mechanical seal catalogue manufacturer

Lidering Safe Industry Empreprise Secteurs Auxiliary Products LC LHP LQT LS LST Spring Seals Stationary Parts Special Designs RMS Seals Repair workshop,Quality control, checking and testing Certifications General Information Chemical Resistance Chart Compatibility Chart Related Products Consult our cartridges catalog Identification Guide Mechanical Seals Notes Axial Spring Seals: Conical FH / FHC FN / LS15 and FN.NU / LS15DIN LS18 / LS19 LS18B LS60IN / LS60IL RN / LS60 and RN.NU / LS60DIN RNB / LS60B and RN.NB / LS60BDIN Axial Spring Seals: Cylindrical I Slim LS40C

We are close to you... As time goes by, we feel extremely satisfied and proud to be able to contribute to and form part of a responsible, safe industry which is striving to build a better world and a safer future. We are convinced we can offer you a solution that will meet your expectations. Lidering was established in 1975 and specialises in designing, manufacturing, repairing and selling mechanical seals. We provide effective solutions worldwide. Our aim is to be recognised in the market for our accessibility and adaptability to the needs of our customers and the availability and...

Sectors Food and pharma The food and pharma sectors are especially demanding with respect to safety in their processes. It is very important to prevent contamination with the manufactured products and the halting of production lines during the entire work flow. For this reason, the use of CIP (Cleaning in place) or SIP (Sterilisation in place) processes is quite usual. The complex chemical mixtures (alkaline solutions) used in CIP processes may damage the seals of the mechanical seals in a short time, and in SIP, high temperatures reaching values of up to 150º C can destroy conventional...

In the chemical industry, the habitual processes require sealing elements for materials with high chemical resistance. For transferring very aggressive or corrosive chemical fluids that are clean or with particles and have high viscosities, along with high temperatures and pressures, the mechanical seal materials and the type of assembly must be correctly defined: single, double, external or in accordance with API plans. Furthermore, the applications require sealing systems that guarantee safety, preventing the leakage of corrosive or flammable products that could enter the atmosphere. In...

Sector Water treatment In water treatment operations, different processes are carried out in order to obtain a product that complies with the stringent health and legal legislation of each country. Even though water is the main element of the whole process and the main fluid used, the difficulties posed in sealing it are just as challenging as in other sectors. During the different treatments to which water is subject, the mechanical seals may come into contact with sediments, organic matter, dissolved substances such as calcium and magnesium (hard water), sulphate and carbon dioxide (acid...

Sector Maritime Pumps installed on ships must be extremely reliable and durable. Use of different machines: cooling pumps, fire fighting pumps or boiler supply pumps, meaning that the types of mechanical seals used in this industry are quite diverse. The main applications are for: • Cooling machinery • Firefighting systems. • Feeding boilers. • Pumping ballast water. A wide range of mechanical seal designs exist for this type of pumps, which operates in especially difficult conditions with high salt concentrations (this parameter varies, depending on the sea), at high pressures, etc. Within...

SPECIAL DESIGNS It is not always possible to use a conventional mechanical seal. Complex applications with special requirements and pumps with small housings need mechanical seals with non-standard profiles. Our engineering centre designs and manufactures customised solutions adapted to the specific needs of our customers, in large or small production runs.

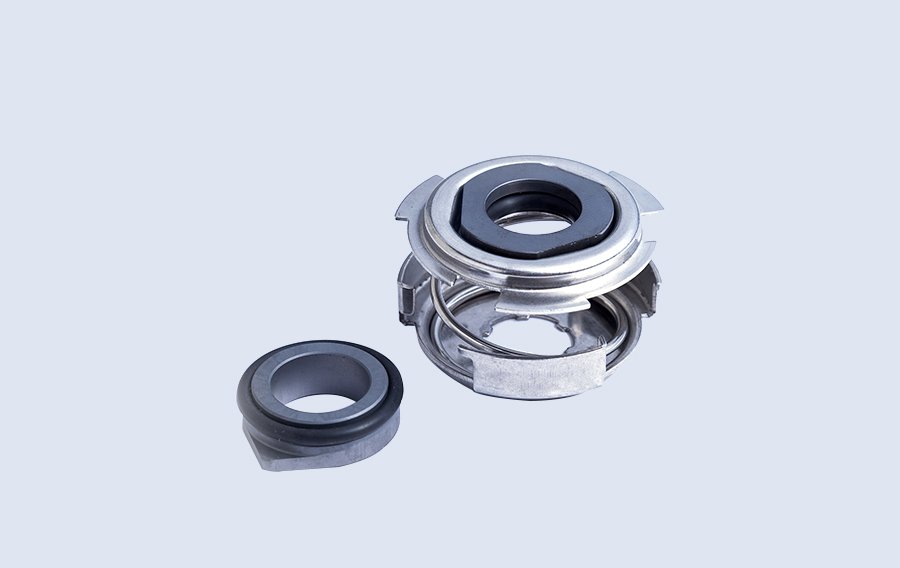

The RMS seal range is compatible with the most popular pump brands: Flygt®, Grundfos-Sarlin®, ABS®, Alfal Laval®, Hilge®, APV®, Fristam®, etc. These mechanical seals have special designs for wastewater pumps, heating, food products, pharmaceuticals and many applications in all kinds of industrial sectors. In most cases, when a pump is repaired, the mechanical seal is not the only element that is replaced. The renewal of other parts is also recommended, such as O-rings or joints with special profiles, bearings, pins, flat gaskets, etc. We offer kits containing these elements which are...

REPAIR WORKSHOP, QUALITY CONTROL Repair workshop Lidering’s modern, adequate equipment enables it to execute repair and transformation operations on mechanical seals and cartridges. The process commences by diagnosing the condition of the part, and after this, we execute the necessary processes for cleaning, polishing and lapping the contact surfaces, grinding parts and replacing components, etc. After carrying out these operations, the sealing of the repaired parts is checked by pressure test, to ensure that the part is ready for operation in any application that requires sealing of the...

CHESTERTON ® Providing value to industry since 1884 A.W. Chesterton Company is a leading international manufacturer and distributor of five distinct product lines. Each product line is positioned to provide value-driven solutions to meet industry needs. Polymer Seals Mechanical Seals Mechanical Packing and Gasketing Since 1884 we have worked closely with our customers to provide solutions that help them operate more reliably, efficiently, and economically. Advanced Reinforced Composites Technical Products A.W. Chesterton Company is ISO 9001/14001 and MRP II Class-A certified. Global...

MECHANICAL SEAL CATALOG The Chesterton Mechanical Seal Catalog is a starter reference source to help users identify standard mechanical seal recommendations. This comprehensive catalog includes product overviews, installation data, seal recommendations by fluid, environmental control plans, and technical reference sections. Section I Product Overviews covers the key benefits of our core product line of mechanical seals and seal support systems and includes cutaway and cross-sectional views of each. Section II Mechanical Seal Installation Data includes seal and installation dimensional data...

Section I — Cartridge Seals Mechanical Seal Catalog Heavy Duty Single Seal Offering maximum reliability in a wide application range The 180 compact chassis is designed to fit ANSI and API610 pumps with no modifications for ease of use. Advanced design features combined with a rigorous testing regime have yielded this “next step” single seal technology. Testing to ISO standards has shown the 180 to be a top performer for emissions control. Using finite element analysis, face designs have proven the dynamic emissions to be extremely low. The full featured Maximum performance for demanding,...

Mechanical Seal Catalog Section I — Cartridge Seals Heavy Duty Dual Seal A dual seal design for severe duty and greatest reliability in difficult applications The 280 is ideal for sealing viscous fluids and tough slurry applications such as paint, coatings, and black liquor—as well as heavy slurries in mineral/ore processing and raw material manufacturing. The 280 incorporates all the latest design advancements in mechanical sealing technology. Its geometric double-balanced design makes it the ideal choice for plant-wide standardization because it accepts process Superior performance for...

Section I — Cartridge Seals Mechanical Seal Catalog Standard Single Seal A single seal designed for plant-wide flexibility and ease of use The 155 low heat generation capability allows it to excel in a wide range of industrial sealing applications ranging from non-lubricating fluids to corrosive chemical environments. Low profile seal faces generate low heat, providing the best solution to non-lubricating fluids. Its simple design and broad range of materials offer the greatest means of repair and plant standardization. Versatile in fit and easy to install The innovative adjustable hub...

Mechanical Seal Catalog Section I — Cartridge Seals Standard Dual Seal A proven design and versatile performer providing reliable dual sealing capability in a wide variation of process and barrier fluids The 225 low profile seal faces generate low heat providing the best solution for heat sensitive fluids. This dual seal is ideal for corrosive services requiring high alloy materials. Designed with simplicity in mind, seal repair is easy and economical. Its geometric double-balanced design accepts pressure reversals easily in challenging chemical pump applications. Its integral pumping...

Section I — Cartridge Seals Mechanical Seal Catalog General Purpose Single Seal This seal is a value leader in its class The 150 is designed for baseline applications and for upgrading packed or component-sealed equipment. The cartridge design minimizes installation error, delivering higher reliability and improved housekeeping. When packed equipment can’t deliver the life cycle expected in a sealing solution, the 150 mechanical seal will increase reliability and address housekeeping concerns associated with packing. When component seals Simple upgrade to reduce plant maintenance costs are...

Mechanical Seal Catalog Section I — Cartridge Seals General Purpose Dual Seal This dual seal is a value leader in its class The 250 is designed for cost-effective upgrading from packing and underperforming single seals—further increasing plant reliability. The 250 is an ideal choice for baseline applications where the need for special alloys doesn’t exist. The off-set gland design is very efficient in barrier fluid exchange when compared to most other cartridge seals in its class. This design has Provides sealing security that conventional single seals cannot match improved heat removal....

Section I — Cassette Seals Mechanical Seal Catalog High Performance Single Seal Unique modular cassette that combines advanced seal technology with flexibility in maintenance and repair In the Streamline series of seals, all the wearing parts are contained in a single, replaceable cassette unit. Single and dual cassettes share a common universal gland. Repair becomes a matter of exchanging cassettes, making it faster and easier, while significantly reducing cost associated with repair. High performance sealing The S10 Streamline seal incorporates Chesterton advanced seal High torque...

Mechanical Seal Catalog Section I — Cassette Seals High Performance Dual Seal Unique modular cassette that combines advanced seal technology with flexibility in maintenance and repair In the Streamline series of seals, all the wearing parts are contained in a single, replaceable cassette unit. Single and dual cassettes share a common universal gland. Repair is a matter of exchanging cassettes, making it fast and easy, while significantly reducing cost associated with repair. The S20 Streamline seal incorporates Chesterton advanced seal technology into the cassette feature. The in-series...

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

Main catalog seal supply systems. The complete product portfolio of systems and components for cooling, flushing, pressurization and supplying liquid and gas-lubricated mechanical seals e.g., quench and thermosiphon systems, heat exchangers, barrier fluid systems, leakage monitoring and seal supply systems in accordance with API682.

Mechanical seals are end-face seals that use a pair of faces perpendicular to the rotating shaft (sliding surfaces) to seal. The sealing faces, smoothly finished with high accuracy, enable long-term maintenance-free usage.

Mechanical seals manufactured by Eagle Industry Co., Ltd. are products achieving excellent performance and low running costs that feature highly accurately finished flat sealing faces, enabling long-term maintenance-free usage.

Mechanical seals withstand usage in various applications in different pumps for automobiles, households, civil engineering and construction, and in processing and chemical fields such as petrochemicals, nuclear energy, and space development, and have a wide range of use.

8613371530291

8613371530291