specially designed to provide close coupling between the pump and the prime mover, ensuring optimised performance of the drive system, minimised wear, reduced maintenance performance and long service life.

Because the overall system design – from pumps and motors to gearboxes, clutches, couplings, bellhousings, flanges, seals, coolers and more – and the specific performance requirements are different for every system, jbj Techniques does not rely simply on a catalogue of off-the-shelf components, but also manufactures and integrates all of the diverse components of a drivetrain to provide a tailored solution. These means the perfect system can be built from an extensive range of components available from stock, or can be manufactured to order.

Within this capability, jbj Techniques manufactures bespoke hydraulic adapters. Each consists of a bellhousing and flexible drive coupling that are fully machined to suit the driving and driven components. These can be to suit either shaft to shaft, flange (flywheel) to shaft or even flange to flange connections.

For connecting the hydraulic pump to an electric motor, jbj’s comprehensive range of bellhousings can accommodate motors with IEC frame sizes from D56 to D400 (0.06-750kW) and can be compatible with electric motor B5 or B14 flange configurations. There is also a complete range of mountings to suit NEMA and imperial frame motors with C face or D flange fitments.

Hydraulic adapters can also be manufactured to couple pumps to electric motors in hazardous area applications, meeting ATEX standards. Couplings supplied for these applications provide an anti-static and flameproof drive which meet zone 1 area requirements, conforming to all of the above standards. Also available are spider and gear couplings which are certified to zone 2 standards.

An area of coupling specification in hazardous area applications that needs to be considered is possible high temperatures generated by a piston pump shaft seal when the pump is cycling between different pressures. This process will often take the seal temperature beyond the levels required by the relevant ATEX standards.

To address this issue jbj Techniques offers the wet mount series of bellhousings. This specially designed assembly allows a pumped cooling flow to be passed over the seal face and through an auxiliary cooler. This in turn reduces the seal face temperature which can be maintained at an acceptable level.

In addition to hydraulic adapters for electric motors, jbj Techniques is also able to provide a complete range of bellhousings and couplings for both petrol and diesel engines. Diesel engine dimensions from SAE 6 to SAE 0 can be accommodated, and couplings to complete the assembly are available in either torsionally flexible or torsionally rigid design.

For hydraulic pumps to be mounted to engines that do not conform to SAE dimensions, JBJ offers a full range of assembly parts. All bellhousings within this range can be finished machined to accept any piston, vane or gear pump interfaces.

For petrol engines, adaptors have been developed to suit Honda, Briggs and Stratton, Kawasaki, Kubota, Hatz, Mag, Robin, Suzuki and Winsconsin engines, to name but a few. All adaptors can be finished to accept most hydraulic pumps. Adaptors to suit engine crankshaft drives and for vertical mounting are available on request.

For all of its hydraulic adapters, jbj’s in-house design team and manufacturing facility provide tailored solutions for customer applications at competitive pricing and with on-time deliveries. jbj Techniques can advise on the correct installation of hydraulic pumps the application and can specify complete driveline systems from its extensive range of components – available from stock or manufactured to order, whether simple or complex, standard or bespoke.

A complete hydraulic system must include an initial energy source. This energy source is referred to as the prime mover, and it must be considered when maintaining or repairing any hydraulic system. The prime mover could be as simple as a manually operated lever on a jack where the input energy is human effort, or it could be a massive diesel engine on earth-moving equipment or on a merchant marine vessel. In either case, there must be energy entering the system to push the fluid doing work. In mobile equipment, the prime mover is often an internal combustion engine. Hydraulic pumps are connected to the engines and convert the mechanical energy at the crank shaft to hydraulic energy.

Methods for connecting a pump to an internal combustion engine vary with each application, but there are some common considerations. The pump shaft and the shaft to which it is connected must be properly aligned to prevent damage. With smaller engines, there are mounting adapters where one side is bolted directly onto the engine face and the other side is machined to accept the pump with an appropriate flexible coupling. These are designed to keep the shafts properly aligned.

If a pump mount is not available, a foot mount can be used with a flexible coupling or a drive shaft. If a drive shaft is used, it is critical that the shaft on the prime mover and the shaft on the pump be properly aligned. A drive shaft uses a set of Cardan universal joints (figure 1) to couple and align the shaft of the prime mover with the shaft of the pump. The yokes of the Cardan joints must be in phase and the drive and driven shafts must be parallel to prevent vibration.

Sometimes the drive shaft is connected directly to the harmonic balancer on the vehicle engine through a modified radiator. The angle of the drive shaft from the pump to the harmonic balancer needs to be considered. The maximum angle varies with the engine rpm.

If a C-face motor and adapter are not available or there are other physical constraints, a foot mount adapter can be used. It is critical that the shafts of the pump and motor are properly aligned.

When the prime mover is an internal combustion engine that is the power source for the entire vehicle, the hydraulic system may be an auxiliary function and will be connected to the prime mover through a power take-off (PTO) attached to the vehicle transmission. The PTO is a gearbox (figure 4) in which the shaft speed (rpm) may be different than the engine rpm. The power potential of the PTO is dependent on its gear ratio and the torque rating of the shaft.

All gearboxes, whether used to increase or decrease speed, have some degree of mechanical inefficiency. This inefficiency will consume some of the power from the prime mover and must be understood when gearing is used.

For example, a hydraulic system requires 45 lpm at 10 MPa (12 gpm at 1,450 psi). The hydraulic system operates at 85% overall efficiency requiring about 9 kW (12 hp). The truck engine can easily supply this much power at 900 rpm. However, the pump requires 1,800 rpm to supply the flow. Raising the engine rpm to 1,800 would provide the necessary flow but would waste a lot of energy. By using a PTO with a step up gear ratio of 2:1, the engine can run at 900 rpm while the PTO shaft would drive the pump at 1,800 rpm. If the PTO has a mechanical efficiency of 90%, the power draw from the engine would have to increase to 10 kW (13 hp).

8613371530291

8613371530291