what is mechanical seal pricelist

Many tools can seal used when installing mechanical sealals that are not readily available, Alibaba.com offers a variety of mechanical seal tools that can seal used when installing mechanical sealals. This seal is not only for mechanic, but they are also in need of this material.

The many benefits of mechanical seals are that they offer, as they are less resistant to wear and tear on all occasions. Mechanical seals are the most durable, and seal option for those that require a lot of water and air at the same time.

Hydraulic seals are ideal for those that require higher pressure to maintain. On the other hand, the plunging seal is a common choice of mechanical seals, such as those with OKO"s, they all use the same functions of water and gas.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

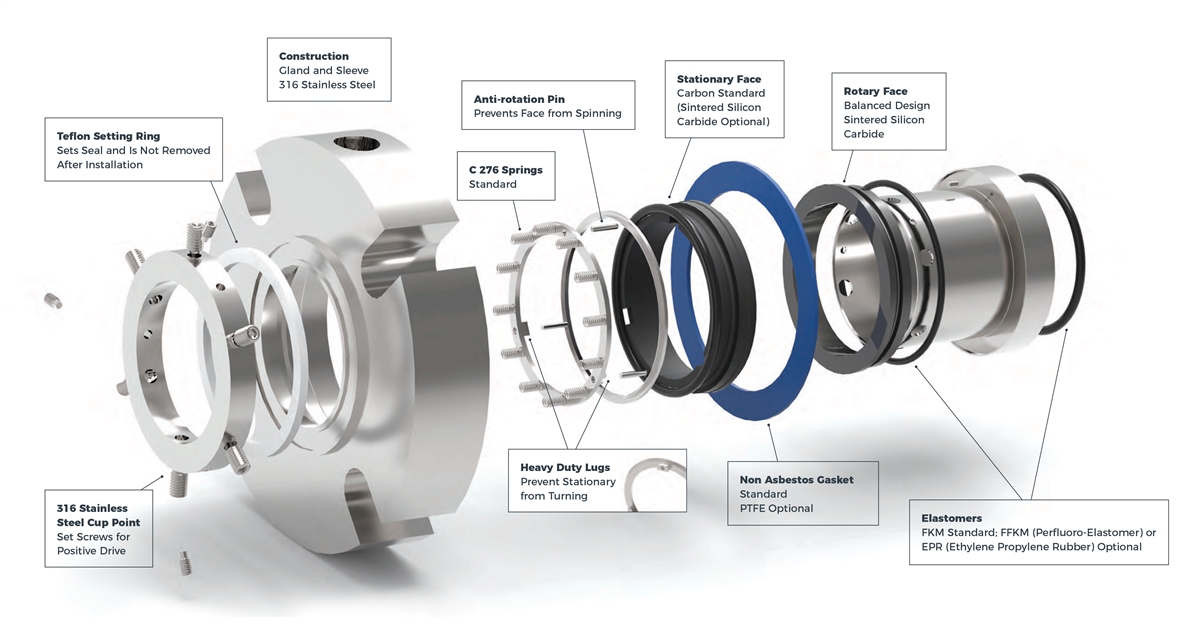

FSI Series 1015 mechanical cartridge seals are a premium grade product without the premium price. They"re ideal for use with most ANSI and DIN (standard and big bore) pumps and other types of pumps and rotating equipment. They have the following features:

Modern pumps, compressors, mixers, agitators and other rotary shaft equipment are assembled using either compression pump packing or mechanical seals to minimize emissions and fluid.

Compression pump packing controls leakage whereas mechanical seals will tend to stop any visible leakage all together, keeping work environment clean and hazard free.

Compared to compression packing the initial cost of a mechanical seal is high, however overtime, the associated cost accrued by using compression packing, for example power consumption, maintenance and downtime, could be far in excess of the initial cost of a mechanical seal, which works unattended for a long time.

Having a definite quality administration system, we are providing a comprehensive assortment of Mechanical Seal to our customers. Valued for their perfect finish, sturdy built and longer life; these are hugely commended. Along with this, the offered product is designed by hard-working engineers, who ensure to comply it with the industry laid standards and norms. The offered product is extremely praised by our clients all over the country. Also the customers can avail these at affordable rates from us within the assured time.

Jogeshwari West, Mumbai AF-17/08, Saraf Kaskar Ind. Premises Co. Op. Society Limited S.V. Road, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai Unit No-BF-10, 1st Floor B Wing, Saraf Kaskar Industrial Premises Co-Op Society Ltd, SV Road, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Goregaon West, Mumbai Unit No. 10, First Floor, Shamroz Industrial Estate, Opposite Movie Star Cinema, Ram Mandir Road, Gorgaon West, Goregaon West, Mumbai - 400104, Dist. Mumbai, Maharashtra

Dudheshwar, Ahmedabad A/17, Chinai Baug Industrial Estate, Near Water Tank Behind Bank Of Baroda, Dudheshwar, Ahmedabad - 380004, Dist. Ahmedabad, Gujarat

Jogeshwari West, Mumbai No. 5/1 - A, Ramjanaksingh Compound, S. V. Road, Opposite Veena Dalwai Industrial Estate, Oshiwara, Jogeshwari West, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Chennimalaipalayam, Tiruppur, Dist. Coimbatore 7/250, B-1, Ground Floor, Srinagar Ganapathipalayam Road, Chennimalaipalayam, Tiruppur - 641605, Dist. Coimbatore, Tamil Nadu

Bavdhan Khurd, Pune Shanti Vihar Apartment, Flat No. C-24, 3rd Floor, S. No. 19/6, 7/2, Bavdhan Vidynan Nagar, Bavdhan Khurd, Pune - 411021, Dist. Pune, Maharashtra

Rakhiyal, Ahmedabad Margh Farm,opp. Khodiyarnagar Police Choki,11 opp. khodiyar nagar police choki, Rakhiyal, Ahmedabad - 380023, Dist. Ahmedabad, Gujarat

Vasai East, Thane Unit No. 3, Ground Floor, Building No. 1, Riddhi Siddhi Sagar Industrial Premises Raj Vishnu Compound Wali Road, Vasai East, Thane - 401208, Dist. Thane, Maharashtra

Bapunagar, Ahmedabad 30, Parvati Nagar, Behind Shastri Stadium, Near Biratnagar Bus Stop, N.H. 8, Khodiyar Nagar, Bapunagar, Ahmedabad - 382350, Dist. Ahmedabad, Gujarat

Malad West, Mumbai No. 122, Vinay Heavy Industrial Estate, Near Inorbit Mall Linking Road, Malad West, Malad West, Mumbai - 400064, Dist. Mumbai, Maharashtra

Mechanical seals are usually made of moving rings, stationary rings, compression elements and sealing elements. These parts are tightly bonded to form a sealing surface to avoid leakage. The liquid in the sealed chamber causes the end face to press against the end face of the stationary ring, and the mechanical seal occurs on the end faces of the two rings and the adhesion is to maintain the compression of the component pressure. The pump can not only work in the state, but also adhere to the end of the paste to ensure that the sealing medium does not leak, and avoid impurities into the sealed end. The sealing element acts as a gap between the sealing ring and the shaft, the action of the static ring and the gap of the gland, and the oscillation of the pump with the elastic element. When running with other components of the pump, the condition of the mechanical seal is closely linked with the external conditions. Only if the parts, auxiliary sealing equipment and technical requirements are ensured that the mechanical seal works well.

First, we need to turn off the pump, and then clean and inspect each part of the pump. Second, remove the impeller by rotating it in the anticlockwise direction. Then take out the seal at the backside of the impeller, and place the mechanical seal on to the shaft. Fix the mechanical seal and screw the impeller onto the motor shaft. Here are some notes of installation:

With its wide range of designs, the mechanical seals can also be made of different materials. In fact, the seal face materials decide the service time of mechanical seals. The most popular materials include rubber, stainless steel, PTFE, carbon, ceramic, Sic, and TC.

In SEALCON, equipped with advanced CNC processing equipment, you can not only buy the mechanical seals, but also buy the mechanical spare parts: sealing rings, spring, O-ring, sleeve and gland. All of our products conform to the standard of DIN24960, EN12756, ISO3069 API610, API682.

Mechanical seals are indispensable for sealing rotating shafts. They make sure that the fluid handled remains in the system, prevent emissions and thus protect the environment from contamination. High-quality shaft seals in the form of mechanical seals also ensure maximum economic efficiency and operating reliability for pumps. This is crucial because the majority of repairs arise due to sealing problems.

And this is where KSB’s mechanical seals can make a difference: as well as impressing with a robust design, they offer straightforward installation and optimal integration in the seal chamber – ensuring reliable and efficient system operation.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291