allweiler ntt pump mechanical seal brands

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

Since the 1860’s, *Allweiler® Pumps have been produced in Germany making them one of the oldest pump manufacturers in Europe and worldwide. *allweiler"s® innovative designs and technology have made them recognized leaders in Pump manufacturing.

At Shanley Pump and Equipment, Inc. we stock *Allweiler® pumps and replacement parts for whatever your pumping necessity. We have the right pumps for many applications and every industry.

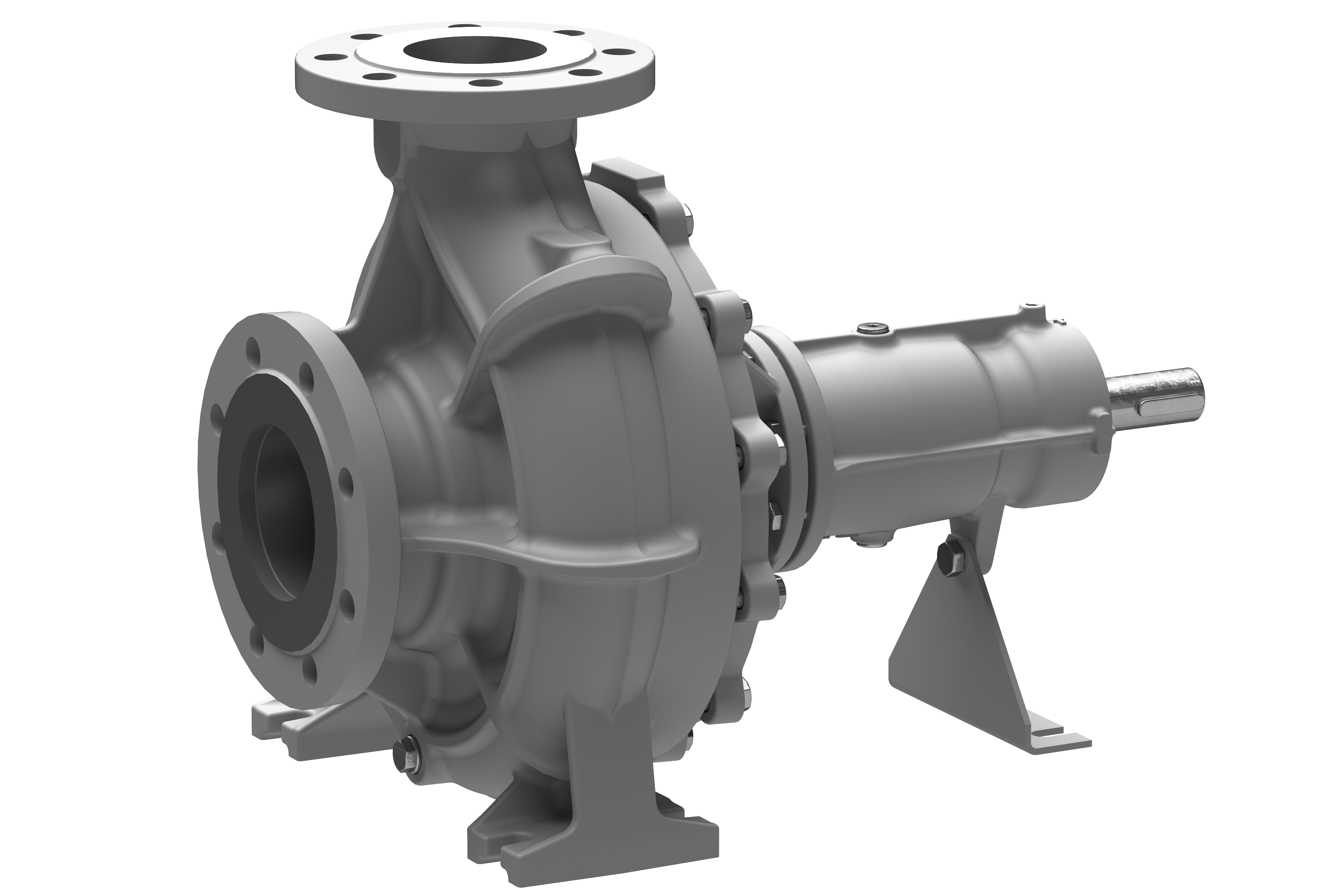

The *Allweiler® NTT Series Centrifugal Pump for heat transfer applications is an ideal solution for the handling of organic heat-transfer oils. The NTT"s unique self-cooling design eliminates the need for additional cooling in any form due to its self-cooling design during operation.

At Shanley Pump and Equipment, Inc. we stock a complete line of *Allweiler® NTT thermal oil pumps. These are horizontal centrifugal pumps that are capable of pumping thermal oil at 660° degrees F (350°C) at up to 6,400 GPM with up to 430" feet of head and require no additional cooling.

Application of the pump: heating heavy oils, fuel oil, in the production of asphalt and roofing cardboard, drying plants, agitators, the production of mineral wool, the supply of hot glue, varnish in the furniture industry, the production of tires, rubber in the automotive industry, the entire rubber and plastic industry - heating presses, smelting boilers, processing of dark oil products - heating bitumen tanks at oil depots, tankers, oil industry - heating vehicles, pipes and storage facilities, preheating oils, in the production of bitumen, heating main pumps on an oil pipeline, impoverished industry - heating bakery and roasting ovens, installations for the production of fatty acids, edible oils, glycerin, dry masses, textile, leather and pulp and paper industry - heating of calenders, drying chambers, rollers, drying cylinders, paint and varnish industry - heating of mixers and mixing tanks, laundry factories: heating in dryers, ironing machines.

Allweiler"s NTT single-channel centrifugal pumps have a practical modular design and are designed for mounting a drive unit with a base plate (cast iron or steel), DIN EN 733. Ideal for pumping high-temperature oils in various industries. The lineup is represented by a wide selection of dimensions for the selection of the optimal option. One- or two-stage design, mechanical shaft seal, efficient self-cooling. The outlet is directed radially upward, the suction is coaxial, the bearings are maintenance-free. On request, it can be equipped with a spacer coupling. Three-phase squirrel-cage motors on feet are used as a drive in the standard.

Mechanical seal for pump Allweiler NTT 25-16, NTT 25-200 NTT 2 /25-20 NTT 32-160 NTT 32-200 NTT 2 /32-20 NTT 40-160 NTT 40-200 NTT 40-250 Allweiler NTT 2 /40-250 NTT 50-160 NTT 50-200 Allweiler NTT 100-160 Allweiler NTT Allweiler NTT 65-200 Allweiler NTT 80-200 Allweiler NTT 80-2NTT 100-200 NTT 100-250 NTT 125-250 LV 25/2, LV 25 /3, LV 25/4, LV 25/5, LV 25/6, LV 25/7, LV 25/7, LV 25/9, LV 25/10, LV 25/11, LV 25/12, LV 25 /13, LV 25/14, LV 25/15 V 32/2, LV 32/3, LV 32/4, LV 32/5, LV32 /6, LV 32/7, LV 32/7, LV 32/9 , LV 32/10, LV 32/11, LV 32/12, LV 32/13, LV 32/14, LV 32/15 LV 40/2, LV 40/3, LV 40/4, LV 40/5, LV 40/6, LV 40/7, LV 40/7, LV 40/9, LV 40/10, LV 40/11, LV 40/12, LV 40 LV 50/2, LV 50/3, LV 50 /4, LV 50/5, LV 50/6, LV 50/7, LV 50/7, LV 50/9, LV 50/10, LV 50/11, LV 50/12 LV 65/2, LV 65/3 , LV 65/4, LV 65/5, LV 65/6, LV

The NTT, NBT and NIT product series are ideal for moving mineral-based thermal oils. Their mechanical seals are located behind a heat barrier, where they are protected from high temperatures. The result is that simple standard gaskets (antimony-carbon/SiC) have a very long service life when used in the pumps. All three types are also available as two stage versions with the same external dimensions, making them ideal for small flow rates with high delivery head.

The ALLHEAT series gives plant operators centrifugal pumps that were designed specifically for high-temperature applications employing low-viscosity heat carriers like synthetic thermal oils and hot water. These pumps have unrivalled versatility; they forgo external cooling and are extraordinarily durable in continuous operation. Very little heat is lost by the entire system and maintenance intervals are usually longer than twelve months even when operated continuously under difficult conditions. The CBWH and CIWH series are the world"s only block-type pumps with an air-cooled shaft seal that pump hot water above 183 °C/361 °F without external cooling. Due to their maximum oil temperature of 400 °C/752 °F, CTWH, CBWH, and CIWH 350°C/662 °F are also ideal for modern applications like solar power stations.

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Mechanical seal to the pump Allweiler: NTT 25-160, NTT 25-200, NTT 2/25-200, NTT 32-160, NTT 32-200, NTT 2/32-200, NTT 40-160, NTT 40-200, NTT 40-250, NTT 2/40-250, NTT 50-160, NTT 50-200, NTT 50-250, NTT 2/50-250, NTT 65-160, NTT 65-200, NTT 80-160, NTT 100-160.

Mechanical seals for pump series Allweiler: AEB, ALLCHEM CNH-B, CNB, CNI, ALLMAG CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, NSL, NST, MI, MA, NISM, NIM, NAM, NAM-F, ALLUB NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF10, SPF20, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S.

The mechanical seal design consists mainly of two parts: a moving part and a stationary part. The stationary part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the stationary part by means of a spring.

The mechanical seal is sealed by secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to select the material of the secondary seals and the friction pair.

Application of the pump: heating heavy oils, fuel oil, in the production of asphalt and roofing cardboard, drying plants, agitators, the production of mineral wool, the supply of hot glue, varnish in the furniture industry, the production of tires, rubber in the automotive industry, the entire rubber and plastic industry - heating presses, smelting boilers, processing of dark oil products - heating bitumen tanks at oil depots, tankers, oil industry - heating vehicles, pipes and storage facilities, preheating oils, in the production of bitumen, heating main pumps on an oil pipeline, impoverished industry - heating bakery and roasting ovens, installations for the production of fatty acids, edible oils, glycerin, dry masses, textile, leather and pulp and paper industry - heating of calenders, drying chambers, rollers, drying cylinders, paint and varnish industry - heating of mixers and mixing tanks, laundry factories: heating in dryers, ironing machines.

Allweiler"s NTT single-channel centrifugal pumps have a practical modular design and are designed for mounting a drive unit with a base plate (cast iron or steel), DIN EN 733. Ideal for pumping high-temperature oils in various industries. The lineup is represented by a wide selection of dimensions for the selection of the optimal option. One- or two-stage design, mechanical shaft seal, efficient self-cooling. The outlet is directed radially upward, the suction is coaxial, the bearings are maintenance-free. On request, it can be equipped with a spacer coupling. Three-phase squirrel-cage motors on feet are used as a drive in the standard.

Seals with shaft size 0.97, 1 inch, 1.375 inch, 1.813, 1.875 inch, 2 inch, 3 inch, 4.5, 10 mm, 11 mm, 12 mm, 14 mm, 15 mm, 17, 21, 22 mm, 23, 26 mm, 27, 30 mm, 34, 35 mm, 42 mm, 48 mm, 50 mm, 53 mm, 55 mm, 57, 58 mm, 60 mm, 63 mm, 65 mm, 67, 68 mm, 72, 73 mm, 74, 75 mm, 76, 80 mm, 85 mm, 95 mm, 110, 120, 190, 200, 242, 260, 270, 275, 300, 335, 385

Mechanical seals are available in a variety of sizes, including 0.97 or 1 inch or 1.375 inch or 1.813 or 1.875 inch or 2 inch or 3 inch or 4.5 or 10 mm or 11 mm or 12 mm or 14 mm or 15 mm or 17 or 21 or 22 mm or 23 or 26 mm or 27 or 30 mm or 34 or 35 mm or 42 mm or 48 mm or 50 mm or 53 mm or 55 mm or 57 or 58 mm or 60 mm or 63 mm or 65 mm or 67 or 68 mm or 72 or 73 mm or 74 or 75 mm or 76 or 80 mm or 85 mm or 95 mm or 110 or 120 or 190 or 200 or 242 or 260 or 270 or 275 or 300 or 335 or 385. Selecting the right size mechanical seal is important for optimal performance and reliability. A mechanical seal with the correct shaft size ensures an accurate and secure fit on the pump shaft, distributing pressure correctly and preventing leakage.

Mechanical seals specifically suited for pumps can make a significant difference in the performance and reliability of your system. Mechanical seals from brands such as Allweiler are designed to meet these challenges, providing a reliable and durable seal for pumps in a wide range of applications. Whether conveying chemicals, water, oil or other liquids, Allweiler mechanical seals are tested and proven to provide high performance under various conditions. Plus, these seals are easy to install and maintain, which means you can spend less time on maintenance and more time doing what you do best.

8613371530291

8613371530291