replacing hydraulic pump on log splitter quotation

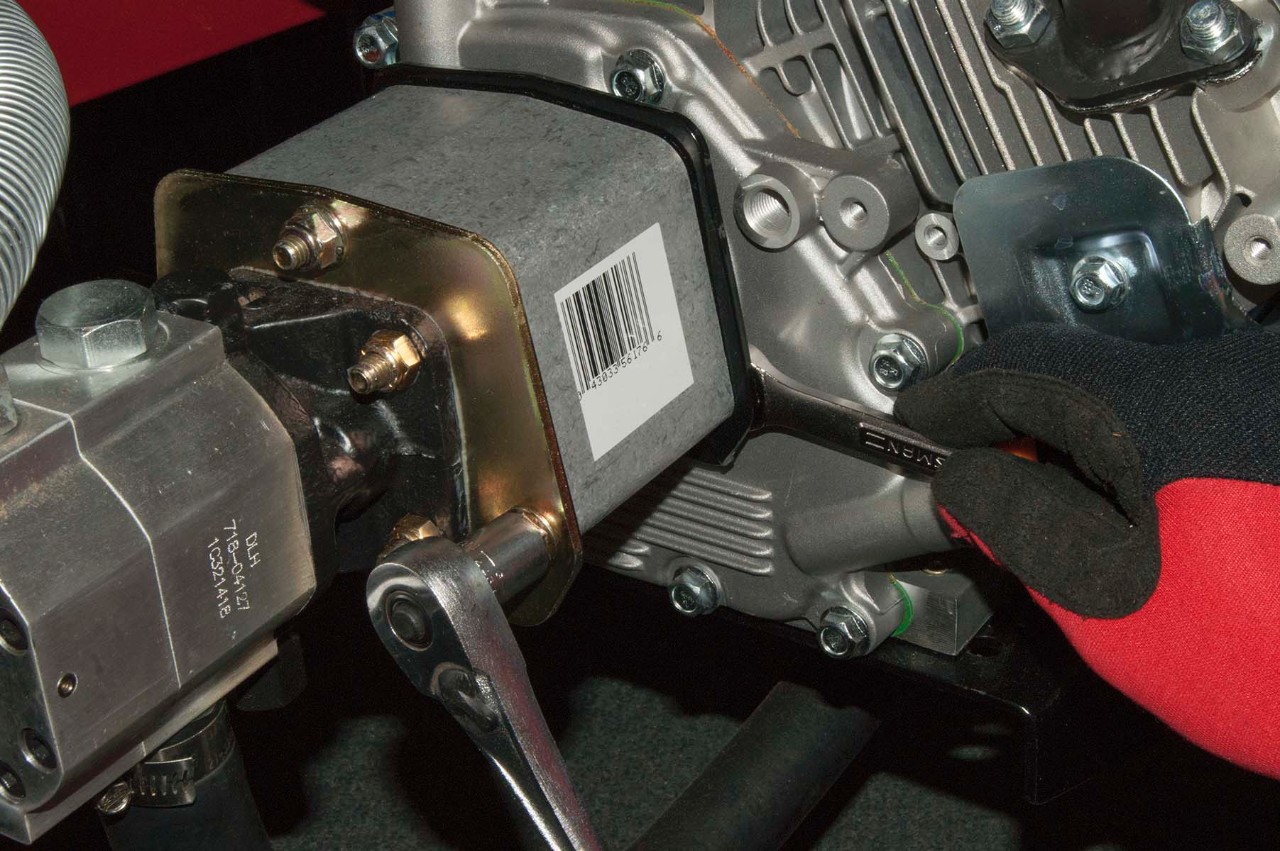

The 257-011, by MTE, is manufactured in the USA. It is commonly used by individuals building their own log splitter. It may also be used as a replacement pump for major log splitter manufacturers like MTD, Timberwolf, Champion, Ariens, and Swisher.

it appears to be a Vickers V series vane pump. They had a few sizes of housings and then various vane and ring cartridge assembly that would go inside of housing to get different pump displacements. Most of them were rated at 1200 RPM because that was a common electric motor speed for industrial equipment with about 2000 RPM Max. The later ones could go I think up to 3000 RPM. The earlier ones were also pressure limited to about 2000 PSI. later ones if they had the smaller cartridge sizes for their housing size were rated up to 3000 PSI if they had the largest cartridge in their housing size than they were de rated on pressure

more importantly it"s a single stage pump, so a pump large enough to give you speed will stall the engine at high load pressure The pump small enough for the engine to be able to turn it at full pressure is going to give you terribly slow speed. I would get it running on the existing system but I wouldn"t put much effort into the pump Depending on if you keep the splitter or not look at spending 150 bucks and put on a two-stage one later on

Beiler Hydraulics offers all the components needed to build your own log splitter as well as supply manufacturers of log splitters. We stock the log splitter two-stage pumps, log splitter valves, and a wide variety of hydraulic cylinders ranging from light duty tie-rod cylinders to heavy duty welded cylinders. So whether you are replacing a part on your log splitter or want a new set up, Beiler Hydraulics can help. Please contact our professional sales team for your specific log splitter needs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Hydraulic pumps are used in almost every type of production system, from plastic mold injection machines to the common conveyor belt. With proper maintenance, most hydraulic pumps will operate smoothly for years, but even with proper maintenance, the pressure inside these devices will eventually cause failures that need to be addressed as soon as possible. The way to avoid total system failure is by monitoring your pumps and looking for the following warning signs.

Liquids should remain in the tubes that were designed for them. If you notice any liquids anywhere else inside the pump, you have a problem. A line may have a break, or a seal may be loose. No matter what the case, an interior leak means your pump has gone bad.

Have you discovered liquid on the outside of your pump? This means either an interior leak has worsened or there could be a leak on the HPU that the pump is mounted to. This leakage results in reduced pressure in the system and immediate action is required to repair and salvage the pump. Leaking reduces the pressure, which increases the temperature of the system. This affects the viscosity of the oil, reducing the pressure in the system.

Increased fluid temperatures can be the result of the system’s inability to dissipate heat. In most systems, heat within the fluid dissipates through the fluid in the reservoir and a heat exchanger. Heat can cause the fluid to thin, which prevents proper lubrication and may cause pump leaks, reducing pump efficiency and system performance.

Hydraulic fluid that has a milky appearance is a clear indication of water contamination. One source is condensation buildup on the walls of the fluid reservoir as a result of temperature changes from warm days to cool nights. Water contamination can also corrode the pump and other critical components, which can shorten component life. Periodic fluid changes and draining of the water from the reservoir ensure water removal from the system.

If your seals continuously leak and fail, your pump may be operating with a bent or misaligned rod. Depending on the extent of the damage, a skilled machine shop may be able to repair your existing equipment, allowing you to get the most out of your equipment and minimizing costs.

System moving slow? If performance decreases, this could be a sign that your hydraulic pump is starting to go bad or your system is designed incorrectly. This lack of efficiency indicates a lack of flow.

You never want to let your system run if your pump is suffering from any of these problems listed above because it means your system is on the verge of experiencing pump failure. These symptoms are an indicator that something could be seriously wrong and could result in some expensive damage to your hydraulic system. The hydraulic experts at Pneumatic And Hydraulic Company can help in identifying the warning signs and replacing your pump before the damage becomes too costly.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

The mounting flange on this pump has a 4-bolt, 2 inches on center, mounting pattern. The bolt circle is 2.85" and the bolt hole diameter is M8 (.344").

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Response and capability to mobilize the right tools and technicians are critical to operators , Gulf vessel ’ engine capabilities are unmatched. As an independent service provider, we routinely work on any and all major makes of larger bore, 2-stroke and 4-stroke, propulsion, auxiliary, stationary power diesel, gas and dual fuel engines. Performing routine overhauls and troubleshooting and diagnosing diesel engine casualties is what we do every day. We also handle new installations and retrofits of engines.

Gulf vessel supports customers with one off maintenance and repair requirements but also offers flexible, planned maintenance agreements. In these arrangements, Gulf vessel works with end customers to define specifically what the scope and periodicity of the support will entail. Gulf vessel can provide full turn-key project support where we supply all of the required spares and perform all maintenance required on the engine. We can also accommodate scenarios where the customer provides parts and components of the required service while Gulf vessel delivers against a more tightly and well-defined scope.

From an efficiency perspective and maintenance programs with operators either with multiple engines of the same execution or those who cannot afford the downtime of component overhaul on site. In these cases, an extra set of major components that generally includes: Cylinder Heads, Fuel Pumps, fuel injectors, cylinder liners, Pistons is purchased for rotation across engines. Customers often also include turbochargers, governors and air coolers. Having a swing set allows component overhaul to be completed in the workshop on a non-rush basis allowing work to be done at a lower price. Also, having a fully overhauled set delivered to the engine eliminates inefficient, on-site overhaul and speeds up the overhaul.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291