what causes hydraulic pump cavitation for sale

The second leading cause of hydraulic pump failure, behind contamination, is cavitation. Cavitation is a condition that can also potentially damage or compromise your hydraulic system. For this reason, understanding cavitation, its symptoms, and methods of prevention are critical to the efficiency and overall health of not just your hydraulic pump, but your hydraulic system as a whole.

The product of excessive vacuum conditions created at the hydraulic pump’s inlet (supply side), cavitation is the formation, and collapse of vapors within a hydraulic pump. High vacuum creates vapor bubbles within the oil, which are carried to the discharge (pressure) side. These bubbles then collapse, thus cavitation.

This type of hydraulic pump failure is caused by poor plumbing, flow restrictions, or high oil viscosity; however, the leading cause of cavitation is poor plumbing. Poor plumbing is the result of incorrectly sized hose or fittings and or an indirect (not straight or vertical) path from the pump to the reservoir. Flow restrictions, for example, include buildup in the strainer or the use of an incorrect length of hose or a valve that is not fully open. Lastly, high oil viscosity—or oil that is too viscous—will not flow easily to the pump. Oil viscosity must be appropriate for the climate and application in which the hydraulic pump is being used.

The greatest damage caused by cavitation results from the excessive heat generated as the vapor bubbles collapse under the pressure at the pump outlet or discharge side. On the discharge side, these vapor bubbles collapse as the pressure causes the gases to return to a liquid state. The collapses of these bubbles result in violent implosions, drawing surrounding material, or debris, into the collapse. The temperature at the point of implosion can exceed 5,000° F. Keep in mind that in order for these implosions to happen, there must be high vacuum at the inlet and high pressure at the outlet.

Cavitation is usually recognized by sound. The pump will either produce a “whining” sound (more mild conditions) or a “rattling” sound (from intense implosions) that can sound like marbles in a can. If you’re hearing either of these sounds, you first need to determine the source. Just because you hear one of these two sounds doesn’t guarantee that your hydraulic pump is the culprit.

To isolate the pump from the power take-off (PTO) to confirm the source, remove the bolts that connect the two components and detach the pump from the PTO. Next, run the PTO with no pump and see if the sound is still present. If not, it is safe to assume your hydraulic pump is the problem.

Another sign you may be experiencing cavitation is physical evidence. As part of your general maintenance, you should be inspecting and replacing the hydraulic oil filter"s elements at regular intervals based on the duty cycle of the application and how often it is used. If at any time during the inspection and replacement of these elements you find metallic debris, it could be a sign that you’re experiencing cavitation in the pump.

The easiest way to determine the health of your complete hydraulic circuit is to check the filter. Every system should have a hydraulic oil filter somewhere in-line. Return line filters should be plumbed in the, you guessed it, return line from the actuator back to tank—as close to the tank as possible. As mentioned earlier, this filter will have elements that should be replaced at regular intervals. If you find metallic debris, your pump could be experiencing cavitation. You’ll then need to flush the entire system and remove the pump for inspection.

Conversely, if you’ve already determined the pump to be damaged, you should remove the filter element, cut it open, and inspect it. If you find a lot of metal, you’ll need to flush the entire system and keep an eye on the other components that may be compromised as a result.

Once cavitation has been detected within the hydraulic pump, you’ll need to determine the exact cause of cavitation. If you don’t, cavitation can result in pump failure and compromise additional components—potentially costing you your system.

Since the pump is fed via gravity and atmospheric pressure, the path between the reservoir and the pump should be as vertical and straight as possible. This means that the pump should be located as close to the reservoir as is practical with no 90-degree fittings or unnecessary bends in the supply hose. Whenever possible, be sure to locate the reservoir above the pump and have the largest supply ports in the reservoir as well. And don"t forget, ensure the reservoir has a proper breather cap or is pressurized (3–5 PSI), either with an air system or pressure breather cap.

Be sure the supply line shut-off valve (if equipped) is fully open with no restrictions. This should be a “full-flow” ball valve with the same inside diameter (i.d.) as the supply hose. If feasible, locate a vacuum gauge that can be T’d into the supply line and plumb it at the pump inlet port. Activate the PTO and operate a hydraulic function while monitoring the gauge. If it reads >5 in. Hg, shut it off, and resume your inspection.

A hose with an inner bladder vulcanized to a heavy spiral is designed to withstand vacuum conditions as opposed to outward pressure. The layline will also denote the size of the hose (i.d.). You can use Muncie Power’s PPC-1 hydraulic hose calculator to determine the optimal diameter for your particular application based on operating flows.

Another consideration, in regards to the inlet plumbing, is laminar flow. To reduce noise and turbulence at the pump inlet, the length of the supply hose should be at least 10 times its diameter. This means that any type of shut-off valve or strainer at the reservoir should be at least 10 diameters from the pump inlet. A flared, flange-style fitting at the pump inlet can also reduce pump noise by at least 50 percent compared to a SAE, JIC, or NPT fitting.

Selecting the proper viscosity of hydraulic fluid for your climate and application is also critical. Oil that is too viscous will not flow as easily to the pump. Consult your local hydraulic oil supplier for help selecting the optimal fluid viscosity.

By maintaining a regular maintenance schedule, remaining vigilant for any signs or symptoms, and taking preventative measures, the good news is that you should be able to prevent cavitation and experience efficient operation for the duration of your pump’s lifespan.

Poor plumbing is the leading cause of cavitation and can be prevented by selecting a properly sized hose, choosing the appropriate fittings, ensuring the most direct, straight routing from the pump to the reservoir, etc.

Two leading causes why hydraulic pumps usually fail are: (1) contamination and (2) cavitation. In order to prevent any potential damage to your entire hydraulic system, it’s imperative to understand cavitation, the indications or symptoms from your system it is occurring, as well as the preventive measures.

How does cavitation happen exactly? It starts when vapor bubbles in the oil are created due to high vacuum. When these vapor bubbles are carried and collapsed on the pump outlet (discharge side), cavitation happens.

Make Sure Oil flow Paths are Straight – Hydraulic pumps are being supplied via atmospheric pressure and gravity, so it’s ideal to place the reservoir above it. Make sure that the path is as straight and vertical as possible. Keep an eye on bent or twisted supply hose.

Check Laminar Flow – If you’re hearing turbulence or noise in pump inlet, make sure that the supply hose length is the correct ratio to its diameter. A flange-style, flared fitting in the pump inlet can also help in eliminating pump noise.

Check Proper Viscosity – It"s important to choose the hydraulic fluid with appropriate viscosity for your application and climate. Consult with your supplier for professional help in choosing the optimal fluid viscosity.

With regular maintenance, keeping an eye on symptoms, and taking preventive measures, you’d be able to avoid cavitation and expect efficient operation from your hydraulic pumps.

Cavitation is the second leading hydraulic pump failure cause, behind contamination. As this can potentially cause damage and compromise your hydraulic system, it is important to understand what it is as well as its symptoms.

Cavitation is the product of excessive vacuum conditions created at the hydraulic pump’s inlet. This causes high vacuums to create vapour bubbles within the hydraulic oil, these are then carried to the discharge side before they then collapse - causing cavitation to occur.

These high vacuums and cavitation are often caused by poor plumbing, flow restrictions, or high oil viscosity. Poor plumbing is often the main cause of this and is due to an incorrectly sized hose or fittings and/or an indirect (not straight or vertical) path from the pump to the reservoir.

The easiest way to identify cavitation is through noise. The hydraulic pump will either emit a “whining” or a “rattling” sound. If you hear either or both of these sounds you will need to isolate the pump to make sure that this is where it is coming from.

As part of your general maintenance, you should be inspecting and replacing the hydraulic oil filter"s elements at regular intervals based on the duty cycle of the application and how often it is used. If when replacing the filter you come to find metallic debris this could be a sign that cavitation is occurring within the pump. In this case it is best to flush the entire system and detach the pump for closer inspection.

When replacing the filter you find that it is damaged, this could be due to cavitation. To find out if this is the case, remove the filter element of the hydraulic system and inspect for metallic debris. If there is some present then flush the system to prevent damage being caused elsewhere. Now that you have identified cavitation has been occurring within the hydraulic pump, you’ll need to determine the exact cause of cavitation.

As there are so many causes and damage results from cavitation, it is important to regularly check your hydraulic pump for signs of cavitation. By simply checking the pump and filter you can prevent your hydraulic system from failing when you most need it.

Hydraulic pumps come in a variety of sizes, styles and fuel types, so if you are having issues with your pump browse our great range for a replacement or get in contact with our expert team for advice on any hydraulic issue.

Although cavitation can occur anywhere in a hydraulic system, it commonly occurs within the suction line of a pump. This will cause excessive noise in the pump – generally a high pitched “whining” sound. However, this excessive noise is only the tip of the iceberg! The real result of this phenomenon is severe pump damage and a decrease in pump life. I have personally seen many instances where a customer was replacing pumps frequently, thinking they were receiving defective pumps from their vendor. In reality, the pump failures were not due to poor pump quality – the failures were occurring because of cavitation.

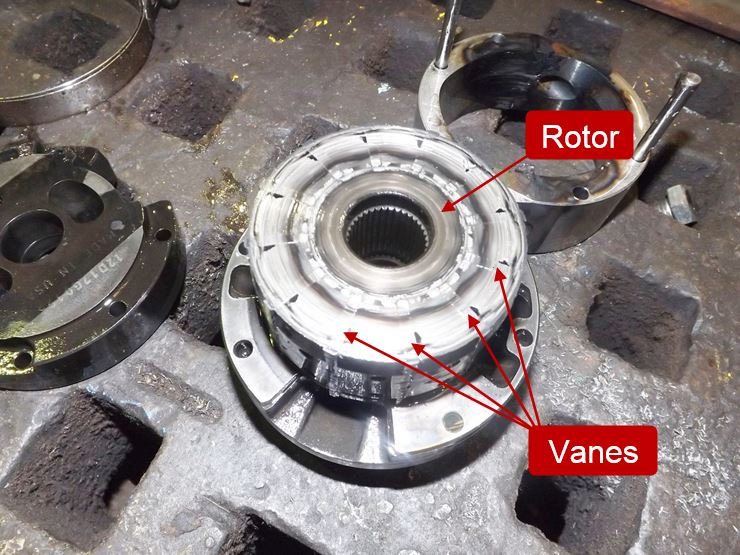

Simply put, cavitation is the formation of vapor cavities in the hydraulic oil. In hydraulic pumps, cavitation will occur any time the pump is attempting to deliver more oil than it receives into the suction (inlet) line. This is commonly referred to as “starvation” and results from a partial vacuum in the suction line. To fully illustrate what is happening when this occurs, we need to discuss vapor pressure. Vapor pressure is the pressure below which a liquid at a given temperature will become a gas, and this pressure varies significantly depending on the liquid. Generally, as the temperature of a liquid rises, the vapor pressure will proportionally increase. Likewise, as the temperature decreases, the vapor pressure will decrease. Most of us know that water will boil (turn to vapor) at 212°F (100°C) at 14.7 PSI (atmospheric pressure at sea level). In other words, the vapor pressure of water at 212°F is 14.7 PSI. If the pressure is reduced, the temperature at which the water boils will be reduced. If the temperature is lowered, the vapor pressure will decrease. In fact, water will boil at room temperature if the pressure is sufficiently reduced! The same principle applies to hydraulic oil, although the vapor pressure will be somewhat different than that of water. The vapor pressure of hydraulic oil is somewhere between 2 and 3 PSI at normal temperatures. In ideal conditions, the pressure in the suction line of the pump will be around 14.7 PSI at sea level. Of course, this pressure decreases with altitude, but sufficient pressure will normally be maintained in the suction line to prevent cavitation of the oil. However, if the pressure in the suction line of the pump is sufficiently reduced to the vapor pressure of the oil, vapor cavities will form. As the oil passes from the suction line to the outlet of the pump, the pressure will increase and the vapor cavities will implode violently. These extremely powerful implosions will cause erosion and premature failure of the pump components. In fact, a brand-new pump can be destroyed in a matter of minutes if the cavitation is severe enough. The picture below shows a rotor and cam ring from a vane pump that had failed due to severe cavitation.

In my 35-plus years of troubleshooting hydraulic components, this is the worst case of cavitation damage I have ever seen. In addition to the usual erosion of the parts, the vanes were actually fused to the rotor slots! Although this is an extreme example, it shows the potential damage to a pump due to cavitation. The good news is that cavitation is preventable and we will look at several conditions that can trigger this phenomenon.

While there are several corrective actions that can be taken to resolve a pump cavitation issue within a hydraulic pump, supercharging, or pressurizing, the pump inlet is probably the easiest and most cost effective way of doing this. There are many different benefits to supercharging (forcing flow into the inlet), which creates an artificial positive head or pressure on the pump inlet, reducing the “suck” a pump must have to get oil into the system. Creating a positive head on the inlet will completely eliminate pump cavitation and increase the longevity of the hydraulic pump. There are different ways in which we can supercharge the pump inlet.

Oil viscosity is greatly impacted by the temperature of the oil, with low temperatures causing increases in viscosity which makes it difficult for the oil to reach the pump. Generally, it is best to avoid starting hydraulic systems with oil colder than 40°F (4°C) or putting under load with oil colder than70°F (21°C).

Reservoirs do not always have heaters, especially in the South. Those that do possess available heaters are usually disconnected. Although the damage may not be instantaneous, a pump regularly started using cold oil will eventually fail prematurely.

Investing in a hydraulic oil of high viscosity index base oils with low pour points for wide temperature range applicability, like CITGO’s Mystik® JT-9™ LeakShield® AW Hydraulic Oil, can help prevent such cavitation.

Once a year at minimum, the suction strainer needs to be removed from the reservoir and cleaned. It is prudent to keep in mind that strainers may become blocked for a variety of reasons. If there seems to be a malfunction with a pump—before taking any drastic action, like making replacements—check to ensure nothing has obstructed the suction line.

Every pump has a maximum drive speed. High speeds require higher volumes of oil at the suction ports. If an electric motor is driving the hydraulic pump at speeds over the pump’s rating, you might be gearing up for a crash course in cavitation.

Adequate oil volume is unable to flow into the suction cavity in the pump due to the port’s size, causing the pump to cavitate. Maximum drive speeds can range from as low as 1,200 revolutions per minute (RPM) to as high as 3,600 RPM — so always check drive speed when replacing a pump with that of a different brand or model. Cavitates tend to be rare but being mindful of your pumps’ maximum drive speeds can prevent costly mishaps, such as leaks and other cavitation-induced damage altogether.

Have you ever heard a loud popping noise when using a hydraulic pump? If so, you’ve likely experienced hydraulic pump cavitation. These phenomena can cause severe damage to your equipment and lead to decreased performance. In this blog post, we’ll take a closer look at what causes hydraulic pump cavitation and how you can prevent it from happening. Stay tuned!

Hydraulic pump cavitation is a condition that can occur when the pump is not primed correctly. Air bubbles get trapped in the fluid and are forced through the pump. As the bubbles pass through, they create a void or low-pressure area. This can cause the pump to become less efficient and can also lead to damage to the equipment.

One of the first signs that something is wrong is when you hear loud popping noises from the equipment. This is caused by the air bubbles being forced through the pump and colliding. The louder the noise, the more severe the cavitation is.

As cavitation starts to occur, you may notice a decrease in the performance of your hydraulic equipment. This is because the pump isn’t able to function as efficiently when there are air bubbles present. If left unchecked, this can lead to severe damage.

If cavitation is not corrected, it can cause damage to your equipment. The air bubbles can cause wear and tear on the pump components, eventually leading to failure. In severe cases, cavitation can even cause the pump to explode.

If you notice any of these symptoms, it’s essential to take action quickly to prevent further damage. Luckily, there are some steps you can take to prevent hydraulic pump cavitation from occurring in the first place.

Finally, check the hoses and fittings to ensure they are the correct size for your application. Using a larger diameter hose will help increase fluid flow and prevent cavitation from occurring.

The short answer is yes. When a pump cavitates, the damage caused by the cavitation can be significant. The most common type of damage is erosion. Erosion from cavitation can cause the pump to become less efficient and can also lead to damage to the equipment. In some cases, the damage caused by cavitation can be so severe that it can cause the pump to fail. Cavitation can also cause other problems such as noise, vibration, and increased wear on the pump.

If you have a hydraulic pump that has gone through cavitation, it is essential to have it inspected by a qualified technician. The technician will be able to assess the damage and determine if the pump can be repaired or if it needs to be replaced. In some cases, the damage caused by cavitation is not severe enough to warrant the pump replacement. However, if the damage is severe, it is essential to replace the pump as soon as possible to avoid further damage to the equipment.

It is also important to note that once a pump has gone through cavitation, it is more likely to experience cavitation. This is why it is essential to inspect the pump after it has gone through cavitation. By having the pump inspected, you can ensure that it is in good working condition and that no damage could cause the pump to fail.

If you have a hydraulic pump that has gone through cavitation, it is essential to take action to prevent it from happening again. Some of the things you can do to prevent cavitation include:

Cavitation can cause a loss of pump efficiency and damage the pump. If left unchecked, cavitation can eventually lead to complete failure of the pump.

Proper priming: One of the best ways to prevent cavitation is to ensure that the pump is properly primed. This will help to avoid air bubbles from becoming trapped in the fluid.

Viscosity control: Another way to prevent or mitigate cavitation is to control the fluid’s viscosity. This can be done using a viscosity stabilizer or keeping the fluid at a constant temperature.

Pressure relief: Pressure relief valves can also prevent or mitigate cavitation. These valves allow air to escape from the pump, which helps avoid air bubbles forming.

Hydraulic pump cavitation is a condition that can occur when the pump is not primed correctly. Air bubbles get trapped in the fluid and are forced through the pump. As the bubbles pass through, they create a void or low-pressure area. This can cause the pump to become less efficient and can also lead to damage to the equipment. Cavitation can cause a loss of pump efficiency and damage the pump. If left unchecked, cavitation can eventually lead to complete failure of the pump. Several common causes of cavitation in hydraulic pumps include insufficient priming, viscosity changes, and pressure changes. Several ways prevent or mitigate cavitation in hydraulic pumps, including proper priming, viscosity control, and pressure relief.

Prime the pump properly, control the fluid’s viscosity, and use pressure relief valves. These methods will help avoid the formation of air bubbles, which can cause cavitation.

Cavitation is a condition that can occur in hydraulic pumps when they are not adequately primed. Air bubbles become trapped in the fluid and are forced through the pump. As these bubbles pass through, they create voids or low-pressure areas. This can cause the pump to be less efficient as well as damage the equipment.

Cavitation can cause a loss of pump efficiency and damage if left unchecked, eventually leading to complete failure. There are ways to prevent or mitigate cavitation in hydraulic pumps by priming the pump properly, controlling fluid viscosity, and using pressure relief valves. These methods can help avoid the formation of air bubbles, which can cause cavitation.

Hydraulic pump cavitation is a condition that can occur when the pump is not primed correctly. Air bubbles get trapped in the fluid and are forced through the pump. As the bubbles pass through, they create a void or low-pressure area. This can cause the pump to become less efficient and can also lead to damage to the equipment. Cavitation can cause a loss of pump efficiency and damage the pump. If left unchecked, cavitation can eventually lead to complete failure of the pump.

Several common causes of cavitation in hydraulic pumps include insufficient priming, viscosity changes, and pressure changes. Several ways prevent or mitigate cavitation in hydraulic pumps, including proper priming, viscosity control, and pressure relief. By following these methods, you can help avoid the formation of air bubbles and cavitation in your hydraulic pump. We hope this guide has helped teach you What Causes Hydraulic Pump Cavitation.

Hydraulic pump cavitation is a condition that can occur when the pump is not primed correctly. Air bubbles get trapped in the fluid and are forced through the pump. As the bubbles pass through, they create a void or low-pressure area. This can cause the pump to become less efficient and can also lead to damage to the equipment

The best way to avoid cavitation in your hydraulic pump is to prime the pump properly, control the fluid’s viscosity, and use pressure relief valves. These methods will help avoid the formation of air bubbles, which can cause cavitation.

When a reliable hydraulic system suddenly starts exhibiting problems, one of the first types of components most technicians assume may need to be replaced are hydraulic pumps, yet the pump should be the last component evaluated since it is often very time-consuming to replace.

There are all sorts of “warning” symptoms a hydraulic system will exhibit long before pump failure. Some of the most common types are changes in the sounds the system makes while it is in operation. If the system suddenly starts sounding different from how it has before, this could indicate various types of problems.

Two of the more common changes in sound are a banging noise, much like water banging in plumbing pipes, and or a very high pitched shrieking noise, similar to the sound sticky car brakes make. These sounds indicate aeration and cavitation in the system, which we will discuss in more detail shortly.

Another thing to check if you notice the system is not working correctly is to verify the pump is turning. Some systems are designed so that you have to manually engage or switch the pump on. You would be surprised by how many system problems are due to the pump not being turned on!

The last thing to check before getting into troubleshooting the pump is the hydraulic fluid level. If the fluid level is too low, it will allow air into the system and cause operational problems. If you discover air in the system, you will need to remove it first to avoid pump failure.

Aeration occurs when air is introduced into the hydraulic system. This can be due to defective seals, through low tank fluid level allowing air into the pump inlet line, damaged inlet hoses and connections. It is easy to check to find out if there is air in the system as the fluid returning to tank will be foamy and the oil in the tank full of bubbles.

Operating the system when air is present may result in the pump being unable to reach the pressures required to operate the system. A by-product of this problem is the generation of excessive heat. Excessive heat is of course another reason in itself for pump failure, in this case secondary to aeration but demonstrates how the primary cause can set off a vicious circle, in this case aeration, leading to excessive heat, leading to lack of lubrication, leading to contamination issues, possible partial or full bearing seizure before complete pump failure.

The opposite of aeration is cavitation. Instead of air being added to the fluid, it is removed very rapidly. Cavitation is where air bubbles form quickly and collapse inward on each other within the fluid. This occurs due to a vacuum at the pump inlet as a result of an insufficient fluid supply. As in excess of 10% by volume of hydraulic fluid is dissolved air when there is an excessive vacuum at the pump inlet it is this air that is being drawn out of the oil.

The effects of cavitation can be seen around the internal pump inlet surfaces as the air is drawn out the oil it causes the removal of tiny amounts of material from the internal pump surfaces on the inlet side. This is always particularly evident in aluminum gear pumps as it leaves a slightly pock marked or frosty looking surfaces on the bearing blocks and inside of the gear housing on the inlet side.

Every hydraulic pump has a maximum design pressure level. If you attempt to operate the pump at a higher pressure than it was designed for, it will cause premature pump failure. The pump simply cannot handle the excessive pressure.

Contaminants are one of the biggest reasons for hydraulic pump replacement. Contaminants can enter into the hydraulic system through a variety of entry points. One of the most common ones is through the hydraulic fluid reservoir.

As contaminant levels grow, they can get stuck in between key surfaces such as between gear end faces and bearing block or pressure plate or between piston barrel and valve plate in a piston pump. This then leads to further wear and the generation of more contaminant and heat. The more contaminant induced wear there is to these surfaces the larger the gap becomes between these critical surfaces leading to loss of pressure capability, overheating and failure.

The viscosity of the hydraulic fluid moving through the system could lead to premature pump failure if it is not properly maintained. Having a fluid of a higher viscosity level than specified for the pump can result in cavitation within the hydraulic pump.

On the other hand, when fluid viscosity is too low, it can lead to excessive leakage between critical surfaces leading to an increase in heat generation. As such, the fluid can become too hot, overheating the entire system, and ultimately causing premature pump failure.

Extreme heat is often caused as a byproduct of other hydraulic system problems. If you notice your system seems to be operating at a higher temperature than it normally does, take it as a warning sign that something is wrong. Continuing to operate the system can lead to more costly repairs.

Excessive heat levels not only cause parts and components to fail but also can damage drive shafts, housings, and other metal components. Additionally, damaged parts and components may not properly seal leading to fluid leaks. Furthermore, inside pumps, misalignment of moving parts could occur, causing internal damages that introduce contaminants into the system.

Many types of hydraulic pump system failures could easily be avoided with regular pump maintenance. Regular maintenance requires checking and inspecting the entire hydraulic system prior to using it. Some of the more common things you should do include:

Another vital part of maintenance is replacing worn out hoses, valves, and related parts and components when they show signs they need to be replaced. It is better to replace hydraulic system parts and components before they fail. Doing so will result in low overall maintenance and repair costs. When replacing components always make certain they are clean of dust and dirt before fitting to avoid unwanted contamination entering the system.

Furthermore, hydraulic fluid should be changed periodically as it starts to slowly break down from extended use. Your objective is to ensure the fluid provides the right viscosity level required for your hydraulic operations. Always flush the system and replace the hydraulic fluid when replacing a pump or motor and be especially vigilant in removing contaminant from every nook and cranny of the system when component failure has been due to contamination damage and the source of contamination has been ascertained.

For further help troubleshooting hydraulic pump system failures, as well as all of your hydraulic system motors, pumps, parts, and component needs, please contact White House Products, Ltd. at +44 (0) 1475 742500 today!

Frequently occurring in pumping applications, cavitation creates bubbles or vapor cavities in a liquid as a result of rapid changes in pressure. These liquid-free voids typically form in low-pressure zones and can burst when subjected to high pressures, sending powerful shockwaves throughout the entire application.

Manufacturers in the chemical processing, food processing, and petroleum industries must consider the risk of cavitation when designing machinery in order to avoid unwanted noise, vibration, and component damage.

Cavitation decreases an application’s efficiency over time and puts repeated stress on critical pump parts, shortening their overall lifespan. Shockwaves can cause significant damage to the pump, which in turn leads to premature valve failure, decreased flow pressure, and, ultimately, breakage. If you’re experiencing any of these issues with your pumping application, our in-house pump experts can help.

There are two types of cavitation that may occur in reciprocating positive displacement applications: suction and discharge. Suction cavitation occurs ahead of the suction stroke, when the pump is starved of flow, either from being in a high-vacuum or low-pressure environment. The opening of the valve is delayed by inertia, causing a lower flow rate on the suction side and resulting in expansion, pressure decrease, and the formation of bubbles close to the plunger.

Discharge cavitation occurs when the pump’s discharge pressure is too high. Under these conditions, it’s difficult for the fluid to flow out of the pump. Instead, it continues moving at high velocities inside the working chamber, forming bubbles in the process.

When working with pumping applications in a processing industry, cavitation should always be kept in mind; being able to recognize the warning signs and identify the root causes of cavitation in your machinery can significantly reduce the risk of long-term damages, saving both time and money.

Triangle Pump Components has nearly a century of experience assisting clients with pump issues such as cavitation. Our pump components are designed to preserve expensive parts such as crankshafts and power frames by transferring the majority of wear to less expensive, more expendable parts such valves, plungers, and packing.

Hydraulic pumps are at the core of many essential factory operations. Unfortunately, there are numerous pitfalls to plan for, mitigate, and overcome to keep them running. Keeping up on routine maintenance is important, but the best way factory techs can avail themselves of costly, frustrating breakdowns is to understand the various catalysts for hydraulic pump failure.

The simplest way to identify the cause of pump failure is to thoroughly inspect and dissect the aftermath of the problem. In most cases, the cause of failure will be evident by the nature of the catalyst(s). Here are eight of the most common problems, some of their defining features, and how they ultimately come to fruition.

1. Fluid contamination is one of the biggest causes of hydraulic pump damage and involves debris mixing with the liquid. This debris causes friction, leading to extenuated wear on the pump itself. The result is inefficiency, culminating in malfunction.

2. Fluid viscosity issues occur when the hydraulic fluid within a pump breaks down over time. Viscosity that’s too high leads to cavitation (another catalyst for damage). Subsequently, if a tech changes and replaces fluid with a viscosity that’s too low, heat and friction become concerns.

3. Over-pressurization occurs because of excessive load on the pump itself, resulting in red-line operation that’s both unsafe and damaging. Hydraulic pumps operating under high duress for extended periods of time will likely experience component wear and premature failure, usually in spectacular fashion.

4. Excess heat can be a product of poor fluid viscosity or environmental factors. This issue is rarely a singular catalyst for pump breakdown, but it exacerbates other factors or masks other issues, such as fluid contamination.

5. Implosion invariably results in extreme failure for hydraulic pumps and is a major safety hazard. Implosion occurs when air bubbles within a hydraulic pump collapse, causing an overload of pressure to the pump that generates an intense shock.

6. Aeration occurs when hydraulic fluid traps air bubbles. The pump subjects the bubbles to pressure, causing high heat and over-pressurization when the bubbles collapse. Aeration at extreme levels leads to implosion.

7. Pump aeration pertains to air not in the hydraulic fluid, but air introduced through unsealed joints or shafts. This air quickly causes pressure instability affecting crucial parts of the pump. This can quickly lead to breakdowns — generally marked by a whine or other high-pitched sound.

8. Cavitation is a symptom of uncontrolled pump speeds, which fail to allow hydraulic fluid to completely fill the pump. It results in destabilized pressure, heat, and excess wear. Cavitation is often marked by the same type of whine or squeal as pump aeration.

Because the factors causing each of these problems differ in nature, it’s best to fully evaluate a damaged hydraulic pump to determine if more than one issue is responsible.

Maintenance is the best approach for ensuring safe, efficient hydraulic pump function. But routine service is just the start. Identifying common issues plaguing your hydraulic pumps will lead to a better quality of targeted maintenance — for example, if you pinpoint a heat issue related to viscosity, that issue may be resolved by opting for a different fluid weight.

Every piece of information learned about your pumps can translate into better care, leading to longer uptimes, fewer issues, and fundamentally better maintenance.

Having trouble identifying the catalysts for your hydraulic pump’s issues? Let the professionals at Global Electronic Services take a look! Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!

In many factories, the hydraulic pump is the heart of the operation — and hydraulic pump failure can cause huge problems. But why do hydraulic pumps break? In order to avoid hydraulic pump failure, it’s helpful to know what some hydraulic pump failure causes are.

Before getting into the reasons hydraulic pumps break, it’s important to know the signs that your hydraulic pump is broken or in danger of breaking. Some of these signs include:

Noisy System:All mechanical systems make some noise, and hydraulic systems are no exception. But if you are hearing very loud banging or knocking, there’s a good chance that your system is experiencing aeration or cavitation, which could lead to pump failure.

High Temperature:If your hydraulic system is exceeding the recommended temperature level of 82 degrees Celsius, this could be due to a buildup of debris in the filters preventing the system from dissipating heat. This is a problem you will want to address quickly, as high heat can damage your system.

Slow System:If your system isn’t operating as quickly as it’s supposed to, you definitely have a problem. A slow hydraulic system means a loss of flow, which typically means internal leakage.

The major cause of hydraulic pump failure is called fluid contamination. This is an invasion of the hydraulic fluid by foreign materials. Hydraulic pumps and valves are only designed to carry hydraulic fluid, and anything else in them will damage the system, especially since this foreign debris may remain in the system and continue to damage the valves and pipes.

Aeration:Air in the hydraulic fluid can create problems when put under pressure by the pump. When this happens, they can implode and dislodge debris, causing contamination and raising the temperature inside the pump.

Cavitation:Cavitation is a situation where the hydraulic fluid doesn’t fully take up the space in the pump because of unusually high fluid viscosity, an intake line that is too long or an overfast pump, among other reasons. It can lead to problems similar as aeration.

Excessive Heat:An overheated hydraulic system can cause some massive problems for your hydraulic system. It can damage seals, degrade the hydraulic fluid and otherwise compromise the system.

Overpressurization:Hydraulic pump systems are very sensitive and should only operate under specific conditions, including precise pressure levels. Exceeding recommended pressure levels puts undue pressure and wear on the system and can cause it to fail more quickly.

The best way to avoid hydraulic system failure is to keep your system clean. Remember: fluid contamination is the main precursor to hydraulic system failure, so keeping those contaminants out of your system is your best chance to maintain healthy hydraulics. This means high-quality filters in your system that you inspect regularly and change when necessary.

The other major way to keep your hydraulic system up and running is by keeping the components cool. An overheated system can result in real problems, and you may not notice the effects until it is too late. You’ll also want to make sure your system is operating under the right pressure specifications.

A well-maintained hydraulic system can last a long time and be extremely efficient. Although there are many problems that can occur with a hydraulic system, most can be avoided with proper care, and the benefits of having a good hydraulic system for your business can be great — well worth taking good care of your system.

Part of that care is taking quick action when necessary. If you suspect that there is a problem with one or more components of your hydraulic system, the best thing to do is have a professional inspect it and repair any faulty parts that are failing or at risk of failing. The longer you let a hydraulic system problem go without addressing it, the worse the failure will be when it does happen.

Global Electronic Services has factory-trained, certified technicians who are well-versed in hydraulic systems and hydraulic problems. If you’re delaying repairing your hydraulics because you’re afraid of taking them offline, you should know that Global Electronic Services can complete your repair in a matter of days. For more information, call 877-249-1701 or contact Global Electronic Services online.

Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!

8613371530291

8613371530291