under hood hydraulic pump factory

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 4400 PSI; Pressure ranges based upon degrees of belt wrap, can vary by kit.

There is a lot to consider when planning the optimal way to power a vocational truck application, such as cost, available space, system power requirements, among many other variables. While it seems the vast majority of hydraulically powered work truck applications today utilize a power take-off as its primary power source, a common alternative is a hydraulic clutch pump.

A hydraulic clutch pump is a belt-driven pump that can be used instead of a power take-off for some applications, such as wreckers and bucket trucks, and is necessary on trucks without a power take-off aperture on the transmission.

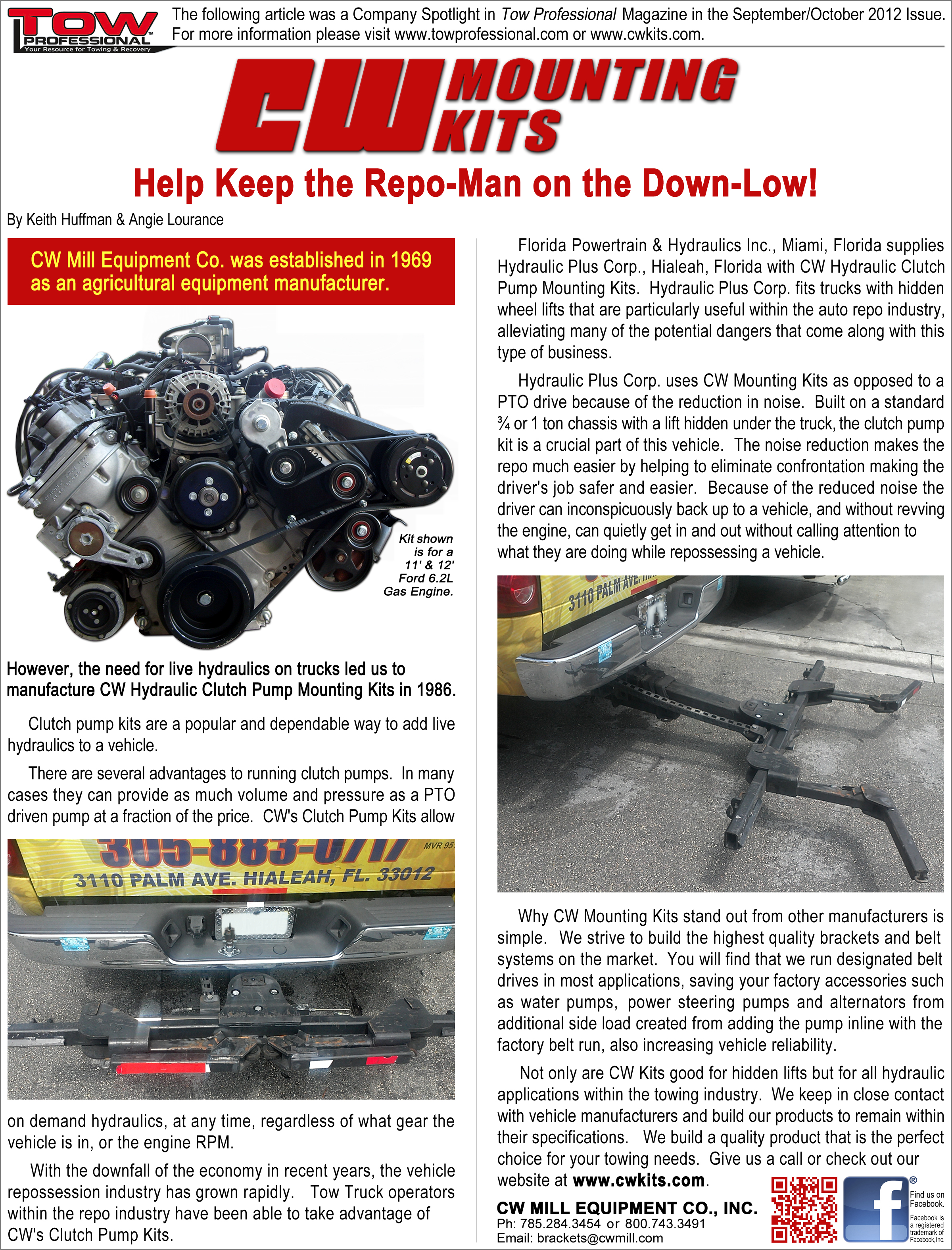

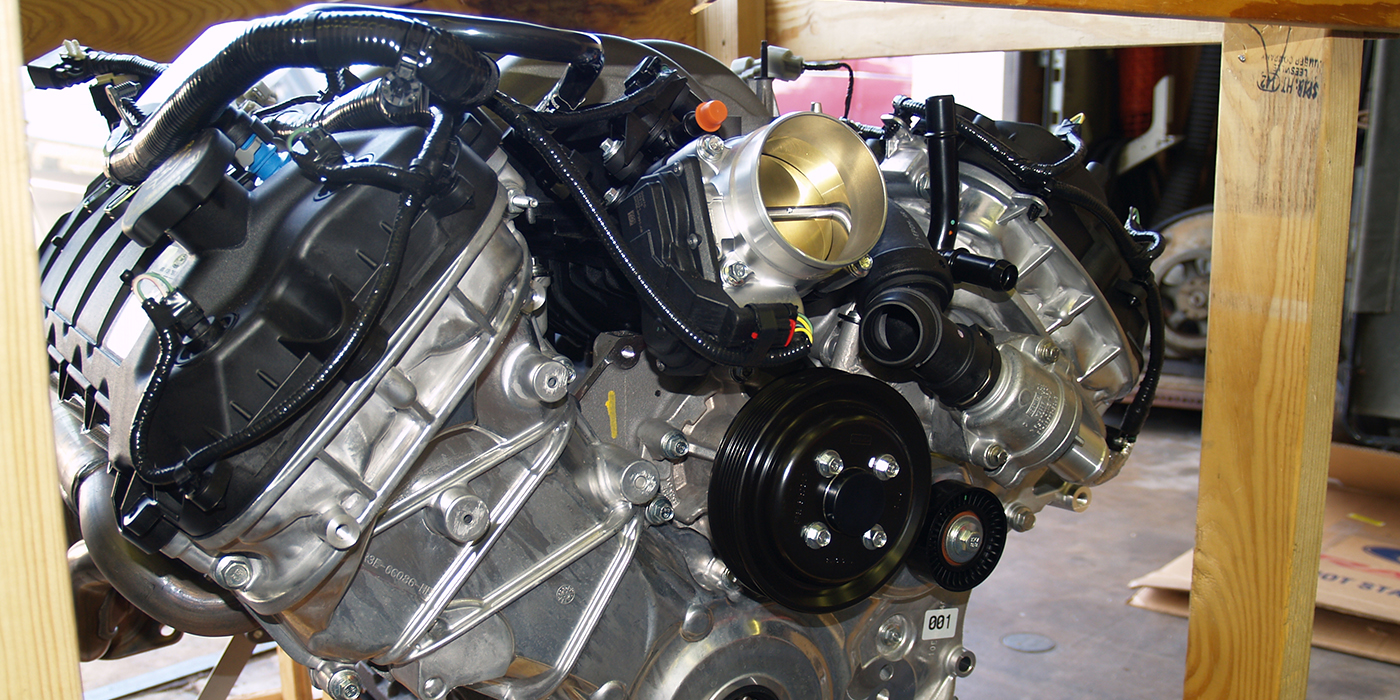

A clutch pump is mounted to the engine compartment of the truck utilizing a mounting kit to secure in place. It is important to make sure there is enough space under the hood to accommodate the appropriately sized pump. The pump is belt-driven from the crankshaft pulley through an electric clutch, similar to what may be found on an automobile air conditioner compressor. Most applications will use a poly-V serpentine belt or two V-belts to drive the pump.

When considering a clutch pump, one critical aspect is to understand the horsepower requirements of your application versus the limitations of the engine belts. Most engine type belts can only drive somewhere between 7–18 horsepower which prohibits the use of large displacement pumps and may not provide enough displacement to effectively power the application at hand. With that said, clutch pumps remain a popular option for hydraulic applications requiring flows up to 15 GPM.

Muncie Power currently has clutch pump options and mounting kits available for most popular truck chassis including current models of Chevy/GMC, Dodge/Ram, Ford, International, and Freightliner.

Reach out to our customer service team (800-367-7867) or utilize our clutch pump online builder module to review available options and determine the best product for your unique application.

If your local hydraulic pump or power take off supplier does not carry CW Mill brand hydraulic clutch pump kits, contact us for the name of a distributor in your area.

Hydraulic pumps, when used in clutch systems, use incompressible fluids, such as oil, to transmit the force necessary to connect and disconnect an engine to the transmission"s input shaft. Clutch systems such as these are used in agriculture, automation and robotics, transit, automotive, transport, military, aerospace and construction industries among others. All kinds of engines and lift systems, ranging from conveyor belts to snow plows and tractors, utilize the power of hydraulic pumps to effectively move heavy loads with minimal effort.

Because these assemblies are used in vehicle power steering and breaking systems, it is essential to select the proper pump for a given application. Considerations include torque rating, power, diameter, cross-sectional width, length, weight, rotational speed and maximum pressure. Additionally, application-specific hydraulic clutch pumps may be either spring-actuated or spring-return. The former requires pressure to disengage the input shaft while the latter uses the hydraulic fluid to engage the power source.

Despite their close connection with engine components, hydraulic clutch pumps are generally foot or hand-powered pumps. In a basic vehicle design, the clutch pedal is used to engage a hydraulic piston pump. The pump may be mounted directly to the clutch, or mounting brackets may be used. Compressing the pedal forces a piston into a hydraulic cylinder, pressurizing the hydraulic fluids already in the enclosure.

The mechanical energy created in this manner is transferred from the engine to related devices such as the transmission and drive wheels, allowing the driver to steer, shift and decelerate as needed. When the clutch is released, the piston is withdrawn. This action draws in hydraulic fluid from a reservoir, which will be compressed with the next engagement of the pedal.

The engine environment and close proximity to possibly corrosive hydraulic fluids necessitates pump components be made of materials that can handle high temperatures created by friction as well as stand up to corrosion. Die cast stainless steel and cast iron components are popular choices, though ceramics such as silicon carbide and alumina are also applicable in some instances. The fluid used must be compatible not only with the hydraulic clutch pump parts but also with the engine itself. Pumps may be mounted directly to the clutch, or mounting brackets may be used.

Hydraulic clutch pumps are systems in which a clutch assembly is accompanied by a pump that allows the user to apply the required pressure to either engage or disengage the clutch system. Hydraulic clutches, like all clutches, are designed to either connect two shafts, lock them together to spin at the same speed, or decouple the shafts, allowing them to spin at different speeds, as is necessary to shift gears or decelerate.

Hydraulic clutch pumps are generally foot or hand-powered despite their close connection with engine components. The clutch pedal is used to engage a hydraulic piston pump in a basic vehicle design. The pump may be mounted directly to the clutch, or mounting brackets may be used. They were compressing the pedal forces a piston into a hydraulic cylinder, pressurizing the hydraulic fluids already in the enclosure. The mechanical energy created in this manner is transferred from the engine to related devices such as the transmission and drive wheels, allowing the driver to steer, shift, and decelerate. When the clutch is released, the piston is withdrawn. This action draws in hydraulic fluid from a reservoir, which will be compressed with the next engagement of the pedal. The engine environment and close proximity to possibly corrosive hydraulic fluids necessitate pump components to be made of materials that can handle high temperatures created by friction and stand up to corrosion. Die cast stainless steel and cast iron components are popular choices, though ceramics such as silicon carbide and alumina are also applicable in some instances. The fluid used must be compatible with the hydraulic clutch pump parts and the engine itself. Pumps may be mounted directly to the clutch, or mounting brackets may be used.

Hydraulic pumps, when used in clutch systems, use incompressible fluids, such as oil to transmit the force necessary to connect and disconnect an engine to the transmission’s input shaft. Clutch systems such as these are used in agriculture, automation, robotics, transit, automotive, transport, military, aerospace, and construction industries, among others. All kinds of engines and lift systems, ranging from conveyor belts to snow plows and tractors, utilize the power of hydraulic pumps to effectively move heavy loads with minimal effort.

Because these assemblies are used in vehicle power steering and braking systems, selecting the proper pump for a given application is essential. Considerations include torque rating, power, diameter, cross-sectional width, length, weight, rotational speed, and maximum pressure. Additionally, application-specific hydraulic clutch pumps may be either spring-actuated or spring-return. The former requires pressure to disengage the input shaft while the latter uses the hydraulic fluid to engage the power source.

Stork"s Plows is your source for complete snow plows, snow plow pumps, and snow plow parts and accessories. We carry Western, Meyer, Fisher, SnowEx, Blizzard, Diamond and Snoway, along with parts for Boss, Curtis, and Hiniker. We have over 1,000 new and used plows in stock all year!

Stork"s Plows is your source for complete snow plows, snow plow pumps, and snow plow parts and accessories. We carry Western, Meyer, Fisher, SnowEx, Blizzard, Diamond and Snoway, along with parts for Boss, Curtis, and Hiniker. We have over 1,000 new and used plows in stock all year!

Zip’s AW Direct has the electric clutch you need for an eight-groove belt pump system. Find this and other clutch pump kits and repair parts today to keep your rig running like it should. We also carry serpentine belts, tensioners and idler pulleys for most makes and models.

Our high-quality hydraulic pumps and motors are designed for performance and durability. We offer a wide variety to meet the needs of on/off road mobile equipment. Our Fluid Power Specialists can assist you in selecting the right product for your application.

Parker"s Hydraulic Pump and Power Systems Division provides a broad selection of piston pumps, hydraulic motors and power units that help our customers meet their industrial and mobile application needs. Our division is the result of the Parker piston pump business’s acquisition of Denison Hydraulics and merger with the Parker Oildyne Division. Reach higher hydraulic working pressures, get better reliability, higher efficiencies, and achieve lower operating costs and improved productivity on your heavy-duty equipment with Parker’s line of piston pumps and vane pumps, electro-hydraulic actuators, hydraulic motors and power units, piston motors and hydrostatic transmissions.

Thermoplastic hydraulic clutch actuation tubing has been used to actuate clutch mechanisms for several decades. Using hydraulic fluids to engage the gearing in a manual transmission is a proven technology, just as the exclusive use of hydraulics in automotive braking systems.

Akron Polymer Products is a leader in providing thermoplastic hydraulic actuation tubing. We offer our customers design, development and manufacturing of small diameter, thick walled thermoplastic tubing that performs in under hood engine environments at pressures required for proper clutch actuation throughout the vehicle’s life.

Akron Polymer Products can extrude and form complex three dimensional shapes, and also assemble and test hydraulic actuation tubing out of many types of high performance polyamide (nylon) compounds. Akron Polymer Products is also capable of over molding the end adaptors and sleeving parts for abrasion or additional thermal protection.

Have a Hydraulic component and not sure exactly what it is, or where to have it fixed? Look no further put out extensive hydraulic knowledge to use and let us help you with your Hydraulic system needs.

2 and fisher plow used a belt driven pump. the 1990 i had with a 6. this heavy duty plow is a fine choice for the small business and independent snow plower. it" s a genuine, factory- tough accessory specifically engineered to securely hold fisher ® hand- held or joystick controls and all types of smart phone devices ( not included with mount). how to remove hydraulic fisher plow - duration: 6: 42. technical support owners manuals. plowing snow with the right equipment makes winter fun. 7945 fisher pump mate belt drive pulley under hood 6 diamond free shipping!

8 v6 belt drive hydraulic plow pump kit. see more videos for fisher under the hood belt driven hydraulic plow manual. this could be used for anything but it was designed for the diamond under hood belt drive plow pumps. this would be great for a diamond or fisher plow. i believe it was a 1- 1 ratio, if it wasn" t then it was very close to that. the unique feature of the diamond plow was the aggressive curve with a good trip edge. they had 2 style tanks a rectangle and a round tank this is the round tank part #.

8shbp- 161 diamond belt drive hydraulic plow pump kit 1992+ gmc. 5741 fisher engine pump sheave chevy 2. old school snow plow action! control cup holder mount. the accessories were drive by a serpentine belt, but the plow pump used v belt was driven by a pulley bolted to the crank pulley. sub- categories snowplows pusher / box plows hopper spreaders under tailgate spreaders tailgate spreaders rotary broom. this style was mounted under the hood. need help fisher under the hood belt driven hydraulic plow manual hooking up a old belt driven fisher snow plow pump. live free 156 views. the control cup holder mount is designed to fit firmly in most vehicle cup holders.

this is 5" round and 4. used a4460 genuine fisher belt drive under hood 7 way control valve 4000 psi cable operated. the hydraulic cylinders make the snow blade move back- and- forth quick and effective. originally they used under- the- hood hydraulic pumps to run the plows but that is no longer the case.

8613371530291

8613371530291