aes mechanical seal price

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

We recognize and understand the vital role of aes mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale aes mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider aes mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Harini Engineering came into being in the year 2010 and carved a niche as the leading Manufacturer, Supplier and Exporter of the wide range of Industrial Spring Seal, O Ring, Pneumatic Diaphragm, Heat Exchanger, Dyeing Machine, Silicone Gasket, Rubber Gasket, Pulley Spindle and many more.

AESSEAL Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs.Seacoast Supply maintains a large inventory of AESSEAL products.

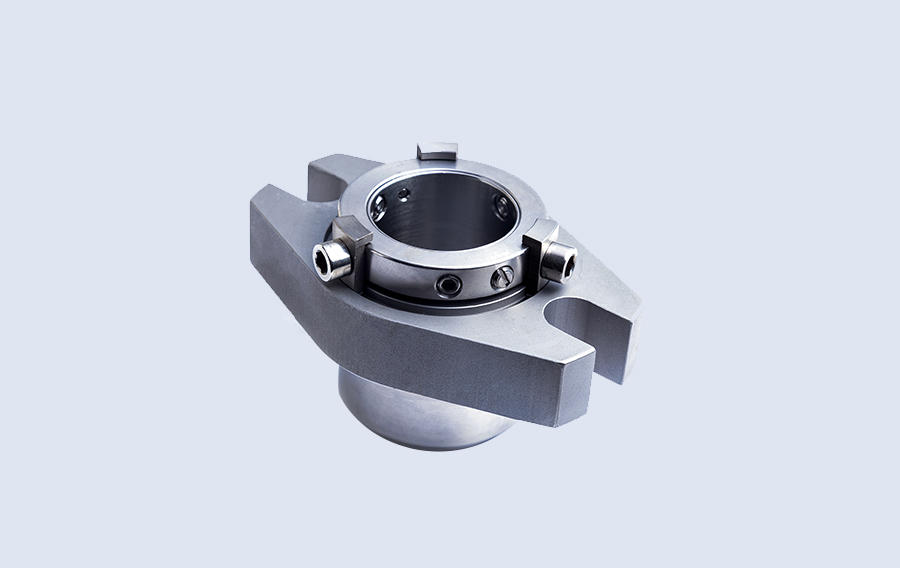

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

This means that no matter how well designed your mechanical seal or bearing systems are, without a reliable Seal Support System there is still the possibility of your mechanical seal failing. The innovative and reliable Seal Support System Range at AESSEAL® gives customers the confidence to remove this root cause of mechanical seal failure.

AESSEAL® offer a range of bearing protection devices suitable for most applications. The innovative LabTecta® and MagTecta™ products include patented features that deliver the best possible bearing housing sealing solution for your motor, pump, plummer block, gear boxes or steam turbine.

AESSEAL®cartridge mechanical sealsare used in a wide variety of pumps and rotating equipment to prevent liquids and gases from escaping into the environment. Here are three benefits of AESSEAL®cartridge mechanical seals.

AESSEAL®cartridge mechanical sealsare pre-assembled at the factory, pressure tested, and shipped as a unit. This seal configuration eliminates the requirement for seal setting measurements at installation.

Spring tension is another crucial factor in a successful seal installation. Withcomponent seals, you must set the tension manually by adjusting the length of the installed seal spring. Withcartridge seals, the spring tension is preset, eliminating the time and potential errors of manual installation. A retaining device holds the rotating and stationary elements in correct alignment until the seal is mounted.

Cartridge seals are capable of handling the most demanding applications, including slurry applications and hazardous process fluid containment. AESSEAL®’s standardcartridge sealline includes the following.

For unusual applications, AESSEAL® also has a Standard Plus line that offers the same benefits as their standard seals while also meeting specific customer needs. This includes competitor replacement seals and seals designed for specific pumps and processes.

Cartridge mechanical sealscost more thancomponent seals. However,cartridge seals will save you money in the long run, thanks to lower maintenance costs. Potential savings come from reduced labor costs and less downtime when in-service seal replacement is required.

Are you interested in improving pump reliability, increasing uptime, and reducing maintenance costs? The experts at C&B Equipment can help you implement the bestAESSEAL®cartridge mechanical sealsand seal support systems for your application. We also offer a suite ofpreventative maintenance programs and repair servicesto ensure your equipment remains in top shape for the duration of its life!

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

At ProSeal Service Group, state-of-the-art mechanical seal products are a way of life. After more than two decades, our partnership with AESSEAL®—a world specialist in mechanical seal R&D—has granted us exclusive rights to distribute in Michigan, Ohio, and Alaska. This allows us to deliver some of the most technologically advanced seal products in Component, Single Cartridge, Double Cartridge, Split, Metal Bellows, Mixer, and API seals to keep you operational.

In addition to cutting-edge modular mechanical seals, we specialize in bearing protectors, gasketing products, and gland packings. All of ProSeal’s products are designed to limit operational and maintenance costs throughout the lifetime of your equipment for maximum ROI. From double bellows to single pushers, we can help you find and maintain the right mechanical seal products for your operation.

AES cartridge mechanical seal convertor II LP318 is designed to replace two-part component seals and conventional packing arrangements. This seal is a cartridge seal type with Short external length.

AES cartridge seal convertor made by lepu seal with a longer durable and resistance even running in bad environment, strong quality stainless steel for the cartridge seal frame, and high density silicon for the seal face, Viton rubber offer more resistance against corrosive medium.

As a leading mechanical seal manufacturer, Lepu seal factory make this AES cartridge seal for a long period, and sell this seal to hundreds of clients, 100% a right replacement for original AES seal.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

AES’s mechanical seals are used in a variety of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. A wide range of mechanical seal types are manufactured to suit different industries and the significant investment made in modular design means that AES provides the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are designed to improve reliability and reduce maintenance costs of rotating equipment. The business is focused on giving customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® is one of the world"s leading manufacturers of mechanical seals. The key to the brand"s success in the sealing market is a wide range of products: mechanical component seals, gas seals, cartridge seals, sealing systems, bearing protection, etc., as well as continuous improvement and innovative developments to optimize each seal. Many well-known manufacturers of pumping equipment use AESSEAL products when completing their pumps and other rotating devices.

We recognize and understand the vital role of aesseal mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale aesseal mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider aesseal mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Robco"s Mechanical Seal Division manufactures, distributes and customizes mechanical seals, as well as being a repair facility for virtually any mechanical seal brand, utilizing the latest technology and state-of-the-art manufacturing equipment. Robco’s seal designs are customer driven to provide the best possible solutions to sealing problems.

Robco will repair: Borg-Warner, Chesterton, John Crane, Durametallic, EG&G, Flex-A-seal, Flexibox, Flowserve, Garlock, Pac-Seal, U.S. Seal, and virtually any other brand.

Mechanical seals are used everywhere liquids and gases are transferred through rotating equipment. Robco’s seals and packing are the first step to efficiently control leakage and reduce operation costs.

The ideal seal for alumina applications, specifically designed to operate in this challenging environment, the Robco DRYTEK seal will provide maintenance-free operation at least five to twenty times longer than your average alumina screw conveyor seal.

•Better abrasion resistance •Dry-seal, no lubricant required •Sealing components rotate with the shaft, maintaining an airtight seal •Adapts to axial and radial movements of the shaft •Available in C.E.M.A. and METRIC standard shaft sizes.

Double balanced cartridge seal for pumps, agitators and mixers that prevents the leakage of toxic, hazardous, corrosive and costly fluids to the atmosphere.

Robco uses specialized equipment to ensure that rebuilt seals operate equal to brand new, with mechanical seal manufacturing and rebuilding experience dating back to 1978, servicing petrochemical, pulp & paper, steel, mining, waste water, utilities, boilers and more...

We rebuild all major brands at competitive prices with premium quality parts that meet all OEM specifications. We offer a free estimate and failure analysis. Rebuild outlay normally varies from a third to half the cost of a new seal, so lower your inventory value and reduce your overall operations cost.

By centralizing your repairs: Robco rebuilds all major brands in one location, simply complete our Seal Repair Form to be enclosed along with your seal shipment and we’ll take care of the rest, returning your seal looking and working like new. Robco tags all rebuilt seals for future rebuild identification, tracking seal life and failure patterns.

![]()

AESSEAL® has one of the most comprehensive component seal product portfolios available. With some 10,000 product lines available from stock, our inventory incorporates seals to suit an extensive range of pump types and applications.

Our unique, patented range of re-engineered component seals enables 44,000 permutations to be configured, allowing AESSEAL® to offer our customers the greatest possible product availability and service. AESSEAL® provides the sealing solutions you require – direct from one source.

Our component seals offer 100% compatible solutions with OEM parts and backwards compatibility ensures our products can be used with our customers’ existing stock holding. AESSEAL® component seals are designed with modularity at their core, allowing faster service whilst also incorporating design features which reduce the lifetime cost of the product.

8613371530291

8613371530291