mechanical seal failure analysis brands

When a mechanical seal fails in one of your operation’s vital pieces of equipment, figuring out the cause of the failure is often even more important than procuring a replacement seal. After all, if there is an underlying issue causing your seals to fail, replacing the seal is only going to be a temporary fix. Unless you plan on purchasing and installing new seals on a regular basis – something that can quickly become both expensive and time-consuming – figuring out the cause of your seal failures is an essential objective.

This is where mechanical seal failure diagnostic services can prove highly valuable. By simply examining your broken seal, we at Gaddis Mechanical Seals are able to pinpoint the exact cause of its failure, enabling you to perform whatever repairs are necessary to keep the same issue from happening again in the future.

At Gaddis Mechanical Seals, we strive to make our seal failure diagnostic services as convenient as possible for our valued customers. All you have to do is send us your broken seal along with any available information regarding where the seal was located and the events leading up to its failure. From there, our expert team will perform a wide range of diagnostics to determine the exact cause behind the seal’s failure.

This includes inspecting the seal’s O-rings, face, springs, gasket, and every other component. By determining the exact component within the seal that failed and analyzing the design of the equipment that it came from, we are able to provide our customers with an accurate and detailed description of exactly what needs to be fixed in order to prevent the same issue from happening again.

When you need a repair or replacement for your damaged mechanical seals, there are a number of excellent reasons to choose Gaddis Inc. With over forty years of experience in the mechanical seal repair industry, our team of engineers and technicians have the knowledge and experience required to tackle any mechanical seal repair project. This expert team, combined with our state-of-the-art facility and cutting-edge equipment, allows us to offer some of the highest quality mechanical seal repair services that you will find on the market today.

The reasons to choose Gaddis Mechanical Seals for all of your mechanical seal repair needs don’t stop there. In addition to providing unparalleled mechanical seal repairs, we at Gaddis Inc. also strive to keep our rates as competitive as possible. By leveraging our numerous, long-standing relationships with our various suppliers and partners, we are able to pass our savings onto our customers and offer the best value that you will find on the market today. Last, but certainly not least, our dedication to customer satisfaction at Gaddis Mechanical Seals is truly second to none. If you would like to work with a company that is committed to going above and beyond your expectations then the mechanical seal repair professionals at Gaddis Inc. look forward to being at your service!

We provide expert Mechanical Seal Repair of all major brands, including John Crane®, Flowserve®, Burgmann®, and more. With locations in Gonzales, LA, and Williston, VT, we are the reliable, convenient single source repair for all styles of mechanical seals.

Our comprehensive library of manufactured design solutions addresses applications in the field and pump-specific challenges providing upgrades and replacement seals manufactured to perform better and last longer.

Flexaseal’s experienced maintenance and repair technicians have worked with mechanical seals from the world"s largest pump and seal manufacturers, including John Crane® and Flowserve®. Below is just a sampling of the many manufacturers and styles that we have repaired. If your seal isn’t listed, just click “Request A Quote” to send us a message.

Each repair that comes to our repair departments in Louisiana or Vermont - whether it is a third-party design or a Flexaseal model - goes through a detailed, 5-step process to ensure customer satisfaction.

Flexaseal offers repair kits for on-site seal repair. These kits are specific to your Flexaseal cartridge and are a great way to have parts on hand for an emergency situation. All items in the kit are packaged and labeled to ensure efficient change-out.

Every mixer, agitator, and reactor model is distinctive and engineered for specific applications. When repairing a mixer seal, Flexaseal evaluates the conditions in which the seal operates. This evaluation ensures we are repairing your seal to your parameters.

Sometimes a failed seal is no longer a candidate for repair. Flexaseal provides straightforward solutions from our comprehensive seal lines or upgraded options designed for your unique operating environment.

The Flexaseal Gulf South location is a fully functional, self-sufficient mechanical seal repair and service facility for mechanical seals. Our Southern U.S. shop - located between Baton Rouge and New Orleans in Gonzales, LA - is a brand new 5,000 square foot, state-of-the-art facility ready for your mechanical seal repair and service needs.

Machining Capabilities – Our Gulf Coast technicians have extensive knowledge and machining experience. These skills enable the team to quickly and efficiently process seal repairs, getting your equipment back into operation with minimal interruption.

Stocking Location – The Gonzales store front has a range of Flexaseal sealing products for immediate off-the-shelf delivery. We are also an assembly and stocking location forseal support systems including barrier fluid reservoirs.

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

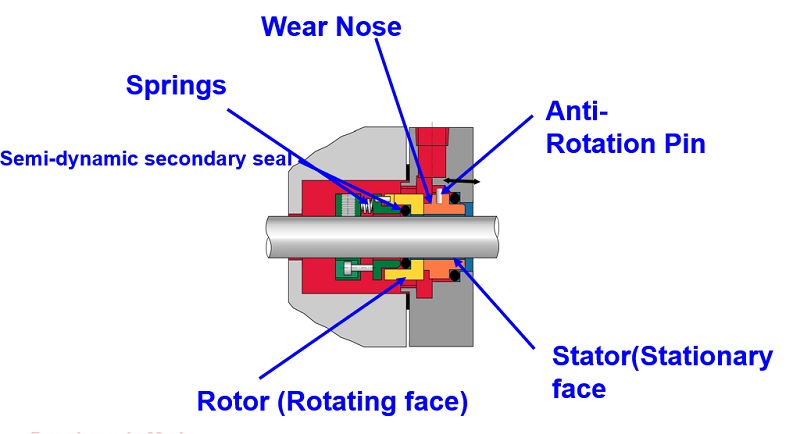

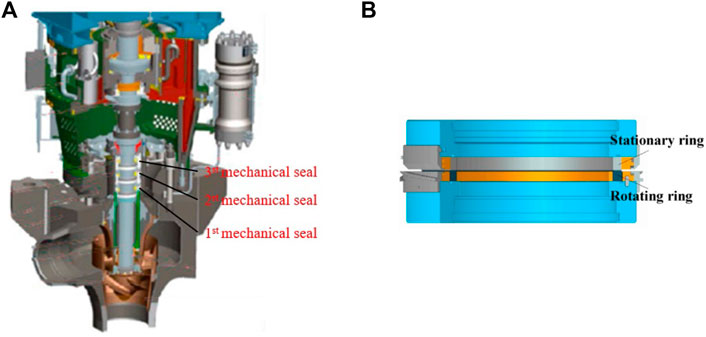

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

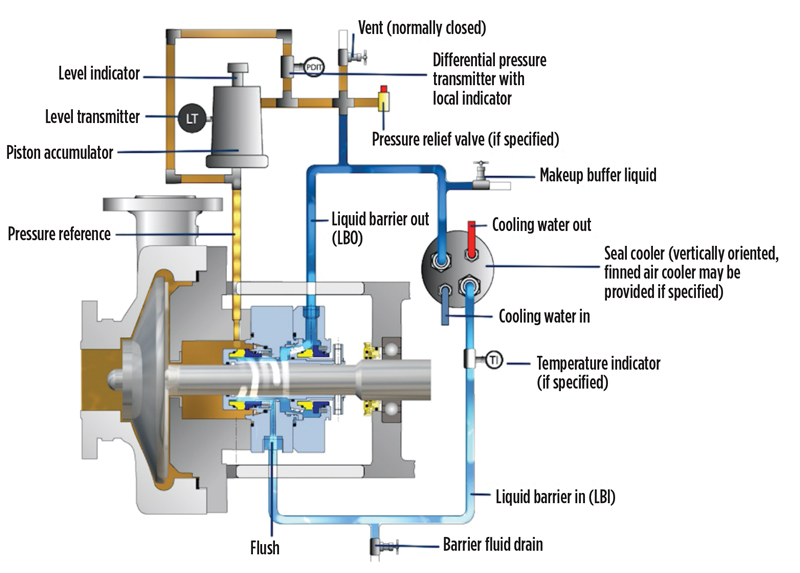

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

SEAL FAILURE ANALYSIS RESULTS The overwhelming reason for a pump to enter the shop is because of failure of the mechanical seal or packing, yet very few companies are regularly troubleshooting these seals. Ten to fifteen minutes spent at this critical juncture can mean doubling or tripling the life of the seal going into service now.

It is not difficult to determine the cause of failure in 80% of the applications common in industry today. Any company buying mechanical seals from a reliable vendor has the right to expect a sensible failure analysis on the majority of their seal failures. The seal rep is seldom at the shop when the pump comes in for repair, but the folks changing the seals can do a very good job of identifying the reason for failure: steps taken at this point can substantially improve the reliability of the application and save the Corporation far more money than the cost of this time invested. Failure to address the problems evident almost certainly dooms the pump to a short service life upon rebuild.

For the purpose of this report, I will not discuss packing failures but will focus on the major causes of seal failure. The following data is compiled from the records kept at two chemical plants on seals I have personally inspected. The totals expressed represent totals for the plant over a two year history and are not application specific. In most cases, the seals were reviewed after the pump was already back in service, but using the form included in this report has allowed these clients to increase the life of the seals used and has increased the Mean Time Between Failure (MTBF) dramatically over the past two years. CLIENT ONE: a large plant with relatively simple processes and over 600 pumps. This plant has a large powerhouse which it can use for co-generation purposes as well as to supply steam needed for processes in-house.

This client uses a wide variety of seal designs and materials of construction. These designs are component seals, split seals, cartridge seals (single and double/tandem). CLIENT TWO: a medium sized plant that two years ago standardized on cartridge seal designs. This plant does not have a large powerhouse, but runs significantly more involved pump/seal applications (evaporation/condensing/reaction loops/etc.) which lead to other concerns.

RESULTS There is a great deal that can be gleaned from these two plants experience. The largest contributing failure in each case was I.D./O.D. rubbing of the rotary seal member against some object, most commonly the bore of the stuffing box. There have been numerous studies completed and documented that clearly prove the value of large bore stuffing box/seal chambers for mechanical seals. The two plants listed have instituted on-going upgrades for their pump populations; if a seal comes out and shows rubbing as the cause of failure, they immediately return to the previous work order on this particular pump. If that failure report also states rubbing as cause of failure, the stuffing box is replaced with a seal chamber on the spot, prior to seal replacement. The concept of “Shaft Deflection Ratio” has been discussed at length in previous issues of this magazine and countless others devoted to our industries. The stiffer the shaft ratio, the better the pump is able to perform off its Best Efficiency Point (BEP).

A good rule of thumb is that a ratio value less than 60 will guarantee seal life is increased dramatically in “Off BEP” operating conditions. Remember that your pump operates where its pump curve crosses the system curve: systems age and change over time ( a gate valve is replaced with a globe valve, long horizontal runs of piping build up solids, etc.). Pumps purchased for design conditions that don’t match those given the pump vendor EXACTLY can become headaches for maintenance and operations from Day One. The second greatest cause of seal failures was related to o-ring failure. The proper o-ring for an application must address both the fluid being dealt with AND any fluid used to clean the system. VITON might be the proper material for the normal application: what if your system is cleaned every shut down with a caustic steam solution?

You lose the seal a week later and the failure analysis states o-ring failure; is the connection made between the caustic steam washout and the failure of VITON? You are far better off stipulating more expensive o-rings which can survive both conditions than losing seals after your turn-around, when the plant and system are up and have to run. Please also note the drop in seal failures due to poor installation when comparing Plant One and Plant Two. With the decrease in maintenance budgets and personnel, the increasing utilization of “multi-craft” people demands simpler seal designs for installation by off-shift personnel. Component seals can be very difficult to install and are sensitive to dimensional information often unknown and/or unavailable to “back-shift” employees. “The road to Hell is paved with good intentions”; if your plant has downsized in the maintenance department ( and whose plant hasn’t?) cartridge designs may justify their additional cost because of their ease of installation. Don’t blame an electrician for shortened seal life when complicated seals are being installed!

Note also the frequency that bearing problems cause seal problems; the two are inextricably intertwined. Lip seals were designed around the time of the Second World War; they were designed for automotive water pumps. They have a limited design life which is far short of bearing design life. Bearings are seldom a failure because of fatigue; far more commonly, they fail from contamination and water emulsions in a pump’s bearing housing.

Upgrade your lip seals every time you change bearings on your pumps and you will see the bearing life triple and quadruple. Upgrade from lip seals to whatever your engineering staff decides is best; labyrinth seals, full face seals, magnetic seals, etc. Which one of us would buy equipment designed in the Forties today for any application in our plants or homes?

Finally, TRAIN YOUR OPERATORS!! They deserve and need training, because they are the people causing the majority of your seal and bearing failures. I have yet to work with a maintenance man who didn’t care about the quality of his work; maintenance people are not the ones wrecking the production equipment. Untrained operators regularly run pumps dry, start them with closed suction or discharge valves, and fail to report increased noise or vibrations from the equipment they run. They don’t do this to sabotage the plant; they do it from ignorance. Production “owns” the equipment: maintenance just “borrows it” when it needs to be repaired.

Stop cursing your maintenance budget and start training your operators: you’ll see how quickly maintenance can become a profit center for your plant instead of “the ugly step-child” it too often is perceived as in the plant budget and planning sessions. CONCLUSIONS Seal failure analysis does not have to be complicated or time consuming. Most of it can be done by your in-house staff in less than ten minutes at the time of failure with reasonable accuracy. Don’t lose the data; gather it on the simple form enclosed, and log it into a simple data retrieval system. Marshall the assets you already have in-house to get a better view of your problem pump applications, make a few simple upgrades on repeat offender pumps, and improve your bottom line today. Plants can readily improve their overall profitability with better training of operators and giving their maintenance people the freedom to make some simple upgrades at the time of seal/bearing failures.

Failure of the mechanical shaft seal is the most common cause of pump downtime. The shaft seal is exposed to widely varying operating conditions. Sometimes operating conditions change to become quite different from the specific conditions for which the seal was intended.

85% of process mechanical seals, fail long before they are worn out. In these series we are going to examine the most common wear patterns that could lead us to critical conclusions regarding the reason of failure.

The inner face of a “back to back” double seal application is not positively locked in position. A snap ring must be installed to prevent the inboard stationary face from moving towards the rotating face when the high pressure barrier fluid pressure is lost or overcome by system pressure.

In each used mechanical seal you provide us, our team in Technoseal will implement the mechanical seal failure analysis and suggest you the best solution as far as the design, the material selection and the installation limitations are concerned.

While lower repair cost and technical advances have transformed the economics of modern ‘high-end’ mechanical seal servicing, in parallel operational efficiency and training also play fundamental roles.

Whether we provide you with a new seal or a repair, NASH can improve your performance in any industry where swift response times, keen pricing, high quality and guaranteed reliability underpin success.

As our continuously updated news blogs and case studies show, we help to improve the performance of all mechanical seal brands and types, while creating attractive new financial returns from both first-time installations and profitable aftermarkets.

NASH’s goal is to make mechanical seals work better, longer, more efficiently and cost-effectively in increasingly demanding business environments across the globe.

Our three-stage strategy for better seal maintenance involves not only performance optimisation but also a pro-active inspection & repair service. Under consultancy, we provide training and troubleshooting too.

At Lidering we count with a large experience in mechanical seals. So we can ensure than99% of mechanical seal failures are caused by what we know as “dry working”.

When we speak about dry working we refer to the situation in which contact faces on seals stopped having the appropriate lubrication needed to perform its best. Consequently, there is a friction that speeded up the wear of the piece causing damage and failure on seals.

Excessive pressure: failure on mechanical seal can be caused by an excess on pressure, that is to say, the mechanical seal can be brought under some values of pressure that are not admitted by this type of mechanical seal. In this case, there is an excess of closing force between both contact faces. This can cause a big trouble during the pass of the fluid between them, so they finally end working into a dry environment.

Excess of speed: every mechanical seal can bear certain conditions. A seal is working over the maximum lineal speed (m/s) what can cause an excess of temperature between the contact faces. This will likely cause an early evaporation of the fluid between the faces. Consequently, the faces of the mechanical seal will end up working in dry conditions.

Problems with the assembly: every seal has its own characteristics and limitations. If a seal is placed into a space that does not respect its right housing dimensions, it can cause an excessive pressure between the contact faces that could result in dry working. Therefore, a dimensional error can have a negative impact causing failure on mechanical seals.

If a mechanical seal falls or breaks during the assembly, it might cause modifications in the design of the piece which can cause potential leaks. It must also be taken into account that, during the installation of the seal in its location, no type of particle is sneaked in there and which could, over time, cause an escape of product fluid.

Dry working is not the only cause that can crucially and directly damage the mechanical seal. There are other situations and products that can cause a fast wear of the piece and which could require a repair or substitution. It is the chemical attack.

We can find acid substances in the contact faces of a mechanical seal that can react against thegraphite, one of the materials frequently used in mechanical seal faces.En Lidering disponemos de grafitos especiales que se adecuan a un amplio rango de aplicaciones. Además de las caras de rozamiento,el carburo de silicio también puede verse altamente afectado por sustancias fuertemente alcalinas, tornándose de color verde y perdiendo dureza. En Lidering te proponemos alternativas, como el Silicio Q1, para evitar esta situación de deterioro.

If talking about secondary seals, as is the case of O’rings, there can also be damage caused by different types of interactions of the materials that compound these secondary seals with the environment. It is the case of the FPM, incompatible with hot water, or EPDM, not recommended mixing with fat and mineral oils. At Lidering we want to advice you to obtain the best choice in every situation within a big range of high quality materials in secondary joints.

We hope to have helped you to improve the product life of your mechanical seal and avoid possible damage. Please contact our experts through our website to solve any doubt you may have.

P-M Industrial has proudly distributed Flowserve Mechanical Seals since 1992. Using Flowserve’s comprehensive product line of standard and custom engineered mechanical seals our Sales Engineers solve mechanical seal reliability problems on all types of rotating equipment . We do this by taking a holistic approach in understanding your machinery, your operating conditions and procedures as well as reviewing the other factors affecting reliability. Taking all of these factors into account, our engineers develop a solution based on Flowserve’s proven technology and your reliability goals to deliver an appropriate reliability enhancing solution.

According to its own analysis, some 98% of mechanical seals fail prematurely before they have reached their optimum design life-time expectancy. The Flowserve Seal Failure Analysis App is a web-based tool designed to visually identify and prevent future mechanical seal failures. Accessible via desktop, tablet and mobile devices, this reference tool is a resource for reliability engineers and maintenance staff, tasked with troubleshooting and preventative maintenance. While mechanical seal failures are the number one cause of pump and mixer down-time, this area represents a great opportunity to reduce whole life costs on site across all pump systems.

While mechanical seal failures are the number one cause of pump and mixer downtime, this area represents a great opportunity to reduce whole life costs on-site across all pump systems, says Flowserve.

Shaun Hampson, general nanager of the Manchester (UK) facility, adds: “When a seal fails, it is often a critical breakdown situation and companies don’t have the time to wait for an engineering expert to visit the site in order to provide a diagnosis. The app is very easy to use and can lead to extended mechanical seal life.”

According to its own analysis, some 98 Percent of mechanical seals fail prematurely before they have reached their optimum design life-time expectancy.

While Mechanical seal failures are the number one cause of Pump and Mixer down-time, this area represents a great opportunity to reduce whole life costs on site across all pump systems.

Shaun Hampson, General Manager of the Manchester (UK) facility said, “This new way of supporting our customers, on a 24/7/365 basis, provides engineers with more than 100 years of acquired knowledge at their finger-tips. When a seal fails, it is often a critical breakdown situation and companies don’t have the time to wait for an engineering expert to visit the site in order to provide a diagnosis. The App is very easy to use and can lead to extended mechanical seal life. Our own staff use this tool!”

The Flowserve Seal Failure Analysis app’ is a web-based tool that has been specifically designed to visually identify and prevent future mechanical seal failures.

While Mechanical seal failures are the number one cause of Pump and Mixer down-time, this area represents a great opportunity to reduce whole life costs on site across all pump systems.

Shaun Hampson, General Manager of the Manchester (UK) facility said, “This new way of supporting our customers, on a 24/7/365 basis, provides engineers with more than 100 years of acquired knowledge at their finger-tips. When a seal fails, it is often a critical breakdown situation and companies don’t have the time to wait for an engineering expert to visit the site in order to provide a diagnosis. The App is incredibly easy to use and can lead to extended mechanical seal life. Our own members of staff use this tool!”

Centrifugal pump leakage is most often the result of a problem with the mechanical seal faces. When properly installed and maintained, a mechanical seal should give you years of reliable service. However, if during the course of operation you fail to maintain the proper seal chamber environment with its many factors—process, barrier, or buffer fluid delivered at the right pressure; adequate heat dissipation; impeller balance and alignment—you’re likely to experience seal face failure that results in leakage.

By closely examining the seal faces in a leaking pump you can often detect the reason for the leakage. The seal face damage can provide a clue to the origins of the problems such as unevenly tightened gland bolts, shaft misalignment, inadequate fluid across the seal faces, fluid vaporization across the faces, thermal and mechanical shock, defective seal face coatings, corrosion, or particulates in the process fluid.

Each of these problems, and the way they can be identified, is extensive. For now, I’ll focus on one that is relatively simple in terms of visually identifying the problem and remedying it: mechanical seal face chipping.

Mechanical seal face chipping typically occurs in the inside and outside diameter edges of a seal face. Chipping can be the result of changes in operating conditions that exceed the design specifications of the currently-installed mechanical seal and/or seal support system. Careless handling of a mechanical seal or improper installation techniques is another cause of chipping. Regardless of the origin, a chipped mechanical seal face allows process fluid to penetrate between the seal faces and can eventually lead to seal failure.

Any mechanical seal and support system should be selected and installed according to the expected operating conditions of the pumping process. When conditions change as the result of different process fluids, higher or lower pressure pumping pressure, or higher process fluid temperatures, there’s a good chance that you could exceed the mechanical seal and support system design specifications.

When process parameters change, fluid vaporization can occur across the seal faces causing rapid separation and then closing, essentially slamming seal faces against each other. These repeated hard contacts can eventually result in chipping that shows on the inside and/or outside edges of the seal faces. This problem typically occurs when processing light hydrocarbons that easily vaporize or pumping hot water close to the liquid"s vapor pressure.

As you analyze the problem, ask “Have there been any changes in process conditions that exceed the original design of the mechanical seal and seal support system?” And, as you might expect with many mechanical seal problems, the remedy is tied to better temperature and pressure management.

Many of these changes are most efficiently accomplished with the help of an experienced mechanical seal support vendor who can conduct an on-site inspection of the pump, help you accurately diagnose the failure, and recommend design changes or upgrades that better match the current pumping conditions.

Excessive vibration can also result in mechanical seal face chipping. To the experienced maintenance engineer with the right diagnostic tools, even the slightest vibration can be detected. However, if the pump is located out of sight or is difficult to access, vibration problems can go undetected until they become obvious such as excessive noise or significant leakage. In those situations, I recommend inspecting the seal faces for chipping as part of the maintenance procedure. If you don’t, even though you’ve remedied the vibration problem—such as updating the alignment, adding new bearings, tightening base bolts, or installing a new impeller—a chipped mechanical seal will eventually result in pump leakage.

Under the right operating conditions, mechanical seals are resilient, yet they can be delicate and damaged easily. This is especially true of the ceramic seals that can be easily chipped between the time they are removed from the packaging until they are installed, if not handled properly. They can just as easily be damaged during routine maintenance. Chipping can also occur on soft carbon seal faces. Careful inspection of the damaged seal face typically finds a fan-shaped fracture on the inside and/or outside diameter of the seal face.

There’s no substitute for the experience and skill of a maintenance technician who has successfully installed dozens to hundreds of mechanical seals. If you don’t have the in-house expertise to handle the installation, work with your mechanical seal vendor to find an experienced technician who can.

If you’re experiencing problems with mechanical seal chipping as the result of changes in process conditions and the need for modifications to seal support systems, the Field Engineering team from Swagelok is available for on-site consulting to assess and work to resolve the issues.

Our local engineers bring industry-specific knowledge with access to a global team of engineers who have successfully solved the most complex fluid systems challenges throughout the world. They can ensure a new seal support system is properly matched and configured to provide the required flush fluid at the proper pressure and flow in order to maintain a seal chamber environment that prevents mechanical seal face chipping. For installed seal support systems they will recommend the appropriate modifications, upgrades, or replacements needed to prevent seal failure.

To learn howSwagelok Northern California"s can help you remedy seal support problems that are leading to mechanical seal face chipping by providing expert consultation and assembly services,contact our team today by calling

Mechanical seals prevent pumps from leaking by containing the pressure of the pumping process and withstanding the friction caused by the rotating shaft. The right seals provide reliable operation, less wasted product, more cost savings, and fewer housekeeping issues. However, why do mechanical seals fail?

In many pump systems, a mechanical seal is the first component to fail. They are also the most common cause of pump downtime and account for more pump repair costs than any other part of a pump. Often, however, the seal is not to blame. Other culprits include:Bearing wear

Therefore, teams must install and maintain seals properly to prevent failures. Teams must pinpoint the root causes of each failure. But how do plant and maintenance managers isolate the root cause though?

One option is to have a seal manufacturer perform a seal failure analysis. Some seal manufacturers offer complimentary seal analysis on any seal, not just theirs.

End users simply send their mechanical seal to the manufacturer’s engineering team. If multiple seals need to be analyzed, they may come on-site to perform the root cause analysis. Most reviews canbe completedin about two weeks.

With a seal failure analysis, experts deliver a complete diagnosis of why the mechanical seal failed and what actions to take to prevent future failures. The experts who examine the seal can ensure that the ideal seal for the application has been selected. If not, they recommend alternate technologies.

After an analysis, the manufacturing ream will also help end users optimize their system conditions and achieve the best possible operation from their assets. Optimizing mechanical seal performance also improves shutdown to shutdown processes. This information, along with alternative proposals as needed, help end users prevent further failures and improve their return on investment.

Many problems with a system may be discovered by investigating a failed mechanical seal. In most instances, a seal problem is not the reason for the failure. Something else happened to cause it.

The story of what the seal experienced during operation, before it failed, can be revealed by investigating the failure. An analysis may determine or confirm:If misalignment or other mechanical problems exist in the pump system

Eliminating the problems identified by the seal failure analysis may have a huge impact on the system. Several improvements may be realized, including:Optimized operating conditions

For instance, a stationary seal face is cracked, originating from the drive pin slot. Also, sticky residue has adhered to the face. This crack means something different than a stationary seal face with a crack located at a different position and product residue that is fairly clean and not tacky.

Both cases look the same on a simple table listing all the seal damage. However, the failure cause is different. In the first example, the crack was caused by the product attempting to stick the rotary and stationary faces together. This adhesion caused increased torque on the stationary pin. This caused the stationary face to crack.

In the second example, the crack was likely caused by impact. This indicated that the seal was not installed properly. Different symptom combinations reveal multiple failure modes.

In conclusion, to determine the true reason that a seal failed, seal failure analysis is required. Without a diagnosis of the system problem, failure will continue.

Jack Ferguson is a seal reliability engineer with Sealing Equipment Products Co. Inc. (SEPCO). He is a recent graduate of Clemson University with a degree in mechanical engineering. Ferguson may be reached at jackf@sepco.com.

Around 98% of mechanical seals will prematurely fail, long before they have reached their optimum design life-time expectancy, according to analysis from Flowserve. Mechanical seal failures are the number one cause of pump and mixer down-time. T

he Flowserve Seal Failure Analysis app is a web-based tool that has been designed to visually identify and prevent future mechanical seal failures. The reference tool is accessible via desktop, tablet and mobile devices, offering a useful new resource for reliability engineers and maintenance staff, responsible for troubleshooting and preventative maintenance.

Shaun Hampson, general manager of the Flowserve UK facility, said: “This new way of supporting our customers, on a 24/7/365 basis, provides engineers at their finger-tips. When a seal fails, it is often a critical breakdown situation and companies don’t have the time to wait for an engineering expert to visit the site in order to provide a diagnosis.”

8613371530291

8613371530291