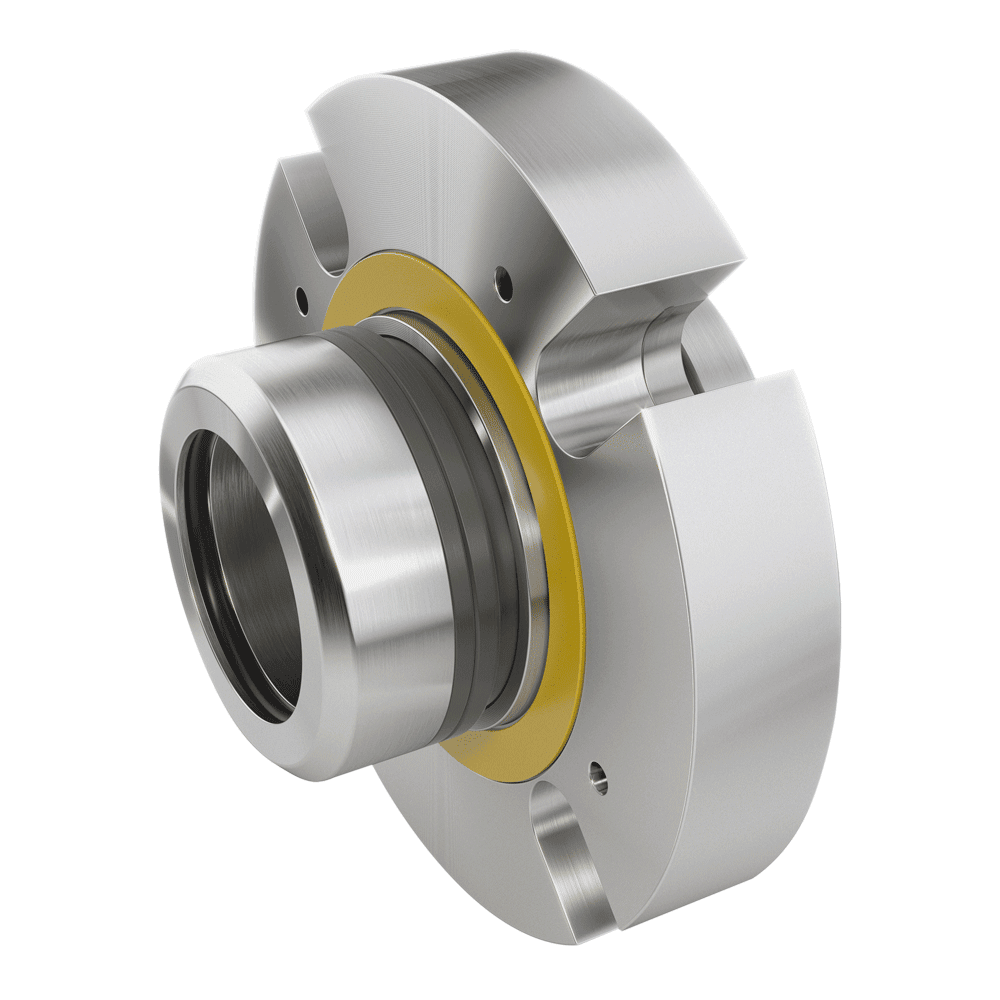

single cartridge mechanical seal in stock

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

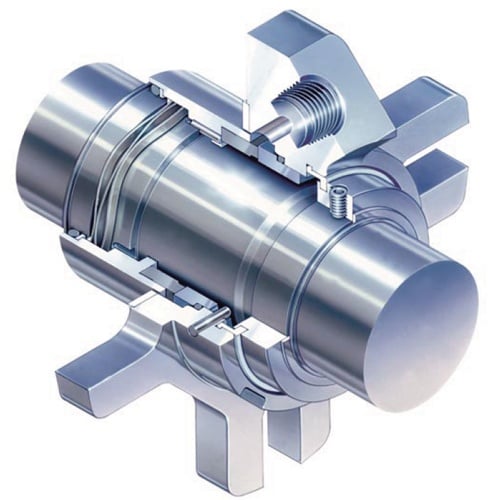

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Style 57 design serves to keep the sealing faces in contact and positively transmits the drive evenly 360° around the full circumference of the rotary face. This is accomplished by the special spring design, which provides an interference fit. The compression spring is wound either right or left hand depending on shaft rotation.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Stationary design accommodates higher shaft-to-stuffing box misalignment. The stationary bellows design only flexes once during installation unlike a rotating design which flexes on every revolution. This reduces face movement and increases seal life.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

These two single cartridge seals are engineered for the most demanding corrosive applications. By minimizing the number of troublesome O-rings and eliminating any media exposure to the sleeves and glands, we have produced two very cost effective solutions to industries’ toughest applications.

In highly corrosive conditions that require expensive upgrades to higher alloy metals like duplex stainless steel, Alloy 20, Hastelloy® C276, the PH seals are an ideal economical solution. Only the wetted parts need to be constructed of these alloys while the larger metal parts such as the gland and sleeve can be 316 stainless steel since they are located out of the product

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

API compliant with piloted gland to positively center seal assembly and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gland packing

Multi-point injection feature available which ensures maximum uniformity of cooling around the entire circumference of the sealing faces, thus eliminating face distortion due to uneven cooling. Ideal for boiler feed and light flashing hydrocarbon services.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Conventional pump stuffing boxes were originally designed to accommodate packing materials. Over the years mechanical seals edged out packing as a preferred sealing method, however stuffing boxes essentially remained the same. This situation posed complications for the effective operation of mechanical seals including installation issues, potential damage from abrasive product, and poor dispersion of seal-generated heat.

The ANSI Standard ASME B73.1 Specifications for Horizontal End Suction Centrifugal Pumps for Chemical Process includes specifications to improve the reliability and safety of the B73.1 pump design. One major specification focuses on cylindrical (big bore) and self-venting (tapered bore) seal chambers. Both of these seal chamber designs address the issues that plagued conventional pump chambers by providing additional radial clearance for mechanical seal operation and for increased liquid circulation around the seal, enabling the seal to run cooler and longer.

Only two (2) static elastomers – eliminate seal failures caused by dynamic O-ring “hang up” and offers cost savings when upgrading to Perfluorelastomers

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

We offer a range of standard inventory cartridge mechanical seals, including single and double seals to suit even the most demanding application and thanks to our modular design system we offer them with the best on-time delivery performance in the industry.

For unusual applications our Standard Plus seal range offers all the benefits of a standard seal while meeting our customer’s specific needs. This covers competitor replacement seals, seals designed for specific pumps and seals designed for pumping specific processes.

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

Chesterton"s cartridge mechanical seals are the product of choice when reliability is a requirement.These products are proven, rugged performers in a wide range of sealing applications across industries. Cartridge seals are ideal for plant-wide standardization and save time witheasy installation. Chesterton"s cartridge seal offerings include exclusive, patented features such as self-centering lock rings and adjustable gland tabs.

The Chesterton 150 is a value leader in its class. It is the ideal single mechanical seal to reduce high maintenance costs and prevent wasteful leakage, shaft fretting damage, and inefficient downtime.

Designed for baseline applications and for upgrading packed or component sealed equipment, the 150 seal makes general industrial sealing simple, reliable, and affordable.

Inheriting the features of the CARLIFE 99® single cartridge mechanical seal, CARLIFE 99SS is primarily designed for slurry, highly solid contents and highly viscous medium environments.

The CarLife 99SS mechanical seal is specifically designed to resist moderate process solids without the need for a flush. Through an advanced design of anti-clogging construction, the seal is capable of providing uninterrupted operation without hanging up due to impurities or abrasive solids. The innovative subcartridge design enables faster maintenance and repair than conventional cartridge seals. Fitting both enlarged bore and tapered bore seal chambers, the CarLife 99SS meets the latest design criteria set by the fluid sealing industry and followed by most main seal manufacturers.

In addition to similar construction and assembly procedure, the CarLife 99SS and MGS series have maximum interchangeability of parts. More shared parts mean simpler maintenance process and inventory management. As a result, our CarLife 99SS customers are able to stock fewer inventory parts and pay much lower maintenance and inventory holding costs. And the more CarLife 99SS products they use, the more benefits they can gain from their cost-effective CarLife 99SS seals.

A single cartridge type mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. The single mechanical seal is a mechanical seal composed of 1 set of seal face. the sealing structure is simple, easy to manufacture and install features. Generally, cartridge type mechanical seal is used for the medium with good lubricity and allows a slight leakage. Single cartridge seals are one of the most commonly used centrifugal pump seal types. Single cartridge pump seals do not work well when the media is the toxic, flammable, explosive and strict requirement of leakage.

Mechanical seals tend to leak a vapor from the high-pressure side to the low-pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it"s common practice to use a single cartridgemechanical seal if the pumped product poses little to no risk to the environment.

When a single cartridge seals used in the oil-filled motor, it is not only necessary to prevent the machine outside the impurities, sandandwater to enter, but also to prevent the leakage of oil within the machine, so sealing requirements is higher, sealing ring material requirements need to be good, its sealing face material is made of tungsten carbide or silicon carbide. If it is installed on the shaft of the water-filled motor shaft, it only requires sand control. The sealing ring can be made of alumina ceramic, silicon nitride or other harder materials, so the cost is relatively low.

The installation error rate of the Common non-cartridge mechanical sea is higher than the cartridge mechanical seal. Therefore, use cartridge shaft seal can greatly reduce the occurrence of mechanical seal failure.

Since the cartridge mechanical seal does not require any adjustment of the mechanical seal by the installer (such as spring, sealing surface, etc.), only the bolts need to be tightened, which greatly improves the reliability of the mechanical seal installation.

The first truly universal cartridge seal, the Type 5610 will change your approach to sealing. Since the 5600 Series components are interchangeable, you can apply one seal family throughout your plant. This gives you the flexibility to cover more applications with less inventory, which means your maintenance is simplified, downtime is reduced, plant operating efficiency is increased and costs are lowered.

A common seal head/mating ring set, utilized throughout all versions, is reversible to allow rotating seat/mating ring or rotating seal head operation, and is interchangeable with metal bellows seal heads.

The TF PJ05D Dual Cartidge-Style Bellows Seal is designed for applications in which the process fluid is incompatible with common elastomers or where the cost of custom O-Rings is prohibitive. The PJ05D Bellows Seal is used primarily in the chemical and petrochemical industries.

Single cartridge mechanical seals are engineered to reliably operate in a wide range of temperature and applications. We partner with the industry-leading mechanical seal manufacturers such as — Flex-A-Seal — to deliver single cartridge seals that are engineered to withstand demanding fluid-handling applications. All of our single cartridge mechanical seals, regardless of application, are designed to provide extended seal life.

Anderson Process offers single cartridge seals that come in a variety of stationary and rotating configurations with various gland types such as, welded metal bellows, single spring, and multi-spring types. The single cartridge seals are a single piece, pre-assembled and preset by the manufacturer prior to installation.

With the many different options, we have a single cartridge seal available for your low/high temperature, corrosive, and heavy duty application. Elastomers include Viton®, Ethylene Propylene, Aflas®, Buna, Neoprene, and Perfluorelastomers. Faces come in Premium Grade Antimony Impregnated Carbon, Nickel Bound Tungsten Carbide, and Silicon Carbide. Single Cartridge models come in the following variations; rotating bellows, stationary multi-spring, stationary single-spring, stationary metal bellows, rotating multi-spring, rotating single-spring, high temperature rotating/stationary bellows, heavy duty API stationary multi-spring and standard/large/taper-bore options.

8613371530291

8613371530291