what size hydraulic pump do i need pricelist

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Power Team P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

Compact design ensures that the Power Team PA6 series pump is lightweight and portable. The PA6 series consists of single-speed pumps designed to drive single-acting cylinders. The power unit of choice for major manufacturers of auto body, frame straighteners and other equipment. Operates at 40-100 psi (3-8 bar) shop air pressure at the pump, dBA 85 at 10,000 psi (700 bar). Serviceable pump motor is not a “throwaway”, providing economical repair. Permanently vented reservoir cap. Internal relief valve protects circuit components, air inlet filter protects motor.

Compact, lightweight and portable the Power Team PA6D series pumps are single-speed pumps for driving double-acting cylinders. The PA6D series pumps operate at 40-100 psi (3-8 bar) shop air pressure at the pump. Designed with longevity in-mind the PA6D series feature internal relief valve protects circuit components, air inlet filter protects motor. Serviceable pump motor is not a “throw away”, providing economical repair. Permanently vented reservoir cap. dBA 85 at 10,000 psi (700 bar) for all PA6 pump.

Ideal for powering single-acting cylinders and portable hydraulic tools, the Power Team PA9 series pumps are easier to operate than a hand pump, designed for efficiency. Built to be economical in service; the PA9 series is not a “throwaway” unit. Unique bladder design for all-position operation and storage. Operates on 40-120 psi (3-8 bar) shop air, at 20 cfm (570 l). Hard-coat anodized aluminum housing. Oil filler with integral safety relief minimizes chance of damage to reservoir bladder if overfilling occurs.

A two-speed pump, the Power Team PA60 series pumps are designed for rapid oil delivery at low pressure to quickly advance cylinder or tool. Equipped with air pressure regulator, air filter and lubricator. Serviceable air motor for economical repair. Internal relief valve protects circuit components. Permanently vented reservoir cap.

Focused on single-speed and low pressure the Power Team PA50 series pump outputs 3,200 PSI / 220 BAR, fitting serviceable requirements for air motor for economical repair. Integrated air inlet filter protects motor. The PA50 series also features a filter in outlet port protects against contaminated systems Assorted reservoirs to suit your application"s requirements.

Rotary-Style Air Motor. Use where air is the preferred source of energy. Two-speed operation for high speed cylinder advance. Durable two gallon thermoplastic reservoir. (Metal reservoir conversion kits are available.) Air motor capable of starting under full load.

Rotary-Style Air Motor. Use where air is the preferred source of energy. 3 hp motor starting under full load. Two-speed operation for rapid cylinder advance. Models available with full remote control over advance and return, except PA554. Tandem center valve holds the load when pump is shut-off.

Compact, Portable, Cordless Hydraulic Pump for MRO Applications. Compact, Li-ion 18VDC, 9.0 Ah battery-powered pump provides extended run-time. Two-stage, high-pressure hydraulic pump offers quick tool advancement in the first stage. Extremely compact, lightweight with an ergonomic handle grip and transport strap to ease portability. Self-contained, rubber bladder reservoir allows pump usage in most positions with an impressive capacity of 70 cu. in. usable. Quiet, smooth-running, serviceable brushed 18VDC motor. High-impact, fiberglass reinforced shroud protects your investment in the most demanding and harsh applications. Interchangeable valve configuration accommodates a vast array of applications. CSA rated for intermittent duty, CE compliant.

The 10 series Power Team hydraulic pumps are designed to have a maximum of 690 bar (10,000 psi) at a flow rate of 164 cc/min (10 cu. in/min). All Power Team pumps come fully assembled, and each with the ability to be valved for either single- or double acting cylinders. Designed to be compact can easily mobile, the power team 10 series includes a portable power source is included for hydraulic cylinders, and tools. The permanent magnet motor is strategically constructed to easily start under load, even with reduced voltage conditions. Battery-operated models have 8 foot (2,4 m) power cord with alligator clips to connect to any 12 volt battery, optional rechargeable battery pack with shoulder strap are alternatives for maximum portability. The Power Team 10 series pump typically delivers 15 minutes of continuous operation at 10,000 psi (700 bar) on a single battery. Built to withstand High-impact, shielded with a flame retardant construction.

The Power Team 17 series pump is delibertly designed for maintenance and construction applications up to 55 Ton. For use with single-acting or double-acting cylinders at operating pressures to 10,000 psi (700 bar). For intermittent duty; starts under full load. Equipped with 1⁄2 hp (0,37 kW), 3,450 rpm, single-phase, thermal protected induction motor; 10 ft. remote control cord (PE172S has 25 ft. (7,6 m) cord) Low amperage draw; small generators and low amperage circuits can be used as power source. Extremely quiet noise level (67-81 dBA).

Vanguard Jr. + Power Team 18 series pumps provide two-speed high performance in a light-weight, compact package. Designed to provide a gauge port and metal reservoir on all pump models. Equipped with a 1⁄2 hp (0,37 kW), 115 volt, 60/50 Hz single phase motor that starts under load, even at reduced voltage. Low amperage draw permits use with smaller generators and low amperage circuits. All pumps have a 10 foot (3 m) remote control. CSA rated for intermittent duty. Noise level of 85-90 dBA. For operating hydraulic crimping, cutting or other tools: No. PE184C - Allows you to alternately operate a spring-return cutting and/or crimping tool without disconnecting either tool. Select a port connection with a manual 4-way valve, start the pump with a remote control hand switch and extend the connected tool. When the hand switch is switched to off, the pump stops and the automatic valve opens, allowing the tool to return. In the center (neutral) position, a manual control valve holds the tool in position at the time valve is shifted.

The 21 series Power Team pump and RD5513 cylinder used in a special press that produces pharmaceutical-grade extracts for herbal medicines. Totally enclosed, fan cooled induction motor: 1 hp (0,75 kW), 1,725 rpm, 60 Hz, single phase. Designed intentional for thermal overload protection. Remote control, with 10 foot (3,1 m) cord is standard on pumps with solenoid valves. Manual valve pumps have “Stop”, “Start” and “Run/Off/Pulse” switches. Pump controls are moisture and dust resistant. Motor drip cover with carrying handles and lifting lug. Low noise level of 70 dBA@ 10,000 psi (700 bar). In the event of electrical interruption, pump shuts off and will not start up until operator presses the pump start button. 24 volt control circuits on units with remote controls provide additional user/operator safety.

Ideal for running multiple tools or cylinders from one power unit. Recommended for cylinders up to 75 tons. Two-speed pumps have the same low pressure and high pressure flows from both valves. Flows and pressures of each pump are independent. Delivers 300 cu. in./min. of oil at 100 psi (4,8 liter/min of oil at 7 bar) and 25 cu. in./min. at 10,000 psi (0,4 liter/min at 700 bar) from each pump. 1 1/2 hp, 110/115 volt, 60 Hz (1,12 kW, 220 volt, 50 Hz) induction motor, 10 foot (3,1 meter) remote control and 5 gallon (19 liter) steel reservoir. Models available for operating single-acting or double-acting cylinders. Each power unit contains two separate pumps and two separate valves allowing operator to control multiple processes with one power unit. Both pumps on each power unit are equipped with an externally adjustable pressure relief valve. Not recommended for frequent starting and stopping.

The Power Team 30 series pump is intently ideal for maintenance and construction applications. Operating both single-acting or double-acting cylinders. A dynamically built, Integral roll cage protects the 30 series pump from many forms of damage. 1 hp (0,75 kW), single phase, permanent magnet motor. High performance to weight ratio. Starts under full load even when voltage is reduced to 50% of nominal rating. Quit operations: 82 dBA @ 10,000 psi (700 bar) and 87 dBA @ 0 psi (0 bar). CSA rated for intermittent duty. Remote controls and/or solenoid valves feature 24 volt controls.

The Power Team 46 series is best suited for under the roof maintenance and production applications. Equipped with two-speed high-performance pump, for use with single- or double-acting cylinders at operating pressures to 10,000 psi (700 bar) the 46 series pump is versitile. With a 1 1⁄2 hp (1.12 kW), 3,450 (2,875) rpm single-phase, 60 (50) Hz thermal protected induction motor that starts under full load. Noise level of 77-81 dBA. All equipped with a 10 foot (3,1 m) remote control except PE462S which has a 25 foot (7,6 m) remote control. 24 volt control circuit on all units with remote control. CSA rated for intermittent duty.

A powerful multifaceted pump, the Power Team 55 pump excels at multiple applications. From heavy construction to concrete stressing this pump series is designed for intensity. With low voltage starting possible, the 50/60 Hz universal motor; draws 25 amps at full load, and can start at reduced voltage. CSA rated for intermittent duty. 10 foot (3,1 m) remote motor control (except PE552S which has a 25 foot (7,6 m) remote motor and valve control). True unloading valve achieves greater pump efficiency, allowing higher flows at maximum pressure. Reservoirs available in sizes up to 10 gallons (38 liter). Lightweight and portable. Best weight-to-performance ratio of all Power Team pumps. “Assemble to Order” System: There are times when a custom pump is required. Power Team’s “Assemble to Order” system allows you to choose from a wide range of pre-engineered, off-the shelf components to build a customized pump to fit specific requirements. By selecting standard components you get a “customized” pump without “customized” prices. All pumps come fully assembled, add oil and ready for work.

A compact lightweight pump, the Power Team 60 series is designed for rugged applications and low voltage starting. Experiencing a long, trouble-free life in the most demanding work environments, the 60 series is durable.. Powered by 1 1⁄8 hp, 115 volt, 60/50 Hz (0,84 kW, 220 volt, 60/50 Hz) single phase motor. Starts under load, even at the reduced voltages at construction sites. Optional fan-driven external oil cooler includes rollover guard. Insulated carrying handle. Integral 4" (102 mm) diameter fluid-filled pressure gauge with steel bezel complies with ASME B40.1 Grade A. 0 to 10,000 psi (0 to 700 bar) pressure range in 100 psi (7 bar) increments. Sealed 3⁄4 gallon (4,34 liter (usable) reservoir. Reservoir drain port is standard. Standard oil level sight gauge for accurate oil level monitoring. External spin-on filter removes contaminants from circulating oil to maximize pump, valve and cylinder/tool life.

The Power Team PQ60 series pumps are designed specifically for heavy-duty, extended cycle operation. Integrating single- or double-acting cylinders the PQ60 series is versatile. Constructed for longevity by employing a metal shroud keeps dirt and moisture out of motor and electrical components. An electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Internal relief valve limits pressure to 10,000 psi (700 bar). External relief valve is adjustable from 1,000 to 10,000 psi (70 to 700 bar). The Power Team PQ60 pumps operate below maximum OSHA noise limitation (74-76 dBA). Start and operate under full load, even with voltage reduced by 10%.

The Power Team 120 series pump is exactingly designed for heavy duty, extended cycle operation up to 400 Ton. Built in grit, the series 120 pump can start and operate under full load, even with voltage reduced 10%. An electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Internal relief valve limits pressure to 10,000 psi (700 bar) and an external relief valve is adjustable from 1,000 to 10,000 psi (70 to 700 bar). Pump prewired at factory with a 3 hp, 460 volt, 60 Hz (2,24 kW, 380 volt, 50 Hz), 3 Phase motor. Other electrical configurations are available. 24 volt control circuits on units with remote controls for added user/operator safety. 3 hp (2,24 kW) 3 phase motor with thermal overload protection. Motor starter and heater element supplied as standard equipment; with an intentionally designed metal shroud to keep dirt and moisture out of motor and electrical components. Pumps operate below maximum OSHA noise limitation.

With high tonnage double-acting cylinders, the Power Team 400 series offers both single or multiple cylinder applications. Two-speed high output pump delivers up to 5 gpm (16 liter/min) of oil, with a low noise level of 73-80 dBA. Integral electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Over-current protection prevents damage to motor as a result of overheating. “Stop” and “Start” control buttons are 24 volt. PE4004 has a 4-way/3-position manual valve. The PE4004S has a 4- way/3-position solenoid valve with a 24 volt remote hand switch. External pressure relief valve is adjustable from 1,500 to 10,000 psi (100 to 700 bar). Heavy duty 4" (50,8 mm) diameter casters assure easy maneuvering. 20 gallon (3,927 cu. in. usable) / 75,7 liter (62,8 liter usable) reservoir has a low oil level sight gauge. Powered by a dual voltage 10 hp (7,46 kW), 3 phase, 1,725 (1,437) rpm motor. 3 phase motor has all the electrical components necessary to operate the pump.The customer has no hidden charges when making purchase. Deliver 1,200 cu. in./min. (16 liter/min) of oil @ 200 psi (15 bar), 420 cu. in./min. (5,6 liter/min) of oil @ 10,000 psi (700 bar).

Power team synchronized lifting and lowering system, the MCS ( motion controller system ) series can be used in many hydraulic applications where load position is critical, requiring cylinder synchronization. Whether it is a bridge, a building or any kind of heavy load, with the SPX FLOW power team motion control system, lifting, lowering, pushing, pulling, tilting or positioning loads can be carried out automatically with a high degree of accuracy. The PLC-controlled system is a combination of digital actuation and digital control providing significant advantages such as time savings, repeatability, and extremely low internal stress in the object one is moving. The system also provides documentation for the movement performed.

Extremely durable yet lightweight and operable under low-line voltage conditions, the Power Team PE-NUT series pumps are constructed for challenging conditions. A 115V 5/8 hp (0,46 kW) universal electric motor (50/60 cycle), employing a two-stage pump for efficiency and designed for use with spring-returned remote tools. The PE-NUT series pumps also feature high-pressure safety relief valve, remote hand control with 10-foot (3,1 meter) cord, and a pressure matched quick-coupler supplied. The PE-NUT series uniquely utilizes intermittent duty, piston-type high-pressure pump supercharged by a low-pressure pump. CAUTION: DESIGNED FOR CRIMPING APPLICATION ONLY! This system should not be used for lifting.

Gasoline power ideal for remote locations. A logical choice at work sites where electricity or compressed air are unavailable. For single or double-acting cylinders at operating pressures up to 10,000 psi. All gasoline engine/hydraulic pumps feature Posi-Check® valve to guard against pressure loss when valve is shifted from “advance” to “hold.”

PG303 is for single-acting cylinders, has a 9520 valve with separate internal return line which allows oil from running pump to return to reservoir, independently of cylinder return oil, when valve is in “return” position.

A logical choice at work sites where electricity or compressed air are unavailable. For single or double-acting cylinders at operating pressures to 10,000 psi.

PG1200 Series pumps powered by a Honda 4-cycle, 5.5 hp engine with automatic decompression and electronic ignition. Deliver over 0.5 gallon (130 cu. in.) of oil per minute at 10,000 psi.

Heavy-duty “roll cage” provides pick-up points for lifting. Horizontal bars on PG1203, PG1204 and PG1204S protect unit, provide hand holds for carrying.

Rubber anti-skid insulation on bottom of reservoir resists skidding and dampens vibration. PG1200M-4 and PG1200M-4D include a pump cart with 12” wheels.

The Power Team HB series is purposefully constructed to convert low-pressure portable hydraulic pumps or on-board hydraulic systems, into high pressure power sources. HB series applications include utilities, railroads, construction, riggers and others. This product operates single or double-acting cylinders, jacks, and tools such as crimpers, spreaders, cable cutters, or tire tools. Version for use with double-acting torque wrenches available. May be used to operate two separate, single-acting tools (with integral valves) independently, without need for additional manifold. Control valve included. Other Power Team valves available as an option to suit your specific application, if needed; consult factory. Compact and rugged for use inside a utility vehicle aerial bucket or stowing in a vehicle. No reservoir level to maintain; uses low pressure system as oil supply. Has 3⁄8" NPTF ports; compatible with standard fittings for low and high pressure systems.

Portable two-speed pump operated in any position (open or closed-center) providing pressures up to 10,000 psi for the operation of high-pressure tools.

Oil from an external source, such as a bucket truck or tractor, is intensified to 10,000 psi maximum. Low pressure from the source is bypassed through the booster for rapid ram advance.

These compact, lightweight boosters do not have reservoirs. The units can be operated in any position on either open- or closed-center (accumulator) hydraulic systems.

“Assemble to Order” means you can choose a basic pump with gas, air or electric motor. Then select the proper valve, gauge, pressure control, motor control and reservoir. You get a two-stage pump that gives high oil volume for fast cylinder approach (and return with double-acting cylinders) in the first stage and high pressure in the second stage.

1-1/8 HP Universal Motor. These motors start under full load and are suitable for operation up to 5,000 or 10,000 psi. The motor is 1-1/8 hp, 12,000 rpm, 115 or 230VAC (specify), 50/60 cycle AC single-phase (25 amp draw at 115VAC). With proper valve they can be used with single or double-acting cylinders. NOTE: Remote control available.

1-1/2 HP Jet Motor, Single & Three-Phase. Feature low noise level, moderate speed for long service and are ideal for fixed applications. Motor is 1-1/2 hp, 3,450 rpm, 115 or 230VAC, 50 or 60 cycle (specify), AC single-phase with thermal overload switch. Can be used with single or double-acting cylinders and equipped with remote control. Also available in 230/460VAC, three-phase (specify). NOTE: These do not start under full load unless valve is in “neutral” (requires open or tandem center valve) and are not recommended for frequent starting and stopping.

3 HP Jet Motor, Three-Phase. Gives low noise level and long life due to its moderate operating speed. Ideal for fixed installations. Consists of basic 10,000 psi pump, jet pump motor: 3 hp, 3,450 rpm, 230/460VAC, 60 or 50 cycle (specify). AC three-phase, with thermal overload switch. Equipped with internal and external relief valve. Will start under load.

or cannot be used. The 5,000 or 10,000 psi pump has a 3 hp air-driven motor at 3,000 rpm (optimum performance based on 80 psi air pressure and 50 cfm at the pump). You can drive single or double-acting cylinders with the correct valve. NOTE: 80 psi air supply required to start under full load.

unavailable. It is capable of continuous operation at full pressure. Consists of basic 10,000 psi pump, 4-cycle Briggs & Stratton “Diamond Edge” gasoline engine, developing 6 hp. As with all these pumps, this unit can be valved for use with either single or double-acting cylinders.

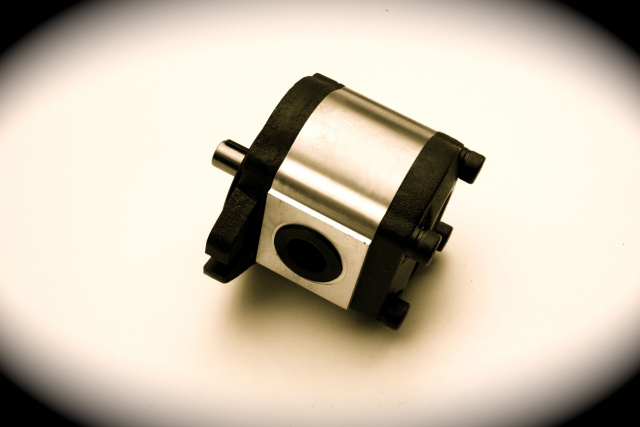

Gear pumps have very few moving parts. They consist of two intermeshing gears. These pumps have a constant flow rate. They operate at pressures generally between 50 and 210 bar. Gear pumps operate at the highest speeds of any pumps at up to 3000-6000 rpm.

In an external-gear pump, only one of the gear wheels, the drive gear, is connected to the drive. The other gear wheel, the driven gear, rotates in the opposite direction, so that the teeth of the rotating gear wheels interlock.

There are also double external-gear pumps, which combine two gear pumps driven by the same coupling shaft. A double external-gear pump has the advantage of supplying two independent hydraulic circuits, and also provides more flow to one circuit.

These New Style Sizing Dies will size your brass based hulls down .001-.003 below the minimum chamber size. Steel based hulls will be sized down .003-.005 below minimum chamber size.

This new, billet aluminum one piece primer tray, was designed to accept the wider foreign primer boxes. No more need for changing out boxes!!! This Primer Tray will come standard on loaders that were ordered after 07/01/22.

The New Style Press Plate greatly accommodates the New Style Sizing Dies as well as loading steel based hulls. It creates an effortless shell ejection during loading.

The New Style Bearing Cap is equipped with a die retaining plunger at the starter crimp station. This upgrade prevents shot from bouncing out of the shell and into the primer track during the downstroke.

The New Style Primer Block Sleeve has been redesigned in a couple of different ways. First off it is made out of High Strength Fatigue Proof Steel. Second, tolerances have been tightened up to compliment the New Precision Ground and Polished Primer Shafts that are coming standard in the new machines. Last of all, the New Style Primer Block Sleeve will prevent the primer in the Female Primer Slide from jumping over the primer that"s on the Primer Seating Shaft when first starting to load.

1 wad shaft roll pin, 2 charge bar cam rollers, 2 lube swabs, 2 spring fingers, 1 counter pin, 1 primer cup, 1 primer cup bolt, 1 primer cup spring, 1 knockout spring, 2 shot and powder washer seals, 1 electric box fuse, 1 bottle super die lube, 1 bottle super dry lube, 1 can Hornady One Shot,1 syringe super grease.

When you consider which high-pressure electric pump is right for an application, there’s a lot of emphasis on getting the proper flow and pressure. And rightly so. Determining proper GPM and PSI is critically important.

Performance is generally determined by the amount of horsepower in electric motors. What is the role of horsepower and how can you determine how much you need?

The term horsepower, often abbreviated HP, stems from the 18th century and was coined by Scottish engineer, James Watt. He developed a calculation that compared the power of draft horses to the output of steam engines which were relatively new technologies at the time. Today, horsepower units are used to measure the output power of numerous types of engines or motors. The electrical equivalent of one horsepower is 746 watts.

So, what’s the significance of horsepower? In vehicles, the more horsepower an engine has, the more towing capacity or speed it can deliver. If you want to increase performance in either regard, you’ll need to increase horsepower.

The same principle applies to pump motors. If you have a pump rated at 6 GPM and 1,000 PSI and you want to increase its performance, you’ll need to use a more powerful motor. Even so, a pump sprayer with a certain GPM and PSI rating won’t necessarily produce those numbers if the motor isn’t powerful enough or efficient enough. Trying to get more output out of a pump than it’s rated for without increasing the motor size will likely cause it to stall, overheat, and fail.

A pump’s motor ratings are more often referred to in amps rather than horsepower. A 30 amp pump is equivalent to about ¼ HP. So, the more horsepower a motor has, the more amps it will draw. When working with battery-powered pump systems, amperage draw becomes a big concern.

Drawing too many amps will drain batteries quickly. Most operators want to get through an entire day on a single charge rather than swapping out batteries multiple times each day or waiting to recharge.

That’s why it’s important to pay attention to efficiency ratings on the pumps you choose for an application, as that can tell you how many amps you’re really getting. Centrifugal pumps, for example, may have efficiency ratings as low as 50%. By comparison, Pumptec plunger pumps are rated at 93% efficiency. Why does it matter?

Take, for example, a 30 amp Pumptec plunger pump (¼ HP). At 93% efficiency, you’re getting near maximum performance. If you only get 50% efficiency from a centrifugal pump, you’re only able to use 15 of those amps, or ⅛ HP. In a 50 amp motor — equivalent to ½ HP — you’d only use 25 amps or ¼ HP. The rest is going to waste.

To get similar performance ratings in a centrifugal pump as with the plunger pump, you’d have to nearly double your amperage and horsepower, meaning a bigger, less mobile pump system at a higher price tag. Even if a pump operates at 80% efficiency, that means you’re still losing one-fifth of its potential power and would have to use a larger (and more expensive) pump motor to make up for it.

Some types ofpositive displacementpumps are more efficient because of their simpler drive mechanism. While centrifugal pumps also have a simple drive and few moving parts, they are less efficient due to hydraulic friction. After the pump has run for a period of time, the impeller wears, the hydraulic loss is increased, and the hydraulic efficiency is lowered. Triplex oil bath pumps are less efficient due to lots of moving parts working against the resistance of the oil. The nature of a Pumptec sealed bearing plunger pump’s design is inherently more efficient.

Some pump operators believe they need a more powerful pump; that if it just had more horsepower, they’d be able to get in and out of jobs faster and get better performance.

Many pump operators purchase pumps that are actually oversized for the job. You might purchase an off-the-shelf 1.5 GPM pump but only use 1.3 GPM, meaning .2 GPM ends up going through bypass. That’s very inefficient. Ideally, you’d use a smaller motor at a lower price point and get better performance. Plus, the smaller pump would offer more mobility and longer battery life. The good news is that pumps can be customized to meet a specific flow rate for an application.

Using a pump performance chart is one way to determine your needs. An even better way is to work with a pump engineer to pinpoint the ideal GPM and PSI for your application and then design a pump solution to your specifications. To help you get started, use our free Guide to Proper Pump GPM and PSI. It outlines common standards for several industries.

Then, reach out to our pump experts. Whether an OEM manufacturer of pump equipment or a commercial business with a team of operators, we’re happy to talk through your needs and explore solutions.

Working oil: A mineral based oil with additives to resist corrosion oxidation, & foaming is recommended. Viscosity at any running condition should be 60 SUS minimum & 250 SUS maximum. 180° F is the maximum recommended system operating temperature

If you’re a pump sprayer operator and you’re performing a soft wash application on a two-story residential home to remove lichen or mold, how do you get the spray pattern to reach the eaves of the home and provide even coverage without having to climb a ladder?

There’s a common misconception that to achieve a broader vertical or horizontal spray pattern, you simply need a pump that puts out more pressure. On the contrary, increasing the flow rate is often the key.

It’s not uncommon to hear pump operators complain that their sprayer doesn’t have enough pressure when, in fact, the issue is the flow rate. In fact, some people use the two terms interchangeably, as though they’re the same thing. They’re not, and knowing the difference and the role each plays is the key to achieving proper pump performance.

A pump’s job is not to deliver pressure; rather, it is to deliver a rate of flow, pumping a certain amount of liquid over a given amount of time from a tank or reservoir to the outlet. Flow rates are often referred to in gallons per minute or GPM. There are some smaller pumps that rate flow at gallons per hour or even gallons per day, outputting extremely small amounts of fluid over a given time.

Pump pressure, however, is a measure of resistance to flow. Without flow, there is no pressure. In a positive displacement pump, such as a plunger pump, the rating in pounds per square inch, or PSI, outlines how much resistance the pump is designed to withstand.

A pump’s PSI rating is important because it indicates that the pump was manufactured out of materials and designed to handle a certain amount of pressure. But for pump operators, they should be equally concerned with a pump’s flow rate which determines how much you want to dispense, spray, or inject.

In general, when pump pressure increases, flow will decrease. Take, for example, a misting pump that needs to produce an ultra-fine mist for cooling or dust suppression. Many misting pumps are rated at 1,000 PSI, yet their flow rate is quite low at .25 GPM.

Clearly, high pressure in this instance is very important to produce the right size droplets. However, it doesn’t indicate more output or vertical or horizontal throw. Instead, the higher pressure combined with the right nozzles results in a fine mist with very little flow that might only cover a small patio area.

On the other hand, a soft wash sprayer can be rated at a mere 100 PSI and have a GPM of 5.4, yet it can achieve a vertical throw of nearly 40 feet and a horizontal throw of more than 50 feet when paired with the proper nozzles.

More pressure changes the velocity of the fluid, but it also decreases the flow or output. The cause of the flow decrease is due to two factors: volumetric efficiency of the pump and reduced motor speed. Volumetric efficiency is a measure of the actual flow compared to expected theoretical (calculated) flow — volumetric efficiency decreases as pressure increases. Our positive displacement plunger pumps have about 90–100% volumetric efficiency compared to centrifugal pumps that range from 0–100%. This means that plunger pumps only lose about 10% of the flow when pumping against back-pressure, while centrifugal pumps will lose all the flow when pressure climbs too high.

Reduced motor speed occurs when motors are loaded heavier. So, when pressure in the pump causes more load on the motor, it slows down. When the motor slows down, the flow rate drops at the same percentage. A motor that operates at about 2000 RPM at low pressures will typically slow down to about 1750 RPM when the pump is pressurized to the maximum rating.

It stands to reason, then, that increasing pump pressure will not increase flow. In the soft wash example, more pressure won’t help the operator reach the eaves of a two-story home with the same amount of coverage. The operator needs a pump motor with an ideal combination of pressure and flow.

Engineering pumps for any application requires an understanding of fluid dynamics, and each industry has varying needs. Too often, a company will choose an off-the-shelf high-pressure pump to get a job done and wonder why it doesn’t perform as expected. It’s likely because the operators lack a full understanding of the relationship between flow and pressure.

The engineering experts at Pumptec have a thorough grasp on fluid dynamics and help OEMs and pump distributors pinpoint their exact needs. They make recommendations based on scientific principles and years of experience serving multiple industries, and can even customize pumps to your application’s precise needs.

In fact, we’ve developed a Guide to GPM and PSI that provides some of those industry recommendations. Take a look through it and then contact the pump experts at Pumptec. We’ll be happy to discuss your needs and determine the right pump for your application.

Jogeshwari East, Mumbai No. 1, Visawa Building, Ground Floor, Plot No. 10 Saraswati Baug, Jogeshwari East, Mumbai - 400060, Dist. Mumbai, Maharashtra

Vasai East, Mumbai Flat No.C-65/103, Shiv Smruti Chs Ltd, Anand Nagar C Shivaji Road, Dahisar East, Vasai East, Mumbai - 400068, Dist. Mumbai, Maharashtra

Chinnavedampatty, Coimbatore No. 23/5, New Layout Athipalayam Road, Chinnavedampatty, Chinnavedampatty, Coimbatore - 641006, Dist. Coimbatore, Tamil Nadu

We are in this business since 1990, with a firm commitment to quality and reliable services, we slowly moved ahead. Today we are among the leading companies in ourread more...

Satellite Road, Ahmedabad F-04 karma Jyot Coop H Soc Ltd, Opp Ramdev Nagar Police Chowkey, Satellite Road, Ahmedabad - 380015, Dist. Ahmedabad, Gujarat

Vasai East, Mumbai No. 112, Vasundhara Industrial Estate, KT Park Phase I, Gorai Pada, Vasai East, Vasai East, Mumbai - 401208, Dist. Mumbai, Maharashtra

GIDC Naroda, Ahmedabad D/49-B, Diamond Park, Opposite Gujarat Agro, N. H. No. 8 Behind Ruby Rushi, G. I. D. C. Estate, Naroda, GIDC Naroda, Ahmedabad - 382330, Dist. Ahmedabad, Gujarat

Owing to our expertise in this domain, we are leading manufacturer of Hydraulic Pumps. The gear pumps offered by us are manufactured using finest material and contemporary technology. In order to conforming to internationalread more...

Pacer Pumps provides a variety of pumps for agriculture, aquaculture, marine, farm/home and industrial markets. From our most popular "S" Series to our hand-operated "HP" Series pumps, we are confident that we will have the pump to fit your specific application. Browse our Pump Series pages and review the Pump/Driver Matrix to learn more about what we can offer. If you need technical support, please contact Pacer Pumps at 1-800-233-3861 or send inquiry to sales@pacerpumps.com.

Selection of the proper pump for a particular application is dependent upon a number of factors such as: material compatibility, liquid being pumped, pump location, pump size, pump type, pump speed and horsepower. Here are some general guidelines to help you make the right choice.

Materials must be compatible with the liquid being pumped. Plastics or polymers may react differently depending on the type of solution or liquid being used. Temperature of solution is also a factor. Pacer Pumps are not ideal for agressive chemicals or high temperature processes. Internal pump parts like seals and o-rings must also be compatible with the liquid being pumped.

Our pumps are of horizontal design coupled with a variety of drivers which achieve multiple flow/pressure combinations. Different pump internals can also be used to achieve various flow and pressure combinations. Centrifugal pumps typically operate at speeds of 1725 RPM or 3450 RPM. The low RPM pump has half the flow, one fourth the pressure and requires one eighth the horsepower of the high RPM pump.

Pump ratings are based on moving a liquid with a specific gravity (SG) of 1. When specific gravities higher than 1 are encountered, oversized drivers must be utilized.

In order to achieve a desired flow and pressure, the pump selected must provide a Total Discharge Head (TDH) at the given flow which must exceed the desired discharge pressure plus friction losses resulting from the length of pipe or hose, fittings and valves in the line along with any other impediments to flow within the line.

The matrix shown below will allow you to see the various pump series and drivers that we offer. The driver is your preferred method of rotating the pump"s impeller. Close-coupled configuration is more compact and the pump is mounted directly to your specified driver. Long-coupled configurations create more separation between your pump and driver. This configuration takes up more space as it utilizes a bearing pedestal and flexible coupling between your pump and driver.

Sudenga Industries is a leading manufacturer of durable ag equipment for grain, feed and seed handling applications. Products can be found in farm and commercial agriculture installations as well as industrial material handling applications worldwide. Sudenga was founded in 1888 in the northwest corner of Iowa where it is still located today.

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flows into torque and angular displacement (rotation). Hydraulic motors serve the electric power, construction, water conservancy, transportation, ships, automobiles, aerospace and military field. Hydraulic systems are widely used in papermaking, textile, plastics, rubber and other light industries. It also plays an important role in heavy industry, like mining, petroleum, metallurgy and pressure processing.

When purchasing a hydraulic motor, the main basis is requirements for the hydraulic system, such as torque, speed, working pressure, displacement, shape and connection size, volumetric efficiency, total efficiency, quality, price, supply, convenience of use and maintenance.

High power-weight ratio: The ratio of the energy transmitted by the hydraulic motor to its own weight is very small compared to other transmission methods.

According to its structure type, hydraulic motors can be divided into gear, vane, piston hydraulic motor and other types. ATO has a wild range of hydraulic motors to meet your buying requirements. Each has its specific purpose and applicable working conditions. This time, some of ATO"s bestselling hydraulic motors are presented below for you to purchase.

After determining the type of hydraulic motor, several specifications that meet the needs can be selected according to the required rotational speed and torque. First, the corresponding pressure drop, flow rate and efficiency are calculated through the characteristic curves of various specifications, and comprehensive analysis could be carried out.

If the original cost is the most important, you should choose a motor that not only meets the torque requirements, but also makes the system flow smaller and lower pressure, so that the hydraulic source, control valve and pipeline specifications can be smaller.

8613371530291

8613371530291