riverhawk hydraulic pump kit made in china

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

![]()

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

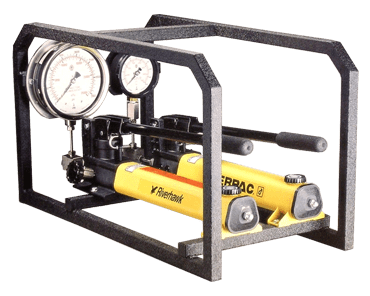

Riverhawk has designed the Manual Hydraulic Pump Kit as a comprehensive solution with two pumps and the associated gauges installed on a welded sledge. The kit, furthermore, comes with all the necessary adapters, fittings and hoses.

The hoses supplied with the hydraulic pump kit feature six layers of wound steel pressure support, a nylon outer cover as well as swivel fittings at both ends and Derlin inner liner.

![]()

ISSUED: 373A4078 Ͳ The Riverhawk Company reserves the right to update this document without dissemination or notice. ThelatestrevisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com.

215ClintonRoad NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 Email:info@riverhawk.com

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

InstructionManualIMͲ364 1.0CautionsandSafetyWarnings WARNING Impropertooluseandthefailuretofollowthecorrectproceduresaretheprimaryroot causesoftoolfailuresandpersonalinjuries.Alackoftrainingorexperiencecanleadto incorrecthardwareinstallationorincorrecttooluse.Onlytrainedoperatorswithcareful, deliberateactionsshouldusehydraulictensioners.ContactRiverhawkCompanywithany trainingneeds. WARNING Riskofhighpressurehydraulicfluidinjection.Riverhawktoolsoperateunderhighpressure. Thoroughlyinspectallhosesandconnectionsfordamageorleakspriortousingthisequipment. CAUTION Personalinjuryandequipmentdamagecanoccuriftheproperhealthandsafetycodesand proceduresarenotfollowed.Contactthesite’shealthandsafetyofficetodetermineall applicablesafetyrulesandregulations. WARNING Theproperpersonalprotectiveequipmentmustbewornatalltimes.Riverhawkrecommends ataminimum,safetyglasses,longsleeveshirt,hardhat,heavyworkgloves,andsteeltoe shoes. CAUTION Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthestud. Threaddamagefrompreviousabusecanleadtofailureofthestudortensioningequipment CAUTION RiverhawkrecommendsthatthetensionershouldbereturnedtoRiverhawkforperiodic inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso recommended.Riverhawkshouldbenotified3Ͳ6monthspriortoaplannedoutagetoschedule aninspectionservice. WARNING Adamagedburstdiscmustbereplacedwithaburstdiscofthesamedesignandpressure rating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferentpressure rating,oraforeignobject.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵͵ͻ

InstructionManualIMͲ364 WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbeinstalled onastudintheflangebeforebleedingandpressurizingthetensioner.Donotusethetensioner atanypressureunlessthetoolisinstalledonastudinaflange. CAUTION Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengaged withthetaperedthreadsofthestud.Properengagementisachievedwhenthepullerscrewis tightinthestudandthetensionerassemblyisfreetoturn. WARNING Thesafetycagemustbeinplaceatalltimes.Whenthetensionerispressurizedhandsmustbe keptoutofdesignatedareastoavoidanypotentialforpersonalinjury. CAUTION Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe stud"sandthepullerscrew"sconicalthreads.Applyalightcoatofcleanturbineoiloraspray lubricanttothepullerscrew.Thisprocedurewilleaseassemblyandassurepositivematingof thethreadsbeforetightening.Donotuse“NeverSeize”ontheconicalthreads. CAUTION Donottightenthenutwhilethetooliscominguptopressure;waituntilpressureisachieved beforeattemptingtotightenthenutwiththespannerring.Ifthetoolisnotproperlyinstalled, thetoolcouldjumpoffthestudwhilecominguptopressure. CAUTION Donotexceedthemaximumpressuremarkedonthetensioner.Excessivepressurecandamage thestudandthetensioner. WARNING FIREHAZARD:DONOTapplyheatwhentensionerisinplace.Personalinjuryorequipment damagemayoccur.UseofanOxyͲAcetylenetorchisnotrecommended. WARNING Donotuseahydraulictensionertoremoveastudwithdamagedconicalthreads.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com Ͷ͵ͻ

InstructionManualIMͲ364 2.0ScopeandGEPartNumberCrossReference Thisdocumentdescribestheproceduretobeusedtoinstallthestudandnutsetssuppliedby theRiverhawkCompanyintheflangesattheGasTurbine/LoadCoupling,Load Coupling/Gearbox,andGearbox/Generatorconnections. ThevariousframeconfigurationscoveredinthismanualarelistedinSections2.1through2.3 withdifferencesasrelatedtoconnectivehardwaredefined.Listedalsoarethepertinent hardwaredrawings(HFͲxxxx).Thesedrawingsaswellastoolingdrawings(HTͲxxxx)formpartof thismanual. 2.16FAGasTurbineto6FAGenerator GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P001 HFͲ0737 359B2521 381A6850P019 HFͲ0737 359B2521 381A6850P020 HFͲ0737 359B2521 The hydraulic tooling used for installation and removal is Riverhawk HTͲ6745 (load coupling) andHTͲ6754(generator). ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto LoadCoupling(1Ͳ1/8”size,Qty27)andLoadCouplingtoGearbox(1Ͳ1/8”size,Qty27)aswell astheGearboxtoGenerator(2”size,Qty18). 2.2Gearboxto6FAGenerator GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P004 HFͲ5204 GE269B8695 ThehydraulictoolingusedforinstallationandremovalisRiverhawkHTͲ6754. ThishardwaredrawingdepictsthecompletestudandnutpackagefortheGearboxto Generator(2”size,Qty18).

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͷ͵ͻ

InstructionManualIMͲ364 2.3HydraulicTooling GEPartNumber RiverhawkP/N GEVENDOCP/N 381A6850P016 HTͲ6745 GE101B0646 381A6850P017 HTͲ6745 GE101B0646 381A6850P018 HTͲ6754 GE101B0647 381A6850P019 HTͲ6745 GE101B0646 HTͲ6754 GE101B0647 APͲ0532 GE359B2502 381A8650P020 HTͲ6745 GE101B0646 HTͲ6754 GE101B0647 APͲ0532 GE359B2502 3.0QuickChecklist ThefollowingchecklistisintendedasasummaryofthestepsneededtousetheRiverhawkͲ suppliedequipment.Newpersonnelorthoseexperiencedpersonnelwhohavenotusedthe Riverhawkequipmentrecentlyareencouragedtoreadtheentiremanual. EQUIPMENTINSPECTION

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͺ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͻ͵ͻ

Ƒ x Movetothenextstudinthepattern. 4.0GeneralPreparations Readandunderstandallinstructionsbeforeinstallingandtensioningstuds. OperatorsshouldbetrainedorhavepreviousexperienceusingRiverhawktensioning equipment.Trainingwillminimizethechanceofimproperuseoftheequipment. Thehydraulictoolingincludingthehydraulichosesshouldbeinspectedpriortouse.Inspection guidelinesarelistedinthefollowingsubͲsections. Thisequipmentproducesveryhighhydraulicpressuresandveryhighforces.Operatorsmust exercisecautionandweartheappropriatepersonalprotectiveequipmentwhenhandlingand operatingthehydraulictooling. HighͲpressureoilfromthehydraulicpumppressurizesthetensionerwhichgeneratesavery largeforcethatactuallystretchesthestud.Asthestudisstretchedthenutliftsofftheflange. Thenutisthenturnedbyhandusingthesuppliedspannerring.Oncethenutistightagainstthe flange,thepressureinthetensionerisreleased.Thehardwareisnowclampingtheflange together. 4.1MachinePreparation Theflangetobetensionedmustbefullyclosedpriortopositioningofstudsintheflanges. Theremustbeprovisionsforturningtheshafts.Also,itwillbeadvantageoustoremoveas manyobstructionsaspossiblefromtheflangearea,suchasspeedprobes,shippingplates, conduit,andotherprotectivematerialsthatmayinterferewiththetensioner. 4.2Hardware–Balance Thestudsaresuppliedinacomponentbalancedsetfortheentireflange.Astudcanbe exchangedwithanotherstudinitssetwithoutaffectedtheoverallbalanceoftheequipment. Donotexchangeastudfromonesetwithanotherstudfromadifferentsetforanotherturbine. WhenshippedfromRiverhawk,thestudsarenotassignedtoanyspecificholeinthebolted flange;thisisoptionalandcanbedoneattheinstallationsite.Thesetsizeisdeterminedbythe relevantGEorderdrawing(seesection2.0). Thenutsaresuppliedincomponentbalancedsetsfortheentireflange.Anutcanbeexchanged withanothernutinitssetwithoutaffectedtheoverallbalanceoftheequipment.Donot exchangeanutfromonesetwithanothernutfromadifferentsetforanotherturbine.When

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͲ͵ͻ

InstructionManualIMͲ364 shippedfromRiverhawk,thenutsarenotassignedtoanyspecificholeintheboltedflange;this isoptionalandcanbedoneattheinstallationsite.ThesetsizeisdeterminedbytherelevantGE orderdrawing(seesection2.0). Aweightbalancecertificationissuppliedwitheachorder.Storethiscertificationinan appropriatelocationasitwillbeneededfortheacquisitionofreplacementequipment. 4.3Tensioner–CareandHandling Whennotinuse,thetensionershallbemaintainedinacleanenvironmentandallcapsand plugsforhydraulicopeningsandfittingsmustbeinplace. UseISO32gradeoil. Wheninuse,thetensionershallbeprotectedfromsandandgrit. Seesection12forlongtermstoragerequirements. 4.4HandTools Severalhandwrenchesandmicrometersmayberequiredtoperforminstallationand measurementofthestuds: 5/8”Wrench 3/4”Wrench AsetofAllenWrenches 1/2”SquareDrive–1/2"HexͲBitSocket 1’to2’(30cmͲ60cm)BreakerBar 3’to4’(90cmͲ120cm)BreakerBar 5”to6”(125mmͲ150mm)MicrometerorCaliper 8”to9”(200mmͲ225mm)MicrometerorCaliper 4.5SpecialTools HydraulicTensionerKit: HTͲ6745HydraulicTensioner,1Ͳ1/8” (recommended) (referenceGEVENDOC101B0646)

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͳ͵ͻ

HTͲ6746HydraulicTensioner,2” (recommended) (referenceGEVENDOC101B0647)

HydraulicPumpKit: APͲ0532AirͲOperatedHydraulicPump (recommended) (referenceGEVENDOC359B2502)

StudCleaningKit: GTͲ4354StudCleaningKit (recommended) (referenceGEVENDOC373A4027) CAUTION RiverhawkrecommendsthatthetensionersbereturnedtoRiverhawkforperiodic inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesare alsorecommended.TheRiverhawkServiceReturnsCoordinatorshouldbenotified3Ͳ6 monthspriortoaplannedoutagetoscheduleaninspectionservice. 5.0HardwareSetPreparations 5.1NutPreparation

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳʹ͵ͻ

InstructionManualIMͲ364 Ifthereisanyvisibledamageonanut,donotusethenutandcontacttheRiverhawkCompany forareplacementnut.Pleasebepreparedtosupplytheturbinenumber,weightcertification, anddigitalphotographsforevaluation. 5.1.1NutCleaningͲNewInstallations Fornewinstallations,thenutsshouldcomesealedfromthefactoryandwillneednocleaning. 5.1.2NutCleaningͲOldInstallations Previouslyinstallednutsrequirecleaningasfollows:WirebrushusingapetroleumͲbased solventtoremoveanyforeignmaterialontheexternalsurfacesandthreads. 5.2StudPreparation Checkthestudforanyvisibledamage.Ifthereisanyvisibledamage,donotusethestudand contacttheRiverhawkCompanyforareplacementstud.Pleasebepreparedtosupplythe turbinenumber,weightcertification,anddigitalphotographsforevaluation. CAUTION Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthe stud.Threaddamagefrompreviousabusecanleadtofailureofthestudortensioning equipment. Theconicalthreadsofeachstudmustbecleanofgritanddirtbeforeinstallationorremoval. Thisensurestheproperseatingofthepullerscrew. 5.2.1StudCleaningͲNewInstallations Fornewinstallations,thestudsshouldcomesealedfromthefactoryandwillneednocleaning. 5.2.2StudCleaningͲOldInstallations Previouslyinstalledstudsmayrequirecleaning.Cleanconicalthreadsshouldhaveabrightand shinyappearance. Ifcleaningisrequired,followthesesteps: 1. Blowoutthethreadswithcompressedairtoremoveloosedebrisanddryconical threads.Donotapplyasolventorothercleaningsolutiontothethreadsasthismay chemicallyattackthestud.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵͵ͻ

InstructionManualIMͲ364 2. UseStudCleaningKit,GTͲ4354orasimilar1/2"diameterBrasspowerbrush.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͶ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͷ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵ͻ

Picture6F–UseofDropGageto Picture6G–UseofCalipersto measurestickͲout measurestickͲout 5. Handtightentheassemblytoasnugfit. 6. RecheckthestudstickͲoutlength.IfthestickͲoutlengthdoesnotmatchthehardware drawing,adjustthenutsasnecessary. 7.0HydraulicTensionerEquipmentAssembly 7.1HydraulicEquipmentInspection

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳ͵ͻ

InstructionManualIMͲ364 7.1.1HydraulicTensionerInspection CAUTION RiverhawkrecommendsthatthetensionerbereturnedtoRiverhawkforperiodicinspections. Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso recommended.Riverhawkshouldbenotified3Ͳ6monthspriortoaplannedoutageto scheduleaninspectionservice. Donotbleedtheairfromthehydrauliclinesandtensioneratthistime.Seesection8for bleedinginstructionsonwhentobleedtheairfromthehydrauliclines. WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbe installedonastudintheflangebeforebleedingandpressurizingthetensioner.Donotuse thetensioneratanypressureunlessthetoolisinstalledonastudinaflange. Cleanpullerscrewandcheckforanydebrisanddents. Inspectthetensionerguardforanysignsofdamageincludingcrackedwelds.Anyguards modifiedinthefieldshouldbereplaced.Bentguardsshouldbereplaced.Also,besurethe rubberpadisinplaceontheguard,ifmissing,replace. Inspecttheoutsideofthetensionerfordiscolorationpatternsthatmayindicatesubmersion andinternaldamage. Performaninventoryofthelooseequipmentsuppliedwiththetensioner.Aninventorylistis providedonthetensioner’stechnicaldrawing(RiverhawkHTͲxxxxlistedinsection2.0and4.5). ReplacementpartsareavailablefromRiverhawk. 7.1.1.1HydraulicTensioner’sBurstDiscReplacement Thehydraulictensioner’sburstdiscisakeyelementintheoverallsafeuseofthehydraulic tensioner.Theburstdisc’slocationisshownonthetensioner’stechnicaldrawing(Riverhawk HTͲxxxxlistedinsection2.0and4.5). Eachtensionerisshippedfromourfactorywithoneburstdiscalreadyinstalledinthetensioner andwithanothersparediscforfieldreplacement.Extraburstdiscsareavailablefrom Riverhawkforreplacementpurposes. Toreplaceadamagedburstdisc: 1. Removethehydraulicport’sdispersionnut,compressionring,anddamagedburstdisc. 2. Discardthedamagedburstdisc.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͺ͵ͻ

InstructionManualIMͲ364 3. Cleanthedispersionnut,compressionring,newburstdisc,andthehydraulicportwitha solventtoensureadirtͲfreeinstallation. 4. Reassemblenewburstdisc,compressionring,anddispersionnutintothesame hydraulicport. Warning Adamagedburstdiscmustbereplacedwithaburstdiscofthesamedesignandpressure rating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferentpressure rating,oraforeignobject. 7.1.2HydraulicPumpKitInspection RefertotheHydraulicPumpKitInstructionManual,IMͲ293(GEVENDOC373A4058).Thelatest revisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com. 7.2HydraulicFittings Riverhawkhydraulicpumpsusea1/4”High Pressureporttoconnectitshydraulichoses.The hoseconnectorismadefromathreepiece assembly:aglandnut,acollar,anda1/4”tubeor 1/4”hoseend.(SeeIllustration1) Toassemblythefitting,slidetheglandnutover the1/4”tubeor1/4”hoseend.Turnthecollar counterͲclockwise(lefthandthread)ontothe tubeorhoseendasshowninIllustration1. Illustration1

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͳͻ͵ͻ

InstructionManualIMͲ364 Slidetheglandnutdownoverthecollar.(See Illustration3)Insertthe1/4”tubeor1/4”hose endintothetensioner’squickcoupler.While firmlyholdingthetubeorhoseendtostopitfrom rotating,turntheglandnutclockwise(righthand thread)andtorquetheglandnutto25FTͲLBS(34 NͲm). Tips: Makesureallpartsarecleanandfreefrom debris. Protecttheconeontheendofthe1/4”tube or1/4”hoseendfromscratchesasthisisthe Illustration3 sealingsurface. Replaceredplasticcapswhenfinishedto protectthethreadsandcone. 8.0AssemblyofTensioneronaStud 8.1HandlingoftheTensioner Thetensionerusedinthisapplicationisdesignedtorequirenospecialliftinginstructions.Do notdropanypartofthetensionerontheoperatororothernearbypersonnel. 8.2KitAssembly Connectthehydraulichosefromthehydraulicpumptothetensioner.Donotpressurizethe tensioneratthistimeoryoumaycausedamagetothetensioner. Refertothehardwareassemblydrawing(HFͲxxxx)listedinSection2.0ofthismanualandthe tensionerassemblydrawing(HTͲxxxx)listedinSection4.5ofthismanualtodeterminehowthe tensionermustbeassembledontheloadcouplingforitscorrectoperation.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͲ͵ͻ

LoadCoupling Flange Foot Hydraulic Cylinder Picture8A–FeaturesoftheHydraulicTensionerHTͲ6745

Knurled SpannerRing Interlock HydraulicCylinder Fitting Picture8B–CutawayviewofHydraulicTensionerHTͲ6745

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͳ͵ͻ

Gearbox Flange Hydraulic Foot Cylinder Picture8C–FeaturesoftheHydraulicTensionerHTͲ6754

SpannerRing HydraulicCylinder Picture8D–CutawayviewofHydraulicTensionerHTͲ6754

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹʹ͵ͻ

InstructionManualIMͲ364 Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboth thestud"sandthepullerscrew"sconicalthreads.Applyalightcoatofcleanturbineoilora spraylubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.This procedurewilleaseassemblyandassurepositivematingofthethreadsbeforetightening. Assemblysequenceisasfollows: 1. Openthehydraulicreturnvalveonthepumptoallowhydraulicfluidtobepushedback fromthepullertoolintothepumpreservoir.(ThisisautomaticontheairͲoperated hydraulicpump) 2. Insertthepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenotto crossͲthreadthepullerscrew. 3. Placethespannerringonthenut. 4. UsinganAllenwrench,tightenthepullerscrewandthenbackoffthepullerscrew1/2a turn. 5. Retightenthepullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFTHEPULLER SCREW. 6. Placethefootoverthepullerscrewandorientateitintoposition. 7. Threadthetensionerontothepullerscrewuntilitstops.Pleasenotethattheinternalstop insidethetensionerwillcauseagapinbetweenthefootandtensioner.Thegapshouldbe 1/16”[1.6mm]to3/16”[4.8mm].DONOTATTEMPTTOTIGHTENTHETENSIONERAGAINST THEFOOT. 8. Placetheguardoverthetensionerandpositiontheguidepinintotheholeinthebackside ofthestud. 9. Tightentheknurledinterlockfittingbyhanduntilitfirmlypressesagainstthetensioner. Thereshouldbenogapbetweenthetensionertheinterlockfitting. 10. Activatethecustomconnectorfromtherearofguardbypushingonthecenterwithyour thumbandpullingthetabswithyourforefingerandmiddlefinger.Pushtheassembly forwarduntilitlocksintothetensioner.Releasefingersfromthetabsandthenremove thumb,Ensureconnectionisfirmlyengagedorelsethetensionerwillnotbeconnectedto thepump.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵͵ͻ

Picture8EͲActivationofthesafetyinterlock 11. Connectthehydraulicpumptothetensioner.Thetensionershouldnowbecompletely assembledandreadyforuse. 8.3BleedingHydraulicSystem WARNING Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbe installedonastudintheflangebeforebleedingandpressurizingthetensioner.Donotuse thetensioneratanypressureunlessthetoolisinstalledonastudinaflange. Bleedingofthehydraulicsystemisnotnecessarywiththistensionerdesign. 9.0StudTensioning Thestudswillbetensionedintwosteps,at50%pressureandatfinalpressure.Followthe tensioningsequenceforeachflangejointasdefinedontherecordsheetsfoundattheendof thismanual. 9.1Tensioningat50%pressure Afterthetensionerisproperlyinstalledapplyhydraulicpressuretothetool.Bringthepressure tothe50%levelinaccordancewiththefollowingtable.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͶ͵ͻ

2” 8000psi Donotmeasure GearboxtoGenerator [51mm] [550bar] Donotuse Firmlytightenthecylindricalnutswithapproximately10ftͼlbs[13.5Nͼm]oftorqueusingthe pinwrenchandspannerring.Continuetoturnthenutuntilitcontactstheflange. 9.2RemovingtheTensionerfromanInstalledStud Thetensionerremovalisaccomplishedbythefollowssteps: 1. ReleasethehydraulicpressurebyeitherreleasingthehandswitchontheAPͲ0532 PumpKitorbyopeningthevalveontheMPͲ0130ManualPumpKitandleavethevalve open. 2. Unscrewtheknurledinterlockfittingattheendoftheguardandremovetheguardfrom thetensioner.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͷ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

Picture10AͲRiverhawkLocknut Mechanicallocknutshavetwosetscrewslocatedinthetopface.Beforethreadingthenut ontothestud,checktobecertainthesetscrewsarefreetoturn.Oncethenutisseatedtorque thesetscrewstothevaluesspecifiedinthefollowingtable.Whenseatedandtorquedtothe

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹ͵ͻ

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͺ͵ͻ

Disassemblysequenceisasfollows: 1. Ifpresent,removethewindageplugsfromthestudsbylooseningtheplug’ssetscrewswith anAllenwrenchandthenunscrewtheplugfromthestud.Itmaybenecessarytouseeither aflatͲbladedscrewdriveroranotherAllenwrenchtostopthewindageplugfromrotating. Donotmisplacethesetscrews. 2. Usingawirebrush(GTͲ4354)andshopair,cleantheinternaltaperedthreadofthestudto removeanydebris/depositswhichmayhaveaccumulatedduringserviceasdescribedin section5.2.2.DonotcontinueuntilALLdebrisisremovedfromthethreads. WARNING Donotuseahydraulictensionertoremoveastudwithdamagedconicalthreads. 3. WithanAllenwrench,loosenthenut’stwolockingsetscrewsbutdonotremovethem fromthenut.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ʹͻ͵ͻ

InstructionManualIMͲ364 4. Connectthehydraulichosefromthehydraulicpumptothetensioner.Donotpressurize thetensioneratthistimeoryoumaycausedamagetothetensioner. 5. Openthehydraulicreturnvalveonthepumptoallowhydraulicfluidtobepushedback fromthepullertoolintothepumpreservoir.(ThisisautomaticontheairͲoperated hydraulicpump) 6. Insertthepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenotto crossͲthreadthepullerscrew. 7. Placethespannerringonthenut. 8. UsinganAllenwrench,tightenthepullerscrewandthenbackoffthepullerscrew1/2a turn. 9. Retightenthepullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFTHEPULLER SCREW. 10. Placethefootoverthepullerscrewandorientateitintoposition. 11. Threadthetensionerontothepullerscrewuntilitstops.Pleasenotethattheinternalstop insidethetensionerwillcauseagapinbetweenthefootandtensioner.Thegapshouldbe 1/16”[1.6mm]to3/16”[4.8mm].DONOTATTEMPTTOTIGHTENTHETENSIONERAGAINST THEFOOT. 12. Placetheguardoverthetensionerandpositiontheguidepinintotheholeinthebackside ofthestud. 13. Tightentheknurledinterlockfittingbyhanduntilitfirmlypressesagainstthetensioner. Thereshouldbenogapbetweenthetensionertheinterlockfitting. 14. Activatethecustomconnectorfromtherearofguardbypushingonthecenterwithyour thumbandpullingthetabswithyourforefingerandmiddlefinger.Pushtheassembly forwarduntilitlocksintothetensioner.Releasefingersfromthetabsandthenremove thumb,Ensureconnectionisfirmlyengagedorelsethetensionerwillnotbeconnectedto thepump.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵Ͳ͵ͻ

Picture11BͲActivationofthesafetyinterlock 15. Connectthehydraulicpumptothetensionerandapplytheappropriatehydraulicpressure perthistable. FlangePosition StudSize Final(100%)Pressure

2” 16000psi GearboxtoGenerator [51mm] [1100bar] 16. Turnthespannerringwiththepinwrench.Loosenandturnthenutapproximately3/4ofa turn. 17. Releasethehydraulicpressure. 11.3.1RemovingtheTensionerfromaStud Thetensionerremovalisaccomplishedbythefollowssteps:

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͳ͵ͻ

InstructionManualIMͲ364 1. ReleasethehydraulicpressurebyeitherreleasingthehandswitchontheAPͲ0532 PumpKitorbyopeningthevalveontheMPͲ0130ManualPumpKitandleavethevalve open. 2. Unscrewtheknurledinterlockfittingattheendoftheguardandremovetheguardfrom thetensioner. 3. Unscrewthetensionerfrompullerscrew. 4. Removefootfromaroundthepullerscrew. 5. Removethespannerringfromthenut. 6. UnscrewthepullerscrewusinganAllenwrench.TappingtheAllenwrenchwitha hammerortheuseofa1’Ͳ2’breakerbarmaybenecessarytoloosenthepullerscrew. Donotuseanimpactwrenchasthiscandamagethepullerscrew. 7. Movethetooltothenextboltholefollowingthetensioningpatternfromthestretched recordsheetsattheendofthismanual. 12.0StorageInstructions Followthesedirectionstoproperlystoreyourhydraulictensionerandhydraulicpumpkitfor longtermstorageandshipment. Ifanydamageisobserved,contacttheRiverhawkCompanytoscheduleamaintenance inspection. 12.1HydraulicPumpKitStorage RefertotheHydraulicPumpKitInstructionManual,IMͲ293(GEVENDOC373A4058).Thelatest revisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com. 12.2HydraulicTensionerStorage Checkthetensionerforanydamage: 1. Cleanpullerscrewandcheckforanydebrisanddents. 2. Knurledinterlockfittingshouldbecleanandfreetorotate. 3. Inspectthetensionerguardforanysignsofdamage.Bentguardsmustbereplaced. Ifanydamageisobserved,contacttheRiverhawkCompanytoscheduleamaintenance inspection. Placetheprotectiveplasticcapontheguard’sknurledinterlockfitting.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ʹ͵ͻ

InstructionManualIMͲ364 Coatthehydraulictensionerwithalightcoatofoilandplacethetensionerintotheoriginal shippingcontainer. 12.3Storeshippingcontainer Securethehydraulicpumpandhydraulictensionerintotheoriginalshippingcontainersusing thesuppliedwoodbraces. Sealtheoriginalshippingcontainerandstoreundershelterandprotectedfrommoisture,sand, andgrit. 13.0FrequentlyAskedQuestions Thissectioncontainssomefrequentlyaskedquestionsandproblems.Ifthestepslistedheredo notsolveyourproblem,contacttheRiverhawkCompanythruourwebsite,email,orphonecall. Q: CanIrentahydraulictensionerkit? A: Yes,Riverhawkhasrentaltensionerkitsavailableformostofourhydraulictensioners. Q: Atensionerhaspulleditselfoutofthestud"sconicalthreads.CanIcontinueusinga tensioneronthisstud? A: No.Boththetensionerandthestudmayhavebeendamagedandmustberemoved fromtheworkarea.Ifthestudistensioned,aNutBusterrepairkit,fromRiverhawk, mustbeusedtoremovethedamagedstudbydrillingoutthenut.Leavingadamaged studinplacewillleadtoasafetyhazardonfutureoutages. Riverhawkcansupplyareplacementstudandnutbasedontheinitialweight certificationsuppliedwiththehardwareset(seesection4.2).Thedamagedtensioner shouldalsobereturnedtoRiverhawkforinspectionandrepair. Ifastudmustbeleftinplace,paintthedamagedstudwithagenerousamountof indelible,brightͲcoloredpaint.NotifytheappropriateGESafetyandServicepersonnel. Notethelocationofthedamagedstudintheservicesnotesforthemachine.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵͵͵ͻ

InstructionManualIMͲ364 Q: Thehydraulictensionerhasbeentakenuptoitsfinalpressure.Thefinalstretchlengthis shortofthefinalstretchtarget.Whatisthenextstep? A: Donotincreasethehydraulicpressure.Checkifthehydraulicpumpissettotheright pressure.InstallthetensionerandreͲpressurizethetensionertothefinalpressurethen recheckthestretchmeasurement.Ifthestretchvalueisstillshort,removethestud fromtheholeandreͲmeasurethestud"sinitiallengththentrytoinstallthestudagain. Q: Thehydraulictensionerhasbeentakenuptoitsfinalpressure.Thefinalstretchlengthis largerthanthefinalstretchtarget.Whatisthenextstep? A: Removethestudfromthebolthole.Checkifthehydraulicpumpissettotheright pressure.ReͲmeasurethestud"sinitiallengththentrytoinstallthestudagain. Q: Thetensionerisatitsfinalpressure,butthenutcannotbeloosened. A: Ifthenutscannotbeloosenedatthefinalpressure,continuallyincreasingthepressure willnothelpandcanbedangerousandinsomecasesmakeithardertoremovethenut. Checkthenuttoseeifitssetscrewshavebeenloosened.Checkforandremoveany corrosionaroundthenut"sthreads.Applypenetratingoilbetweenthestudandthenut. Q: HowdoIcleantheconicalthreadsonastud? A: Theconicalthreadsarebestcleanedusingaspiralwoundbrassbrushinadrillas describedinsection5.2.2 Q: Duringtheinitialstepsofremovingatensionedstud,thestickͲoutlengthisfoundtobe wrong. A: Donotproceed.ContactRiverhawkforassistance.WiththewrongstickͲoutlength,the hydraulictensionerhasalimitedstrokeandmaynotworkproperlyandcanbe damaged.

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵Ͷ͵ͻ

InstructionManualIMͲ364 Q: Thehydraulicpumpappearstobeleaking. A: Checkthehoseconnectiontothehydraulicpump.Ifthe1/4"highpressurefittingisnot assembledcorrectlyasshowninsection7.2,itmaylooklikethepumpisleaking.Ifthe problemcontinues,itmaybenecessarytoopenthepumpkit.ContactRiverhawkfor guidance. Q: Thehydraulichosehasacollaronitthatcan"tbemovedbyhand A: Thehydraulicfittingisshowninsection7.2.Thecollarissometimesheldinplacewitha threadlockingcompound.Thispreventsthecollarfrommovingtooeasily.Itmaybe necessarytoadjustthiscollarwithasetofviseͲgrippliers.Becarefultonotstripthe threadsoffthetubeorhoseend. 14.0RevisionHistory Revision EffectiveDate Description Letter

215ClintonRoad GEDRAWINGNUMBER REV NewHartford,NY13413 Tel:+13157684855 Fax:+13157684941 373A4078 Ͳ Email:info@riverhawk.com ͵ͷ͵ͻ

InstructionManualIMͲ364 AppendixA1 ECDeclarationofConformity Manufacturer: RiverhawkCompany Address: 215ClintonRoad NewHartfordNY,13413,USA Thehydraulicpumpandbolttensioningtooldescribedinthismanualareusedforinstallingand applyingtensiontolargeboltsthatarespecificallydesignedbyRiverhawkCompanytobe tensionedhydraulically. AllapplicablesectionsofEuropeanDirective2006/42/ECformachineryhavebeenappliedand fulfilledinthedesignandmanufactureofthehydraulicpumpandbolttensioningtool describedinthismanual.ReferencealsoISO12100:2010,ISO4413,andISO4414. Furthermore,thisequipmenthasbeenmanufacturedundertheRiverhawkqualitysystemper ENISO9001:2008 ConsulttheDeclarationofConformanceincludedwiththeshipmentofthisequipmentthat

8613371530291

8613371530291