schwing hydraulic pump brands

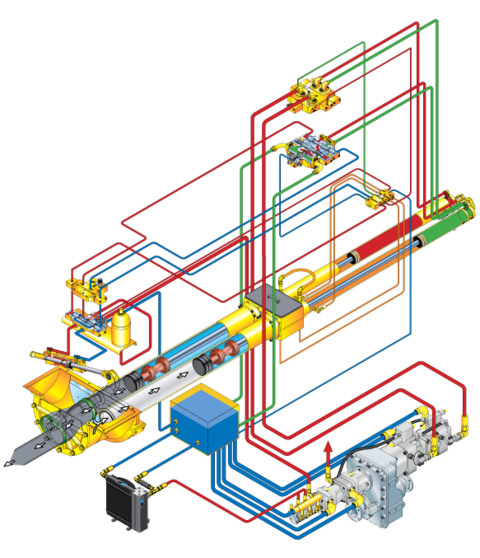

Proper cooling of the hydraulic oil is critical to continuous operation under demanding conditions. In addition, filtration is the single most important method of keeping the hydraulic system operational. That’s why the Schwing G3 design continuously draws hydraulic oil from the tank and circulates it through the filter and high efficiency cooler. Even when the concrete pump is not engaged, this separate hydraulic circuit continues to operate for protection and performance.

Redesigned for 800 LPM of oil, the 3 High Flow Control Block is the brain for the all hydraulic system. The block incorporates the Soft Switch into the relief valve and the accumulator manifold into the S3 spool valve for a compact, simpler design. Multi Port Shifting is an important part of the twin circuit system, which uses accumulator pressure to switch the S3 valve. Faster switching of the S3 translates to smoother pumping. The S3 block and system accumulator are separated from the control block and located near the hopper for easy access.

The material cylinders contain rubber rams that are connected to the differential cylinder rods. One side will push the concrete through the Rock Valve™ while the opposite side will draw concrete from the hopper. Now available with up to 10 inch (250mm) diameter and 98-inch (2500mm) stroke length, G3 pumpkits deliver 30% more concrete with every stroke than competitive brands. Fewer strokes translate to smoother pumping, less wear and longer boom life.

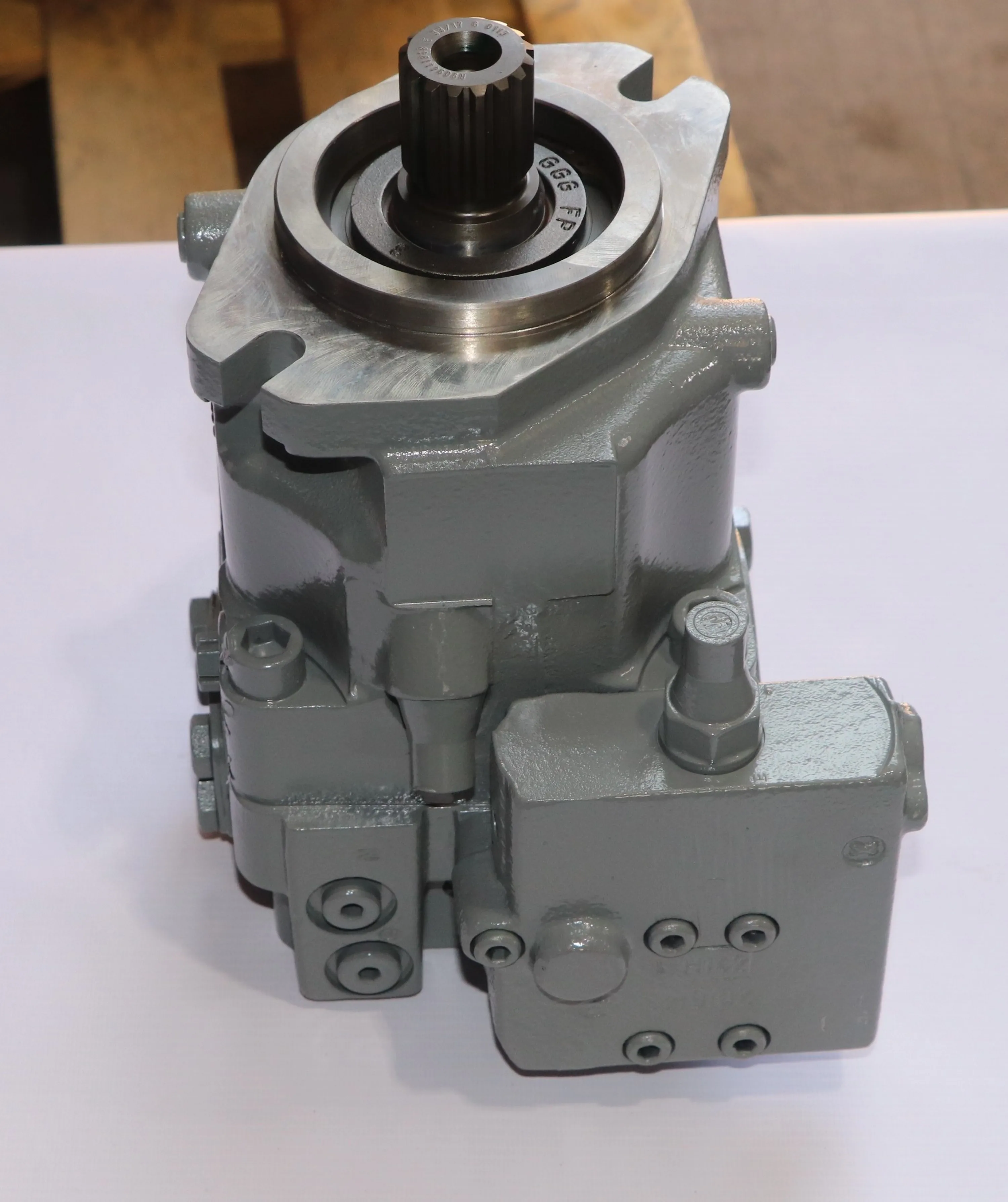

The hydraulic pumps for the concrete pump circuit are bent axis, variable displacement, piston pumps. They are horsepower controlled, which means that as pressure rises towards maximum, the flow can decrease, so the power consumption remains constant. This pump assures that the truck engine will not bog down under difficult pumping conditions. The pump also accepts external signals from the hydraulic stroke limiter for control of the output.

Schwing truck mounted boom pumps provide reach, versatility, and unparalleled reliability. A wide range of boom configurations combine with long stroking pumpkits for smooth pumping performance. Open loop hydraulics combine with the Schwing Rock Valve providing owners and operators performance, reliability, and the lowest total cost of operation. Harsh mixes are no problem for Schwing’s legendary Rock valve that cleans out faster with less water than any other valve, allowing operators to increase profits by completing more jobs per day.

For many decades SCHWING has been pursuing a high-level quality-oriented development strategy which ensures that only technically mature systems and components with an application-oriented...

The new hydraulic oils Classico, Ultimo and Organico from SCHWING-Stetter are specially tailored to the requirements of SCHWING hydraulic systems and ensure excellent power delivery and comprehensive protection of the hydraulic components. With Ultimo high-performance hydraulic oil, the oil change intervals are more than doubled. For more operating times and less downtimes.

Avoid any downtime at your construction site with the range of schwing hydraulic pump from Alibaba.com. You can check out the fully-stocked parts at Alibaba by manufacturer and model and affordable wholesale prices. The wholesale schwing hydraulic pump collection of spare parts from China’s wholesaler, Alibaba, fits well with a wide range of heavy-duty equipment, from bulldozers, excavators, and hammers, among others. Plus, you can find parts for your tractors, skid steer loaders, wheel loaders, backhoe loaders, and crawler dozers.

If you have a limited cash allocation, the used or remodeled parts will go a long way in accommodating your budget. Alibaba’s schwing hydraulic pump and tools make it easy to replace, modify and enhance your equipment for their optimal performance. For electrical and mechanical applications, you can find your match at Alibaba.com for everything you need to make your vehicle perform better. Get engine oils, batteries, hydraulic parts, transmissions, injectors, hoses, and starters from the schwing hydraulic pump at Alibaba.com.

The new parts from manufacturers have warranties, and you can buy them by matching the part numbers. Such parts, including hoses, plugs, or filters, will help you quickly deal with downtime on site. The used parts, on the other hand, sell for a lower price. Remember, Alibaba partners with sellers who have certificates of operation. So, you can use these second-hand schwing hydraulic pump to get your heavy machine running. You can also get rebuild models from the collection at Alibaba.com. These are sustainable choices that use recycled materials and perform as well as the new parts. And depending on your seller of choice, you might get a warranty to accompany them.

Hard work, determination and a commitment to quality along with Schwing’s leading-edge technology, has driven us to satisfy our customers since 1966. And it’s these customers that we thank for allowing us to be a part of many successful and challenging concrete pumping projects.

Trustworth Infracore Private Limited,establishes in the year of 2013in Bengaluru, Karnataka, (India) are the leading eading Wholesale Trader and Exporter of Hydraulic Pumps, Concrete Pump Spare Parts, Excavator Spare Parts, Hydraulic Pump Spares, Soil Compactor Spares and many more. We are also a Service Provider of Pump Repair Service. The main motive of our company is to provide goods of superior quality at affordable prices. In very mean time, we become pioneer in this domain among other which is only possible by our strong workers efforts. This ground requires technical innovative things which is essential for the firm to maintain in this place last long. Corporation has an ultra and high tech infrastructure which is placed in departments and units who help in producing goods in stipulated time and in huge to fulfill the demands. Many new tools are engaged in the sections for good flow of transitions without any type of hindrances and same is kept in the warehouse in customized way to protect from uncertainties. All the time there is the keeper to look after the products. With the high tech technologies and inventive thoughts, everything is done in appropriate way. Association laid necessary improvements for the sake of the consumers. In order to supply most adorable commodities many changes are made like the packaging quality is modify just for attracting more buyers and for safely delivery of them in mean time frame. Different modes of payments are held for their conveyance while they ordered them.

Schwing manufactures boom truck pumps, trailer and line pumps, placing – placement booms to provide a model for every application. These include boom truck pumps with more than 60-meters of reach. Schwing trailer pumps and stationary line pumps are offered in several ball valve and larger rock valve models.

Schwing trailer and line pumps are available in small to medium ball-valve models that are suitable for lightweight concrete, shotcrete, flowable fill and slurry pumping. The bigger rock-valve models pump harsh-mix concrete with large aggregate in large volumes over long distances.

Schwing is one of the world’s largest concrete pump manufacturers. Schwing concrete pumps are renowned for their superior quality, performance and high resale value.

Schwing GmbH is a German manufacturer of mobile and stationary concrete pumps and truck mixers, headquartered in Herne, as well as the parent company of Schwing Stetter in Memmingen. The business group is the world"s second largest concrete pump manufacturer, behind Putzmeister, also a German manufacturer and subsidiary of the XCMG group. The company employs more than 3300 people worldwide in seven countries. In addition, there are individual distribution companies in more than 100 countries.

The Schwing Group was founded as a medium-sized enterprise on 17 March 1934, by Friedrich Wilhelm Schwing (* 1909; † 1992), a locksmith from Wanne-Eickel. In 1957, Schwing built the world"s first oil-hydraulic two-cylinder concrete pump. Starting in 1964, the company also built the first large concrete mixers. In 1965, the company launched its first concrete pump which was mounted on a vehicle, and improved it in 1968 with the addition of a distribution mast. In 1973, the company built a high-speed concrete pump vehicle with a 45-meter-wide large distribution mast, an outstanding innovation at that time. In 1976, Schwing launched the first residual concrete processing plant on the market.

After the company founder handed over the company management to his two sons in 1980, they acquired the company Stetter GmbH in Memmingen in 1982, which produced truck mixers. The company"s market domicile and the company"s portfolio expanded. The company was now able to offer combined mixers with a concrete pump mounted on it and developed into a market leader.

At the end of the nineties there was a dispute between the owners, the company was about to sell to an American company. With the help of banks, a state guarantee and private assets, Gerhard Schwing succeeded in buying his brothers shares.XCMG for €300 million.

Proper cooling of the hydraulic oil is critical to continuous operation under demanding conditions. In addition, filtration is the single most important method of keeping the hydraulic system operational. That’s why the Schwing G3 design continuously draws hydraulic oil from the tank and circulates it through the filter and high efficiency cooler. Even when the concrete pump is not engaged, this separate hydraulic circuit continues to operate for protection and performance.

Redesigned for 800 LPM of oil, the 3 High Flow Control Block is the brain for the all hydraulic system. The block incorporates the Soft Switch into the relief valve and the accumulator manifold into the S3 spool valve for a compact, simpler design. Multi Port Shifting is an important part of the twin circuit system, which uses accumulator pressure to switch the S3 valve. Faster switching of the S3 translates to smoother pumping. The S3 block and system accumulator are separated from the control block and located near the hopper for easy access.

The material cylinders contain rubber rams that are connected to the differential cylinder rods. One side will push the concrete through the Rock Valve™ while the opposite side will draw concrete from the hopper. Now available with up to 10 inch (250mm) diameter and 98-inch (2500mm) stroke length, G3 pumpkits deliver 30% more concrete with every stroke than competitive brands. Fewer strokes translate to smoother pumping, less wear and longer boom life.

The hydraulic pumps for the concrete pump circuit are bent axis, variable displacement, piston pumps. They are horsepower controlled, which means that as pressure rises towards maximum, the flow can decrease, so the power consumption remains constant. This pump assures that the truck engine will not bog down under difficult pumping conditions. The pump also accepts external signals from the hydraulic stroke limiter for control of the output.

Operators are fully informed of the pump’s status even when they are hundreds of feet from the pump. No need to shutdown and return to the pump when an operator can view the following critical information at the remote box:

A High level alarm notifies the operator of situations that may cause damage to the pump. The VECTOR will activate the Emergency Stop and the operator can evaluate the situation. In all cases the operator has the display on the remote box and the VECTOR graphic displays to assist in diagnosis.

Visit any large wastewater treatment plant in the United States or Canada and chances are Schwing Bioset equipment, whether piston pumps or sliding frames, is handling the dewatered biosolids. As with our biosolids handling equipment, our selection of Class `A` processes afford Municipalities best-in-class options when it comes to reliability, safety, ease of operation, consistent results, and affordability.

From the remote Canadian wilderness to the mountainous regions of South America, Schwing Bioset piston pumps are called upon for reliable service in some of the harshest environments on the planet to pump tailings to surface and sub-surface disposal. Schwing Bioset Fluidized Bed dryers and conditioners are trusted when reliability and performance are a must to process coal at your power generation facilities. Schwing Bioset piston pumps can be used to pump wood waste, coal slurries and fly ash at ethanol and power ...

Schwing Bioset, Inc.`s technical expertise and innovative approach to the design of Fluidized Bed dryers, coolers, and conditioners has resulted in Schwing Bioset fast becoming a preferred partner of companies processing municipal solids and companies processing coal. The versatility of Schwing Bioset`s piston pumps allow them to be used in many industries to pump a wide range of materials such as oil sludges, dredging spoils, food wastes, and coal slurries. In fact, Schwing Bioset pumps are so versatile they can ...

First, make sure to close the “A-Line” on the Power Pack. Place the pump into load and check to see if it builds up to system pressure (pressure should reach the level reflected in the Hydraulic Schematic Prints).

If the pressure does not develop, verify there is power to the Load/Bypass coil. This is done by checking the LED light on the angle plug of the Load/Bypass Valve located on the power unit. The LED light should be lit “ON”. If there is no power (Angle Plug Light – OFF), check the Fuse and the Output Module in the electrical panel to verify that the Pump Load Solenoid Output is “ON”.

If there is power to the Load/Bypass Valve (Angle Plug Light – “ON”), but the pressure does not come up to the system pressure shown in the Hydraulic Schematic prints, check the manual override function of this block by pressing the Manual Override button. If it is possible to build up pressure with the Manual Override button engaged, the Coil on the Load/Bypass Valve needs to be replaced.

If there is pressure with the A-Line Valve closed and the pump will not stroke, open the A-Line Valve and make sure there is power to the FWD Solenoid on the control block of the pump by confirming the LED light is lit. If there is no power (Angle Plug Light – OFF), check the Fuse and Output Module to the Forward Coil in the Electrical Panel to verify they are “ON”. If there is power (Angle Plug Light – “ON”), manually override the coil by pushing the Manual Override button. If the pump starts pumping with the Manual Override button engaged, the Forward Coil needs to be replaced.

8613371530291

8613371530291