silicon carbide mechanical seal factory

Silicon carbide faces in mechanical seal assemblies result in improved performance, increased seal life, lower maintenance costs, and lower running costs for rotating equipment such as turbines, compressors, and centrifugal pumps. CoorsTek seal faces help reduce the possibility of leakage and catastrophic failure to safeguard the environment from the risk of fugitive emissions. They also lower energy consumption with reduced friction on startup and shutdown, as well as reduced wear and erosion during operation.CoorsTekseal faces are exceptionally durable and help increase the mean time between failures,resulting in greater productivity and lower total cost of ownership for processing equipment.

Distributor of industrial tools & equipment. Products include abrasives, adhesives, bushings, coolants, boring bars, broaches, hand tools, cutters, tool holders, coatings, cleaners, reamers, lubricants, drills, fasteners & gauges. Positioners, knives, brushes, crimpers, cylinders, adhesive dispensers, drill presses, acutators, seals, bulbs, lamps, lifts, pins, polishers, fittings, pumps, punches, saws, sealants & wrenches are also available. Capabilities include sharpening, kitting, repairing, vending, fabricating, heat treating, outsourced storeroom management, reverse engineering, band saw welding, calibration, hardening, bar coding, inventory & process consulting & outsourced procurement. Kan Ban programs.

Due to their advanced performance characteristics, Morgan silicon carbide materials are used across many challenging industrial applications. Their robust properties make them ideal for use as mechanical components and wear parts that are specified in applications such as but not limited to:

Take advantage of amazing silicon carbide mechanical seals at Alibaba.com. Choose the most applicable to you according to your specifications. You will discover incredible effectiveness with them and appreciate that they are worth every coin. If you are a business person, enjoy captivating discounts tailored for silicon carbide mechanical seals wholesalers and suppliers and increase your profitability.

Did you move into a new house? Are you looking into making the doors and windows by yourself? Need a sealant to get the job done? Look no further, and browse wholesale silicon carbide mechanical seals on Alibaba.com to find the solution to your problems! Are your neighbors making too much noise? Get that window seal to make sure less sound goes through the window to enjoy your weekends" peace! silicon carbide mechanical seals on Alibaba.com are made of quality materials and made by leading manufacturers. Get them to better soundproof your house now!

Are you looking for a wholesale silicon carbide mechanical seals for your personal use or your shop? Look no further; Alibaba.com has everything you need and can provide all the required rubber products. The products have been widely and popularly used ever since their inception. The demand for rubber products has increased lately in modern society due to their; strength, durability, and the ability to be applied in many different fields. The dealers offer all types of rubber products available on the market. Visit Alibaba.com and order your preferred sil carb mechanical mechanicalalsals at an affordable price thanks to reputable Alibaba.com dealers.

![]()

3) Other mechanical parts and related seals includingmade to order Silicon Carbide seal rings, sintered silicon carbide seal rings, graphite carbon seal rings ,tungsten carbide seal rings, O rings, springs, CNC machining service.

water pumps, chemical industry, pump mechanical seals,kettle with mechanical seals,fan mechanical seals,separation machinery, washing machines, high temperature dyeing machine, reducer, reciprocating compressor crankcase and other mechanical equipment mechanical seals

With our diverse selection of tungsten carbide and silicon carbide materials, we can recommend the appropriate grade of material to optimize the performance of your unique fluid handling applications. Our years of industry experience create value for our customers as we work with them to develop highly engineered carbide components for their fluid handling needs. In particular, we specialize in tungsten carbide and silicon carbide seal faces for:

The benefits we offer not only come from our industry knowledge and engineering capability but also from our control over the entire carbide manufacturing process. From powder processing to press and sintering, from finished product grinding, machining and lapping to full carbide and metal assemblies, Penn United Technologies - Carbide Division is your one-stop-shop for quality carbide components.

Lepuseal was founded in 1998, located in Guangzhou, China. We focus on manufacturing mechanical seal and seal spare parts in the past 20 years. now lepuseal is one of the leading mechanical seal manufacturer in china, and maybe the best cartridge mechanical seal manufacturer in south of china.

Lepuseal have more than 20 years experience in manufacturing mechanical seal, we established a strong technology team include 20+ engineer R&D team, more than 150 skilled workers team, more than 10 person quality control team, that help us to provide strong technology support to our users.

Lepuseal have more than 10000 square meters workshop and 60+ advanced CNC machine to provide strong ability for production. And make sure we can offer fast delivery service to our clients.

Tungsten carbide mechanical seals had been the preferred thing for several years. However, in recent times, they have been replaced by a strong competitor, silicon carbide seal faces. What could be the secret of this change of preference? Well, it is because of some prominent benefits.

This blog, not just rates rate a particular type of seal face higher to the other, but it gives a comprehensive analysis of the two. Thus, a user may pick the most suitable seals for the application.

The seal has two parts- one stationary and one rotating. The rotating or stationary part is made from either of the two materials that is used in the seal.

The coefficient of friction in a silicon carbide seal is lower. Hence, the seal wastes lesser energy and prevents the seal from locking up when it is inactive.

As far as the user standpoint is concerned, the manufacturing of Silicon carbide is at high volume. Therefore, its price is cheaper,and the lead time is shorter than a tungsten carbide seal.

As a hard face in the majority of the seal applications, silicon carbide outperforms tungsten carbide. With its tribological properties, it offers a lower coefficient of friction and long life.

A silicon carbide seal with a silicon carbide impregnated with graphite will be effective in extreme pumping conditions such as heavy slurry. It brings higher corrosion and abrasion resistance. It checks heat and offers lower resistance to face damage.

These comparisons are based on the widespread industrial usage experience and research. However, you should ask experts for the best suitable seal before buying one because every situation offers different challenges.

Leak-Pack is ISO 9001:2008 certified company and leading mechanical seals manufacturer & supplier in India, providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

We are manufacturing seal in different types of material like Carbon, CY 10, Carbon filled Teflon, Antimony , SiC (Silicon Carbide), Ceramic, Tungstun Carbide (TC)

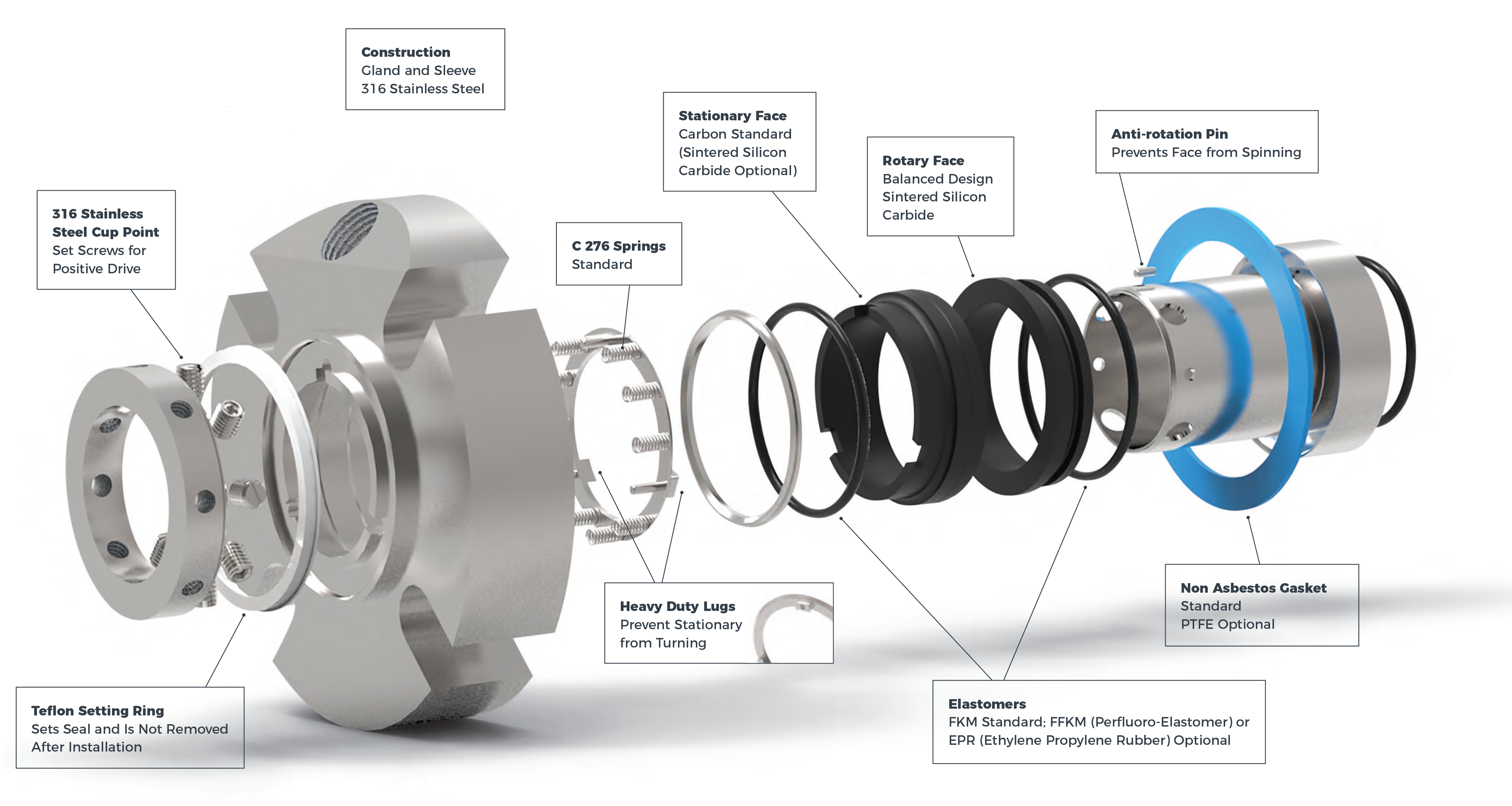

FSI Series 1015 mechanical cartridge seals are a premium grade product without the premium price. They"re ideal for use with most ANSI and DIN (standard and big bore) pumps and other types of pumps and rotating equipment. They have the following features:

8613371530291

8613371530291