what is mechanical seal price

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Many tools can seal used when installing mechanical sealals that are not readily available, Alibaba.com offers a variety of mechanical seal tools that can seal used when installing mechanical sealals. This seal is not only for mechanic, but they are also in need of this material.

The many benefits of mechanical seals are that they offer, as they are less resistant to wear and tear on all occasions. Mechanical seals are the most durable, and seal option for those that require a lot of water and air at the same time.

Hydraulic seals are ideal for those that require higher pressure to maintain. On the other hand, the plunging seal is a common choice of mechanical seals, such as those with OKO"s, they all use the same functions of water and gas.

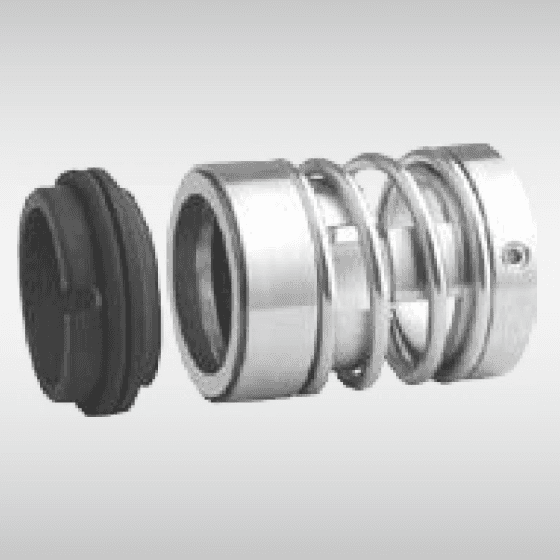

We recognize and understand the vital role of pump mechanical seal price in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale pump mechanical seal price in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider pump mechanical seal price requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Replacement seals for PRICE PUMP CO.® Mechanical Seals products. Search by the OEM Part Number using the SEARCH function at the top of the page or use search by specification.

OEM names, brands, model or part numbers are for identification purposes only. Our components are designed to provide performance and service life equal to or better than the OE part when properly installed and properly applied. Springer Parts® carry a warranty equal to the OE component. PRICE PUMP CO.® Mechanical Seals is a registered trademarks of its respective company. Springer Pumps, LLC is not a representative of, nor affiliated with PRICE PUMP CO.® Mechanical Seals.

FSI Series 1015 mechanical cartridge seals are a premium grade product without the premium price. They"re ideal for use with most ANSI and DIN (standard and big bore) pumps and other types of pumps and rotating equipment. They have the following features:

Jogeshwari West, Mumbai Zorastrian Compound, Adarsh Nagar, Behind Oriental School New Link Road, Jogeshwari West, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai Unit No-BF-10, 1st Floor B Wing, Saraf Kaskar Industrial Premises Co-Op Society Ltd, SV Road, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Dudheshwar, Ahmedabad A/17, Chinai Baug Industrial Estate, Near Water Tank Behind Bank Of Baroda, Dudheshwar, Ahmedabad - 380004, Dist. Ahmedabad, Gujarat

Chennimalaipalayam, Tiruppur, Dist. Coimbatore 7/250, B-1, Ground Floor, Srinagar Ganapathipalayam Road, Chennimalaipalayam, Tiruppur - 641605, Dist. Coimbatore, Tamil Nadu

Jogeshwari West, Mumbai No. 5/1 - A, Ramjanaksingh Compound, S. V. Road, Opposite Veena Dalwai Industrial Estate, Oshiwara, Jogeshwari West, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Bapunagar, Ahmedabad 30, Parvati Nagar, Behind Shastri Stadium, Near Biratnagar Bus Stop, N.H. 8, Khodiyar Nagar, Bapunagar, Ahmedabad - 382350, Dist. Ahmedabad, Gujarat

Vasai East, Thane Unit No. 3, Ground Floor, Building No. 1, Riddhi Siddhi Sagar Industrial Premises Raj Vishnu Compound Wali Road, Vasai East, Thane - 401208, Dist. Thane, Maharashtra

Goregaon West, Mumbai Unit No. 10, First Floor, Shamroz Industrial Estate, Opposite Movie Star Cinema, Ram Mandir Road, Gorgaon West, Goregaon West, Mumbai - 400104, Dist. Mumbai, Maharashtra

Bavdhan Khurd, Pune Shanti Vihar Apartment, Flat No. C-24, 3rd Floor, S. No. 19/6, 7/2, Bavdhan Vidynan Nagar, Bavdhan Khurd, Pune - 411021, Dist. Pune, Maharashtra

Rakhiyal, Ahmedabad Margh Farm,opp. Khodiyarnagar Police Choki,11 opp. khodiyar nagar police choki, Rakhiyal, Ahmedabad - 380023, Dist. Ahmedabad, Gujarat

Pune Near Indrayani Sweets, 1st Floor, Pap-j-90 / Shop No 6, Sankeshwar Complex, Anandrao Lande Road Bhosari, Pimpri Chinchwad, Pune - 411026, Dist. Pune, Maharashtra

Jogeshwari West, Mumbai Unit no. 30, Mishra Compound, behind Tashkend Hotel, opp, Ruby hospital.S.V.Road, jogeshwari (w) Mumbai-400102., Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Odhav, Ahmedabad 331, Yamuna Park, Opposite Grand Vishala Estate SP Ring Road, Beside Madhav Orchid Bulding, Odhav, Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Virar West, Mumbai B-5/108, floor-1ST FLOOR, 5-STAR SOCIETY, VEERA DESA- 306, Shagun CHS, Uni Tech Road, Tirupati Nagar Phase 2, Boolinj, Virar West, Virar West, Mumbai - 401303, Dist. Mumbai, Maharashtra

Having a definite quality administration system, we are providing a comprehensive assortment of Mechanical Seal to our customers. Valued for their perfect finish, sturdy built and longer life; these are hugely commended. Along with this, the offered product is designed by hard-working engineers, who ensure to comply it with the industry laid standards and norms. The offered product is extremely praised by our clients all over the country. Also the customers can avail these at affordable rates from us within the assured time.

Springer Pumps, LLC is pleased to offer our clients Springer® Parts! Springer® Parts are replacement pump parts, pump replacement kits and replacement mechanical seals. SPLLC proudly offers them 20% - 40% below OEM.

Mechanical SealsManufacturer of a wide range of products which include john crane type mechanical seal, johnson pump mechanical seal, multi spring mechanical seals, water pump mechanical seals, grundfos pump mechanical seals and metal bellow mechanical seals.

We are listed amongst the renowned organizations in this domain, engaged in offering a superior quality range of Rod Seal that is widely used in the industrial sector. This seal is manufactured by our experienced diligent professionals using advanced technology in adherence with set industry standards. Offered seal is precisely used in the electrical and mechanical industries for sealing rod, plunger, and piston. Furthermore, this Rod Seal can be availed from us in diverse specifications at market leading price.

We have been ranked as the most dependable and leading firm all over the nation and actively emerged in providing Multi Spring Mechanical Seals. The offered oil seals are for sealing non-pressure medium, particularly for grease. In addition to this, the entire range of oil seals is passed through a series of practical tests for assuring quality. Customers can avail these oil seals at nominal rates.

Water Pump Mechanical Seals We are globally known for our high quality Engineered products. Our Products are efficient for energy consumption parameters at constant speed with cutting angle set to suit material, thickness minimizes the distortion of cut sheets. Fabricated out of best quality and durable materials, facilitates superb quality in downstream operations viz. pressing, punching, bending and drawing. We manufacture and supply to all our customers in India as well as to the International clients.

Being the recognized name in the industry, we bring forth the appealing array of MECHANICAL SHAFT SEAL that is delivered with unique patterns and ensures exclusive looks. This Rotary Joint is extensively used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, etc.

On the other hand, mechanical seals can become limiting factors in any high-head applications. Mechanical seals can’t run dry, so they’re susceptible to air in the pumping system, and they don’t handle solids well. Cavitation is an issue as any kind of impact, excessive vibration, or excessive heat can harm mechanical seals. Seals also require a different kind of shaft sleeve that’s much tighter. If the pump runs dry, elastomers fail, or contamination enters the system, mechanical seals can fail as a result.

Price —Stuffing boxes are more forgiving and less expensive than mechanical seals. While mechanical seals can range in price from $6,000 to $40,000, stuffing boxes range from $500 to $3,000, depending on shaft size. Expellers can also be more cost-effective than mechanical seals and, since repairing mechanical seals can cost up to 60% of the installation, price is a factor for many.

Maintenance —“Knowing you have a maintenance crew that understands mechanical seals very well and can maintain them properly is another factor,” said GIW Southern Region Manager and slurry pump expert Angela Bryant.

Materials —“There’s a lot of variables that go along when you’re selecting a mechanical seal,” Bryant said. “You’ve got to know temperature, if there’s any chemicals that are going through and what kind of chloride in parts per million is involved so you know what elastomers to use with it. You want to make sure any O-rings in a mechanical seal aren"t going to fail because of the temperature or pH of the materials.”

In addition, mechanical seals don’t handle large particles well and they’ve got to be chemically compatible with the system, so they’re best for thin slurry applications.

“You don’t want anything that’s going to have heavy solids because if the seal faces should open, solids could penetrate and destroy the faces of the ceramic seals,” Bryant said.

“If installing or replacing a mechanical seal, you’re going to bolt the seal adapter plate to the pedestal, and you’re going to hand-tighten it on,” Bryant explains. “Then, you’re going to locate the seal fit of the adapter of the shaft to make sure it’s centered and everything is concentric. Of course, with mechanical seals, that concentricity has a very close tolerance, much closer than a stuffing box.”

You’ve also got to mount the adapter plate perpendicular to the shaft. Once you’ve got the seal cartridge in, draw it into the adapter on the pedestal evenly by attaching the gland bolts so as not to crack the seal. Check the seal instructions and drawing against the actual parts. Note the location of gaskets and O-rings. Be certain that the locking tabs holding the rotating shaft section of the seal are in place and the fasteners are tight. This keeps the seal faces in contact to prevent damage. Check the fit of the shaft sleeve into the seal bore, and make sure the seal adapter fits into the hub plate or pedestal mounting bore.

Carefully slide the mechanical seal over the shaft sleeve toward the bearing assembly. Do not use any type of tool that could result in impact damage on the seal or any rotating pump part. Move the bearing assembly into position on the pedestal and install the bearing hold-down bolts. Remember that you’ll have to adjust the impeller nose gap later.

Each mechanical seal is equipped with a number of lock tabs to hold the inner section in the proper location during assembly and adjustment. Never rotate the shaft with lock tabs in place. Remove the tabs and store them with their fasteners since they will be required for all future maintenance procedures. If you’re using a quench or lubricating system, install it now.

To adjust the nose gap, install the lock tabs in the seal and then loosen the shaft clamp. This allows the shaft to move axially. Do not rotate the shaft with the faces locked, or it may damage the O-ring between the seal and shaft sleeve. Loosen the bearing assembly hold-down bolts and move it forward carefully until it just contacts the suction plate. Leave one bolt on the drive end snug to keep the housing from tilting. Tighten the shaft clamp, loosen the lock tabs, and rotate the shaft one full turn to verify that the “high spot” is actually making contact.

Before recommending a mechanical seal, the experts at GIW can help you determine if it’s the best shaft seal option for your operation. To see a list of all our offerings and how they can benefit you, check out our Technical & After Sales Services brochure.

8613371530291

8613371530291