wood splitter hydraulic pump problems brands

Hydraulic Log Splitter systems use pressurised fluid to power a force that is used behind a wedge to split wood. If the log splitter seems weak or not performing as it should then there is a strong likelihood that something is not right with how the splitter system is operating.

To begin with, check your log splitter and the wood you are trying to split. If a log is not splitting all the way through then the log may be too green or too large, meaning that it would require a greater force than your log splitting machine can manage. Also make sure the log is loaded properly and isn’t on an angle or is too long. If this is in order, then take a look at the wedge itself, as with heavy use they can become blunt and stop cutting as they should.

These vibrations or shaking could be due to the log splitter being low in hydraulic oil. If the levels look correct when checking this could mean that there is air within the oil lines. To fix this the bleed valve needs to be opened and the pressure plate needs to be cycled back and forth a few times.

Temperature could also be the culprit for loss of driving force, as hydraulic oil is more viscose in cold weather resulting in a weak response until the machine warms up.

The nut for the ram has possibly come off the piston if the ram has extended but not retracted. With the engine off, hold open the valve and push it back in using a narrow rod. However, with this issue you may need to bring it in or contact one of the Flowfit team to discuss replacing the nut to prevent damaging your hydraulic log splitter system if you use it again.

Log splitters are a relatively simple design, making them easy to maintain and fix, but if issues are persisting or you aren’t confident with fixing this machine then please do seek professional advice.

Depending on your model, you may have a bit of exploration to do to discover what is causing issues with your log splitter. The simplicity of the design, however, can help you pinpoint your exact concern. Luckily, you can correct many problems on your own, and this guide helps explain some of the most common ones to help narrow down your log splitter troubleshooting. Get out there and you’ll be back up and running sooner than later!

Themost popular log splitters use hydraulicsto power the force needed to split various-sized logs. Because of this, common problems are related to the power source provided to the hydraulics or the hydraulic pressure.

Gas splitters are powered bya 4-stroke enginethat requires regular maintenance. If you neglect your engine, you may have problems with your log splitter working properly. It is especially true if your splitter won’t start or stay running.

Unfortunately, electric engines are not something you can work on easily. Often, they require a professional if you feel the problem is located in the engine, and many times the cost of the engine repair is more than what a new splitter might cost.

You are the power source for a manual hydraulic splitter, and these simple designs are pretty easy to troubleshoot simply because there is not much to the overall design.

Hydraulic issues are common and generally easy to pinpoint. Hydraulic systems use pressurized fluid to power a force. In a log splitter, the engine pressurized fluid which powers the driving force behind the wedge to split the wood.

If your splitter is bogging down under pressure or seems weak, chances are there is something wrong with how this system operates about the size of the hydraulic pump and what it is capable of. There are a few things you can do to address these issues correctly.

First, you need to narrow down the problem through your observations. You also need to look at actions before blaming the hydraulic system. A good knowledge of what your splitter is capable of and how a log splitter works is a great place to start.

If your log is not splitting through, it may be too green or too large and require a greater force than what your machine can handle, and you should check the tonnage. If you know this is not the case, then taking a closer look at the hydraulic system is in need.

If you experience vibration or shaking during operation, chances are you have a low hydraulic oil level. Check the level and top it off if needed. If the levels are correct, you may have air in the lines.

If your cylinder rod won’t move and the hydraulics are not engaging, you might have a simple solution if this is the first time you have used your splitter. First, check to see if the shipping plugs are still in place by disconnecting the hydraulic hoses, removing the plugs, and putting them back on.

If this isn’t the first time you have used your splitter, and it just started, something else might be blocking the hoses. You can remove the hoses and flush them or change the hydraulic fluid. You may have a blocked control valve which can also be cleared by flushing the hydraulic system.

As seen, common issues surround engine maintenance and hydraulics. Many problems are simply from regular wear and tear and are uncomplicated to fix with new filters, seals, and hoses. However, if problems persist or seem worse despite your care and attention, you may need to take a closer look at the piston and replace it.

Log splitters are made for heavy, long-term use, and the materials used in their design are durable and efficient. Because of this, most companies also provide excellent customer support to help narrow down any issues you may be experiencing. There are also manuals included to help solve your problems.

Are you trying to buy a new hydraulic pump for your log splitter or do you need a perfect replacement pump kit for your wood splitter? Then, you should start your buying journey by reading this post. In this article, we’ll review the six best log splitter hydraulic pumps in 2022.

We compiled our list of the best gear pumps available after considering thoroughly their construction, splitting power, the flow rate for cycle time, operating speed, safety features, and overall benefits. We also included a buyer’s guide, FAQs, and summary to help you make a well-informed choice that suits your log splitter’s requirements and needs.

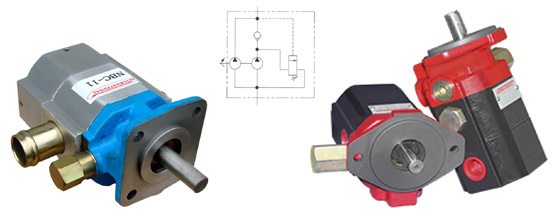

Log splitters are powerful machines designed to split logs efficiently. The machines offer effective splitting power to logs of various sizes. Almost all log splitters (including electric and gas types) use a hydraulic pump which is the integral component of a hydraulic machine that helps achieve the basic splitting of logs. The major components of a log splitter include an engine, hydraulic oil pump, valve, and hydraulic oil tank.

A typical hydraulic pump used for a log splitter is designed to feature a 5 hp gasoline engine, two-stage pumping sections, a hydraulic cylinder (4” diameter, 24” long), a 20 tons rated splitting force, and a 3-5-gallon hydraulic oil reservoir. Log splitters often use a two-stage pump to generate the right amount of pressure and flow rate required for splitting logs.

It’s tough to pick one product when you have many products from different brands making similar claims. So, we’ve done the hard work for you. Here are the best six pumps for a log splitter on the market. After reading this review, making a decision will become easier for you.

The RuggedMade 11 GPM 2-Stage Hydraulic Log Splitter Pump is perfect for log splitters with a rated force not up to 35 tons. It’s built with aluminum material for a longer service lifespan.

This hydraulic pump boasts up to 3000 PSI capable of powering log splitters and outdoor power requirements that range from 5 to 37 tons, depending on the hydraulic cylinder diameter (inner).

The two-stage pump operates at a maximum speed of 3600 rpm for faster cycle times during unloading. It’s preset to gear down mode at 500 PSI to help relieve the pump’s pressure; thus, ensuring the proper functioning of your splitter hydraulic system.

The Yaegoo 11GPM 2-Stage Hydraulic Log Splitter Pump is suitable for any log splitters application. It features a flow rate of 11 GPM capable of creating a stream of high-pressure oil required for generating maximum splitting force.

This two-stage hydraulic pump works at 3000 PSI to ensure effective splitting power without a loss of pressure. It’s built to automatically switch from high-pressure to low-pressure at 500 PSI for quick drawing back of the piston after splitting the log.

This log splitter hydraulic pump is ideal for log splitters with a rated splitting force of about 35 tons. It supports both vertical and horizontal applications.

The Bestauto Log Splitter Pump Kit is a suitable replacement pump kit for log splitters. It’s built with extrusion aluminum material that can resist wear and tears for an extended service life cycle.

This kit comes with a two-stage hydraulic pump, pump bracket, and jaw coupler. The 2-stage hydraulic pump works at 3600RPM maximum to ensure the fastest possible cycle times. The pump offers 13 GPM flow at 3000PSI maximum operation pressure to provide quick oil output.

The pump bracket and jaw coupler make lifting, pressure type, elbow, bending row, straightening, cutting, assembly, and more possible for a hydraulic log splitter. It’s compatible with a wide range of engine sizes.

The RuggedMade 16 GPM 2 Stage Hydraulic Log Splitter Pump features a body built with aluminum material for longevity. It’s designed to contain two pumping stages and a bypass valve to allow for efficient log splitting.

The first stage of the pump generates 16 GPM at 650 PSI required to reset the entire splitting system back after splitting. The second stage of the pump delivers 3.5 GPM at 2500 PSI to generate the maximum splitting force required to push the piston into a log for effective splitting performance.

The TooTuff Log Splitter Build Kit is a perfect kit for a DIY splitter project. It provides two-stage pump action to allow for maximum log splitting efficiency. The 1st pumping stage operates with a maximum flow rate (13 GPM) at a lower pressure of 650 PSI to help ensure a quicker cylinder return position.

In the second stage, the pump switches to a lower flow rate (3 GPM) and higher pressure (2500 PSI) to generate the maximum effective splitting power to split the log.

This hydraulic pump provides faster cycle times (16 GPM at 3600RPM) and higher possible pressure (up to 4000 PSI) with a small engine or most 8-14HP gas engines.

The Bestauto Log Splitter Pump Kit consists of a powerful hydraulic pump and hydraulic tools such as a jaw coupler and pump bracket. This hydraulic pump is built with sturdy and durable materials that can withstand even harsh environments.

The pump offers two-stage hydraulic actions to keep your log splitter running correctly. The 1st stage of the pump is preset to operate with a maximum flow rate of 16 GPM at 650 PSI for quicker withdrawing of the piston after the log has been split.

While the 2nd stage of the pump operates with the lower flow (3.5 GPM maximum) at higher pressure (2500 PSI maximum) to ensure excellent splitting efficiency.

The materials used in the construction of a hydraulic pump for log splitters would determine the longevity and performance of such a pump. Log splitter pumps built with high-quality materials such as aluminum have a longer service lifespan.

It’s important to ensure that all the components of the pump you intend to buy are built with materials of high strength and hardness that can resist wear and tear over multiple uses. It’s also important to check if the pump’s quality is well-assured by the manufacturer so that you can have a great user experience.

The splitting power of a hydraulic pump for log splitters is largely dependent on the maximum pressure that such a pump can generate. The amount of pressure that a pump generate vary from brand to brand.

However, the higher the pump’s maximum pressure, the more effective its splitting power. We don’t recommend more than 3000 PSI, which is the practical maximum pressure that most 2-stage gear pumps required for excellent log splitting.

The flow rate of the hydraulic pump determines the periods of time the pump would take to work through a pile of logs. The pump’s flow rate is largely dependent on the size of the engine powering the system.

A two-stage hydraulic pump for log splitters often requires minimum horsepower such as 5-7 hp engines with 11 GPM pump, 6hp engine with 13 GPM pump, 8 hp with 16 GPM pump, and 11 hp with 22 GPM pump.

You don’t have to worry too much when choosing a hydraulic pump based on the flow rate as virtually all log splitter pumps out there are rated for the same pressure.

It’s important to know that the operating speed of the hydraulic pump is hugely dependent on the hydraulic flow rate (GPM). Generally, larger pumps produce more flow which means more operating speed. However, bigger gear pumps require larger engines or powerful engines to drive them. Small pumps produce less flow but don’t require more horsepower to function properly.

The safety valve ensures smooth operation and performance of the hydraulic pumps. It helps to control the maximum pressure created by the hydraulic pump. Without a safety valve, most hydraulic pumps will build pressure up to a point that something break. Uncontrolled maximum pressure is likely to break your hydraulic hoses, garden hoses, hydraulic pressure hoses, the cylinder, or the pump itself.

To ensure the entire safety of your hydraulic system, you should go for 2-stage pumps with features such as a hydraulic relief valve, check valve, directional control valve, unloader valve, or hydraulic valve. Any of these safety features would help keep your pump’s pressure in check.

Besides, you should check if the pump you want to buy comes with a return filter, filter element, or filter head. Any of this would function to keep dirt out of its hydraulic reservoir (fluid reservoir).

Most simple wood splitters use a 2-stage gear pump for efficient log splitting. The two-stage pumps give log splitters effective splitting power using small engines. They can help generate the highest possible pressure required to keep most log splitters working smoothly and efficiently.

The approved fluid types for the hydraulic system of most wood splitters are AW-32 10-Weight (ISO 32) and AW-46 20-Weight (ISO 46). These hydraulic fluid types help lubricate your gear pumps and other hydraulic parts for protection against corrosion and weariness during extreme cold and heat.

We recommend changing the hydraulic oil in your log splitter every 100 hours of work. Regular changing of the hydraulic oil in your log splitter would help improve the performance of your log splitter hydraulic system. In addition to replacing your log splitter hydraulic oil as recommended, you also need to change your filter to keep dirt away.

A single-stage hydraulic pump features only a single pumping section or setting. It’s designed to generate just one flow rate (maximum GPM) at one maximum pressure to create the maximum splitting force. While a two-stage hydraulic pump features two pumping sections or settings. It’s designed to generate two flow rates at two different pressure levels.

A two-stage pump automatically switches to its ‘high-pressure/low-flow stage to split the blog (something that can’t be achieved with a single-stage pump). Two-stage pumps generally save splitting time than its counterpart (that’s one-stage pumps).

Look no further than this review if you would like to try out the best hydraulic pumps for log splitters out there. Any of the review gear pumps are capable of giving your splitters the power required to split log efficiently. We’re certain that you won’t go wrong with choosing to buy any of the above products. They are the best anyone can find on the internet at the moment.

A broken flexible pump coupler, clogged hydraulic fluid filter, failed hydraulic control valve, broken hydraulic pump or faulty hydraulic cylinder can prevent the hydraulic cylinder from extending the wedge on a log splitter.

Accessing the flexible pump coupler is fairly easy, so check that part first. The flexible pump coupler connects the engine drive shaft to the hydraulic pump. The coupler is designed to break if the hydraulic pump seizes up, protecting the engine from damage. Because the flexible coupler is plastic, the coupler can deteriorate over time and crack or break. Replace the flexible coupler if it"s broken or damaged.

If the flexible coupler broke, try to rotate the hydraulic pump drive shaft with the drive shaft disconnected from the engine drive shaft to check for a locked-up hydraulic pump. If you can"t rotate the hydraulic pump shaft, you"ll likely need to replace the hydraulic pump. You"ll also need to replace the hydraulic pump if it"s leaking hydraulic fluid because the pump can"t build up hydraulic fluid pressure to extend the wedge to split a piece of wood if its seals leak.

Hydraulic fluid leaking from the hydraulic control valve or hydraulic cylinder often indicates that the leaking part has failed. You"ll likely need to replace the control valve and/or cylinder if they leak hydraulic fluid.

Although it doesn"t happen often, a clogged hydraulic fluid filter can impede hydraulic fluid flow and prevent the cylinder from extending the wedge. Check the hydraulic fluid filter and replace the filter if it"s clogged.

When you see your log splitter leaking hydraulic fluid from the pump, failed pump seals are likely allowing hydraulic fluid to leak out from gaps around the pump"s drive shaft. The pump will eventually fail to build up enough hydraulic pressure to move the piston and wedge because hydraulic fluid leaks past the seals.

Troubleshooting your log splitter really isn’t as daunting a task as you’d think it’d be. Thanks to the great design of our log splitters, pretty much nothing can go wrong which is unfixable. We stock all the spare parts you could ever need, but first, we need to work out the problem.

There are four main categories of troubleshooting; power issues, log splitter ram failing to move correctly, oil leakage or the log splitter failing to split logs.

It may often appear as though something critical has affected your log splitter, such as the ram failing to move or it appears as though there’s no power getting to the log splitter. More often than not, there are small errors that can be easily fixed.

If you’re not comfortable playing around with your log splitter – let us take a look for you. We offer a log splitter repair service, no matter the brand. We offer a full repair of your log splitter. This includes collecting your machine, repairing it in our workshop and delivery back to yourself. The repair may include a full strip-down, rebuild or fitting of replacement parts.

Check that the plastic knob of the lever is screwed on fully. If this becomes unscrewed it then prevents the lever from being pushed right down, and this prevents the log splitter from operating.

The oil level in your log splitter may be running low, you can check this by using the dipstick. You can also run a quick test by raising the front end of the log splitter on a block of wood or something similar. If you raise the front of the log splitter and the log splitter then starts operating as normal, then this is a clear sign that you are low on oil.

This is similar to the last, but when the log splitter is pointing downhill it struggles to circulate the fluid right around the machine. This causes it to fail when operating.

The log splitter should always be operated on level ground or pointing uphill. If your log splitter is failing to split any logs, 90% of the time this will be the issue. If the log splitter is not pointing downhill then it’s likely low oil.

Now that we’ve covered the most common issues and quick fixes. Let’s look at some of the rare problems which can affect the performance of the log splitter.

Place the log splitter back upright and try the splitter again, if it produces the same noise then loosen the bolts a little from the end of the pump (13mm) and try again.

The capacitor in the electric motor can fail from misuse over time. When operating the log splitter, we strongly advise that you press the power button before operating the lever, this allows time for the motor to gather speed before attempting to split logs.

As stated previously, the capacitor failing will also stop the motor from starting up. After you have checked the previous solutions, unplug the log splitter from the mains. Then remove the six screws on the outside of the switch cover, take the switch cover off and you will then see the capacitor.

Pump gears binding is an issue that can sometimes present itself within a log splitter which would cause a trip. This is easily fixed by loosening each of the 6 bolts on the back of the pump by ¼ of a turn and then checking to see if the motor turns freely.

Pump gears can also get jammed. To fix this you should remove the 6 bolts from the pump and separate the motor and pump. You can then check the gears for any silicone sealant or other material. When you’re reassembling, the torque for the bolts is 12 ft-lb, 16 N m.

If the ram of the log splitter is not returning fully or is jerking upon return, there are a couple of fixes you can perform to get it back up and running smoothly.

First, check that the moving carriage isn’t obstructed. You can do this by checking underneath the blade/pusher and down the sides of the carriage for any splinters of wood that may be obstructing the carriage.

This one is fairly simple to figure out but check the log bed of the splitter for a build-up of sap. You can then also apply a thin layer of workshop grease to the bed to allow it to operate more smoothly. Avoid using WD-40 to grease the bed as this can lead to the log splitter ram ‘juddering’ rather than solving the issue.

Another possibility is that the ram is bent. Remove the DuoCut blade from the splitter. If the ram does not return after removing the DuoCut blade, loosen the 2 rear lock nuts on the carriage arms and remove the 2 nuts in front of the crosspiece. You can then remove the carriage from the log splitter. If the ram does not return then the next part is a bit tricky so give us a call.

Keep your hydraulics in motion with a wood splitter hydraulic pump from RuggedMade. Designed to meet the needs of high-force log splitting, our precision 2-stage hydraulic pumps ensure cylinders perform smoothly and rapidly, helping to shave down cycle times.

Our expanded line of one and two-stage log splitter pumps are constructed to produce up to 3,000 PSI and can also be used at the heart of a variety of hydraulic applications to keep fluid flowing freely and steadily, throughout the life of your machine.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

A: To determine which pump to purchase, you will need to know the following: what HP engine will you be powering my log splitter with, what size reservoir capacity do you have available, what type of pump mount you will be using?

A: There are two common types of mounts used on log-splitters. There is a four-bolt mount and a two-bolt mount. The four-bolt mount pumps generally come in 5gpm-16 gpm sizes and have a ½” keyed shaft about 1-1/2” long. The two-bolt mount pumps come in 22gpm and 28gpm sizes and have a 5/8” keyed shaft that can differ in length.

A: If your log-splitter is moving slow but still capable of splitting the wood it always has, it is most likely stuck in its second stage. In the second stage (or low flow/high-pressure stage) the pump produces 25% or less of its rated GPM but it does it at a higher pressure. The transition from the first stage (or high flow/low-pressure) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

1. If the engine bogs down and stalls out, the pump is likely stuck in its first stage. In the first stage (or high flow/low-pressure stage) the pump produces its rated GPM but it does it at about 400-900psi. The transition from the first stage (or high flow/low-pressure) to the second stage (or low flow/high-pressure stage) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

2. If the engine bogs down slightly but fails to stall out, you most likely have a bad seal on the cylinder piston. It is often more cost effective to rebuild a cylinder than to replace it depending on the extent of any internal damage. Consult with your local hydraulics shop.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. Most 2-stage Log-splitter pumps will safely create 3000 psi regardless of how quickly they transfer the fluid doing it. So, there is not actually a more “powerful” pump, just slower or faster.

A: The size of splitter is typically specified in tons of splitting force. This number is determined by the surface area of the piston multiplied by the pressure applied by the pump. The amount of tonnage that you will need depends predominately on the type and size of wood that you will be splitting. Hardwoods such as oak and hickory take more force to split than most coniferous soft woods like spruce and fir. The Janka rating is the measurement that they use to rate the hardness of wood. The higher the number, the harder the wood. Log diameter size is another important factor in the amount of force required to split the log. One of the most important factors in determining the Tonnage required to split logs is the moisture content. See below for a decent chart for tonnage requirements for seasoned wood. You will need 50-75% more tonnage for splitting green wood.

A: The tonnage rating on your log-splitter is determined by two distinct factors; piston surface area and pounds of force per square inch (psi) supplied by the pump acting upon that surface. To determine the piston surface area, you must take half of the bore diameter, and multiply that number by itself. Then take that number and multiply by pi (approximately 3.14). This will give you the surface area in square inches. Although your hydraulic pump will be rated to a certain maximum pressure rating, typically 3500psi, most log splitter hydraulic systems have a relief valve limiting the amount of pressure supplied to the cylinder and other components. To find the tonnage of your log-splitter you will take the relief valve setting in pounds per square inch multiplied by the surface area of the piston in square inches, then divide that number by 2000 pounds per ton. See example below for a 4-1/2”cylinder at 3000psi:

A: Your valve will have four ports. The IN port is supplied by the hydraulic line coming directly from the pump. The OUT port will return the flow of oil directly to the reservoir. That leaves the two work ports on the valve. The work port closest to the valve handle will be connected to the barrel port (extending) on the cylinder. Attach the other valve port to the rod port (collapsing) side. See the figure below.

A: Typical Log-splitter valves have three positions. Extend – Center – Retract. The extend position directs flow to where the cylinder expands thus forcing the wedge through the log to be split. The handle must be held in this position to maintain cylinder movement. The valve will spring to center from the extend position when the handle is released. The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal workings of the valve will force the handle back into the center position automatically.

A: The hoses on your log-splitter should have the rating printed or embossed onto the outside sheathing of the line. If it is not visible or readable it is a distinct indicator of weather damage and or rot, and you should look to have them replaced.

Your log-splitter requires multiple hoses and could potentially have three different pressure ratings (see figure below). The suction line shown in green does not see any pressure, on the contrary they usually have some sort of structure to keep the hose from collapsing. The return lines shown in orange do not typically see much for pressure, but they are typically rated to 350 psi. The actual pressure lines shown in red should be rated to at least 3500psi for your typical log-splitter application.

A: Most Hydraulic systems can be safely operated with either ATF (automatic Transmission Fluid) or a standard petroleum based hydraulic oil. Some Log-splitters have a replaceable filter assembly to help clean the oil clean. If your log-splitter does not have a replaceable filter it would be beneficial to use ATF and allow the detergents in the fluid to help keep things clean.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the seal kit.

If this is not an option for you for whatever reason, you can disassemble your cylinder and match up the seals by example with your local hydraulics shop. If you do not have a local shop, or they do not offer this type of service, you will need to measure the hard component dimensions of your cylinder. You will then need to match them with the dimensions of available seals with a seal supplier such as Seal Source, Hercules Sealing Products, or any other national seal supplier. Many of them have an online interface to help you make this selection.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the cylinder that they used on that specific unit.

A: The first step in selecting a replacement cylinder for your log-splitter is identifying what style of cylinder that you currently have. While many manufacturers utilize common style cylinders, many do not. Please see the figures below for the most readily available styles.

If your cylinder is mounted on lugs coming out of the side of the cylinder, this is what they would call a trunnion style cylinder. Trunnion mount cylinders are almost entirely exclusive to the log-splitter manufacturer. You will need to get a replacement from the original manufacturer or contact a machine shop to recreate the mounts on a more common cylinder.

Once you have determined the style of cylinder you are looking for, you will need to determine bore size, the mounting pin to pin length (both collapsed and extended), the rod diameter, and pin hole sizes. Drawings are usually available for individual cylinders to insure a proper fit. It might be necessary to have a local shop alter your log-splitter frame to accept the cylinder, or alter the cylinder to fit your machine.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. While operating below the bypass setting the pump will transfer that number of gallons per minute.

A: Availability of replacement parts for log-splitter valves depends on the manufacturer of the valve. You will first need to identify the manufacturer of the valve. Northern Hydraulics carries replacement handles and brackets for Cross MFG valves and replacement brackets and detents for the Energy MFG log-splitter valves

A:The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal passages in the valve will force the spool back into the center position automatically.

Call 1-800-823-4937 for information on choosing the hydraulic log splitter pumps, valves or cylinders that are right for you. Wood splitter parts and accessories are available to build your own hydraulic log splitter or repair one that is factory made.

.On that two stage pump it could have sucked some dirt,dust whatever into the pump and stuck the pump bypass valve which switches it to high pressure low volume .That valve should be set at around 900-1000 PSI . The relief valve in the main control valve is where the max system pressure is set on most splitters

If you can figure out what brand of pump it is more than likely an internet search will provide some troubleshooting information .You might try "Surplus Center" hydraulics which has some information available .

This pump is the same as our standard pumps with clockwise rotation but is designed for opposite rotation. Some splitters that use a belt drive like Swisher would use this pump.

We are not responsible and will not warranty customer cross threading hydraulic fittings or stripping out threads into this pump, if you are not familiar with tightening or installing pipe threads into aluminum then you will need to have someone familiar with doing so.

Brand new 19GPM, 2 stage hydraulic replacement pump for log splitters. Fits many different applications, including newest models sold at Tractor Supply Co.

- The 2-stage pump can give you faster cycle times and higher possible pressure with a small engine. Excellent for use on log splitters. 85% efficient.

- This 2 stage pump can give you much faster cycle times and higher possible pressures with a small engine. Excellent for use on log splitters. 85% efficient.

First let me start by saying I have never owned or even used a log splitter before, so this is an amateur"s opinion. With this in mind, I have been heating entirely with wood for the past 10 years. I recently scored some really large, green oak logs that were beyond my ability to split with a maul. I decided to finally bite the bullet and purchase a log splitter. I chose the Campion 27 from home depot for $1349. Note that Home Depot also has a 34 ton for$1779. With advise from this forum, I decided that the 27 would get the job done.

First of all, this splitter has split everything I have thrown at it. Even knotty oak logs have not been a problem. The hydraulics are solid and the Champion brand motor has started on the first pull every time to far.

The splitter came assembled by home depot, but the kid that assembled it did not tighten the hydraulic reservoir cap an it was leaking fluid. That was easy to fix.

The motor is solid, but in a bad location. It is easy to drop a log on it by mistake. Also, the air filter cover does not stay in place, so I had to zip tie it to prevent it from falling off during use of the splitter. Also to shut off the motor, you have to reach over from the opposite side of the hydraulic controls.

Overall I am pleased with this splitter, but improvements can be made to the design. I plan to make a new shelf for the logs and a cover to deflect logs dropped on the motor. The ram and wedge are a beast. Cycle time is pretty quick. I am sure if I take good care of this splitter it will handle many cords of firewood for years to come.

8613371530291

8613371530291