kelly bushing oil and gas in stock

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly. The kelly is a 4 or 6 sided steel pipe.

The purpose of the rotary table is to generate the rotary action (torque) and power necessary to rotate the drillstring and drill a well. The torque generated by the rotary table is useless if it is not transferred to the kelly (the drillstring is connected to the kelly).

Hence, through the kelly bushing the torque generated at the rotary table is transferred to the kelly. To achieve this connection, the inside profile of the kelly bushing matches the outer profile of the kelly so that the kelly fits or “sits” comfortably in the kelly bushing.

There are various designs for the kelly bushing including the split type, the pin-drive type and the square-drive type. Each of these designs has different ways in which they are connected and disconnected from the rotary table.

The internal diameter of the kelly bushing can be cut into the shape of a square (4-sided) or a hexagon (6-sided) depending on the outer shape of the kelly that will be used. The internals of a Kelly bushing is designed to resemble the outer shape of a Kelly just like the insides of a key lock is cut to exactly match the outer shape of the key.

The kelly bushing is not designed to hold tightly onto the Kelly; the kelly is still permitted to move up and down through the kelly bushing. This requirement is a must since drilling cannot progress if the kelly remains on a fixed spot. As the well is drilled deeper, the kelly also moves downward through the Kelly bushing.

The kelly bushing is sometimes used as a reference point from which depth measurements can be taken. All depths must be recorded with respect to a reference point; the kelly bushing (KB) is one of the depth references used in the oil and gas industry.

The top of the kelly bushing is normally used as the depth reference.For example, 7500ft KB means 7500ft below the kelly bushing or 7500ft measured from the top of the kelly bushing down to that point in the well.

In some other cases, depths could be recorded as 7500ft MDBKB meaning 7500ft measured depth below the kelly bushing. This is mostly used when the measured depth is different from the true vertical depth of the well, common with deviated and horizontal wells.

An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the kelly and the kelly bushing. The kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself. Depth measurements are commonly referenced to the KB, such as 8327 ft KB, meaning 8327 feet below the kelly bushing.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, “depth” also refers to the location itself.

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

Driller’s Depth below rotary table (DDbrt): The depth of a well or features within the wellbore as measured while drilling. The measured length of each joint of drillpipe or tubing is added to provide a total depth or measurement to the point of interest. Drillers depth is the first depth measurement of a wellbore and is taken from the rotary table level on the rig floor. In most cases, subsequent depth measurements, such as those made during the well completion phase, are corrected to the wellhead datum that is based on drillers depth (reference: Schlumberger Oilfield Glossary).

True vertical depth is obtained from a record of the deviation survey report. These surveys are generally run on deviated wellbores. It records measured depth (MD), inclination (deviation angle), azimuth angle, true vertical depth, and dogleg severity at various increments. To obtain a TVD, simply obtain a measured depth, go to the survey, and read off the TVD. If the desired measured depth is not in the survey, then extrapolate between the two closest points.

NB: Inclination is taken to be the angle of the well course from the vertical. Azimuth is taken clockwise from geographic north. In other words, the inclination angle measures the vertical direction and the azimuthal angle examines the horizontal direction.

Jiangsu Xinxiang share Co., Ltd was founded in 1994, its predecessor was established in 1955, it‘s located in high-tech industrial concentration zone of Nantong City, Jiangsu Province; near to a new developing international deep-water port Yangkou Port which commitment to ship 200,000 tons goods; world famous modern city Shanghai is only 2.5 hours away from it by car; company registered capital is 60,000,000 RMB, the total assets is 119.85 million RMB, it covers an area of 160,000 square meters and currently over 500 employees. Jiangsu Xinxiang Share Co., Ltd is "self-import and export enterprise", "private technology enterprises in Jiangsu Province", "high-tech enterprises in Jiangsu Province", it is top ten companies of the first national large and medium-sized industrial enterprises in independent innovation capacity of the industry; it accessed to API7, 7K, 8A, 8C, and has the right to use the logo, and also passed the ISO9001:2000 quality system certification in the earlier stage within the same industry.

The IADC Lexicon is © IADC. However, the documents from which the definitions were drawn may be copyrighted by the original sources, and may not be used without express permission of the copyright holders. IADC expressly recognizes the copyrights of contributors to this Lexicon, including API, OGP, ISO, NORSOK and DNV.

The square or hexagonal shaped steel pipe connecting the swivel to the drill string. The kelly moves through the rotary table and transmits torque to the drill string.

Source: API RP 7G, Recommended Practice for Drill Stem Design and Operating Limits, Upstream Segment, Sixteenth Edition, August 1998 (Addendum 2: September 2009). Global Standards

Square- or hexagonal-shaped steel pipe connecting the swivel to the drill pipe. NOTE The kelly moves through the rotary table and transmits torque to the drill stem.

Square or hexagonally shaped steel pipe connecting the swivel to the drill pipe that moves through the rotary table and transmits torque to the drill stem.

The square, hexagonal or other shaped steel pipe connecting the swivel to the drill pipe. The kelly moves through the kelly bushings, rotary table and rotates the drill string.

Source: API RP 54, Recommended Practice for Occupational Safety for Oil and Gas Well Drilling and Servicing Operations, Third Edition, August 1999 (2007). Global Standards

The uppermost component of the drill string; the kelly is an extra-heavy joint of pipe with flat or fluted sides that is free to move vertically through a “kelly bushing” in the rotary table; the kelly bushing imparts torque to the kelly and thereby the drill string is rotated.

The uppermost component of the drill string; the kelly is an extra-heavy joint of pipe with flat or fluted sides that is free to move vertically through a “kelly bushing” in the rotary table; the kelly bushing imparts torque to the kelly and thereby the drill string is rotated.

Source: API RP 64, Recommended Practice for Diverter Systems Equipment and Operations, Second Edition, November 2001 (March 1, 2007). Global Standards

“Kelly” means a 3 or more sided shaped steel pipe connecting the swivel to the drill pipe. The kelly moves through the kelly bushing and the rotary table and transmits torque to the drill string. [Mich. Admin. Code R 408 (2013)].

The square or other shaped steel pipe connecting the swivel to the drill pipe. The kelly moves through the rotary table and transmits torque to the drill string.

This is the brief explanation of a Kelly rotating system on the rig. Kelly rig is on an old style rigs and nowadays it is mostly used on land operations. For offshore operation, a top drive system is used instead.

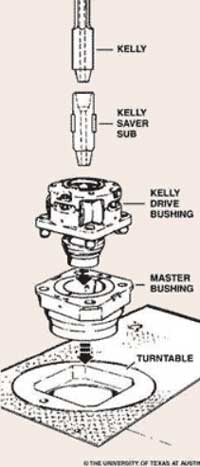

First of all, it is important for new people to look at these images before reading the information below because they show the equipment’s name and where they are on the rig.

The upper end of the drill pipe is screwed onto the saver sub. The saver sub is used to protect and minimize wearr and tear on the threads at the bottom of the Kelly. The Kelly is about 40 ft in length with a square or hexagonal shape and it is hollow throughout in order to transport the drilling mud. Kelly moves freely through a Kelly bushing even though the drill stem is rotated.

A Kelly cock valve is located at the top of a Kelly and it is a safety valve which can be closed to stop back pressure from coming back to damage other surface equipment.

A swivel attached to the hook does not rotate, but at the bottom part it supports the Kelly which is being rotated while drilling. Drilling mud is pumped from a mud pump to a stand pipe manifold, Kelly hose and then to a gooseneck connection at a swivel.

A rotary table rotates a Kelly bushing and it simultaneously rotates a Kelly and a drill string and a drill bit. A rotary table has two main functions. The first one is to provide rotation to a drill stem and a bit and the second function is to hold slip in order to support the weight of a drill stem when it is not connected to a Kelly.

Generally, a rotary drive consists of a chain and rotary-drive sprocket. A rotary-drive sprocket is a part of the draw-works. In other rig power systems, an independent electric motor or engine with a direct drive to a rotary table is utilized. For this case, the rotary is normally driven by a drive shaft instead of a chain and rotary-drive sprocket.

A master bushing severs its function as a rotary motion transmission from a rotary table to a Kelly. Additionally, it is a link between a slip and a rotary table.

A Kelly bushing (some people call “rotary Kelly bushing”) engages a master bushing via four pins and rollers inside a Kelly bushing to allow a Kelly to move up or down freely while it is rotated or in a static mode.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

A large valve, usually installed above the ram preventers, that forms a seal in the annular space between the pipe and well bore. If no pipe is present, it forms a seal on the well bore itself. See blowout preventer.†

One or more valves installed at the wellhead to prevent the escape of pressure either in the annular space between the casing and the drill pipe or in open hole (for example, hole with no drill pipe) during drilling or completion operations. See annular blowout preventer and ram blowout preventer.†

A heavy, flanged steel fitting connected to the first string of casing. It provides a housing for slips and packing assemblies, allows suspension of intermediate and production strings of casing, and supplies the means for the annulus to be sealed off. Also called a spool.†

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

The arrangement of piping and special valves, called chokes, through which drilling mud is circulated when the blowout preventers are closed to control the pressures encountered during a kick.†

A centrifugal device for removing sand from drilling fluid to prevent abrasion of the pumps. It may be operated mechanically or by a fast-moving stream of fluid inside a special cone-shaped vessel, in which case it is sometimes called a hydrocyclone.†

A centrifugal device, similar to a desander, used to remove very fine particles, or silt, from drilling fluid. This keeps the amount of solids in the fluid to the lowest possible level.†

The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus raises or lowers the drill stem and bit.†

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

A heavy, thick-walled tube, usually steel, used between the drill pipe and the bit in the drill stem. It is used to put weight on the bit so that the bit can drill.†

The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.†

A wire rope hoisting line, reeved on sheaves of the crown block and traveling block (in effect a block and tackle). Its primary purpose is to hoist or lower drill pipe or casing from or into a well. Also, a wire rope used to support the drilling tools.†

On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.†

A large, hook-shaped device from which the elevator bails or the swivel is suspended. It is designed to carry maximum loads ranging from 100 to 650 tons and turns on bearings in its supporting housing.†

A device fitted to the rotary table through which the kelly passes. It is the means by which the torque of the rotary table is transmitted to the kelly and to the drill stem. Also called the drive bushing.†

A portable derrick capable of being erected as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit.†

A series of open tanks, usually made of steel plates, through which the drilling mud is cycled to allow sand and sediments to settle out. Additives are mixed with the mud in the pit, and the fluid is temporarily stored there before being pumped back into the well. Mud pit compartments are also called shaker pits, settling pits, and suction pits, depending on their main purpose.†

A trough or pipe, placed between the surface connections at the well bore and the shale shaker. Drilling mud flows through it upon its return to the surface from the hole.†

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

A mud pit in which a supply of drilling fluid has been stored. Also, a waste pit, usually an excavated, earthen-walled pit. It may be lined with plastic to prevent soil contamination.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

A series of trays with sieves or screens that vibrate to remove cuttings from circulating fluid in rotary drilling operations. The size of the openings in the sieve is selected to match the size of the solids in the drilling fluid and the anticipated size of cuttings. Also called a shaker.†

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

A relatively short length of chain attached to the tong pull chain on the manual tongs used to make up drill pipe. The spinning chain is attached to the pull chain so that a crew member can wrap the spinning chain several times around the tool joint box of a joint of drill pipe suspended in the rotary table. After crew members stab the pin of another tool joint into the box end, one of them then grasps the end of the spinning chain and with a rapid upward motion of the wrist "throws the spinning chain"-that is, causes it to unwrap from the box and coil upward onto the body of the joint stabbed into the box. The driller then actuates the makeup cathead to pull the chain off of the pipe body, which causes the pipe to spin and thus the pin threads to spin into the box.†

A vertical pipe rising along the side of the derrick or mast. It joins the discharge line leading from the mud pump to the rotary hose and through which mud is pumped going into the hole.†

A rotary tool that is hung from the rotary hook and traveling block to suspend and permit free rotation of the drill stem. It also provides a connection for the rotary hose and a passageway for the flow of drilling fluid into the drill stem.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

The global kelly drive market was valued at $1.6 billion in 2021, and is projected to reach $2.3 billion by 2031, growing at a CAGR of 3.7% from 2022 to 2031.

Report Key HighlightersThe kelly drive market is consolidated in nature with few players such as NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH. that hold significant share of the market.

The study covers in-depth analysis of 16 countries from different regions including North America, Europe, Asia-Pacific, and LAMEA. In addition, country-wise data of every country has been provided for better understanding of kelly drive market dynamics in every country.

A kelly drive is a particular kind of well drilling tool which uses a section of pipe with a polygonal or splined outer surface and feeds it through a rotary table and matching kelly (mating) bushing which have the same shape or splines. The Kelly is a long, four- or six-sided steel bar having a hole bored through the center to allow drilling fluid to pass through. The kelly bushing allows the drill string to be lifted or lowered while it rotates by transferring rotating motion from the rotary table or kelly bushing to the drill string. Crewmembers make up several attachments to the kelly. The attachments include the upper kelly cock, the lower kelly cock (drill pipe safety valve), and the kelly saver sub.

Kelly drilling is one of the most used dry rotary drilling techniques. The kelly drive is used to create large-diameter bored piles (from a size of approx. 500 mm). With the increasing drilling activities is booting the kelly drive market share in coming year. The kelly drive works with almost any kind of rock and soil. According to kelly drive market forecast, the demand for short rotary drilling instruments, such as augers, core barrels, buckets, and specialized drilling tools which are used to move the dirt will be more in the market. The drill rod which is also known as a kelly bar, is a typical component of this drilling technique. The strong kelly bars enables deep drilling and help in boosting the kelly drive market trend in forecast period.

Globally, there has been a surge in oil exploration activity, which is driving the demand for kelly drive in rig and drilling industry. Apart from the pandemic time, a boom in exploration has tripled over the last five years. Kelly drive market analysis showcase the owing to a global boom in exploration of oil reserves, several oil companies are getting into the rig sector. With the ongoing expansion in petroleum products, large oil extraction companies are contracting with drilling equipment manufacturers for the rent and sale of drilling equipment. Oil exploration companies and equipment companies collaborate to provide offshore support services that can increase production. Factor such as oil exploration activities is likely to boost the market for kelly drive in near future.

Advances in technology and equipment have enabled more oil and natural gas to be recovered from the length of each well, improving production and reducing the environmental footprint of energy production. Kelly drive is cheaper however, technology is slow, inefficient, and unsafe as compared to the other technology which are present or coming in the market. These factors may restrain customers from using kelly drive; thus, hampering the market growth.

With combination of seismic surveys and drilling wells, companies are doing the search of oil reserve and deposits beneath the surface of the earth. Exploration projects can be expensive, time-consuming, and risky, drilling a well may cost tens of millions of dollars. Several factors are considered the number of wells to be drilled, recovery method, type of installation to be used, separation systems for the gas & fluids, and how the oil and gas will be transported to a processing facility. High demand for the petroleum products in the market resulting into several new excavations projects in different regions. This factor is anticipated to increase the sales of kelly drive; thus, creating lucrative kelly drive market opportunities.

The kelly drive market is segmented into product type, and region. On the basis of product type, the market is bifurcated into cleaners, braking oil, grease and lubes, degreaser, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the square kelly segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.6% during the forecast period. With the increasing horizontal drilling operations result in increasing demand for square kelly in the market. To increase the output from a single well, drilling square kelly equipment are being used frequently in the market. Square Kelly is advantageous for end-users, however equipment can be used for both onshore and offshore drilling operations. Drilling activities are becoming more challenging which are demanding the high quality of kelly equipment. Several oil firms engage in new types of drilling on land, such as horizontal well drilling which covers a significantly larger area under the earth. With the increasing horizontal well drilling creates the opportunity for square kelly segment in global kelly drive market.

In 2021, the kelly bar segment was the largest revenue generator, and is anticipated to grow at a CAGR of 4.0% during the forecast period. With the increasing number of excavation projects and finding of deep oil reserves will increase the demand for kelly bars in the market. Companies are entering into the agreement for the drilling operations which is driving the kelly bars market. Today, reserves are found very deep under the land of sea which require the high strength bars for handling the pressure. Vertical and horizontal drilling activities are increasing which is increasing the demand for different shapes of kelly bars.

In 2021, the onshore segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.8% during the forecast period. The rise in production activities and decrease in non-productive time are anticipated to propel the market for the onshore segment during the coming years. The onshore oilfields in North America and LAMEA have witnessed a high market share, regions mainly focus on efficiency improvement, decline in non-productive drilling activity time, and enhancement in health, safety, and environment aspects while drilling.

The North America kelly drive market size is projected to grow at the highest CAGR during the forecast period. The region is experiencing more drilling activities of oil and gas extraction as the demand for oil-related goods rises worldwide. Kelly drive equipment is particularly helpful for drilling through hard rock and getting to the oil deposits. The Kelly Drive can be used to reduce operational expenses in drilling operations. For field operators and engineers, it ensures long-term project success and a high rate of return.

LAMEA was the second-largest contributor in terms of revenue in the global kelly drive market in 2021, and is anticipated to grow at a CAGR of 3.8% during the forecast period. Accelerated investment across the upstream sector along with crude oil price recovery will foster the drilling activities in the region. Robust growth in petrochemical products demand along with increase in industrial and commercial activities across the developing economies will boost the kelly drive market growth in LAMEA region.

For instance, The natural gas production in Saudi Arabia has been planned to increase by two-fold in the coming decade, which is expected to result in increased drilling activities related to gas production.

The leading players operating in the global kelly drive market include, NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH, Bridges Equipment LTD, Lake Petro., TEXAS INTERNATIONAL OILFIELD TOOLS, LTD, Goldman, Tianhe Oil Group Co. Ltd., XI"AN KINGWELL OILFIELD MACHINERY CO.,LTD, El Didi Group.

Key benefits for stakeholdersPorter’s five forces analysis helps analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

It outlines the current Kelly drive market trends and future estimations from 2021 to 2031 to understand the prevailing opportunities and potential investment pockets.

The invasion of Russia has further worsened an already precarious scenario for the energy and drilling markets, notably in Europe. To minimize the possibility of an interruption in Russian oil and gas supply, oil and gas corporations must collaborate with governments. In longer term, the sector needs to increase its adaptability and relevance in a rapidly evolving energy environment. The scenario brought about by the conflict between Russia and Ukraine influences the Kelly Drive market as well. Many projects that were previously underway in the nations are now on hold, and new projects are being delayed, which has slowed the market"s expansion in recent years.

The College of Earth and Mineral Sciences is committed to making its websites accessible to all users, and welcomes comments or suggestions on access improvements. Please send comments or suggestions on accessibility to the site editor. The site editor may also be contacted with questions or comments about this Open Educational Resource.

The College of Earth and Mineral Sciences is committed to making its websites accessible to all users, and welcomes comments or suggestions on access improvements. Please send comments or suggestions on accessibility to the site editor. The site editor may also be contacted with questions or comments about this course.

The NOV CUL & CB Casing Bushings are inserted directly into the rotary table and insure that the casing being run is perfectly aligned with the center of the hole. Model CU is a solid bushing and model CB is a split bushing. All of the bushings accept bowls of different sizes to accommodate a wide range of casing. Using CMS-XL or CP-S slips, since these bushings fit into the rotary table, the casing string can be easily rotated during cementing operations.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, "depth" also refers to the location itself.

Because wells are not always drilled vertically, there may be two "depths" for every given point in a wellbore: the borehole, and the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), Rotary table (RT), kelly bushing (KB or RKB) and mean sea level (MSL).

Well depth values taken during the drilling operation are referred to as "driller"s depth". The "total depth" for the well, core depths and all analysis of core / mud and other materials from the drilling hole are measured in "drillers depth".

The differences between loggers and drillers depths are due to different stretch in the drilling string when drilling, and the wire line entered into the bore hole during wireline logging operations. This difference is estimated and referred to as "core shift". A core from a certain drillers depth is lined up with a wireline log (loggers depth) and structures in the core are compared with the log and matched.

Sign Convention - Depth increases positive in the downward direction. This may seem intuitive but confusion can arise when using certain references while integrating data from different sources. Workers mapping surfaces typically use elevation which, by convention, increases positive in the upward direction. Be mindful when integrating depth and elevation. For example, shallow wells drilled onshore often encounter reservoir at negative depths when referenced to sea level, mappers would define these same reservoirs at positive elevations when referenced to sea level.

The acronym TVDSS is commonly used in the oil industry to represent TVD minus the elevation above mean sea level of the depth reference point of the well. The depth reference point is the kelly bushing in the United States and a few other nations, but is the drill floor in most places.

Differential (or relative) depths or thicknesses should generally be specified with at least two components: a unit and a path, plus any eventual specifiers to remove any possible ambiguity. No specifier should ever be left "implicit" or "understood". There are cases where a path is not needed and in fact should not be specified, because it is defined by the specifier, e.g. isochore (true stratigraphic thickness, independent of well path or inclination).

The distinction between "loggers" depth" and "drillers" depth" is becoming blurred due to the increasing use of logs acquired while drilling (LWD). At the time of writing, the common practice remains that the petrophysicists or geologists define the "official depths" in a well, and these depths are frequently different from the "drillers" depth", after various corrections, tie-ins, etc., have been applied.

Petrophysicists and drilling operations tend to express depths with reference to the rotary table or the original drill floor; geologists tend to use a common datum such as the mean sea level; geophysicists use the mean sea level. This can introduce much confusion when a unit is not specified with all 3 components: unit, path, and reference.

Path: common expressions of path are measured depth (MD) – elsewhere often known as along hole depth (AHD) – and true vertical depth (TVD). Note that using TV for true vertical depth is not consistent with the use of MD for measured depth, hence the recommended TVD.

the legal datum offshore Australia is Lowest Astronomical Tide (LAT) – (Ref. 1 & 2). Note that this requirement in itself can cause difficulties as it is difficult to measure offshore and can vary greatly between locations and even with time. There is, however, an advantage to this convention: tidal corrections should always be of the same sign (negative depth), i.e. the sea level is always higher than or equal to LAT.

Common references used in operations include: Rotary Table (RT), Drill Floor (DF), Kelly Bushing (KB), Sea Bottom (SB), Ground Level (GL), Casing Bowl Flange (CBF).

Any combination of unit, path, and reference can be used, as long as they result in fully specified, unambiguous depths. A well may reach to many kilometers.

Specification of an absolute depth: in Figure 1 above, point P1 might be at 3207 mMDRT and 2370 mTVDMSL, while point P2 might be at 2530 mMDRT and 2502 mTVDLAT.

Specification of a differential depth or a thickness: in Figure 2 above, the thickness of the reservoir penetrated by the well might be 57 mMD or 42 mTVD, even though the reservoir true stratigraphic thickness in that area (or isopach) might be only 10 m, and its true vertical thickness (isochore), 14 m.

RF2EWWE3C–Close--up of oil well pump jack out in a field enclosed in a metal cattle fence with two other pumping wells in the distance all set on the horizon of

RF2C7MTW3–Close--up of oil well pump jack out in a field enclosed in a metal cattle fence with two other pumping wells in the distance all set on the horizon of

RF2D596CH–Cropped close-up snapshot of a man wearing blue overalls orange vest and gloves, holding a pipe wrench and a helmet on foreground, oil pump jack on background. Concept of petroleum industry.

RF2K4WH28–Oil drilling derrick pumps oil from ground. Petroleum industry, crude oil extraction. Production of fuel from natural resources. Oil crisis.

RF2BR3GEE–Close-up, macro. Old soviet brass nuts. Texture, background of brass nuts laid out in the form of honeycombs. Nuts of gold color. Dirty nuts in oil. B

RFR6JA4F–Close up view on brand new drill bit roller cutter for drilling machines and equipment for oil and gas industry. Modern drill bits with diamond and co

RF2DRGA1J–Close up of oil businessman holding protective helmet, clipboard, pen. Oil man standing on territory of oil field with pump jack on blurred background. Concept of petroleum industry and oil production

RF2BR3GEW–Close-up, macro. Old soviet brass nuts. Texture, background of brass nuts laid out in the form of honeycombs. Nuts of gold color. Dirty nuts in oil. B

RFR6JA1E–Close up view on brand new drill bit roller cutter for drilling machines and equipment for oil and gas industry. Modern drill bits with diamond and co

RF2HCRFJP–Auto mechanic changing a car tire in mechanics garage and using a electric drill to loosen the bolts. Repair service. authentic close-up shot

RF2BBYEPC–Cropped close-up of man engineer holding his note and pen in one hand and white helmet in the other, standing in oil field, oil pump jack is on background, concept of oil business, petroleum industry

RF2BR3GCT–Close-up, macro. Old soviet brass nuts. Texture, background of brass nuts laid out in the form of honeycombs. Nuts of gold color. Dirty nuts in oil. B

RMC10BNP–Cuadrilla Resources Drilling equipment carousel; Shale Gas exploration Drill Site, Grange Hill Farm, Poulton-le-Fylde, Blackpool, Lancashire, UK

At a previous employer a coworker came to me and told me that a group within our company had asked for all the KB (kelly bushing) elevations for every well in Colorado. I replied that it made no sense and asked my coworker to see if the reference elevations were what they really wanted. The coworker returned the next day and indicated that they had insisted on the KB elevations. We supplied the KB elevations and sure enough, about a week later they came back and asked for the reference elevations.

Data sometimes takes on an almost mystical quality, where the meaning and intent have been lost because of inaccurate use or overuse. The oil and gas industry has so many buzz words and so many things that are typically done that we sometimes lose the actual meaning of why or how things are done and worse still, fail to understand the data.

It’s really important to understand the data you’re working with – what it is, where it came from, and what it can be used for. The problem is sometimes actually harder than it seems. If we use the example above, most logs are measured from the KB elevation, correct? So you want KB elevations when normalizing logs to the sea-level datum?

Yes, most logs are measured from the KB. No, never use just the KB. Some logs are measured from the DF (derrick floor), GR (ground), or CHF (casing head flange), and there are a few other strange places logs are measured from. In today’s world, where multiple rigs can drill multiple sections of a well, the KB can have different elevations depending on the run of the log. It’s really important to put things back together on a common reference point so the logs aren’t off and formations can be correlated and depth corrected. (Side note: the definition of MSL, mean sea-level, is also probably a good topic of future discussion. It’s probably not what or where you think it is).

I really like to use the CHF as the reference elevation because after surface casing is run and cemented in, it is a constant point that has a single elevation point throughout the drilling and completion cycle. No matter what the elevation of the rig or completion is, the CHF is always at the same elevation.

So the KB is a physical place on the rig and the reference elevation is the physical place where the log was measured from. They can be the same thing but equating them everywhere will certainly create incorrect data.

Where the elevations come from is another question. Elevations are often supplied on the drilling permit, the completion report, the logs, and probably a couple of other reports.

The elevation starts when the surveyor goes out and measures precisely where the oil and gas company wants the well. Today everything is done by GPS, and the surveyor gets a latitude, longitude, and elevation. At the precise spot, the surveyor pounds a steak into the ground and ties an orange surveyor’s ribbon on it. It’s usually in some pasture and hopefully not on the side of a hill or in the middle of some pond. That does happen, however, despite the fact that the geologist spends months studying the subsurface. The thing is, they probably don’t spend more than 10 minutes looking at the surface.

A day or two before the well spuds, a bulldozer arrives and scrapes the land flat so the rig will have a solid footing while it is drilling the well. The excess dirt gets piled up so that any water gets trapped on site and doesn’t run off to the nearest stream or pond. A curious artifact often appears on one of the piles of dirt – a surveyor’s stake with an orange ribbon on it.

I’ve been at a few rig locations and as I drove on site and glanced over at the surveyor’s stick sitting in the dirt pile, I often wondered how the guys setting up the rig knew the exact spot where the hole was supposed to be located with the location stick sitting far away in the dirt. The answer is they don’t. They position the rig on the pad where it will best fit given the generator, tanks, pipe, and all the other equipment that needs to be located, along with space for parking.

Some companies will actually call back the surveyor to have him give a final elevation of the ground and of the KB and/or DF. If you’re really lucky, the company will have also asked the surveyor to respot the well location so there is an updated lat/long, but don’t count on it. One of the most shocking comments I’ve heard about well locations is, “I don’t worry about well locations anymore because everyone uses a GPS.” Yes, the surveyor used a GPS to place the stake in the ground … just before the bulldozer pushed it into the dirt pile.

If the ground elevation changed between the permit and the completion report, there’s an excellent chance the surveyor came back and resurveyed (and hopefully he also included an elevation to something permanent, like the CHF).

So the question is, now that we have established that we might have several different elevations, what is the best one to use? Oh how I wish that were the only question that needed answering. Elevations are reported to the state and elsewhere from lots of different sources. Permits, completions, activity reports, and logs are the main documents where this data can be found. Locations are a different story, and it is a rare event to see a correction.

The elevations off the log are probably the best to use. Though I have seen them wrong on the log, it’s a rare occurrence. The elevations are generally captured to support the geologist in making structure maps, so there’s a good chance they’ve been checked and verified.

So the next time you are looking for an elevation, ask yourself, what was it referenced to, what document did it come from and, probably most importantly, is it a reasonable value?

Well depth is a very important piece of information. There are several TDs and several ways to measure them. The major TDs we deal with are the driller’s total depth (DTD) and the logger’s total depth (LTD). In general, the DTD is considered to be the official depth of the well.

The LTD is a nice backup that gives confirmation that the DTD is in the ballpark. The DTD and the LTD almost never agree exactly. A lot of that has to do with cable stretch and steel drill pipe. We don’t normally think that steel drill pipe stretches, but when it’s strung together to make a length of 2-4 miles, it does indeed stretch. The pipe is also under immense tension. At the bottom of the drill pipe, near the bit, there’s special drill pipe called drill collars. Drill collars are designed to put weight on the bit and make it drill better. However, rather than adding drill collars or removing them as the well drills, they add more weight than they will ever need at the start of the well and the driller uses a brake that holds the drill string, which prevents all of the weight from ending on top of the drill bit. Too much weight and the bit will not drill straight and it will prematurely wear out the bit. If there is too little weight, the drill bit will not drill efficiently. It is this tension on the drill string that adds to the stretching.

A couple of other TDs come into play when you are drilling directional or horizontal wells. MTD is the measured total depth, which is the distance along the wellbore. The other piece of information is the true vertical depth (TVD), which is the distance of the well from the surface. There is actually one other measurement, called true vertical depth subsea (TVDSS), which is the TVD as referenced from the reference elevation. In many instances this ends up with data below the sea level and the values are negative. Think of this like a thermometer, where some values are below zero (below sea-level).

Operator is another thing that can cause confusion. Current operator and original operator can be two different companies, and often a property can be bought and sold several times. The original operator will have a lot of information with the state because they are the one who filed the permit, completion information, and other initial documentation. The current operator is the one listed on the production data file. If you are trying to match wells, never assume that two different operators are two different wells.

When working between states, well name and lease name will drive you crazy. I haven’t worked everywhere in the U.S., but my experience is they are often equivalent with a couple of exceptions. The lease name is the lessor of the minerals. However, where the state has a well name and a not a lease name, the operator is free to name the well whatever they want. In most cases they use the lease name. However, there are lots of well names with the word “lucky” in them. Prospect names are also used as the well name, which leads to some very interesting well names.

California and a couple of other states require operators to file a permit when plugging wells, recompleting them, or almost anything associated with a well. Other states just require a permit to drill and then have standard forms for plugging and other things.

Understand the origin of the data you are looking at, where it came from, and the correct use of it. Before you do any analysis, know what the limits or reasonable values of the data should be before you start.

John Fierstien is Director of Product Management for P2 Tobin Data. He started his career in oil and gas in 1978 after finishing his MS in Geology from the University of Pittsburgh and his BS in both Geology and Biology from Central Michigan University. He has worked as both a development and exploration geologist. John has been a product manager in oil and gas for the better part of the last 20 years. He’s also spoken at various meetings and conferences and written about sub-surface modeling, oil and gas software, and oil and gas data. John enjoys photography and growing his home automation system. John currently lives west of Austin, in the Texas Hill Country.

8613371530291

8613371530291