what is hydraulic pump cavitation quotation

The second leading cause of hydraulic pump failure, behind contamination, is cavitation. Cavitation is a condition that can also potentially damage or compromise your hydraulic system. For this reason, understanding cavitation, its symptoms, and methods of prevention are critical to the efficiency and overall health of not just your hydraulic pump, but your hydraulic system as a whole.

The product of excessive vacuum conditions created at the hydraulic pump’s inlet (supply side), cavitation is the formation, and collapse of vapors within a hydraulic pump. High vacuum creates vapor bubbles within the oil, which are carried to the discharge (pressure) side. These bubbles then collapse, thus cavitation.

This type of hydraulic pump failure is caused by poor plumbing, flow restrictions, or high oil viscosity; however, the leading cause of cavitation is poor plumbing. Poor plumbing is the result of incorrectly sized hose or fittings and or an indirect (not straight or vertical) path from the pump to the reservoir. Flow restrictions, for example, include buildup in the strainer or the use of an incorrect length of hose or a valve that is not fully open. Lastly, high oil viscosity—or oil that is too viscous—will not flow easily to the pump. Oil viscosity must be appropriate for the climate and application in which the hydraulic pump is being used.

The greatest damage caused by cavitation results from the excessive heat generated as the vapor bubbles collapse under the pressure at the pump outlet or discharge side. On the discharge side, these vapor bubbles collapse as the pressure causes the gases to return to a liquid state. The collapses of these bubbles result in violent implosions, drawing surrounding material, or debris, into the collapse. The temperature at the point of implosion can exceed 5,000° F. Keep in mind that in order for these implosions to happen, there must be high vacuum at the inlet and high pressure at the outlet.

Without a pressure condition at the outlet, or discharge side, these vapors merely form voids in the oil that reduce lubrication effectiveness. This results in friction and wear, which while seemingly mild compared to the excessive heat and violent implosions, can become detrimental over time.

Cavitation is usually recognized by sound. The pump will either produce a “whining” sound (more mild conditions) or a “rattling” sound (from intense implosions) that can sound like marbles in a can. If you’re hearing either of these sounds, you first need to determine the source. Just because you hear one of these two sounds doesn’t guarantee that your hydraulic pump is the culprit.

To isolate the pump from the power take-off (PTO) to confirm the source, remove the bolts that connect the two components and detach the pump from the PTO. Next, run the PTO with no pump and see if the sound is still present. If not, it is safe to assume your hydraulic pump is the problem.

Another sign you may be experiencing cavitation is physical evidence. As part of your general maintenance, you should be inspecting and replacing the hydraulic oil filter"s elements at regular intervals based on the duty cycle of the application and how often it is used. If at any time during the inspection and replacement of these elements you find metallic debris, it could be a sign that you’re experiencing cavitation in the pump.

The easiest way to determine the health of your complete hydraulic circuit is to check the filter. Every system should have a hydraulic oil filter somewhere in-line. Return line filters should be plumbed in the, you guessed it, return line from the actuator back to tank—as close to the tank as possible. As mentioned earlier, this filter will have elements that should be replaced at regular intervals. If you find metallic debris, your pump could be experiencing cavitation. You’ll then need to flush the entire system and remove the pump for inspection.

Conversely, if you’ve already determined the pump to be damaged, you should remove the filter element, cut it open, and inspect it. If you find a lot of metal, you’ll need to flush the entire system and keep an eye on the other components that may be compromised as a result.

Once cavitation has been detected within the hydraulic pump, you’ll need to determine the exact cause of cavitation. If you don’t, cavitation can result in pump failure and compromise additional components—potentially costing you your system.

Since the pump is fed via gravity and atmospheric pressure, the path between the reservoir and the pump should be as vertical and straight as possible. This means that the pump should be located as close to the reservoir as is practical with no 90-degree fittings or unnecessary bends in the supply hose. Whenever possible, be sure to locate the reservoir above the pump and have the largest supply ports in the reservoir as well. And don"t forget, ensure the reservoir has a proper breather cap or is pressurized (3–5 PSI), either with an air system or pressure breather cap.

Be sure the supply line shut-off valve (if equipped) is fully open with no restrictions. This should be a “full-flow” ball valve with the same inside diameter (i.d.) as the supply hose. If feasible, locate a vacuum gauge that can be T’d into the supply line and plumb it at the pump inlet port. Activate the PTO and operate a hydraulic function while monitoring the gauge. If it reads >5 in. Hg, shut it off, and resume your inspection.

If a strainer is present in the reservoir, inspect it, and remove any gunk or buildup that may be restricting supply flow. Next, check the inlet (suction) hose for any visible layline (descriptive markings on the hose). The industry standard “suction” hose nomenclature will read 100R4, or possibly SAER4. This will indicate the hose has an inner bladder that’s been vulcanized to a heavy spiral wire.

A hose with an inner bladder vulcanized to a heavy spiral is designed to withstand vacuum conditions as opposed to outward pressure. The layline will also denote the size of the hose (i.d.). You can use Muncie Power’s PPC-1 hydraulic hose calculator to determine the optimal diameter for your particular application based on operating flows.

Another consideration, in regards to the inlet plumbing, is laminar flow. To reduce noise and turbulence at the pump inlet, the length of the supply hose should be at least 10 times its diameter. This means that any type of shut-off valve or strainer at the reservoir should be at least 10 diameters from the pump inlet. A flared, flange-style fitting at the pump inlet can also reduce pump noise by at least 50 percent compared to a SAE, JIC, or NPT fitting.

Selecting the proper viscosity of hydraulic fluid for your climate and application is also critical. Oil that is too viscous will not flow as easily to the pump. Consult your local hydraulic oil supplier for help selecting the optimal fluid viscosity.

By maintaining a regular maintenance schedule, remaining vigilant for any signs or symptoms, and taking preventative measures, the good news is that you should be able to prevent cavitation and experience efficient operation for the duration of your pump’s lifespan.

Poor plumbing is the leading cause of cavitation and can be prevented by selecting a properly sized hose, choosing the appropriate fittings, ensuring the most direct, straight routing from the pump to the reservoir, etc.

Since joining the company in 2007, Ben Gillum has served in various capacities including shipping and receiving clerk, CS assembly, customer service manager, product application specialist, training and education assistant manager, and warranty and returns manager.

A variety of factors within the system could produce such a vacuum. When fluid enters the hydraulic pump and is compressed, the small air bubbles implode on a molecular level. Each implosion is extremely powerful and can remove material from the inside of the pump until it is no longer functional. Cavitation can destroy brand new pumps in a matter of minutes, leaving signs of physical damage including specific wear patterns. The process of cavitation destroying a hydraulic pump also has a distinctly audible sound similar to a growl.

The good news is that cavitation need not be a common problem in hydraulic systems. A few design flaws are largely responsible for causing cavitation: improper configuration of pump suction lines and the use of suction-line filters or strainers. To prevent these causes of cavitation and ensure the creation of a quality hydraulic system with a long, productive life, seven design elements must be properly executed:

In addition to improper pump suction-line configurations, suction-line filters or strainers can be a leading cause of cavitation. These filters are often placed under the oil reservoir, and thus are rarely serviced properly due to their inconvenient location. With this configuration, the entire reservoir has to be drained and disassembled in order to the reach the filter, so this necessary task is often neglected. As the filter becomes increasingly full of debris over time due to a lack of regular maintenance, not enough fluid will flow to the pump, and cavitation will occur.

Such causes of cavitation can be prevented using a series of correct design practices based on the specific needs and functions of a hydraulic system. Many systems are unique, so an experienced engineer with a firm grasp on each of these concepts must ensure the proper installation and maintenance of a hydraulic system.

Air bubbles in hydraulic fluid first originate is in the reservoir. New oil being introduced into the reservoir can cause turbulent flow, stirring up the oil and introducing air into the fluid, which can lead to cavitation. A correctly designed reservoir tank will prevent this issue.

The size of the tank and the amount of fluid that needs to rest before being extracted depends on the amount of system flow. However, a minimum 4 to 1 tank capacity to flow rate ratio is recommended — four times the oil available in the reservoir at any given time than is needed for extraction to send to the pump. This ensures that the pump will receive clean oil and the oil spends enough time in the reservoir for air bubbles and impurities to work their way out.

Beyond properly designing the reservoir itself, it’s important to include the correct accessories to ensure proper functionality. The breather filter is perhaps the most important accessory for maintaining the correct conditions for the hydraulic fluid in the tank.

When fluid is drawn from the reservoir by the pump, and an equal amount isn"t returned, the oil level will drop. To regulate the pressure and prevent forming a vacuum, air needs to be introduced to the tank to occupy the extra volume created upon removal of the oil. A breather filter performs this function, which helps avoid cavitation.

Incorrect design and configuration of suction lines is the primary cause of cavitation in hydraulic systems. For this reason, it’s crucial to use correct design practices when designing the suction lines, such as using the proper line size, minimizing fittings on the line, and properly sizing the ball valve to handle the amount of flow through the line.

The size of a suction line should be large enough for the liquid’s area to flow through at the correct rate and in the correct amount. Because the pump needs to be constantly supplied with oil, it becomes obvious how a line that’s too small could prevent this essential function. The exact specifications of a suction line in terms of length and width can’t be determined in a general sense — it requires a skilled engineer with a firm grasp of the process to make the correct decision on this specification.

Another best practice to consider when configuring suction lines is to include a lock on the suction ball valve, preventing it from being accidentally closed or left partially closed during the pump’s operation. Shutting off the flow of a suction line during pump operation will have cataclysmic effects on the system.

For example, the oil can be filtered upon entering the reservoir tank rather than when leaving the tank. Or a off-line (kidney loop) filtration system can be used to pull the oil out of the tank, filter it, and reinsert it before it’s extracted and sent to a hydraulic pump. These solutions allow for greater ease of maintenance and lower the chance of system failure.

A key aspect of a hydraulic system is a pump that’s properly sized to handle the flow rate and amount of fluid in the system. Again, this decision must be made by an experienced engineer with a good understanding of the entire process. A pump’s size can be determined by incorporating several variables of the process into a standard equation while also considering unique application conditions.

Another key element within a hydraulic system is to maintain the proper fluid temperature. If the hydraulic fluid gets too cold, it can become too viscous, increasing pressure drop in fluid lines and eventual cavitation in the pump. On the other hand, overheated hydraulic fluid can become too thin, compromising its ability to lubricate the hydraulic pump.

To regulate the temperature of the fluid, electric heating elements can be placed in the reservoir to keep the fluid at the ideal temperature of 110°F. Hydraulic systems often heat themselves naturally, so it’s also important to monitor for temperatures in excess of 110° and provide a heat exchanger or operate the system at reduced capacity.

Most systems use a flooded suction design, meaning that the pump is placed below the oil level to achieve net positive suction. The oil comes out of the reservoir above the location of the pump, which means gravity is used to assist in creating pressure into the pump and suction line. This represents the ideal configuration for a pump in a hydraulic system.

The alternative to this layout is non-flooded suction, in which the pump is placed on top of the tank. This configuration is often used to save space in a system with a limited footprint, but results in several disadvantages. For instance, the pump has to perform the extra work of pulling the oil up against gravity to create a vacuum and then pump the fluid out, which inherently creates restrictions by working against gravity. Also, certain types of pumps will function poorly in a non-flooded suction layout. In these cases, a charge pump can be used to provide positive pressure in the pump suction line.

If each of these design elements is carefully considered while engineering a hydraulic system, the risk of cavitation damaging or destroying hydraulic pumps should decrease significantly. Latest from Valin"s Blog

The NIST Chemistry WebBook contains a great deal of information regarding the properties of a broad range of chemicals and is helpful for those who deal with chemical processes.In this article, Jon Monsen has outlined the procedure for finding the actual density of a gas using the WebBook.

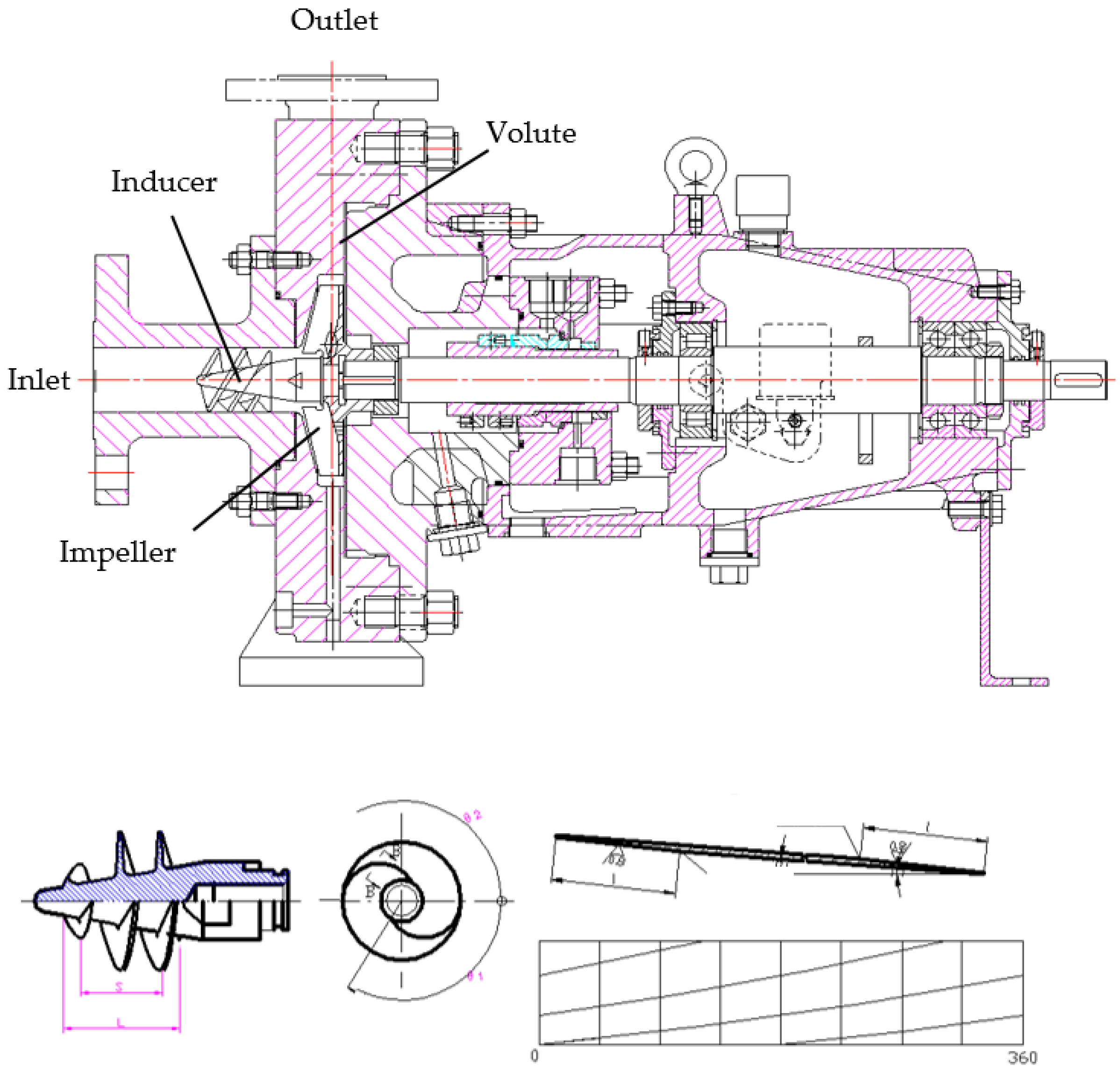

Across any pumping system there is a complex pressure profile. This arises from many properties of the system: the throughput rate, head pressure, friction losses both inside the pump and across the system as a whole. In a centrifugal pump, for example, there is a large drop in pressure at the impeller’s eye and an increase within its vanes (see Figure 1). In a positive displacement pump, the fluid’s pressure drops when it is drawn, essentially from rest, into the pumping chamber. The fluid’s pressure increases again when it is expelled.

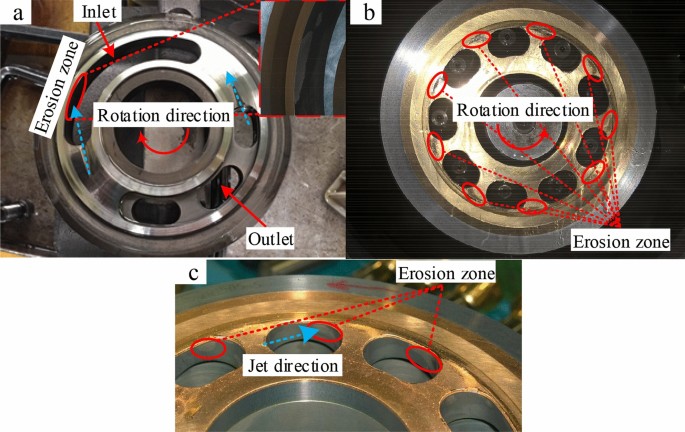

If the pressure of the fluid at any point in a pump is lower than its vapour pressure, it will literally boil, forming vapour bubbles within the pump. The formation of bubbles leads to a loss in throughput and increased vibration and noise. However, when the bubbles pass on into a section of the pump at higher pressure, the vapour condenses and the bubbles implode, releasing, locally, damaging amounts of energy. This can cause severe erosion of pump components.

To avoid cavitation, it is important to match your pump to the fluid, system and application. This is a complex area and you are advised to discuss your application with the pump supplier.

The obvious symptoms of cavitation are noise and vibration. When bubbles of vapour implode they can make a series of bubbling, crackling, sounds as if gravel is rattling around the pump housing or pipework. In addition to the noise, there may be unusual vibrations not normally experienced when operating the pump and its associated equipment.

With centrifugal pumps, the discharge pressure will be reduced from that normally observed or predicted by the pump manufacturer. In positive displacement pumps, cavitation causes a reduction in flow rather than head or pressure because vapour bubbles displace fluid from the pumping chamber reducing its capacity.

Power consumption may also be affected under the erratic conditions associated with cavitation. It may fluctuate and will be higher to achieve the same throughput. Also, in extreme cases, when cavitation is damaging pump components, you may observe debris in the discharged liquid from pump components including seals and bearings.

Under the conditions favouring cavitation, vapour bubbles are seeded by surface defects on metal components within the pump: for example, the impeller of a centrifugal pump or the piston or gear of a positive displacement pump. When the bubbles are subjected to higher pressures at discharge they implode energetically, directing intense and highly focussed shockwaves, as high as 10,000MPa, at the metal surface on which the bubbles had nucleated. Since the bubbles preferentially form on tiny imperfections, more erosion occurs at these points.

When a pump is new, it is more resistant to cavitation because the metal components have few surface imperfections to seed bubble formation. There may be a period of operation before any damage occurs but, eventually, as surface defects accumulate, cavitation damage will become increasingly apparent.

Classic (or classical) cavitation occurs when a pump is essentially starved of fluid (it is also called vaporization cavitation and inadequate NPSH-A cavitation). This can occur because of clogged filters, narrow upstream pipework or restricting (perhaps partially closed) valves. If the pump is fed from a tank, the level of liquid (or pressure above it) may have fallen below a critical level.

In a centrifugal pump, ‘classic’ cavitation occurs at the eye of the impeller as it imparts velocity on the liquid (see Figure 1). In a positive displacement pump, it can happen in an expanding piston, plunger or suction-side chamber in a gear pump. Reciprocating pumps, for example, should not be used in self-priming applications without careful evaluation of the operating conditions. During the suction phase, the pump chamber could fill completely with vapour, which then condenses in a shockwave during the compression phase.

Vane Passing Syndrome, also known as vane syndrome, is a type of cavitation that occurs when the spacing between the vanes of a centrifugal pump’s impeller and its housing is too small, leading to turbulent and restricted flow and frictional heating. The pumped liquid expands as it passes beyond the constriction and cavitation occurs.

Suction recirculation (also called internal recirculation) is a potential problem observed with centrifugal pumps when operated at reduced flow rate. This might occur, for example, when a discharge valve has been left partially closed or when the pump is being operated at a flow below the minimum recommended by the pump manufacturer. Under these conditions, liquid may be ejected from the vanes back towards the suction pipe rather than up the discharge port. This causes turbulence and pressure pulses throughout the pump which may lead to intense cavitation.

Air can be sucked into a pumping system through leaking valves or other fittings and carried along, dissolved in the liquid. Air bubbles may form within the pump on the suction side, collapsing again with the higher pressure on the discharge side. This can create shock waves through the pump.

To avoid cavitation, the pressure of the fluid must be maintained above its vapour pressure at all points as it passes through the pump. Manufacturers of centrifugal pumps specify a property referred to as the Net Positive Suction Head Required or NPSH-R – this is the minimum recommended fluid inlet pressure. The documentation supplied with your pump may contain charts showing how NPSH-R varies with flow.

In fact, NPSH-R is defined as the suction-side pressure at which cavitation reduces the discharge pressure by 3%: a pump is already experiencing cavitation at this pressure. Consequently, it is important to build in a safety margin (about 0.5 to 1m) to take account of this and other factors such as:

So, in designing the suction-side pipework for your system, you must ensure that it exceeds the manufacturer’s NPSH-R rating for the operating conditions. Your calculated value is termed the NPSH-Available (NPSH-A).

Positive displacement pumps require an inlet pressure to be a certain differential greater than the vapour pressure of the fluid to avoid cavitation during the suction phase. This is discussed in terms of Net Positive Inlet Pressure (NPIP) in a similar manner to NPSH for centrifugal pumps. NPSH is measured in feet or meters and NPIP is measured in pressure such as psi or bar. When converted to the same units, NPSH and NPIP are the same. Manufacturers may quote NPIP-R as the recommended inlet pressure and provide charts showing how it varies with pump speed. The available or actual inlet pressure on an operating system is termed NPIP-A.

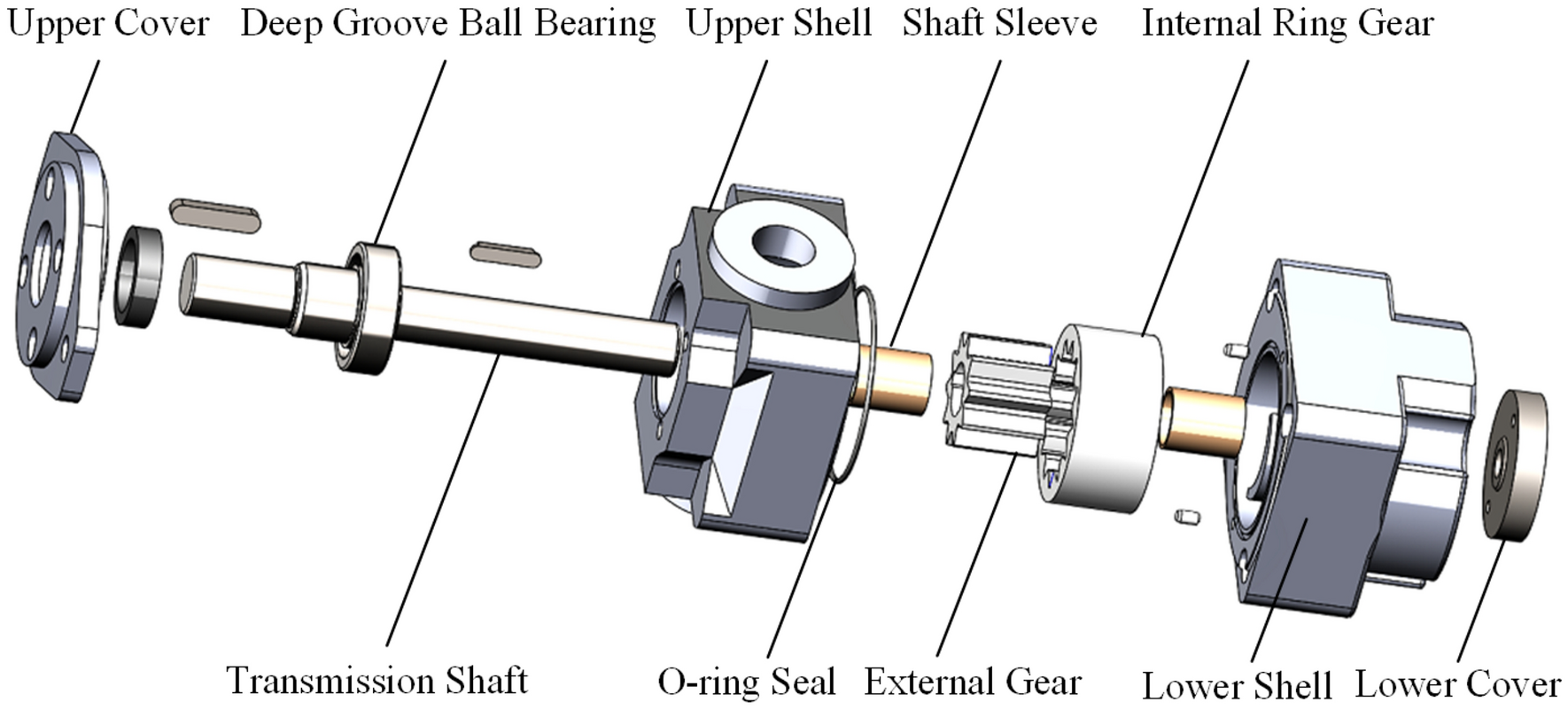

Cavitation is a potentially damaging effect that occurs when the pressure of a liquid drops below its saturated vapour pressure. Under these conditions it forms bubbles of vapour within the fluid. If the pressure is increased again, the bubbles implode, releasing damaging shockwaves. This can cause severe erosion of components. A common example of cavitation is when a centrifugal pump is starved of feed: vapour bubbles form in the eye of the impeller as it imparts velocity on the liquid and collapse again on the discharge side of the vanes as the fluid pressure increases. This can lead to damage to an impeller’s vanes, seal or bearing. Cavitation can also occur in positive displacement pumps such as gear pumps and plunger pumps.

With a centrifugal pump, ensure that NPSH-A is at least 0.5m greater than NPSH-R during operation. For example, if the pump is fed from a tank, ensure that the level of liquid in the tank (or pressure above it) is sufficient. For a positive displacement pump, make sure that the inlet pressure complies with the manufacturer’s NPIP requirements.

Have a pump that makes popping sounds, or sounds like it"s pumping marbles? If so, you may have a cavitation problem. Pump cavitation can cause a number of issues for your pumping system, including excess noise and energy usage, not to mention serious damage to the pump itself.

Simply defined, cavitation is the formation of bubbles or cavities in liquid, developed in areas of relatively low pressure around an impeller. The imploding or collapsing of these bubbles trigger intense shockwaves inside the pump, causing significant damage to the impeller and/or the pump housing.

When a pump is under low pressure or high vacuum conditions, suction cavitation occurs. If the pump is "starved" or is not receiving enough flow, bubbles or cavities will form at the eye of the impeller. As the bubbles carry over to the discharge side of the pump, the fluid conditions change, compressing the bubble into liquid and causing it to implode against the face of the impeller.

An impeller that has fallen victim to suction cavitation will have large chunks or very small bits of material missing, causing it to look like a sponge. Damage to the impeller appears around the eye of the impeller when suction cavitation is present.

When a pump"s discharge pressure is extremely high or runs at less than 10% of its best efficiency point (BEP), discharge cavitation occurs. The high discharge pressure makes it difficult for the fluid to flow out of the pump, so it circulates inside the pump. Liquid flows between the impeller and the housing at very high velocity, causing a vacuum at the housing wall and the formation of bubbles.

As with suction cavitation, the implosion of those bubbles triggers intense shockwaves, causing premature wear of the impeller tips and pump housing. In extreme cases, discharge cavitation can cause the impeller shaft to break.

Reference the pump"s curve - Use a pressure gauge and/or a flowmeter to understand where your pump is operating on the curve. Make sure it is running at its best efficiency point. Running the pump off its best efficiency point not only causes excess recirculation, expect excessive heat, radial loads, vibration, high seal temperatures, and lowered efficiency.

Re-evaluate pipe design - Ensure the path the liquid takes to get to and from your pump is ideal for the pump"s operating conditions. Designs with inverted “U”s on the suction side can trap air, while designs with a 90° immediately before the pump can cause turbulence inside the pump. Both result in suction problems and pump cavitation.

For more information about how to detect and prevent pump cavitation, be sure to check out our post: Technologies To Detect and Prevent Pump Cavitation.

Cavitation is a common problem in pumping systems, but with proper pump sizing, pipe design, and care of filters and strainers, damage to pumps and their impellers can be largely avoided.

Pump cavitation is always a serious concern in the fluid power industry that leads to pump failure/breakdown. Cavitation occurs when liquid/oil contains dissolved gas and collapse during machine operation. In short, cavitation is the formation and collapse of air cavities in the liquid. The factors that affect air bubble formation are system pressure, temperature, fluid type, and external/internal leakages. This article will highlight all important facts about pump cavitation that includes its symptoms, method of prevention, and more.

What is pump cavitation? As we mentioned earlier, cavitation is the process of forming an air bubble in the hydraulic fluid. The primary reason for this issue is the partial pressure drop at the suction side of the pump caused while pumping fluid from the reservoir to the hydraulic pump. This pressure various will lead to the creation of a cavity inside the hydraulic pump. The produced air bubble will explode inside the pump causing system failure. There are numerous other causes for pump cavitation that includes the following.

Also, it is common for every hydraulic oil to contain 9% of dissolved air. The air will be pulled out of the oil when the pump doesn’t get sufficient oil. When this air bubble reaches a high-pressure area, it will explode or collapse.

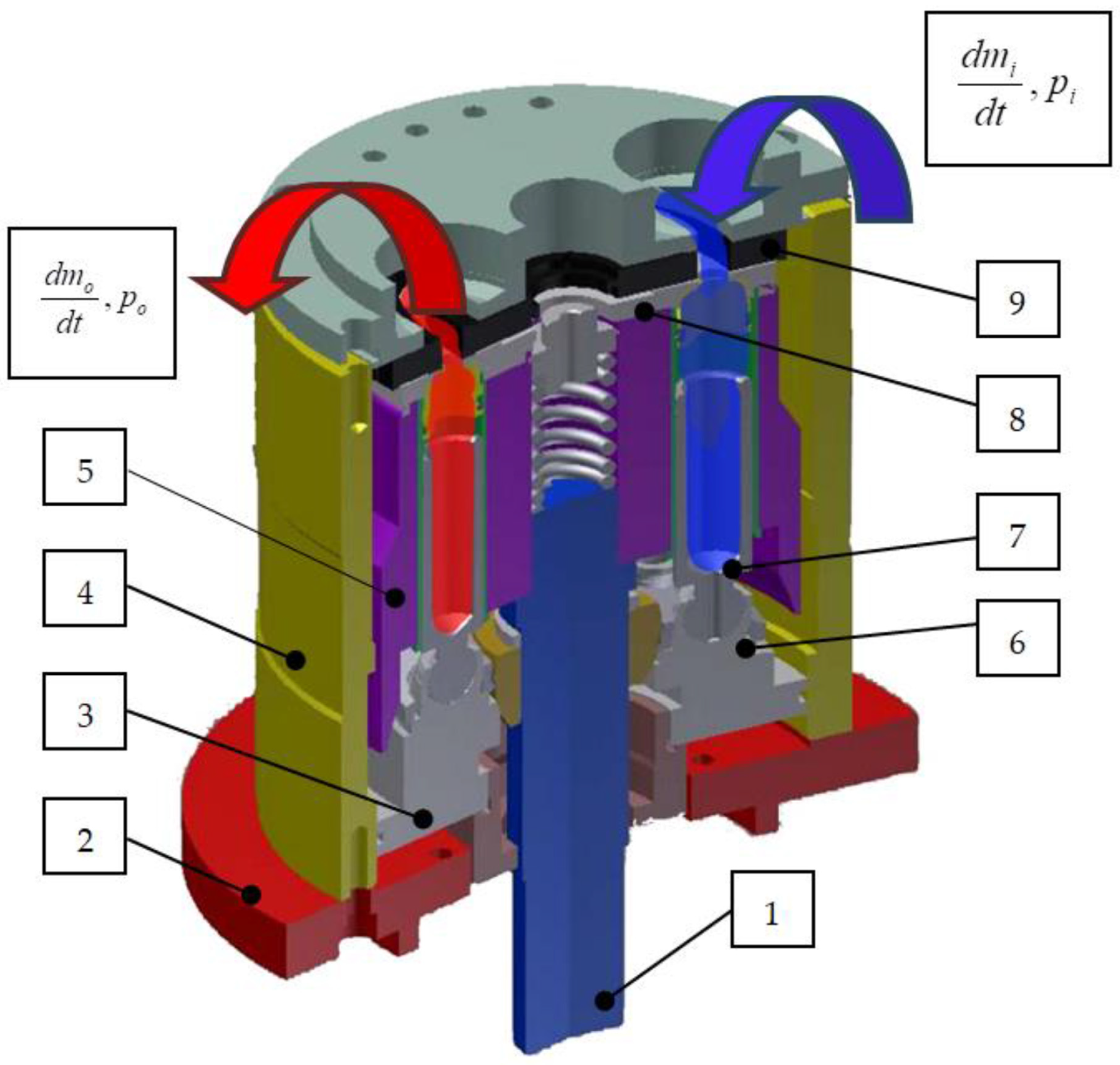

Cavitation can be categorized based on its effect and different conditions. Based on the effects, cavitation can be of two types called inertial cavitation and non-inertial cavitation. Inertial cavitation will produce a shock wave when a bubble or void present in a liquid collapses. Whereas, non-inertial cavitation occurs when the air bubble in fluid changes its shape due to an acoustic field or some other type of energy input. Similarly, suction cavitation and discharge cavitation are two cavitation categories based on different conditions. I.e; suction cavitation occurs under high vacuum or low-pressure conditions that effects flow and discharge cavitation occurs when the pump’s discharge pressure becomes abnormally high.

The results of cavitation are excessive heat, reduced lubrication, violent implosions, friction and wear. These issues can cause serious damages to the pump leading to hydraulic system breakdown. The symptoms of cavitation are unusual sound while pump operation, presence of metal debris, and damage. When these symptoms occur, proper inspection and troubleshooting are necessary.

If pump cavitation is avoided, the pump will deliver maximum performance to a longer time period. Some tips for avoiding cavitation are mentioned below.

An abundant amount of literature covering the topic of cavitation was published during the 1940s and the 1950s. During this period, the subject received a great deal of attention from both pump and hydraulic turbine manufacturers. This led to an increase in research and development, which resulted in higher pump speeds and safer operation. Today cavitation is still very important to the successful operation of a fluid system and good pump design.

Cavitation is a condition that occurs within a pump. The pumped fluid experiences a local pressure drop, causing portions of the liquid to fill with vapor. This may sound complex, but if you"ve ever boiled water, you"ve experienced something very similar to what happens during cavitation. As the water boils, vapor cavities (bubbles) form in the liquid.

As you know, liquid is not “sucked” into a pump, it is pushed. The liquid being pushed into the pump (available pressure) compensates for the low pressure created by the rapid movement of fluid by the pumping parts. Consequently, when the available pressure is reduced or the local pressure in the pump cavity is low, vapor formation occurs or increases (see Fig. 1).

All fluids form vapor cavities when the pressure on the liquid is reduced to the liquid"s vapor pressure at the pumping temperature. These vapor-filled cavities travel through the pump; when the cavities reach regions of relatively high pressure, they collapse. Cavitation damage is caused by the shock waves created when the vapor cavities collapse near the elements in the pump. Cavitation occurs along stationary and moving elements in a pump. For example, the inlet flow hole in a gear pump and the low-pressure side of a gear tooth are places where cavitation could occur. An entire system experiences a drop in available pressure when:

Material failure. The sudden destructive forces of the collapsing bubbles are powerful enough to cause pitting on the pump body or gear. Cavitation pitting has a distinctly different appearance than corrosion or erosion.

Many methods have been used to combat cavitation. In large centrifugal pumps or valves, admitting air into the inlet provides a cushion for the collapsing bubbles and also reduces the noise and pitting caused by cavitation.

Installing an accumulator (a mechanical device that stores the energy of fluid under pressure) close to the inlet port of a piston pump will reduce the effective inlet tubing length, pressurize the inlet, and absorb excess energy (see Fig. 2).

Pitting can be reduced by changing the hardness of the pumping element material or by applying a protective coating; however, these are not long-term solutions to the problem because pitting will attack areas with nicks, scratches, flaws, or sharp corners.

To reduce the undesirable characteristics of cavitation requires an understanding of the interrelationships of system, pump, and liquid. The following techniques have been used to reduce cavitation, but success is dependent upon the application:

Provide adequate pressure to the inlet of the pump, especially in applications with warm or hot liquids, thick viscous fluids, evacuated systems, or when the pumped liquid is volatile. Inlet pressures can be increased by raising the reservoir, lowering the pump, reducing the friction losses of the inlet tubing, or cooling the liquid.

Solutions to cavitation problems are not simple. System changes in gear pump applications can be expensive, time consuming, or both. In the early stages of a project, the design team, consisting of the user and the pump designer, must combine their knowledge to reduce the likelihood of cavitation within a fluid system.

As pressures and temperatures fluctuate in a hydraulic system, the fluid will absorb gas or release dissolved gases to main this equilibrium. The release process is gaseous cavitation.

It’s important to understand that the bubbles are not a result of a phase change. Unlike vaporous cavitation, there is no final gas-to-liquid phase change. Thus, the material erosion caused when vapor bubbles violently collapse does not occur with gaseous cavitation.

It is important to understand that aeration and cavitation are not the same thing, but a relationship exists between them. Aeration simply refers to a presence of air in a liquid.

Vaporous cavitation is not related to aeration. Again, the bubbles created by this process are simply a liquid-to-vapor phase change—they do not contain any air.

If free air in the crankcase becomes bound to the oil (by agitation, for example), the resulting entrained air bubbles may be unable to escape before reaching the suction inlet of the oil pump. These air bubbles will diffuse into the oil due to the higher pressure on the discharge outlet. As the pressure drops through the oil galleries and return to the sump, the air bubbles will re-emerge through the process of gaseous cavitation.

Frequently occurring in pumping applications, cavitation creates bubbles or vapor cavities in a liquid as a result of rapid changes in pressure. These liquid-free voids typically form in low-pressure zones and can burst when subjected to high pressures, sending powerful shockwaves throughout the entire application.

Manufacturers in the chemical processing, food processing, and petroleum industries must consider the risk of cavitation when designing machinery in order to avoid unwanted noise, vibration, and component damage.

Cavitation decreases an application’s efficiency over time and puts repeated stress on critical pump parts, shortening their overall lifespan. Shockwaves can cause significant damage to the pump, which in turn leads to premature valve failure, decreased flow pressure, and, ultimately, breakage. If you’re experiencing any of these issues with your pumping application, our in-house pump experts can help.

There are two types of cavitation that may occur in reciprocating positive displacement applications: suction and discharge. Suction cavitation occurs ahead of the suction stroke, when the pump is starved of flow, either from being in a high-vacuum or low-pressure environment. The opening of the valve is delayed by inertia, causing a lower flow rate on the suction side and resulting in expansion, pressure decrease, and the formation of bubbles close to the plunger.

Discharge cavitation occurs when the pump’s discharge pressure is too high. Under these conditions, it’s difficult for the fluid to flow out of the pump. Instead, it continues moving at high velocities inside the working chamber, forming bubbles in the process.

When working with pumping applications in a processing industry, cavitation should always be kept in mind; being able to recognize the warning signs and identify the root causes of cavitation in your machinery can significantly reduce the risk of long-term damages, saving both time and money.

Triangle Pump Components has nearly a century of experience assisting clients with pump issues such as cavitation. Our pump components are designed to preserve expensive parts such as crankshafts and power frames by transferring the majority of wear to less expensive, more expendable parts such valves, plungers, and packing.

"Over two decades ago I was teaching a class in Salt Lake City, Utah. One of my students, a teacher from a technical college in northern California, was so impressed with my training “system” that he asked if I would make a duplicate of it for him. I did, and the rest is history! Today, you will find my hydraulic training systems in the USA, Canada, Australia, Africa, Asia, South America, and Saudi Arabia ... It is also the number one choice for Corporate Technical Training Centers.

FPTI™ is the fastest growing fluid power training systems provider in the world - ask any teacher who uses our system, or any student who has attended our workshops. There"s nothing else like it."

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The damage due to cavitation can range from minor pitting to a total breach of the inside of the pump. Some people describe the damage as looking like Swiss cheese or as if "iron worms" have attacked it. As evidenced by the pictures, severe cavitation destroys the parts it contacts.

Cavitation damage can also reduce performance. Additionally, air pockets in the impeller can cause considerable hydraulic imbalance and resulting vibration. As the impeller is eroded, the uneven wear may cause further imbalance and vibration.

While Gorman-Rupp pumps are engineered to handle the deflection and loads created by cavitation, prolonged operation in this condition could eventually lead to bearing and/or shaft failure.

It is important to properly design the pumping system. (Contact distributor for calculating NPSH to avoid suction cavitation. Always calculate the total dynamic head to be within the operating range of the pump.) Correcting cavitation can be difficult if not impossible to do in an existing system.

To correct discharge cavitation (operating on the far left side of the curve) may require reducing the head or increasing the flow of the pump. Changing to a higher or lower speed may help in some cases, but a system head curve must be plotted to know the correct solution before corrective action is taken. The pump must be brought back inside its operating range.

Suction cavitation is caused by an NPSH problem. A vacuum gauge will indicate a high vacuum, not the source of that high vacuum. The cause of the high vacuum needs to be identified.

A plugged suction line should always be cleaned, not blown back to the liquid source. It will just come back to plug the line again. If the suction lift is too high the pump should be moved closer to the liquid or the liquid moved closer to the pump by raising the sump level. Suction lines that are too long or too small need to be shortened and/or enlarged.

Air is quite convenient for the support of all life forms; however, it can be extremely detrimental when allowed to infiltrate oil hydraulic systems. Air must therefore be considered a contaminant just like dirt, sludge and water. Air can cause problems such as:

Hydraulic components, particularly pumps, rely upon a specific lubricating film of fluid to separate moving parts. When this film is compromised by a percentage of air, the fluid film strength and therefore its lubricating qualities are diminished, resulting in metal to metal contact and premature wear.

Air bubbles traveling from inlet to outlet port of the pump are subjected to rapidly increasing pressures. Bubbles implode violently causing excessive noise. Bubbles under pressure will explode violently when moving from the pumps’ pressure zone to the suction zone also causing excessive noise. These implosions and explosions are capable of ripping hardened steel away from the pumping chambers.

Hydraulic systems transfer energy through a medium (oil) of a known density. If density, or the fluids’ bulk modulus is altered by air, system stiffness is negatively effected. Jerky, slow and sometimes uncontrolled motion may result.

Keeping your hydraulic system from overheating is paramount to system and component life. As much as 30 to 50% of the horsepower input to a system can be released to the oil as heat. Temperature can be limited or even controlled by devices such as heat exchangers, chillers or by the radiant capabilities of the reservoir itself.

Cavitation is the drawing of intermolecular and entrained gases out of solution.Oil is sometimes referred to as being non-compressible; however, this is not entirely true. The rule of thumb is that oil is typically compressible to one half of one percent per 1000 PSI. The compressed agents are intermolecular and entrained gases (sometimes referred to as air) dissolved within the oil.

Atmospheric pressure is the weight of one square inch of Earths atmosphere from its’ highest point to mean sea level. This is generally considered to be 14.7 pounds per square inch (PSI) or approximately 29.92” of mercury. Hydraulic pump manufacturers generally rate the inlet characteristics of their pumping equipment as being capable of drawing a specific maximum amount of vacuum on their inlet ports. Frequently, this is expressed in inches of Mercury (In. Hg) at sea level, while operating on a specific type of fluid (i.e. oil). A hydraulic pump manufacturers’ rating of a maximum 6 In. Hg @ sea level on petroleum based fluid, is very common. In this case the manufacturer is saying their pump requires a net positive inlet pressure of at least 23.92 In. Hg, in part to avoid pulling the gases out of suspension.

Atmospheric pressure acts on the entire surface area of the fluid within the hydraulic reservoir. When a pump creates a vacuum at its’ inlet port, atmospheric pressure pushes the reservoir fluid into the pump. If the pump is creating a 6 in. Hg vacuum, the resultant net positive inlet pressure will be:

29.92 In. Hg (atmospheric pressure @ sea level) – 6 In. Hg = 23.92 In. Hg net positive inlet pressure. This is in line with the pump manufacturers specifications above.

If, however, the system is operating at an elevation of 5,000 ft. above sea level, the ball game changes. The weight of this column of air at 5,000 ft. will be less; approximately 11.7 PSI or 23.8” of mercury. This situation will result in less net positive inlet pressure available to the pump and will likely result in pump cavitation per below:

23.8 In. Hg (atmospheric pressure @ 5,000 ft.) – 6 In. Hg = 17.8 In. Hg net positive inlet pressure. This is far below the pump manufactures specifications as noted above.

Any restrictions in the pump inlet line will have an orificing effect; thereby reducing the amount of net positive inlet pressure available to the pump.

Any of the following will reduce the amount of net positive atmospheric supercharge pressure available at the pumps’ inlet port, potentially resulting in cavitation:

Operating on fluids with a specific gravity greater than that at which the pumps’ inlet rating was based upon (especially high water content and water glycol fluids)

Place the pump below the reservoir fluid level (overhead or “L” shaped reservoir). This is an absolute necessity at elevations at or above 5000 ft. above sea level on oil or 2,500 ft. above sea level on water content fluids

Whether they come from cavitation or air infiltration, air (or gasses) can be extremely detrimental to pump life. While contamination is not uncommon, many of the specific causes can be avoided by good system design and fabrication practices. However, preventative maintenance is also routinely required.

Note: “Tech Tips” offered by Flodraulic Group or its companies are presented as a convenience to those who may wish to use them and are not presented as an alternative to formal fluid power education or professional system design assistance.

The effects of cavitation are usually pretty easy to identify -- it causes a metal surface to have a pitted, crater-like appearance. What happens when cavitation takes place, and how it actually causes damage to normally resistant metals, isn’t quite as well known. In this Shop Talk Blog post, we’ll be talking about what causes cavitation and why it can result in so much damage.

There are three basic stages to cavitation: nucleation, bubble formation and growth, and bubble collapse. Note that damage doesn’t occur until the third stage -- collapse -- is reached.

Nucleation is actually a phase change, from liquid to vapor, that occurs due to a pressure drop. Now, in order to this phase change to occur, nucleation sites must be present. What is a nucleation site, you ask? Nucleation sites promote the occurrence of the phase changes, and include …

The critical pressure of most hydraulic systems is close to the equilibrium vapor pressure at the operating temperature of the hydraulic fluid, which means it is very easy for the fluid to become a vapor. As liquid flashes into vapor, the result is bubbles that are filled with a mixture of air and oil vapor. The result is a wide assortment of bubbles that begin to expand in size.

The bubbles are carried away from the nucleation site by the flow of hydraulic fluid. They travel to a region of higher pressure. Then, as the bubble expands, the pressure immediately around the bubble begins to increase. As that pressure goes up, it begins to deform the bubble into a kidney shape.

Bubble collapse is when the damage occurs. As the pressure external to the bubble deforms it, a tiny, tiny droplet called a microjet forms inside the bubble. The bubble collapses, or implodes, as the microjet hits the wall of the bubble at terrific speed. A shockwave is released as the bubble collapses in on itself, its walls colliding against each other.

Any nearby solid surfaces get hit with pulse loads from multiple implosions as the nearby bubbles rapidly collapse. The result is a repeated stress that, over time, leads to fatigue failure of the surface of the material.

Cavitation is, to some degree, inevitable. However, one of the secrets to minimizing cavitation lies in keeping your hydraulic fluid as clean as possible, including free from air bubbles. The cleaner your hydraulic fluid, the less likely you will be to have nucleation sites that lead to cavitation.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

If you ended up on this page doing normal allowed operations, please contact our support at support@mdpi.com. Please include what you were doing when this page came up and the Ray ID & Your IP found at the

8613371530291

8613371530291