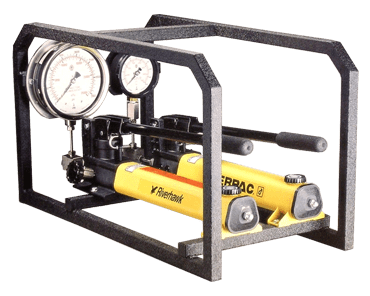

riverhawk hydraulic pump kit brands

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

First and foremost, you should consider the desired pressure rating that you need for your application. You will want to review the job with your engineering team and field service personnel to help determine the appropriate pressure output that is needed for your hydraulic equipment.

Manual pumps typically come in two pressure ranges: a low-pressure range and a high-pressure range. Low pressure pumps are rated for 10,000 psi or lower and are used to supply hydraulic pressure to a variety of hydraulic tooling. High pressurehydraulicpumps can reach operational pressures of up to 40,000 psi and are commonly used for dilation during the installation or removal of a keyless tapered coupling hub.

Air driven pumps can be preset to a desired maximum pressure rating at the factory, and traditionally have a maximum operational pressure of 22,000 – 40,000 psi.Air operated hydraulic pumpsare commonly used for tensioning bolts and nuts during the installation of compressors and other machinery.

There will be times where you will find yourself in need of a varying supply of hydraulic pressure to your equipment or tooling in order to finish a job. Determining the type of supply that is needed will help you select the appropriate pump for the job.

One of the main differences between a manual pump and an air driven pump is the quantity of hydraulic pressure that is supplied to your tooling or equipment.

A Riverhawk hydraulic pusher mated with a low-pressure pump allows the operator to accurately install the coupling to the desired position along the tapered shaft while maintaining control of the hydraulic pressure feeding to the pusher tool.

Anair powered hydraulic pumpconstantly supplies a set amount of hydraulic pressure so long as the pump is actuated. This makes the pump ideal for operating multiple pieces of equipment at once without requiring constant mechanical input from the operator. An example of this would be the installation of a casing on a compressor.

The casing requires multiple studs and nuts be properly and evenly tightened, which can be difficult to achieve through mechanical torquing methods. By utilizing an air driven pump and multiple Riverhawk hydraulic nuts daisy-chained in succession, hydraulic pressure is applied evenly to each of the nuts. This allows for even load distribution to each of the studs, thus eliminating the concerns of excessive or erratic bolt loads.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

When it comes to portable hydraulic air-driven pumps, Riverhawk"s offering makes for an excellent choice. Their pumps supply instant, reliable hydraulic power. The incoming air is filtered before intake.

The pumps feature an air regulator which ensures that the system can maintain any desired output pressure within the units total range. Swivel fittings facilitate easy and safe connection of the equipment to be pressurized.

![]()

Riverhawk designs and manufactures hydraulically tensioned studs and nuts, tensioning tools, and plug and ring gauges. We also provide source inspections and training seminars.

At Riverhawk, we meet the daily challenges of the rotation equipment industry by offering auxiliary equipment such as air driven and manual hydraulic pressure kits and pusher/pullers for the installation of coupling hubs, thrust discs, and compressor wheels.

Our equipment is proudly supplied to the top OEMs and end users of the turbomachinery industry. No matter what your needs, Riverhawk’s team of engineers is ready to assist you. Contact us for more information on how we can provide the products and services you need.

Riverhawk is a member of the American Petroleum Institute (API) and sits on the coupling committee of the American Gear Manufacturers Association (AGMA).

![]()

ENERPAC HYDRAULIC HAND PUMPS P391 & P2282 W/ RIVERHAWK FRAME MP-0273 & HARD CASE. ENERPAC HYDRAULIC HAND PUMPS ASSEMBLY CONSISTS OF: QTY (1) ENERPAC #P391 MAX: 10,000 PSI / 700 BAR & QTY (1) ENERPAC #P2282 MAX: 40,000 PSI / 2800 BAR W/ (2) GAUGES, FITTINGS, QTY (2) HOSES & (1) ADAPTER PART & W/ RIVERHAWK FRAME MODEL#: MP-0273 & LARGE RIVERHAWK STORAGE CASE & SMALLER CARRYING CASE W/ MANUAL ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ITEM IS UNUSED - SOLD AS IS INTERNATIONAL SHIPPING: Shipping will be arranged by a local freight forwarder and based on 2 service options: DAP – Door to door excluding duty and tax to most cities CIP – Door to Airport Import licenses and other local customs requirements must be accessed by the buyer prior to purchase. Seller will not be held responsible for any customs issues once order arrives at the destination. Order must be fully custom cleared to allow delivery to the door. Terms and conditions: EXPORT COMPLIANCE These Terms of Use involve the sale of Assets which are subject to U.S. government export control laws and regulations and may, in certain cases, also be subject to foreign export laws and regulations. In order to ensure compliance with such laws and regulations, Buyer agrees as follows: Buyer acknowledges that its receipt and use of the Assets are subject to U.S. export control laws and regulations and may be subject to other foreign export laws and regulations. Buyer is not a citizen, national, permanent resident of, or incorporated or organized to do business in, and is not under the control of, the governments of Cuba, Iran, North Korea, Sudan or Syria. Buyer will not sell, transfer or otherwise re-export the Assets, directly or indirectly, to the above mentioned countries or to citizens, nationals or permanent residents of those countries. Buyer is eligible to receive exports of the Assets in that Buyer is not listed on any of OFAC’s list of Specially Designated Nationals or on the U.S. Department of Commerce’s Table of Denial Orders or Entity List or Unverified List. Buyer will not sell, transfer or otherwise re-export the Assets, directly or indirectly, to any ineligible persons. Buyer will not use the Assets and will not enable the Assets to be used for any purposes prohibited by U.S. export laws and regulations, including the development, design, manufacture or production of nuclear, missile, chemical and biological weapons and technology. Buyer will not export or import the Assets in contravention of any applicable foreign export or import laws. ***A signed confirmation of above terms must be received prior to shipment***

Condition: New – Open box, Condition: Please allow us time to invoice you. Once purchased, your order will be picked, packed & weighed to provide you with an added shipping rate. If you should receive a message that we do not ship to your state, this is INCORRECT. Please ignore this as we actually ship Worldwide! ***See Item Description Section for Condition Notes***, Brand: ENERPAC, MPN: P391 & P2282, Type: HYDRAULIC HAND PUMP

Char-Lynn Spool Valve Hydraulic Motors Repair Information W Series Geroler Motors with Parking Brake 004 Nut Key Ring, Retaining Bearing Ring, Retaining Ring, Retaining Washer (Thick), Pressure Washer,

RANGE OF HYDRAULIC BOLT TENSIONERS TensionMax The Next Generation of Bolt Tensioners has Arrived Hydratight, one of the world s leading bolt tensioning and joint integrity companies, introduces TensionMax.

M113 VEHICLE FAMILY RUBBER TRACK INSTALLATION INSTRUCTIONS (SPLIT IDLER) 1 # TABLE OF CONTENTS List of parts and tools................................................3 Installation of complete kit...................................................5

APPLICATIONS Process Industry Weak Acids Alkalies Compressed Air Pulp & Paper MODELS ASM - Flanged Connection OPTIONS Control Rods Oil & Gas Water & Waste Pump suction & discharge Sea water Chemical lines

FAG Hydraulic nuts Technical Product Information Contents Application 2 Design 2 Design variants 3 Pressure generators, connectors 4 Dimension tables for FAG hydraulic nuts (metric) 6 Dimension tables

Char-Lynn Hydraulic Motor October, 1997 Repair Information Geroler Motor Two Speed 001 27 Retainer inside bore of valve plate bearingless motors only 4 15 16 3 6 35 Parts Drawing 25 2 2 1 19 17 36 40 47

WHAT YOU DON T KNOW ABOUT ACCUMULATORS CAN KILL YOU! Atlanta (Monroe) GA 770-267-3787 gpm@gpmhydraulic.com www.gpmhydraulic.com What You Don t Know About Hydraulic Accumulators Can Kill You TABLE OF CONTENTS

47 Brakes - Hydraulic Components (Page GR-47) FS III front brake calipers, servicing Front brake caliper piston, removing and installing FN 3 front brake calipers, servicing Front caliper piston, removing

P7100 PUMP INSTALLATION INSTRUCTIONS Diesel Care & Performance Inc Installation Timing Pin Location CAUTION: Before installing the injection pump, be sure that number 1 cylinder is at the Top Dead Center

-J0 REV. 0-0-0 DYNA RIDER FOOTBOARD KIT GENERAL Kit Number 000 Models For model fitment information, see the P&A Retail Catalog or the Parts and Accessories section of www.harley-davidson.com (English

Rexroth Hydraulic Pump A10VO Series User Manual Rexroth Hydraulic pump A10VO Series User Manual Revised 5/1/2009 Page 1 of 12 Functional Purpose This pump is preferred over a fixed displacement (gear)

Char-Lynn Hydraulic Motors April, 1999 Repair Information W Series Geroler Motors 002, 003 W Series Geroler Motors Tools Required 5/16 inch Hex Key Bullet for Shaft Installation - Eaton Tool No. 600633

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

Part#: 013255 Ford F-250 / 350 2-1/2 Coil Kit Ford F-250, F350 2011-2015 Rev.040815 491 W. Garfield Ave., Coldwater, MI 49036. Phone: 517-279-2135 Web/live chat: www.bds-suspension.com. E-mail: tech@bds-suspension.com

92154000 Thank you for choosing Rough Country for your suspension needs. 2011-14 F250 6 RADIUS ARM KIT Rough Country recommends a certified technician installs this system. In addition to these instructions,

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

VERTICAL TURBINE AND PROPELLER PUMPS INTRODUCTION Vertical Turbine and Propeller Pumps Model 7000 Series Turbine Pump Model 800 Series Axial Flow Propeller Pump Model 800 Series Mixed Flow Propeller Pump

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

Table of Contents Overview 1 Pump Disassembly 2 Control Disassembly / Reassembly 7 Pump Reassembly 13 Adjustment Procedures DR Control 19 Adjustment Procedures DRG Control 20 Adjustment Procedures DFR

TELEDYNE CONTINENTAL AIRCRAFT ENGINE SERVICE ULLETIN Compliance Will Enhance Safety SUJECT: PROPELLER STRIKES AND HYDRAULIC LOCKS. CATEGORY 3 S96-11 FAA APPROVED Supersedes S96-11A, S96-11, M84-16 PURPOSE:

Part #: HT-1 1965-82 CORVETTE O-RING CONVERSION front CALIpER REbUILdING TUTORIAL Choosing a Brake Caliper Rebuild Kit Standard Lip Seals vs. O-Ring Seals Lip seal design seals are used on 1965-1982 Corvette

![]()

General InfoFounded in 1993, Riverhawk Company is an engineering and consulting firm that provides hydraulic bolt tensioners, high-temperature envelops, torque blockers, peak shavers, clamp rings, internal shaft clamps, lapping tools and vibration monitoring systems. It serves power generation and petro chemical markets. The company also serves the mining, construction, wind power, nuclear, manufacturing, reciprocating and steel industries. Riverhawk Company also offers manual pump kits, hydraulic fittings, bolt loading calculators and gas turbine hardware systems. It offers various hydraulic pump and accessories, including air-operated pump kits and high-pressure flexible hose assemblies. In addition, the company provides online installation manuals. Located in New Hartford, N.Y., Riverhawk Company organizes various in-house or off-site training seminars on a variety of topics on the installation and operation of products.EmailBBB RatingPayment methodamex, master card, visaAKARiverhawk Corporation

Incorporated in the year 2005, at Ludhiana (Punjab, India), we, “Ranjit Hydraulics Engineers”, are engaged in manufacturing, exporting and supplying Deep Draw Press Machine, Hydraulic Shearing Machine, Hydraulic Press Brake Machine Type Press Machine, C Frame Press Machine, 4 Pillar Press Machine, Workshop Press Machine, Hydraulic Cylinders & Power Packetc. leading organizations engaged in manufacturing and supplying a wide range of Hydraulic Presses (Sheet Metal Machinery).The presses offered by us are manufactured using optimum quality raw material, which is sourced from reliable and authentic vendors of the market. Owing to their features like optimum performance, low maintenance, longer function and easy installation, these presses are widely demanded by customers. Moreover, clients can also avail of these presses in customized forms as per their specific requirements.

ISSUED: 373A4078 Ͳ The Riverhawk Company reserves the right to update this document without dissemination or notice. ThelatestrevisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com.

215ClintonRoad NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 Email:info@riverhawk.com

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

InstructionManualIMͲ364 1.0CautionsandSafetyWarnings WARNING Impropertooluseandthefailuretofollowthecorrectproceduresaretheprimaryroot causesoftoolfailuresandpersonalinjuries.Alackoftrainingorexperiencecanleadto incorrecthardwareinstallationorincorrecttooluse.Onlytrainedoperatorswithcareful, deliberateactionsshouldusehydraulictensioners.ContactRiverhawkCompanywithany trainingneeds. WARNING Riskofhighpressurehydraulicfluidinjection.Riverhawktoolsoperateunderhighpressure. Thoroughlyinspectallhosesandconnectionsfordamageorleakspriortousingthisequipment. CAUTION Personalinjuryandequipmentdamagecanoccuriftheproperhealthandsafetycodesand proceduresarenotfollowed.Contactthesite’shealthandsafetyofficetodetermineall applicablesafetyrulesandregulations. WARNING Theproperpersonalprotectiveequipmentmustbewornatalltimes.Riverhawkrecommends ataminimum,safetyglasses,longsleeveshirt,hardhat,heavyworkgloves,andsteeltoe shoes. CAUTION Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthestud. Threaddamagefrompreviousabusecanleadtofailureofthestudortensioningequipment CAUTION RiverhawkrecommendsthatthetensionershouldbereturnedtoRiverhawkforperiodic inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso recommended.Riverhawkshouldbenotified3Ͳ6monthspriortoaplannedoutagetoschedule aninspectionservice. WARNING Adamagedburstdiscmustbereplacedwithaburstdiscofthesamedesignandpressure rating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferentpressure rating,oraforeignobject.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵͵ͻ

InstructionManualIMͲ364 WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbeinstalled onastudintheflangebeforebleedingandpressurizingthetensioner.Donotusethetensioner atanypressureunlessthetoolisinstalledonastudinaflange. CAUTION Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengaged withthetaperedthreadsofthestud.Properengagementisachievedwhenthepullerscrewis tightinthestudandthetensionerassemblyisfreetoturn. WARNING Thesafetycagemustbeinplaceatalltimes.Whenthetensionerispressurizedhandsmustbe keptoutofdesignatedareastoavoidanypotentialforpersonalinjury. CAUTION Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe stud"sandthepullerscrew"sconicalthreads.Applyalightcoatofcleanturbineoiloraspray lubricanttothepullerscrew.Thisprocedurewilleaseassemblyandassurepositivematingof thethreadsbeforetightening.Donotuse“NeverSeize”ontheconicalthreads. CAUTION Donottightenthenutwhilethetooliscominguptopressure;waituntilpressureisachieved beforeattemptingtotightenthenutwiththespannerring.Ifthetoolisnotproperlyinstalled, thetoolcouldjumpoffthestudwhilecominguptopressure. CAUTION Donotexceedthemaximumpressuremarkedonthetensioner.Excessivepressurecandamage thestudandthetensioner. WARNING FIREHAZARD:DONOTapplyheatwhentensionerisinplace.Personalinjuryorequipment damagemayoccur.UseofanOxyͲAcetylenetorchisnotrecommended. WARNING Donotuseahydraulictensionertoremoveastudwithdamagedconicalthreads.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com Ͷ͵ͻ

InstructionManualIMͲ364 2.0ScopeandGEPartNumberCrossReference Thisdocumentdescribestheproceduretobeusedtoinstallthestudandnutsetssuppliedby theRiverhawkCompanyintheflangesattheGasTurbine/LoadCoupling,Load Coupling/Gearbox,andGearbox/Generatorconnections. ThevariousframeconfigurationscoveredinthismanualarelistedinSections2.1through2.3 withdifferencesasrelatedtoconnectivehardwaredefined.Listedalsoarethepertinent hardwaredrawings(HFͲxxxx).Thesedrawingsaswellastoolingdrawings(HTͲxxxx)formpartof thismanual. 2.16FAGasTurbineto6FAGenerator GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P001 HFͲ0737 359B2521 381A6850P019 HFͲ0737 359B2521 381A6850P020 HFͲ0737 359B2521 The hydraulic tooling used for installation and removal is Riverhawk HTͲ6745 (load coupling) andHTͲ6754(generator). ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto LoadCoupling(1Ͳ1/8”size,Qty27)andLoadCouplingtoGearbox(1Ͳ1/8”size,Qty27)aswell astheGearboxtoGenerator(2”size,Qty18). 2.2Gearboxto6FAGenerator GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P004 HFͲ5204 GE269B8695 ThehydraulictoolingusedforinstallationandremovalisRiverhawkHTͲ6754. ThishardwaredrawingdepictsthecompletestudandnutpackagefortheGearboxto Generator(2”size,Qty18).

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͷ͵ͻ

InstructionManualIMͲ364 2.3HydraulicTooling GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P016 HTͲ6745 GE101B0646 381A6850P017 HTͲ6745 GE101B0646 381A6850P018 HTͲ6754 GE101B0647 381A6850P019 HTͲ6745 GE101B0646 HTͲ6754 GE101B0647 APͲ0532 GE359B2502 381A8650P020 HTͲ6745 GE101B0646 HTͲ6754 GE101B0647 APͲ0532 GE359B2502 3.0QuickChecklist ThefollowingchecklistisintendedasasummaryofthestepsneededtousetheRiverhawkͲ suppliedequipment.Newpersonnelorthoseexperiencedpersonnelwhohavenotusedthe Riverhawkequipmentrecentlyareencouragedtoreadtheentiremanual. EQUIPMENTINSPECTION

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͺ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͻ͵ͻ

Ƒ x Movetothenextstudinthepattern. 4.0GeneralPreparations Readandunderstandallinstructionsbeforeinstallingandtensioningstuds. OperatorsshouldbetrainedorhavepreviousexperienceusingRiverhawktensioning equipment.Trainingwillminimizethechanceofimproperuseoftheequipment. Thehydraulictoolingincludingthehydraulichosesshouldbeinspectedpriortouse.Inspection guidelinesarelistedinthefollowingsubͲsections. Thisequipmentproducesveryhighhydraulicpressuresandveryhighforces.Operatorsmust exercisecautionandweartheappropriatepersonalprotectiveequipmentwhenhandlingand operatingthehydraulictooling. HighͲpressureoilfromthehydraulicpumppressurizesthetensionerwhichgeneratesavery largeforcethatactuallystretchesthestud.Asthestudisstretchedthenutliftsofftheflange. Thenutisthenturnedbyhandusingthesuppliedspannerring.Oncethenutistightagainstthe flange,thepressureinthetensionerisreleased.Thehardwareisnowclampingtheflange together. 4.1MachinePreparation Theflangetobetensionedmustbefullyclosedpriortopositioningofstudsintheflanges. Theremustbeprovisionsforturningtheshafts.Also,itwillbeadvantageoustoremoveas manyobstructionsaspossiblefromtheflangearea,suchasspeedprobes,shippingplates, conduit,andotherprotectivematerialsthatmayinterferewiththetensioner. 4.2Hardware–Balance Thestudsaresuppliedinacomponentbalancedsetfortheentireflange.Astudcanbe exchangedwithanotherstudinitssetwithoutaffectedtheoverallbalanceoftheequipment. Donotexchangeastudfromonesetwithanotherstudfromadifferentsetforanotherturbine. WhenshippedfromRiverhawk,thestudsarenotassignedtoanyspecificholeinthebolted flange;thisisoptionalandcanbedoneattheinstallationsite.Thesetsizeisdeterminedbythe relevantGEorderdrawing(seesection2.0). Thenutsaresuppliedincomponentbalancedsetsfortheentireflange.Anutcanbeexchanged withanothernutinitssetwithoutaffectedtheoverallbalanceoftheequipment.Donot exchangeanutfromonesetwithanothernutfromadifferentsetforanotherturbine.When

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͲ͵ͻ

InstructionManualIMͲ364 shippedfromRiverhawk,thenutsarenotassignedtoanyspecificholeintheboltedflange;this isoptionalandcanbedoneattheinstallationsite.ThesetsizeisdeterminedbytherelevantGE orderdrawing(seesection2.0). Aweightbalancecertificationissuppliedwitheachorder.Storethiscertificationinan appropriatelocationasitwillbeneededfortheacquisitionofreplacementequipment. 4.3Tensioner–CareandHandling Whennotinuse,thetensionershallbemaintainedinacleanenvironmentandallcapsand plugsforhydraulicopeningsandfittingsmustbeinplace. UseISO32gradeoil. Wheninuse,thetensionershallbeprotectedfromsandandgrit. Seesection12forlongtermstoragerequirements. 4.4HandTools Severalhandwrenchesandmicrometersmayberequiredtoperforminstallationand measurementofthestuds: 5/8”Wrench 3/4”Wrench AsetofAllenWrenches 1/2”SquareDrive–1/2"HexͲBitSocket 1’to2’(30cmͲ60cm)BreakerBar 3’to4’(90cmͲ120cm)BreakerBar 5”to6”(125mmͲ150mm)MicrometerorCaliper 8”to9”(200mmͲ225mm)MicrometerorCaliper 4.5SpecialTools HydraulicTensionerKit: HTͲ6745HydraulicTensioner,1Ͳ1/8” (recommended) (referenceGEVENDOC101B0646)

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͳ͵ͻ

HTͲ6746HydraulicTensioner,2” (recommended) (referenceGEVENDOC101B0647)

HydraulicPumpKit: APͲ0532AirͲOperatedHydraulicPump (recommended) (referenceGEVENDOC359B2502)

StudCleaningKit: GTͲ4354StudCleaningKit (recommended) (referenceGEVENDOC373A4027) CAUTION RiverhawkrecommendsthatthetensionersbereturnedtoRiverhawkforperiodic inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesare alsorecommended.TheRiverhawkServiceReturnsCoordinatorshouldbenotified3Ͳ6 monthspriortoaplannedoutagetoscheduleaninspectionservice. 5.0HardwareSetPreparations 5.1NutPreparation

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳʹ͵ͻ

InstructionManualIMͲ364 Ifthereisanyvisibledamageonanut,donotusethenutandcontacttheRiverhawkCompany forareplacementnut.Pleasebepreparedtosupplytheturbinenumber,weightcertification, anddigitalphotographsforevaluation. 5.1.1NutCleaningͲNewInstallations Fornewinstallations,thenutsshouldcomesealedfromthefactoryandwillneednocleaning. 5.1.2NutCleaningͲOldInstallations Previouslyinstallednutsrequirecleaningasfollows:WirebrushusingapetroleumͲbased solventtoremoveanyforeignmaterialontheexternalsurfacesandthreads. 5.2StudPreparation Checkthestudforanyvisibledamage.Ifthereisanyvisibledamage,donotusethestudand contacttheRiverhawkCompanyforareplacementstud.Pleasebepreparedtosupplythe turbinenumber,weightcertification,anddigitalphotographsforevaluation. CAUTION Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthe stud.Threaddamagefrompreviousabusecanleadtofailureofthestudortensioning equipment. Theconicalthreadsofeachstudmustbecleanofgritanddirtbeforeinstallationorremoval. Thisensurestheproperseatingofthepullerscrew. 5.2.1StudCleaningͲNewInstallations Fornewinstallations,thestudsshouldcomesealedfromthefactoryandwillneednocleaning. 5.2.2StudCleaningͲOldInstallations Previouslyinstalledstudsmayrequirecleaning.Cleanconicalthreadsshouldhaveabrightand shinyappearance. Ifcleaningisrequired,followthesesteps: 1. Blowoutthethreadswithcompressedairtoremoveloosedebrisanddryconical threads.Donotapplyasolventorothercleaningsolutiontothethreadsasthismay chemicallyattackthestud.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵͵ͻ

InstructionManualIMͲ364 2. UseStudCleaningKit,GTͲ4354orasimilar1/2"diameterBrasspowerbrush.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͶ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͷ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵ͻ

Picture6F–UseofDropGageto Picture6G–UseofCalipersto measurestickͲout measurestickͲout 5. Handtightentheassemblytoasnugfit. 6. RecheckthestudstickͲoutlength.IfthestickͲoutlengthdoesnotmatchthehardware drawing,adjustthenutsasnecessary. 7.0HydraulicTensionerEquipmentAssembly 7.1HydraulicEquipmentInspection

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵ͻ

InstructionManualIMͲ364 7.1.1HydraulicTensionerInspection CAUTION RiverhawkrecommendsthatthetensionerbereturnedtoRiverhawkforperiodicinspections. Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso recommended.Riverhawkshouldbenotified3Ͳ6monthspriortoaplannedoutageto scheduleaninspectionservice. Donotbleedtheairfromthehydrauliclinesandtensioneratthistime.Seesection8for bleedinginstructionsonwhentobleedtheairfromthehydrauliclines. WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbe installedonastudintheflangebeforebleedingandpressurizingthetensioner.Donotuse thetensioneratanypressureunlessthetoolisinstalledonastudinaflange. Cleanpullerscrewandcheckforanydebrisanddents. Inspectthetensionerguardforanysignsofdamageincludingcrackedwelds.Anyguards modifiedinthefieldshouldbereplaced.Bentguardsshouldbereplaced.Also,besurethe rubberpadisinplaceontheguard,ifmissing,replace. Inspecttheoutsideofthetensionerfordiscolorationpatternsthatmayindicatesubmersion andinternaldamage. Performaninventoryofthelooseequipmentsuppliedwiththetensioner.Aninventorylistis providedonthetensioner’stechnicaldrawing(RiverhawkHTͲxxxxlistedinsection2.0and4.5). ReplacementpartsareavailablefromRiverhawk. 7.1.1.1HydraulicTensioner’sBurstDiscReplacement Thehydraulictensioner’sburstdiscisakeyelementintheoverallsafeuseofthehydraulic tensioner.Theburstdisc’slocationisshownonthetensioner’stechnicaldrawing(Riverhawk HTͲxxxxlistedinsection2.0and4.5). Eachtensionerisshippedfromourfactorywithoneburstdiscalreadyinstalledinthetensioner andwithanothersparediscforfieldreplacement.Extraburstdiscsareavailablefrom Riverhawkforreplacementpurposes. Toreplaceadamagedburstdisc: 1. Removethehydraulicport’sdispersionnut,compressionring,anddamagedburstdisc. 2. Discardthedamagedburstdisc.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͺ͵ͻ

InstructionManualIMͲ364 3. Cleanthedispersionnut,compressionring,newburstdisc,andthehydraulicportwitha solventtoensureadirtͲfreeinstallation. 4. Reassemblenewburstdisc,compressionring,anddispersionnutintothesame hydraulicport. Warning Adamagedburstdiscmustbereplacedwithaburstdiscofthesamedesignandpressure rating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferentpressure rating,oraforeignobject. 7.1.2HydraulicPumpKitInspection RefertotheHydraulicPumpKitInstructionManual,IMͲ293(GEVENDOC373A4058).Thelatest revisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com. 7.2HydraulicFittings Riverhawkhydraulicpumpsusea1/4”High Pressureporttoconnectitshydraulichoses.The hoseconnectorismadefromathreepiece assembly:aglandnut,acollar,anda1/4”tubeor 1/4”hoseend.(SeeIllustration1) Toassemblythefitting,slidetheglandnutover the1/4”tubeor1/4”hoseend.Turnthecollar counterͲclockwise(lefthandthread)ontothe tubeorhoseendasshowninIllustration1. Illustration1

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͻ͵ͻ

InstructionManualIMͲ364 Slidetheglandnutdownoverthecollar.(See Illustration3)Insertthe1/4”tubeor1/4”hose endintothetensioner’squickcoupler.While firmlyholdingthetubeorhoseendtostopitfrom rotating,turntheglandnutclockwise(righthand thread)andtorquetheglandnutto25FTͲLBS(34 NͲm). Tips: Makesureallpartsarecleanandfreefrom debris. Protecttheconeontheendofthe1/4”tube or1/4”hoseendfromscratchesasthisisthe Illustration3 sealingsurface. Replaceredplasticcapswhenfinishedto protectthethreadsandcone. 8.0AssemblyofTensioneronaStud 8.1HandlingoftheTensioner Thetensionerusedinthisapplicationisdesignedtorequirenospecialliftinginstructions.Do notdropanypartofthetensionerontheoperatororothernearbypersonnel. 8.2KitAssembly Connectthehydraulichosefromthehydraulicpumptothetensioner.Donotpressurizethe tensioneratthistimeoryoumaycausedamagetothetensioner. Refertothehardwareassemblydrawing(HFͲxxxx)listedinSection2.0ofthismanualandthe tensionerassemblydrawing(HTͲxxxx)listedinSection4.5ofthismanualtodeterminehowthe tensionermustbeassembledontheloadcouplingforitscorrectoperation.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͲ͵ͻ

LoadCoupling Flange Foot Hydraulic Cylinder Picture8A–FeaturesoftheHydraulicTensionerHTͲ6745

Knurled SpannerRing Interlock HydraulicCylinder Fitting Picture8B–CutawayviewofHydraulicTensionerHTͲ6745

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͳ͵ͻ

Gearbox Flange Hydraulic Foot Cylinder Picture8C–FeaturesoftheHydraulicTensionerHTͲ6754

SpannerRing HydraulicCylinder Picture8D–CutawayviewofHydraulicTensionerHTͲ6754

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹʹ͵ͻ

InstructionManualIMͲ364 Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboth thestud"sandthepullerscrew"sconicalthreads.Applyalightcoatofcleanturbineoilora spraylubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.This procedurewilleaseassemblyandassurepositivematingofthethreadsbeforetightening. Assemblysequenceisasfollows: 1. Openthehydraulicreturnvalveonthepumptoallowhydraulicfluidtobepushedback fromthepullertoolintothepumpreservoir.(ThisisautomaticontheairͲoperated hydraulicpump) 2. Insertthepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenotto crossͲthreadthepullerscrew. 3. Placethespannerringonthenut. 4. UsinganAllenwrench,tightenthepullerscrewandthenbackoffthepullerscrew1/2a turn. 5. Retightenthepullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFTHEPULLER SCREW. 6. Placethefootoverthepullerscrewandorientateitintoposition. 7. Threadthetensionerontothepullerscrewuntilitstops.Pleasenotethattheinternalstop insidethetensionerwillcauseagapinbetweenthefootandtensioner.Thegapshouldbe 1/16”[1.6mm]to3/16”[4.8mm].DONOTATTEMPTTOTIGHTENTHETENSIONERAGAINST THEFOOT. 8. Placetheguardoverthetensionerandpositiontheguidepinintotheholeinthebackside ofthestud. 9. Tightentheknurledinterlockfittingbyhanduntilitfirmlypressesagainstthetensioner. Thereshouldbenogapbetweenthetensionertheinterlockfitting. 10. Activatethecustomconnectorfromtherearofguardbypushingonthecenterwithyour thumbandpullingthetabswithyourforefingerandmiddlefinger.Pushtheassembly forwarduntilitlocksintothetensioner.Releasefingersfromthetabsandthenremove thumb,Ensureconnectionisfirmlyengagedorelsethetensionerwillnotbeconnectedto thepump.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵͵ͻ

Picture8EͲActivationofthesafetyinterlock 11. Connectthehydraulicpumptothetensioner.Thetensionershouldnowbecompletely assembledandreadyforuse. 8.3BleedingHydraulicSystem WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbe installedonastudintheflangebeforebleedingandpressurizingthetensioner.Donotuse thetensioneratanypressureunlessthetoolisinstalledonastudinaflange. Bleedingofthehydraulicsystemisnotnecessarywiththistensionerdesign. 9.0StudTensioning Thestudswillbetensionedintwosteps,at50%pressureandatfinalpressure.Followthe tensioningsequenceforeachflangejointasdefinedontherecordsheetsfoundattheendof thismanual. 9.1Tensioningat50%pressure Afterthetensionerisproperlyinstalledapplyhydraulicpressuretothetool.Bringthepressure tothe50%levelinaccordancewiththefollowingtable.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͶ͵ͻ

2” 8000psi Donotmeasure GearboxtoGenerator [51mm] [550bar] Donotuse Firmlytightenthecylindricalnutswithapproximately10ftͼlbs[13.5Nͼm]oftorqueusingthe pinwrenchandspannerring.Continuetoturnthenutuntilitcontactstheflange. 9.2RemovingtheTensionerfromanInstalledStud Thetensionerremovalisaccomplishedbythefollowssteps: 1. ReleasethehydraulicpressurebyeitherreleasingthehandswitchontheAPͲ0532 PumpKitorbyopeningthevalveontheMPͲ0130ManualPumpKitandleavethevalve open. 2. Unscrewtheknurledinterlockfittingattheendoftheguardandremovetheguardfrom thetensioner.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͷ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

Picture10AͲRiverhawkLocknut Mechanicallocknutshavetwosetscrewslocatedinthetopface.Beforethreadingthenut ontothestud,checktobecertainthesetscrewsarefreetoturn.Oncethenutisseatedtorque thesetscrewstothevaluesspecifiedinthefollowingtable.Whenseatedandtorquedtothe

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͺ͵ͻ

Disassemblysequenceisasfollows: 1. Ifpresent,removethewindageplugsfromthestudsbylooseningtheplug’ssetscrewswith anAllenwrenchandthenunscrewtheplugfromthestud.Itmaybenecessarytouseeither aflatͲbladedscrewdriveroranotherAllenwrenchtostopthewindageplugfromrotating. Donotmisplacethesetscrews. 2. Usingawirebrush(GTͲ4354)andshopair,cleantheinternaltaperedthreadofthestudto removeanydebris/depositswhichmayhaveaccumulatedduringserviceasdescribedin section5.2.2.DonotcontinueuntilALLdebrisisremovedfromthethreads. WARNING Donotuseahydraulictensionertoremoveastudwithdamagedconicalthreads. 3. WithanAllenwrench,loosenthenut’stwolockingsetscrewsbutdonotremovethem fromthenut.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͻ͵ͻ

InstructionManualIMͲ364 4. Connectthehydraulichosefromthehydraulicpumptothetensioner.Donotpressurize thetensioneratthistimeoryoumaycausedamagetothetensioner. 5. Openthehydraulicreturnvalveonthepumptoallowhydraulicfluidtobepushedback fromthepullertoolintothepumpreservoir.(ThisisautomaticontheairͲoperated hydraulicpump) 6. Insertthepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenotto crossͲthreadthepullerscrew. 7. Placethespannerringonthenut. 8. UsinganAllenwrench,tightenthepullerscrewandthenbackoffthepullerscrew1/2a turn. 9. Retightenthepullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFTHEPULLER SCREW. 10. Placethefootoverthepullerscrewandorientateitintoposition. 11. Threadthetensionerontothepullerscrewuntilitstops.Pleasenotethattheinternalstop insidethetensionerwillcauseagapinbetweenthefootandtensioner.Thegapshouldbe 1/16”[1.6mm]to3/16”[4.8mm].DONOTATTEMPTTOTIGHTENTHETENSIONERAGAINST THEFOOT. 12. Placetheguardoverthetensionerandpositiontheguidepinintotheholeinthebackside ofthestud. 13. Tightentheknurledinterlockfittingbyhanduntilitfirmlypressesagainstthetensioner. Thereshouldbenogapbetweenthetensionertheinterlockfitting. 14. Activatethecustomconnectorfromtherearofguardbypushingonthecenterwithyour

8613371530291

8613371530291