high temperature mechanical seal for sale

Munaco Sealing Solutions provides OEM and MRO gaskets from in house CNC tool-less gasket cutting equipment. Munaco"s CNC gasket cutter provides prototype, one off, low volume, and high volume gasket cutting services. The precision CNC machine"s reciprocating blade technology yields precision gaskets without waiting on tooling. Munaco"s customers simply send dimensions, drawings, DXF files, or even used gaskets for quick turn around. Precision cut custom gaskets from Munaco require no-tooling cost solutions from most. Call Munaco today for quick turnaround custom gaskets. CLICK HERE FOR CUSTOM GASKET DETAILS

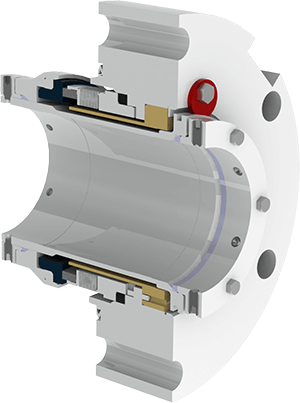

We recognize and understand the vital role of high temperature mechanical seals in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale high temperature mechanical seals in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider high temperature mechanical seals requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

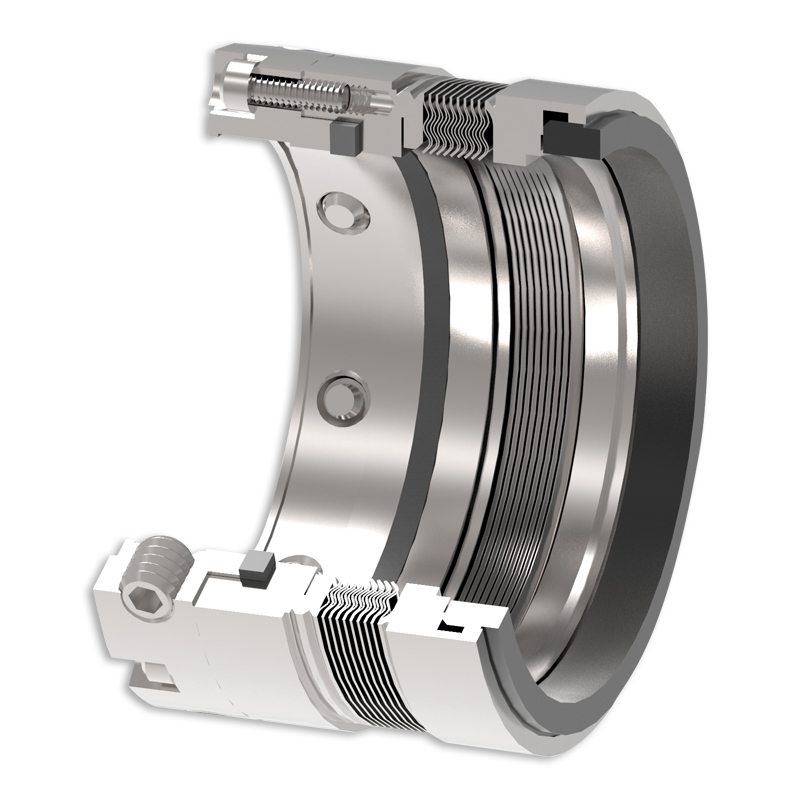

The Type 609HTC is a high-temperature bellows assembly intended for those demanding applications where a dependable, high-strength, rotating seal is preferred. Typical applications for these seals include hydrocarbons, aromatic fractionation products, crude oil fractionation products and heat transfer fluids, as well as chemicals, caustics, some acids, aqueous solutions and lubricating liquids. This seal utilizes "HTC" technology with an all-Inconel, corrosion-resistant welded metal bellows for reliably sealing fluids in harsh high-temperature, corrosive environments and, at the same time, provides superior face stability at elevated temperatures. This all-Inconel seal is ideally suited for applications that contain organic acids (naphthenic acid), and sulfur compounds that attack most other alloys at high temperatures. The Type 609HTC is utilized in our Type 2609HTC and Type 3609HTC API 682 Type C Arrangement 2 and 3 cartridge seals.

In applications where the process temperature exceeds elastomer capabilities, metal bellows mechanical seals with graphite secondary seals are a good sealing option. The 886HT Bellows Single Seal is designed for high-temperature services typically found in chemical and petrochemical processes. Graphite secondary seals replace O-Rings to achieve the higher temperature requirements.

Advanced bellows design distributes pressure uniformly across the span of the bellows plate to reduce stress and minimize weld fatigue. Component design replaces most OEM seals.

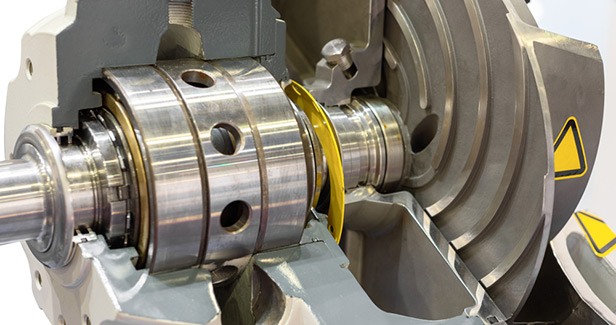

The Flexaseal Style 63A/66A cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services. The Style 63A features a stationary bellows unit for superior performance in applications that require higher shaft runount or large assembly tolerances. The Style 66 is a rotating bellows unit for enhanced solids handling.

Grafoil packing throughout allows for operating temperatures up to 800F, while improving reliability by eliminating the dynamic secondary sealing element.

The Flexaseal Style 63A/66A cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services. The Style 63A features a stationary bellows unit for superior performance in applications that require higher shaft runount or large assembly tolerances. The Style 66 is a rotating bellows unit for enhanced solids handling.

Grafoil packing throughout allows for operating temperatures up to 800F, while improving reliability by eliminating the dynamic secondary sealing element.

A mechanical seal consists of two extremely flat faces running against each other, one fixed and one rotating. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process fluid leaking between the rotating and stationary areas of the pump.

Various materials can be chosen for the seal face combination. Generally, this comprises two, non-identical materials. Depending on the application and the fluids being sealed, the design engineer has to choose the most appropriate material combination. In independent tests mechanical seals incorporating REFEL reaction bonded silicon carbide have exhibited the lowest levels of counter face wear. This is due to the fine grain structure of REFEL and the high degree of bonding between the silicon carbide grains resulting in incredible stiffness properties. Mechanical seals made with REFEL have longer life, reduced propensity for leakage, and hence less seal failure.

REFEL also has the highest thermal conductivity of any commercially available silicon carbide which means any excess heat generated by, for example, dry running, can be dissipated faster than other available material combinations. REFEL gives the mechanical seal designer peace of mind knowing he has the best material available.

Some of the most difficult applications get as high as 500 degrees F and shaft speeds up to 3600 RPM. Even those can be sealed with single spring seals. If the application is even tougher, we only need to upgrade to another design such as a metal bellows, Multi Spring or Cartridge mechancial seals. We have mechanical seals that can be furnished to meet the most demanding of industrial applications.

Mechanical seals designs range from the work horse "single spring" mechanical seals, to highly engineered double cartridge seals for extreme applications.

Utilize Single Spring Mechanical Seals coiled in a right of left hand design to accommodate left and right hand turning pumps. They have the flexibility to accommodate misalignment, shaft deflection, and break away shock loading. It resists clogging in extremely viscous fluids.

Knowing what seal you need when ordering is easy enough to determine. If you know the part number you last ordered it with, such as PS-100 or the industry did standardize so our ASP-100 will be an equal. If you don"t know the part number we may be able to cross it by the pump model or simplyidentify your mechanical seal by the dimensions. You will need to identify the seal type, and materials of construction. You can also refer to our step by step to size your pump seal.

Getting the working length of you seal right will determine it"s expected life span. Over compression of the spring will increase the friction and wear on your seal. Undercompress the spring and system pressure can overcome the spring tension and allow leakage.

To make sure your pump seals stationary seat fits, it"s a good idea to provide the inside dimension of the bore it will be fitting into. The outside dimension of your mechanical seals stationary seat is helpful but more difficult to obtain an accurate measurement. Most pump seal stationary seats have rubber cups or o-rings that must be compressed when they are installed.

Extreme temperatures characterize many refinery processes. Gasoline boiling between 90° and 220° F seems low when compared to kerosene at 315° to 450° F and gas oil at 450° at 800° F. Asset reliability is critical to running these high-temperature processes round the clock. You can reasonably make the case that every major asset and component is critical to an efficient refining process.

But here I want to emphasize the importance of pumps, mechanical seals, and seal support systems. Without pumps, there is no process. Without the proper seal support systems, high temperatures in seal chambers may damage mechanical seals and lead to pump leakage.

While leakage can cause small problems or big ones, you always need to have the risk of sanctions in your mind, especially in high regulation states like California. And with Bay Area refinery budgets as lean as they are currently, it makes sense to choose the right systems from the start to avoid something costly going wrong in the future.

Several factors contribute to high temperatures in the seal chamber, which in turn leads to mechanical seal degradation. A mechanical seal and seal support system may have been perfectly matched to the initial process, working reliably for years. However, a change to a higher-temperature process can exceed the capability of the mechanical seal and capacity of the seal support system.

At higher temperatures, elastomeric components in the mechanical seal may begin to deteriorate. For example, beyond 300° Fahrenheit (150° C) ethylene propylene components eventually degrade and leak. Some hydrocarbons coke at higher temperatures and impede the free movement of mechanical seal components. And process fluids at high temperatures are prone to vaporize, or flash, across the seal faces, causing fugitive emissions.

With increased temperatures of process fluids, the seal support system may no longer be able to maintain the barrier or buffer fluid temperature or flow rate required to maintain the integrity of a dual seal arrangement. When mechanical seals and seal support systems can no longer ensure pump reliability it’s time to select seals, support systems, and components better suited for the job.

If a change to a higher process temperature is causing unanticipated leakage, consult with your preferred mechanical seal vendor. The materials alone can present an overwhelming number of options as seal technology and design continue to evolve. There are now more choices than ever, including:

⇒ Seal faces—carbon, stainless, ceramic, tungsten, and variants incorporating silicon, graphite, or nickel—engineered for resilience and compatibility with process fluids

The benefit of these choices is the ability to match mechanical seals to the specific needs of the process, maximizing seal performance and reliability.

The mechanical seal requirements of high-temperature hydrocarbon processes are best met with dual/ between seal arrangements. A dual seal support system provides fluid between two seals, buffer fluid at a lower pressure than the process fluid, and barrier fluid at a higher pressure than process fluid.

In contrast to a single mechanical seal arrangement where seal degradation or failure results in fugitive emissions or outright leakage, the two seal arrangement provides a more reliable means of preventing high-temperature hydrocarbons from leaking. Here too, rotating equipment and reliability engineers have a number of dual seal design options to choose from, including:

Face-to-face configurations are used in space-constrained areas that cannot accommodate back-to-back or tandem arrangements. Seals share a common stationary component which, if compromised, leads to leakage. You can select from buffer or barrier fluid options.

Gradual or sudden changes in barrier or buffer fluid pressure provide evidence of problems with seals. An experienced mechanical seal vendor can help you navigate the options available to ensure mechanical seals and their components meet each of your specific needs.

Equally important to the reliable functioning of mechanical seals in high-temperature processes is the selection of seal support systems. The mechanical seal you choose will guide the seal support system plan that best meets your needs.

Seal support systems for dual seals are divided into two categories: buffer and barrier. While that seems to simplify the selection, there are a variety of options for each category. To give you an idea of what’s available, I’ve listed a few of the mechanical seal support system options below.

Circulates pressurized barrier fluid from a reservoir to the dual seals. Use plant nitrogen, bladder accumulator, or piston accumulator to supply seal pot pressure. Any leakage across the process side seal is barrier fluid that lubricates seal faces and migrates into process fluid.

Provides clean, dry pressurized barrier gas (typically nitrogen) to the dual seals from an external source. Any leakage past the atmospheric seal is pure nitrogen.

For each of these plans, there are options to fine-tune the seal support system and provide a greater level of reliability for mechanical seals operating in high-temperature environments. Among the many options you may want to include:

An experienced seal support vendor can save you time and money, helping you select and configure the seal support systems with the right components for each of your high-temperature hydrocarbon pumping needs.

Swagelok has been meeting the mechanical seal support system needs of Northern California refineries for more than 50 years. When you work with Swagelok, you have the benefit of a local vendor with facilities in Concord, Fremont, and Santa Clara. Being local translates into on-site support, field verification of your requirements, and rapid delivery of seal support system assemblies, components, and parts.

To find out more about howSwagelok Northern California can help you address the challenges of maintaining the proper environment for mechanical seals in high-temperature serviceContact our team today by calling 510-933-6200.

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

We are a manufacturer. All seals have bulk inventory and can be shipped to you quickly. We promise to ship you in small quantities within 3 days.Advanced technology, excellence, replace original

1. Different models of mechanicals seals for a wide variety of Grundfos® pumps, among them: CR(N), NB, NK, CLM, LP, TP, etc. Available in diverse combinations of materials and different diameters: 12, 16, 22, 28, 33, etc. Also mechanical seals for Sarlin®. Division of waster pumps. Available in various materials: silicon-graphite carbide, silicon carbide-silicon carbide; combined with EPDM and FKM elastomers.

2. Mechanical seals are available for different references Gorman-Rupp® pumps. Special models for the transfer of clean water, sewage, oil industry, agriculture and others.

3. Mechanical seals for Fristam® pumps. Wide range of models and materials in the most standard diameters: 22,30 and 35 mm. Different assembly possibilities for the most well-known pump models: FP, FL and FT.

4. Broad range of mechanical seals compatible with Flygt® and Grindex® waste water pumps. These mechanical seals are characterized by their easy and fast installation, without having to make any modification to the pump. Manufactured in stainless steel and in solid tungsten carbide. Special tools are not necessary for their installation.

6. Different designs of mechanical seals for Ebara® pumps, single and double seals in combinations carbide-silicon carbide and graphite-aluminium oxide.

7. Mechanical seals for all types of Calpeda® pumps: centrifugal pumps, multistage, submersible. Different models of mechanical seals in a wide range of materials.

8. Mechanical seals compatible for APV® pumps, among them: Puma, ZMA, ZMB, ZMD, ZMS, ZMH, ZMK. Rosista® and Pasilac®, W and W+. Some designs with wave spring like the special seals for APV Howard® pumps and Crepaco Clean Line®. All of them have been manufactured in materials suitable for working with fluids such as juices, milk and drinks in general.

2. The radial acting deviation for the shaft(shaft sleeve) of the installed mechanical seal shall be 0.04mm by maximum while the axial movement value of the rotor shall be no more than 0.1mm.

3. The seal cover (or shaft cover) of the stationary ring of the installed mechanical seals,the vertical degree of the seal face should be 0.04mm by maximum.

4. When installing the mechanical seals,the shaft(shaft sleeve),seal chamber,seal face as well as the mechanical seal must be cleaned in order to keep from any medium to sealing part.

5. When conveying medium of over high or low temperature,with medium which are easy catch fire,easy for explosion. Related mechanical seal standards must be referred to take appropriate measures such as quench,rinsing,coolong and filtrating.

6. Appropricate lubrication must be choosen when mechanical seal is installed.The installment size of the mechanical seal must be guaranteed to the installment instruction.

This High Temperature Mechanical Seal Market report includes the estimation of market size for value (million USD) and volume (K Units). Both top-down and bottom-up approaches have been used to estimate and validate the market size of High Temperature Mechanical Seal market, to estimate the size of various other dependent submarkets in the overall market. Key players in the market have been identified through secondary research, and their market shares have been determined through primary and secondary research. All percentage shares, splits, and breakdowns have been determined using secondary sources and verified primary sources.

The Global High Temperature Mechanical Seal market is anticipated to rise at a considerable rate during the forecast period, between 2023 and 2028. In 2022, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

The global High Temperature Mechanical Seal market size is expected to growth from USD million in 2022 to USD million by 2028; it is expected to grow at a CAGR of Percent during 2023-2028.

The United States High Temperature Mechanical Seal market was valued at USD million in 2022 and is projected to reach USD million by 2028, at a CAGR of Percent during the forecast period.

QYResearch has surveyed the High Temperature Mechanical Seal manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Report further studies the market development status and future High Temperature Mechanical Seal Market trend across the world. Also, it splits High Temperature Mechanical Seal market Segmentation by Type and by Applications to fully and deeply research and reveal market profile and prospects.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of High Temperature Mechanical Seal in these regions, from 2015 to 2028, covering ● North America (United States, Canada and Mexico)

Some of the key questions answered in this report: ● What is the global (North America, Europe, Asia-Pacific, South America, Middle East and Africa) sales value, production value, consumption value, import and export of High Temperature Mechanical Seal?

● Who are the global key manufacturers of the High Temperature Mechanical Seal Industry? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)?

● What are the High Temperature Mechanical Seal market opportunities and threats faced by the vendors in the global High Temperature Mechanical Seal Industry?

● What are the upstream raw materials and manufacturing equipment of High Temperature Mechanical Seal along with the manufacturing process of High Temperature Mechanical Seal?

● What are the key drivers, restraints, opportunities, and challenges of the High Temperature Mechanical Seal market, and how they are expected to impact the market?

4. Mechanical seals are suitable for water treatment systems, cleaning systems, seawater systems, ultrafiltration systems, and reverse osmosis systems.

8613371530291

8613371530291