what causes hydraulic pump whine quotation

Every hydraulic pump makes some noise. If all is well with a pump, then this noise stays more or less the same. However, if something goes wrong with the pump or its connected system parts, then you may start to hear sounds that you haven"t heard before.

The fluid that flows through your system needs to move at a smooth and even rate. The pump has to deliver the fluid at a specific flow for things to work.

If something prevents the fluid from achieving and maintaining its optimum flow, then your pump may start to make unusual noises. For example, you may hear a high-pitched whine coming from the pump. This can be a constant or intermittent sound.

If your pump whines constantly, then you may have a cavitation problem. Here, the pump can"t deliver its fluid at the right volume or rate. There isn"t enough fluid coming through the pump"s suction line.

In some cases, this is a sign that your pump"s motor is on the wrong setting. So, the pump itself is working at the wrong speed to create the right flow.

A hydraulic pump might get noisy if one of its parts or connections has a problem. A faulty or failing pressure control, bearing, valve, seal, or coupling can make a noise you haven"t heard before.

In some cases, you may hear vibrating clunks as your pump works if you have a problem with a connecting pipe. A loose seal or connector might allow the pipe to move. It then passes vibrations along to the pump itself.

While some noise problems are easy to fix, some are a sign that your pump is close to the end of its working life. Sometimes, this is due to natural wear, usage, and age. However, in some cases, minor problems cause more widespread damage if you don"t fix them quickly.

For example, if you"ve had cavitation problems for a while, then your system may not have been getting the lubrication it needs; it may have overheated regularly. Even if you fix the cavitation issue, you may be left with a damaged pump that needs a more significant repair, rebuild, or replacement.

So, while new sounds or an increase in operating noise don"t necessarily mean that you have a serious pump problem, you should investigate any unusual noise. Typically, this is a sign that something isn"t working right.

A minor problem in your system could go on to cause significant damage. For an expert diagnosis, contact Quad Fluid Dynamics, Inc. Ourhydraulic pump repair and rebuild servicewill get your pump running smoothly and efficiently again.

Longer cycle times are often the first indication that there is something wrong with a hydraulic system. Decreased speed of hydraulic actuators (such as cylinders) points to decreased flow through the system.

Decreased flow can be caused by either external or internal leaks. External leakage can often be spotted very easily. Look for leaking/busted hydraulic hose, hydraulic fluid around connectors or under components.

See the related blogs on preventive maintenance of hydraulic hoses and knowing when to replace a hydraulic hose. Another related blog, “What is Causing Your Hydraulic System to Leak” has a free download of our Port End Assembly Guide, which can educate your maintenance personnel on preventing connector leaks in the first place.

Internal leaks (such as high-pressure fluid passing around the cylinder piston, or incorrectly set relief valve pressure) are more challenging to identify. One way to identify an internal leak is by detecting elevated temperature of a failing component. A leak generates heat. Higher temperature results in decreased viscosity of the hydraulic fluid. Decreased viscosity of the fluid further increases leakage, leading to additional increases in temperature… You get the picture of how the situation escalates.

In some cases, temperature measurement is not conclusive. If an internal leak cannot be detected by locating a component generating abnormal heat, use a hydraulic flow meter.

Knocking, loud whining, or screeching often indicates aeration or cavitation. Aeration means air inclusion in the hydraulic fluid, cavitation is the presence of vaporized hydraulic fluid in the system.

Banging or knocking noises can indicate that air is included in the hydraulic fluid. Other symptoms of air inclusion are foaming of the fluid, and erratic actuator movements.

Air in the system accelerates breakdown of the hydraulic fluid and decreases hydraulic fluid’s lubricating properties. Both conditions lead to increased wear of the system’s components, through increased friction, overheating, and burning of seals.

Air usually enters the system through the pump intake. Check the fluid level and a condition of the suction hose. If the hose is old or shows any warning signs, replace it. See related blogs on knowing when to replace a hydraulic hose, scheduled hydraulic hose replacement, and preventive maintenance of hydraulic hoses for more information on the subject.

Cavitation results from demand for hydraulic fluid not being met. Typically (but not exclusively), this happens at the pump. The insufficient flow causes the absolute pressure in the affected part of the circuit to fall below the vapor pressure of the hydraulic fluid, which in turns causes formation of vapor cavities within the fluid. When the vapor cavities are compressed, they implode and produce a knocking noise.

Excessive temperature of hydraulic fluid (generally above 180°F), reduces its working life and damages seals in the system. In addition, viscosity of hydraulic fluid decreases with increasing temperature, which in turn results in inadequate lubrication and increased wear of the system"s components.

There are two general causes for increased hydraulic fluid temperature: either a component produces more heat than it should, or the heat dissipation capacity of the system is reduced/inadequate.

Regularly check the hydraulic oil level and viscosity. Check the heat exchanger for any obstructions in both coolant lines and hydraulic fluid lines. Make sure that the heat exchanger has adequate space around it.

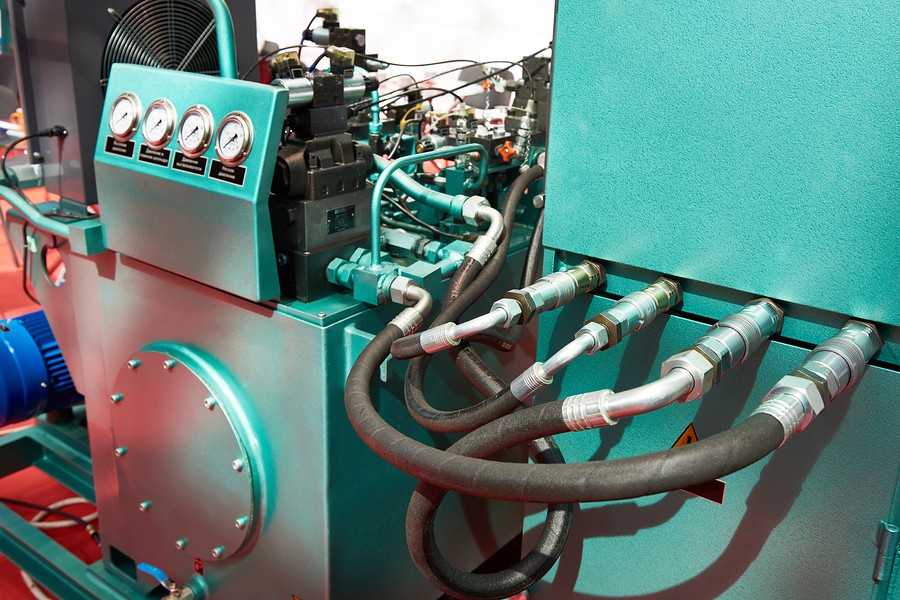

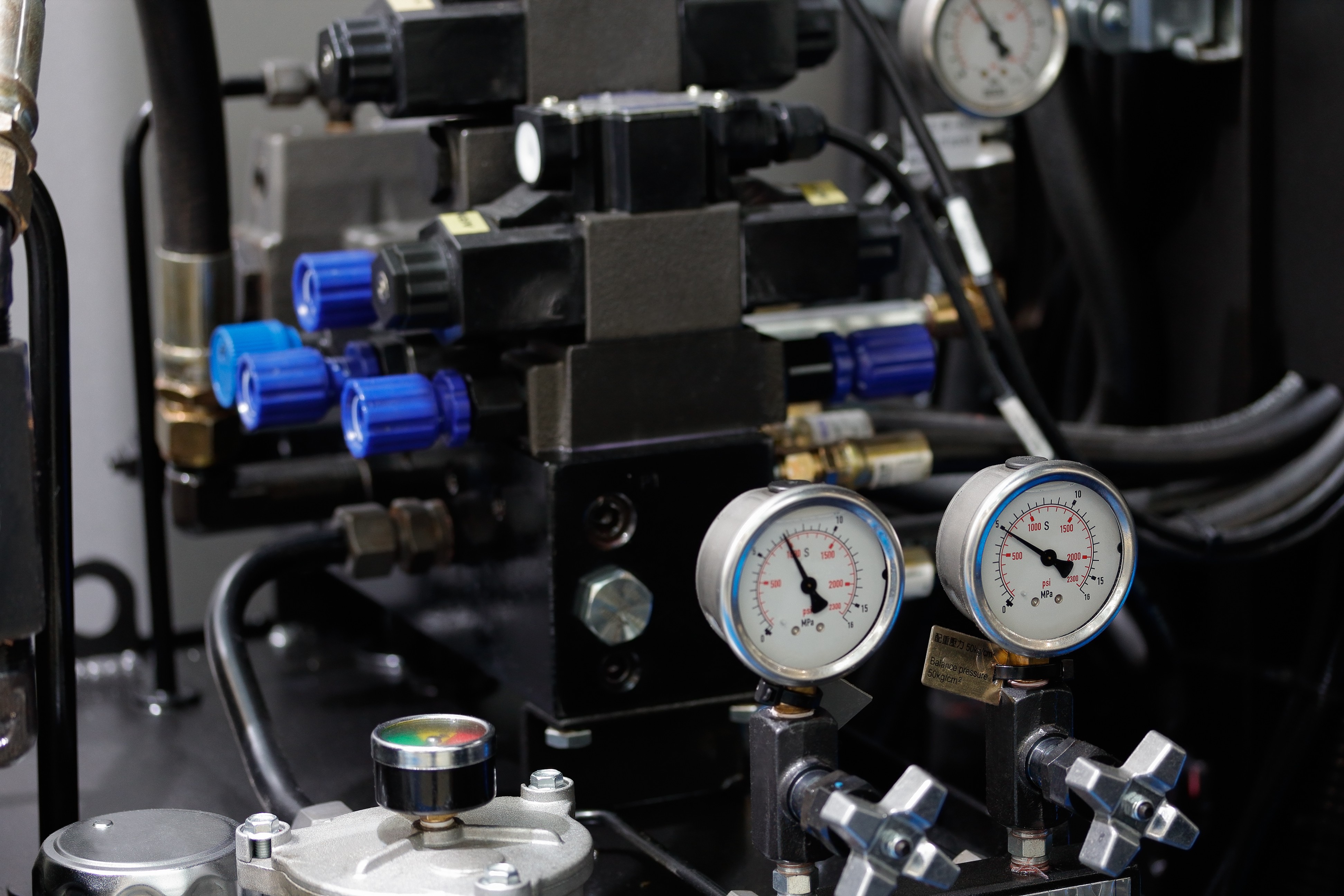

To properly analyze and/or troubleshoot your hydraulic system, you will need some tools. At minimum, you need to be able to measure pressure, temperature, and flow at different parts of your circuit. The more complex your hydraulic system, the more sophisticated meters you will need to get the job done.

Parker SensoControl family of diagnostic meters offers four different diagnostic solutions to address the needs of maintenance personnel, based on the complexity of their hydraulic circuits.

Pump cavitation is first and foremost caused by insufficient flow. This happens when the volume of fluid being supplied doesn’t meet the demands of the hydraulic circuit, and the pressure at the suction end of the pump isn’t sufficient. This leads to the absolute pressure falling below the vapor pressure of the liquid, which leads to air bubbles being formed. These tiny bubbles implode as they pass through the system, creating shockwaves and causing pump vibrations.

The process of these bubbles forming and collapsing is done with a great deal of force, and leads to eventual metal erosion inside the pump. The mechanical damage caused by cavitation can have irreversible impacts on system components and may possibly lead to complete failure. Cavitation happens only on the suction side of the pump, and may be caused by a series of different malfunctions, including:

Cavitation is typically characterised as a high-pitched whining or screeching sound, and in some extreme cases, can present itself as a loud rattling sound. Whilst these hydraulic pump whine noises are generally the most obvious telltale signs of cavitation, other symptoms to look out for also include:

By design, hydraulic pumps contain a miniscule amount of air which allows space for the hydraulic fluid to heat up and expand. However, too much air in the pump can cause serious issues – this is known as aeration.

Aeration in a hydraulic pump occurs when there is an air leak in the suction line. When outside air enters the pump through a damaged connector, loose pump seal, pipe fitting, or any other damage, it gets drawn into the pump’s hydraulic fluid supply. This unwanted air quickly gets dissolved into the hydraulic fluid and leads to contamination.

Contaminated hydraulic fluid can have serious implications for the system, as the excess air means that it cannot conduct heat as efficiently and can cause the fluid to foam. This can lead to overheating and in some cases, a substantial decrease in power. Aeration may happen on both sides of the pump, and has several causes including:

Similar to cavitation, aeration is usually indicated by a sudden change in noise, which can sometimes make it difficult to differentiate between the two causes However, aeration tends to produce a more erratic low-pitched ‘rumbling’ or ‘rattling sound, as opposed to the more consistent whining noise of cavitation.

Hydraulic pumps are at the core of many essential factory operations. Unfortunately, there are numerous pitfalls to plan for, mitigate, and overcome to keep them running. Keeping up on routine maintenance is important, but the best way factory techs can avail themselves of costly, frustrating breakdowns is to understand the various catalysts for hydraulic pump failure.

The simplest way to identify the cause of pump failure is to thoroughly inspect and dissect the aftermath of the problem. In most cases, the cause of failure will be evident by the nature of the catalyst(s). Here are eight of the most common problems, some of their defining features, and how they ultimately come to fruition.

1. Fluid contamination is one of the biggest causes of hydraulic pump damage and involves debris mixing with the liquid. This debris causes friction, leading to extenuated wear on the pump itself. The result is inefficiency, culminating in malfunction.

2. Fluid viscosity issues occur when the hydraulic fluid within a pump breaks down over time. Viscosity that’s too high leads to cavitation (another catalyst for damage). Subsequently, if a tech changes and replaces fluid with a viscosity that’s too low, heat and friction become concerns.

3. Over-pressurization occurs because of excessive load on the pump itself, resulting in red-line operation that’s both unsafe and damaging. Hydraulic pumps operating under high duress for extended periods of time will likely experience component wear and premature failure, usually in spectacular fashion.

4. Excess heat can be a product of poor fluid viscosity or environmental factors. This issue is rarely a singular catalyst for pump breakdown, but it exacerbates other factors or masks other issues, such as fluid contamination.

5. Implosion invariably results in extreme failure for hydraulic pumps and is a major safety hazard. Implosion occurs when air bubbles within a hydraulic pump collapse, causing an overload of pressure to the pump that generates an intense shock.

6. Aeration occurs when hydraulic fluid traps air bubbles. The pump subjects the bubbles to pressure, causing high heat and over-pressurization when the bubbles collapse. Aeration at extreme levels leads to implosion.

7. Pump aeration pertains to air not in the hydraulic fluid, but air introduced through unsealed joints or shafts. This air quickly causes pressure instability affecting crucial parts of the pump. This can quickly lead to breakdowns — generally marked by a whine or other high-pitched sound.

8. Cavitation is a symptom of uncontrolled pump speeds, which fail to allow hydraulic fluid to completely fill the pump. It results in destabilized pressure, heat, and excess wear. Cavitation is often marked by the same type of whine or squeal as pump aeration.

Because the factors causing each of these problems differ in nature, it’s best to fully evaluate a damaged hydraulic pump to determine if more than one issue is responsible.

Maintenance is the best approach for ensuring safe, efficient hydraulic pump function. But routine service is just the start. Identifying common issues plaguing your hydraulic pumps will lead to a better quality of targeted maintenance — for example, if you pinpoint a heat issue related to viscosity, that issue may be resolved by opting for a different fluid weight.

Every piece of information learned about your pumps can translate into better care, leading to longer uptimes, fewer issues, and fundamentally better maintenance.

Having trouble identifying the catalysts for your hydraulic pump’s issues? Let the professionals at Global Electronic Services take a look! Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!

Hydraulic systems can be extremely useful in a lot of machine solutions, but they can also be extremely loud. Any industrial location with active machines will make some noise, but when the noise rises to a certain level, it can be a problem. Systems that are too loud can cause headaches, hearing loss and elevated stress — and the noise may make it difficult for your workers to focus on what they are doing.

For this reason and others, it can be very useful to your operation for you to know how to reduce hydraulic system noise. While each situation is a little bit different, here are some tips and guidelines for noise control in hydraulic systems.

While it is impossible to completely eliminate hydraulic system noise, quality noise control in hydraulic systems is definitely possible. It starts with understanding the source of hydraulic system noise. Once you know where the noise is coming from, you are in a much better position to control it. While hydraulic noise originates from the pump, the power unit is the greatest contributor to hydraulic system noise.

Pressure fluctuations and vibrations of the various components of the system can amplify hydraulic noise as well. Each part of the hydraulic system has a potential noise control solution.

You’ve probably noticed that everything with an electric motor makes some noise. In many cases, very loud noise. A hydraulic system is no different. The movement of the fan, the vibrating of the bearings and the rotor and stator assembly all translate into what can be some very grating noise.

Hydraulic motors and other actuators can be some of the noisiest components of the system. A few tricks for keeping the hydraulic motor quiet include using very long tubing with a hose assembly at both ends and using a mesh screen set 30 degrees form horizontal.

Bearings, pistons, gears and the many other components of the pump can all combine to make a lot of noise, especially when you join the pump to the loud electric motor. Submerging the entire motor-pump assembly in oil or some other liquid can create a barrier that significantly dampens the sound of the system. You can also make the pump quieter by running it at a lower speed or using multiple small pumps instead of one or two large pumps.

One of the most important tools for reducing hydraulic system noise is the use of vibration-dampening mounts. You can mount the motor-pump assembly to a subframe with vibration-dampening mounts and you can mount the subframe to the power unit with vibration dampening mounts. Other industrial soundproofing materials wrapped around your hydraulic system can also be useful in reducing unwanted noise.

If the manufacturer is of no help, you can always contact a local engineering lab. These labs often have hydraulic experts that are highly knowledgeable and may relish the chance to take a look at your system and come up with ways to make it quieter and more efficient.

It’s also possible that your hydraulic system is making so much noise because it is in need of repair. If you suspect this is the case, either because you are having other problems with the system or you are seeing other possible symptoms of a problem like heavy shaking or sounds that you have not heard before, it can pay to have a professional take a look.

You can call Global Electronic Services anytime to have a certified professional inspect your system and perform a fast, efficient repair if necessary. For an estimate on hydraulics repair, call 877-249-1701 or contact Global Electronic Services online today.

The pump is the most expensive and critical component in any hydraulic system—it works by first creating a vacuum at the pump inlet, which generates atmospheric pressure. Liquid from the reservoir tank is then propelled through the inlet line to the pump, past a hydraulic filter or strainer, and into the hydraulic system. On a macro-level, the mechanical energy of the pump’s gears is transferred through fluid “flow” and used to power the attached hydraulic machinery.

Although hydraulic systems can be used in many everyday objects, they’re usually best suited for products that require high-power density or systems with changing load requirements. This simple yet elegant design offers exceptional consistency and speed compared to other driving mechanisms. Hydraulic systems are widely used across industries because they are reliable, easy to maintain, long-lasting, and safe. But despite their many advantages, hydraulic systems still require some degree of maintenance. The following guide explains what can make a hydraulic pump fail, as well as tips for extending its useful lifespan as much as possible.

Fluid contamination is the leading cause of pump failure and usually happens when particulates circulate through the system via a breather valve or cylinder rod, or as a result of repairs, welding slag, sealant, or refilling. Once contaminants enter the system, they can degrade parts, create buildup, change the fluid’s physical and chemical properties, corrode equipment, and lower the system’s overall efficiency.

Hydraulic pumps are designed to work within a specific pressure range. If pressures exceed the pump’s rating, it will likely overburden the pump, cause damage, and eventually halt operations completely. If the pressure changes are extreme, it could even cause an explosion.

Joints and shafts must be completely sealed for the hydraulic pump to work properly. If air gets trapped inside the system, bubbles can cause pressure and temperature fluctuations, which eventually will cause the pump to break down. Usually the first sign there’s air in the pump is a high-pitched whine.

Cavitation occurs when the pump speed is inconsistent, creating air bubbles that rapidly form and then collapse. When this happens, the pump won’t completely fill with fluid, which destabilizes pressure in the system and produces the same type of high-pitched squeal as pump aeration. A blocked pipe, clogged filter, or poor system design can all cause cavitation.

Hydraulic systems need high-quality cooling and lubrication oil with the right mineral content and viscosity. Purity is particularly important for high-pressure systems that operate with larger loads.

The best way to prevent hydraulic pump failure is to inspect and maintain your hydraulic system. Hydraulic filters and strainers will help you avoid fluid contamination, which in turn will stabilize the temperature and pressure inside the system. Filters remove particulates that are smaller than 50 microns, and strainers work tangentially to remove contaminants larger than 50 microns. Various options are available for both filters and strainers using different ratings, mesh sizes, and materials.

After they’re installed, filters and strainers need to be routinely checked and cleaned. Operators should familiarize themselves with their hydraulic system to identify any aberrant conditions as soon as possible, if problems should arise. If you maintain your hydraulic system, it will work more efficiently, necessitate fewer repairs, require less downtime, and last as long as possible.

With over 60 years of experience manufacturing high-quality suction filters, suction strainers, gauges, and diffusers for hydraulic systems, the experts at DOMS Incorporated have the expertise to keep your operation in peak condition. We’ve worked closely with organizations from many industries, including construction, forestry, mining, energy development, industrial manufacturing, aircraft equipment manufacturing, plant processing, and more.

Excessive or erratic hydraulic pump noise is a symptom of malfunction that could cause damage or accelerated wear if not addressed quickly and correctly. While it’s never nice to hear strange noises emitted from your pump, different forms of noise, which are related to different faults can provide valuable clues that can help you to diagnose your problem and get it fixed before it turns into something major.

So it pays to know what different pump noises mean and with practice you can quickly distinguish between the normal operating sounds and signs that something is wrong. In this article, we’ll talk about what causes some of these sounds, so you can identify them.

A constant hissing sound is indicative of a relief valve that is set too low or is stuck open and is continually releasing pressure. An erratic whistling sound is a symptom that a relief valve is set incorrectly or is damaged. It is common for pump settings to be changed carelessly or inadvertently - sometimes to overcome other issues with the hydraulic system - sometimes due to a lack of understanding of the correct operating conditions, so include this in your regular checks. In addition to noise problems, relief valve damage can be accompanied by slamming of actuators, stalls and excessive heat generation.

Noise issues are just one symptom that gives you a clue when things go wrong with your hydraulic pump. There are several other issues to know and understand, which could help you to identify pump problems quicker. Which means you can sort them out sooner - potentially saving big money down the road. These include heat problems, pressure problems and flow problems.

Noise is undesirable because it can cause additional load on hydraulic components leading to premature failure, additional system cost, operator fatigue and potential hearing loss. The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) states that exposure to 85 dB(A) of noise for more than eight hours per day can result in permanent noise-induced hearing loss (NIHL)1.

Noise is known to cause many issues with components in hydraulic systems but in particular steel tube assemblies are known to be very susceptible to vibration failure.

Vibration can travel through the system via the fluid and/or metal components transmitting to all parts of the equipment. Noise travels easily through the metal components such as pumps, valves, cylinders, steel tubes and elbow fittings but can also travel through the steel wire reinforcement in the hose.

A quick and easy solution that some designers have discovered to eliminate noise in power steering systems, hydrostatic pumps, pump outlets, motor inlet/outlet and PTOs is to utilize thermoplastic fiber reinforced hose. This hose is constructed using a variety of smooth bore polymer inner cores for a high degree of chemical compatibility, high strength fibers, and a polymer jacket. Fiber braided thermoplastic hose is available in pressure ratings from 500 psi to 7500 psi.

Parker"s Parflex Division is contacted at least once a month by companies looking to bring the noise down below audible noise level (vibration). Through years of studying noise and its effects on hydraulic systems, as well as, working closely with our customers to reduce application-specific noise, Parflex has developed an extensive line of thermoplastic hoses with a high degree of dampening effects.

Parflex 510D, 518D, 520Nand 53DM are most suited for reducing noise and have a working pressure range of 1500 to 5000 psi at a 4:1 design factor. Hose selection tools and application engineering expertise are available through Parflex for your equipment hydraulic design needs.

The hydraulic pumps on construction equipment are critical components of the machines and even though they are often designed to work under vigorous and intense conditions, no pump will last forever. Discovering a problematic pump can be complicated as the effects might seem to originate in other connected parts, and, if failures are gradual, the cascading effects of a pump failure can spread throughout a machine.

To help in your diagnosis — and with a small dash of preventive maintenance — we’ve put together this basic, short list of common pump problems and their causes.

Not every hydraulic pump on a machine is simple to inspect, but this Volvo main hydraulic pump on a EC220B-LC excavator sits behind a quick access door so an operator can check it often.

A failing hydraulic pump can be a long and subtle process, a sudden and catastrophic calamity, and all shades in-between, but often a perceptive operator will notice the signs of a pump failure in advance. It might take a few minutes of stopping and inspecting, but knowing what to watch for and taking the time to inspect your hydraulic pumps can often pay off in the long run and lead to fast and simple fixes, instead of prolonged and labor-intensive downtimes.

A hydraulic pump is often secured behind a door or guard or integrated deeply into the body of a machine, but taking the time to inspect the pump for the presence of oil (or oil and dirt clumping) can lead to the early discovery of problems. If the issue is simply a loose connection, a quick tightening can often stop a small issue from growing.

Since a hydraulic pump has both seals to prevent fluid from exiting the pump and also fluid from prematurely entering from one chamber to the next, failing seals can be both internal and external. Spotting an exterior leak is, of course, simpler, but being aware of where seals exist inside the pump can also help you diagnose a failing internal seal.

The most frequently noticed indication of a failing pump is often the start of a new sound coming from the hydraulic pump. An experienced operator will often immediately know and recognize a pump that is indicating issues through sounds, but for many it can be harder to pinpoint.

A problem with a pump can cause it to simply become louder in its operations, develop a whining sound, or even create a knocking sound. The sounds can indicate a number of problems, but often the cause is either cavitation or aeration in the pump.

Over long spans of work and under intense conditions, a hydraulic pump will often heat up, but excessive heating is often a sign of internal issues in the hydraulic pump. Checking a hydraulic pump for excess heat should always be done with safety in mind and with a secure machine and proper protective equipment. Periodically ensuring a hydraulic pump isn’t overheating allows an operator to discover if the pump is under undue strain and on a path to failure.

Overheating in a hydraulic pump can also cause fluid to thin, cause internal components to more rapidly degrade, and introduce dangerous working conditions to the machine. Overheating in a pump is both a sign of current trouble and a cause of other growing problems.

Unexpected and non-fluid movement of parts can be caused by issues with the hydraulic pump, but since the culprit can be a number of other parts in the system, diagnosing pump issues from these movements isn’t always simple. Still, if you do notice non-uniform movements in your machine, taking time to rule out the hydraulic pump is important.

A main hydraulic pump, like this one from a Komatsu PC400LC-6 excavator, comes with a working life and will need to be replaced or rebuilt at some time. This one is fresh from an H&R Recon and Rebuild shop and is headed to a customer.

Knowing some of the common causes of hydraulic pump failures is a proven way of proactively discovering developing issues and correcting them before they become disastrous to the pump and the machine.

The internals of a hydraulic pump are designed to work with fluid that meets exacting specifications. When hydraulic fluid is contaminated it can lead to issues developing in the pump, force the pump to work harder, and cause the pump to work erratically. One common culprit for contamination is water, and it can quickly lead to increased corrosion, changes in viscosity that lead to inefficiencies, and the inability to properly regulate heat in the pump.

Other debris, either introduced from outside or from the degradation of internal elements, can also lead to issues in the pump and signal failing seals or other parts.

A hydraulic pump is often containing a high level of pressure and as this pressure exerts force on seals in the pump, the seals can begin to leak or fail. Even minor leaks in seals can lead to loss of fluid and create issues in the system. Leaks can be both external and internal. For an internal leak, fluid will move from one part of the pump to another in unintended ways and force inefficiencies into the pump as it has to work harder to compensate.

While many hydraulic pumps are built to stand up to tough and continuous working conditions, every hydraulic pump is designed with an upper limit. Every time a hydraulic pump is subjected to overpressuring and overloading beyond what the manufacturer has specified, the pump is more prone to damage.

All hydraulic oil has a defined amount of air dissolved in it, but increases to this amount can lead to inefficiencies in the pump and force the pump to work harder or erratically. An increase in air can also happen inside the pump and create similar problems. Even though the pump and hydraulic system have mechanisms in place to regulate air in the system, if excess air is introduced the system should be returned to a balanced system before prolonged use of the pump.

The hydraulic system on a construction equipment machine is designed to work within defined parameters. Operating a machine with too little oil or too much oil for even the briefest amount of time can cause the pump to overwork, lead to increases in working temperatures, or create conditions for non-uniform movement. The exact type of oil used — matched to the machine and the working environment — can also impact how the hydraulic pump operates.

The operator’s guide of your machine will define the hydraulic oil change schedule and adhering to that schedule can extend the life of your hydraulic pump. When oil is changed, take time to examine the spent oil for signs of debris

Keeping a pump on a hard-working machine looking new every day is nearly impossible, but routinely peeling back dirt, grime, and oil can help catch issues early.

No one wants to take a machine out of work for cleaning, but keeping the machine clean and ensuring pumps are not covered in mud, dirt, or other debris can allow them to be inspected more easily and avoid contamination and overheating.

The hydraulic hoses connected to a hydraulic pump can wear out over time and ensuring they are well-maintained can help you avoid the introduction of debris and even catastrophic issues in the case of sudden failures.

If a hydraulic pump fails on your machine, taking time to ensure you properly diagnose why and how the failure occurred will help you avoid repeating the failure with your replacement pump. Even if the pump failed simply from prolonged use and age, taking time to confirm that can lead to insights about how to extend the life of the next pump.

A hydraulic pump on an excavator, wheel loader, dozer, or articulated truck can be an often ignored component of the machine — until it starts to act up and cause issues. If problems have brought a pump to the forefront of your mind, hopefully, this short guide has helped simplify your pump problem solving.

If you find yourself in need of a replacement hydraulic pump, our Parts Specialists are always here to help. As a supplier of new, used, and rebuilt hydraulic pumps and with our deep inventory of parts, our Parts Specialists can often find the perfect solution to get a customer back up and running quickly. Simplify your search and give them a call.

Don"t see what you are looking for? With access to specialized search tools and our extensive vendor network, our parts specialists are here to search for you and to connect you to your parts, fast and simple.

The look and design of a hydraulic pump is customized to fit the machine and the available space. This main hydraulic pump is freshly reconditioned from a Kobelco SK160LC-VI excavator.

Hydraulic pumps come in a wide range of shapes and sizes. This large Volvo main hydraulic pump requires assistive overhead cranes and forklifts to move around the warehouse.

When a hydraulic system fails, finding the source of the problem can be a challenge. Though hydraulic systems primarily consist of a sump, motor, pump, valves, actuators and hydraulic fluid, any of these parts could be the source of failure. That"s not to mention the additional potential for failure through human error and faulty maintenance practices. If your system fails, you need to know why it fails, how to find the failure and how to keep it running smoothly in the future, all while keeping personnel safe.

It"s often easy to tell when a hydraulic system fails — symptoms can include high temperatures, low pressure readings and slow or erratic operation are glaring problems. But what are the most common causes of hydraulic systems failures? We can trace most hydraulic issues back to a few common causes, listed below.

Air and water contamination are the leading causes of hydraulic failure, accounting for 80 to 90% of hydraulic failures. Faulty pumps, system breaches or temperature issues often cause both types of contamination.

Air contamination is the entrance of air into a hydraulic system and consists of two types — aeration and cavitation. Both can cause severe damage to the hydraulic system over time by wearing down the pump and surrounding components, contaminating hydraulic fluids and even overheating the system. Although we are not pump manufacturers, we know it is essential to be aware of these types of contamination and how to identify their symptoms.

Cavitation:Hydraulic oil consists of about 9% dissolved air, which the pump can pull out and implode, causing pump problems and damage to the pump and to other components in a hydraulic system over time. You can identify this problem if your hydraulic pump is making a whining noise.

Aeration:Aeration occurs when air enters the pump cavity from an outside source. Usually, loose connections or leaks in the system cause this issue. Aeration also creates a sound when the pump is running, which sounds like knocking.

Water contamination is also a common problem in hydraulic systems, often caused by system leaks or condensation due to temperature changes. Water can degrade hydraulic components over time through oxidation and freeze damage. A milky appearance in hydraulic fluid can help you identify water contamination.

Fluid oxidization: Extreme heat can cause hydraulic fluid to oxidize and thicken. This fluid thickening can cause buildups in the system that restrict flow, but can also further reduce the ability of the system to dissipate heat.

Fluid thickening:Low temperatures increase the viscosity of hydraulic oil, making it harder for the oil to reach the pump. Putting systems under load before the oil reaches 70 degrees or more can damage the system through cavitation.

Fluid levels and quality can affect hydraulic system performance. Low fluid levels and inappropriate filtration can result in air contamination, while fluid contamination can cause temperature problems. Leaks can further exacerbate both issues.

Using the correct type of fluid is also essential, as certain hydraulic oils are compatible with specific applications. There are even oil options that offer higher resistance to temperature-related problems. Some oils even offer anti-wear and anti-foam additives to help prevent against wear and air contamination, respectively.

Human error is the base cause of many hydraulic system problems. Some of the most common errors that may result in your hydraulic pump not building pressure include the following.

Faulty installations: Improper installation of any component in a hydraulic system can result in severe errors. For example, the pump shaft may be rotating in the wrong direction, negatively affecting pressure buildup, or pipes may be incorrectly fitted, resulting in leaks.

Incompatible parts: An inexperienced installer may put mismatched components together, resulting in functional failures. For example, a pump may have a motor that runs beyond its maximum drive speed.

Improper maintenance or usage:Using systems outside their operational capabilities or failing to perform regular maintenance are some of the most common causes of hydraulic system damage, but are easy to rectify through updated maintenance policies and training.

The sources of system failures can be tricky to identify, but some hydraulic troubleshooting steps can help narrow down the options. So how do you troubleshoot a hydraulic system? Here are some of the fundamentals.

Check the pump: Take the pump assembly apart and assess all parts to ensure that they are functional and installed correctly. The most common problem areas include the pump shaft, coupling and filter.

Check the fluids:Check the level, color and viscosity of the hydraulic oil to ensure it meets specifications and has not become contaminated. Low hydraulic fluid symptoms include pressure or power loss. When in doubt, drain and replace the fluids.

Check the seals: Look for evidence of any fluid leakage around your hydraulic system"s seals, especially the shaft seal. Leakage can indicate worn-out or blown seals that can cause malfunctions with pumps, motors and control valves.

Check the filters: Ensure filters are clear of plugs and blockages. Common clogged hydraulic filter symptoms include sluggish operation and noisy operation.

Hydraulic system issues are inevitable at some point. However, simple steps can help you avoid these issues and increase the longevity of your hydraulic system. On top of effective troubleshooting, you can prevent hydraulic system failure by taking the following steps.

Follow specifications: We can trace the most common hydraulic system issues back to fundamental system problems like incompatible or improperly installed parts. For this reason, it"s essential to always double-check specifications to ensure your purchased parts can work together seamlessly.

Consult with professionals: When purchasing new equipment, consult with industry peers and professionals to discover what they recommend. While manufacturers can tell you how a product should work, industry professionals can provide concrete examples of how well the equipment works for their industry.

On top of these steps, look into hydraulic system products that are specifically designed to help prevent failures. One such product is Bear-Loc® by York Precision. This innovative locking actuator is a safe, reliable feature for hydraulic components, automatically locking when sleeve pressure is relieved, preventing movement if a hydraulic system fails. This way, your can protect your personnel from injuries related to hydraulic failures. Even better, York Precision offers in-house design, engineering expertise and machining and manufacturing capabilities to produce a hydraulic locking device that meets your exact specifications.

Regularly review hydraulic system maintenance, always following manufacturer recommendations and industry best practices. Also, consider the storage condition, external influences, working pressure and usage frequency of your system to tailor your maintenance schedule and procedures.

Daily tasks:Take care of a few simple daily checks to avoid issues. For example, personnel should check the oil levels, hoses and connections and listen to the pump for abnormal sounds.

Be mindful of location:Do not stand at endpoints while working on hydraulic systems. This safety measure can help prevent loss of limb and life, as there is a lot of pressure built up in these areas that can release and result in life-threatening situations.

The best safety measures, however, are to perform excellent maintenance and use high-quality parts. If you"re looking for a quality hydraulic component manufacturer, York Precision Machining & Hydraulics can help.

Here’s another Flint Hydraulics Tech Tip: Noise in a hydraulic system can mean serious trouble. A rattling sound from the pump may indicate cavitation of the fluid, caused by excessive vacuum at the pump’s inlet. Even moderate cavitation can destroy a pump within a few hours of operation. What causes cavitation? It may be excessive pump shaft speed, high oil viscosity, a restriction or too many elbows in the inlet plumbing, or a collapsed inlet hose, among other causes. Need help troubleshooting? Contact any of our Certified Fluid Power Specialists today at 901-794-4884 or email sales@laurenc60.sg-host.com.

In any hydraulic system, the hydraulic pump is usually the most expensive component and if it fails the whole system can be rendered inactive. Hydraulic pumps are extremely sensitive to contaminants and have the highest reliability risk. When a hydraulic pump starts to fail, it can force contaminants and debris further down the system and if this is not intercepted by an effective filter, the debris can then cause damage to other components. With this in mind, it is worth knowing the warning signs of common hydraulic problems and the precautions or actions that should be taken to prevent the lost work time and expense resulting from pump failure. As experts in hydraulic pump repairs, we at CJ Plant reveal the common causes of hydraulic pump failure.

In any mechanical system, components will be subject to wear and tear throughout their working life and will eventually wear out. Poor quality components will obviously have a shorter lifespan and should, therefore, be avoided, but there are a number of system failures common to all models of hydraulic pump that can easily be prevented if users are vigilant and pay attention to the operation of the system they are using. There are three common hydraulic pump failure symptoms that operators should be aware of that can be an indication of impending hydraulic pump failure:

If the hydraulic pump is making a whining noise or producing banging or knocking sounds, it can be assign of aeration or cavitation inside the pump. As the piston operates, pressure inside the pump drops and the resulting higher atmospheric pressure in the reservoir pushes hydraulic fluid along the inlet line into the pump. Anything that reduces this inlet flow can cause dissolved air in the oil to be drawn out forming air bubbles. When these reach an area of high pressure, the bubbles will implode under pressure and the resulting shockwaves will produce a high pitched whining sound. This can be assign of a damaged or blocked suction strainer or a plugged breather cap. High temperature in the fluid can also cause air to be released or low temperature can increase viscosity and slow fluid entering the pump so fluid temperature should be monitored closely. While not a common problem in the UK, systems operating high above sea level can also suffer from insufficient fluid entering the inlet due to atmospheric pressure being too low to push it through. Air from outside entering the system will result in aeration and will result in a knocking or rattling sound in the pump. As the pressure inside the system is lower than outside, any leaks in the suction line or the cylinder seal will cause air to enter the system. Poorly tightened connections on the suction line can also result in this problem. If this is suspected apply a layer of oil over any suspected location for a leak. If a hole appears in the oil as air is drawn in, the leak has been located. The noise will subside momentarily as this happens if aeration is the cause of the sound. If a leak is not located, check the reservoir. If the fluid level is too low, air can also been drawn in here or if the fluid entering the reservoir is dropping from a height it can cause bubbles to form as the fluid splashes which again can then enter the system. Any foaming of the fluid in the reservoir is another sign of aeration as the air exiting the system will cause foam to form.

Hydraulic fluid in a working system should never be above a temperature of eighty two degrees Celsius. A temperature exceeding this can be an indication of a malfunctioning heat exchanger or an overheating final drive motor. Cooler fins and the cooling fan should be cleaned and inspected for any damage, along with the fan belt, Any change in the pressure in the system from the manufactures settings will lead to an increase in temperature, along with other problems. Pressure levels should be checked in case deliberate or accidental adjustment of pressure has been carried out and relief valves checked in case they are damaged or incorrectly adjusted, as this can also lead to a change in system pressure and subsequent overheating. A lowered level of hydraulic fluid in the reservoir can also lead to overheating. if this is the case, the level of fluid should be topped up and the reservoir checked for any leaks that could be leading to this. All filters should checked for build up of debris or blockage as this can also affect pressure in the case of internal filters or cause insufficient flow of air in cooling systems. It is also worth considering the use of an offline filter

If your hydraulic system is running slower than usual, or showing increased cycle times, this is an indication of a drop in pressure within the system which can then lead to a subsequent overheating. This can be an indication of a leak in the system. If it is an external leak, it will usually be easy to locate and repair. However, if no external leak is visible it could be a sign of an internal leak in the gear pump or actuators and a hydraulic flow tester should be employed to test for this and locate the leak for repair.

While using good quality hydraulic fluid and implementing good contamination control systems can avoid many problems, sometimes the worst can still happen. If any of the above indicators are observed, they should not be ignored and the source of the problem located and repaired before they cause further damage. The implosion of air bubbles during cavitation can cause internal wear on the pump and dislodge debris or metallic fragments that can travel through the system, causing wear and erosion to components. These can then lead to further system failure. Aeration can lead to lowered lubrication inside the pump, leading to friction between metal components and the pump seizing up. This can not only damage the pump but also alter the pressure in the system, causing overheating and damage to other components. Overheating can lower the viscosity of hydraulic fluid, lowering its ability to lubricate and degrading it and shortening its lifespan and causing heat damage to seals, leading to leaks.

Any one of these issues can lead to a cascade effect, causing damage to multiple parts of the overall system and resulting in lost work hours and revenue and expensive repairs. If your equipment is displaying any of these symptoms, call CJ Plant maintenance today. We understand that when your equipment is malfunctioning or damaged you need fast and efficient diagnosis and thorough professional repairs as soon as possible. We carry out hydraulic pump repair and plant maintenance to customers throughout the UK and offer free collection, wherever you are located if we cannot perform repairs on site. We will thoroughly inspect your faulty equipment and offer a full evaluation and no obligation quote for repair. After repair we will return your equipment fully restored to OEM standards with a written twelve month warranty. For further information on the services we provide, please contact us, we will be happy to help.

Once a pump is properly selected and installed in a sanitary system, function would ideally be trouble-free. However, problems can develop in existing systems, or as pump and process system is modified. Due to this, we have gathered up some troubleshooting tips to help identify and solve the problem of noisy pump operation.

For all pump application problems, cavitation is the most common and it happens with all types of pumps. When discovered, excessive pump speed or adverse suction conditions will likely be the cause. Generally reducing pump speed and/or remedying the suction condition will get rid of this problem. Cavitation is especially true if the discharge pressure is fluctuating or pulsating.

Particularly on the discharge side of the pump, valves can sometimes go into a hydraulic vibration mode caused by operating pressure, flow rate and the valve design. Resetting or a change in an internal valve component is often sufficient to solve the problem.

If you are stumped by excessive pump noise, review our tips below for troubleshooting a noisy pump or consult an industry expert to help diagnose and remedy your issue.

(2) The fuel tank of the oil level is too low, the oil pump blockage makes the pump suction oil resistance caused by a larger pump into the air or oil leakage, the pump inhaled air. Treatment: Add the required oil; cleaning filter, and clear the intake pipe; check and tighten the oil inlet pipe connection screws.

(3) Improper installation of the pump and motor, which means the shaft concentricity with the motor shaft is inconsistent, so that the pump bearing radial force by noise. Solution: Check and adjust the concentricity of the pump and the motor.

(4) The viscosity of hydraulic oil is too large, making the pump"s self-absorption capacity, the volumetric efficiency decreases. Treatment: Use the appropriate viscosity of the hydraulic oil, if the oil temperature is too low should turn on the heating.

8613371530291

8613371530291