allweiler ntt pump mechanical seal made in china

Since the 1860’s, *Allweiler® Pumps have been produced in Germany making them one of the oldest pump manufacturers in Europe and worldwide. *allweiler"s® innovative designs and technology have made them recognized leaders in Pump manufacturing.

At Shanley Pump and Equipment, Inc. we stock *Allweiler® pumps and replacement parts for whatever your pumping necessity. We have the right pumps for many applications and every industry.

The *Allweiler® NTT Series Centrifugal Pump for heat transfer applications is an ideal solution for the handling of organic heat-transfer oils. The NTT"s unique self-cooling design eliminates the need for additional cooling in any form due to its self-cooling design during operation.

At Shanley Pump and Equipment, Inc. we stock a complete line of *Allweiler® NTT thermal oil pumps. These are horizontal centrifugal pumps that are capable of pumping thermal oil at 660° degrees F (350°C) at up to 6,400 GPM with up to 430" feet of head and require no additional cooling.

Any use of company names, trademarks, model no, item no or part no is only for reference purpose only, Sino-Seals Co,.Ltd is not an authorized distributors or serives for the products of any company mentioned in this website

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Allweiler GmbH, a business unit of CIRCOR, was founded in Germany in 1860. As a German manufacturer of pumps, today Allweiler is a leading supplier in the fields of shipbuilding, power generation and special industrial applications. Its product portfolio includes centrifugal pumps, propeller pumps, screw pumps, as well as complete pump systems.

Allweiler GmbH is a premium manufacturer of pumps of all styles and types. In addition to individual pumps, they also offer a variety of complete pump units for various industry applications. So you can save money as early as the proposal stage and continue to benefit from simplified installation, maintenance of the pumps.

As one of trusted Allweiler mechanical seal suppliers in China for years, OKmarts can provide a broad series of Allweiler mechanical seals/ Allweiler mechanical shaft seals. Here you can get the quickest response, largest available inventory, shortest lead times and competitive Allweiler mechanical seal price.

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

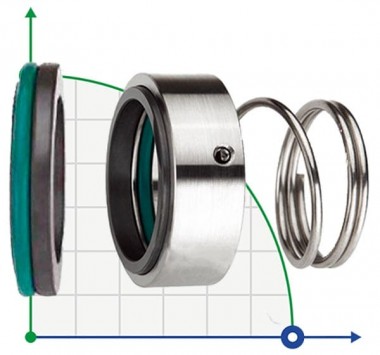

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

Circor International Inc has recently supplied three NTT 250-400 thermal oil pumps with variable frequency drive (VFD) for use on a medical glove production line in Yingke, China.

Working together, the application team in Germany and the sales team in China delivered the pumps in just 10 weeks, considerably shorter than average.

At an operating temperature of 280°C and almost atmospheric inlet pressure, the application requires a flow rate of 900 sq m per hour at 55 meters head. The NTT pump’s compact design enables it to operate at 1800 revolutions per minute (rpm), which is necessary to achieve the required flow rate.

Specially designed for thermal oil applications, the NTT pumps can handle high temperature and avoid thermal expansion problems during heat up and cool down phases. The mechanical seals are designed to avoid dangerous spillage of hot oil during normal operation or in the event of seal failures. High temperature anti-friction bearings ensure nearly maintenance free operation. To control the pump speed, the pumps are equipped with a VFD to provide the electrical power at the required frequency to the 4-pole induction-motor.

Application For handling organic heat-transfer oils in heat transfer plants (DIN 4754). The fluids pumped must not contain any abrasive particles nor chemically attack the pump materials. Main Fields of application Chemical and pharmaceutical industry: Heating and drying plants, stirring apparatuses, autoclaves, reaction tanks, in plants for the production of synthetic fibres, plastics, lacquer raw materials, in mixing and storage facilities for viscous media. Food industry: Heating of baking and roasting ovens, plants for the production of fatty acids, edible oils, glycerine, dry pastes. Textile, leather and paper industry: Heating of calendars, drying chambers, rolls, drying cylinders. Rubber and plastic industry: Heating of presses, automatic injection, moulding machines, calendars, fusion kettles. Paint and lacquer industry: Heating of agitators and mixing vessels. Tar and bitumen-processing industry: Heating of storage tanks, tankers, for heating up heavy oil, in asphalt processing and roofing-felt production. Mineral-oil industry: Heating of transportation means, pipes and storage installations, for pre-heating of oils, in the bitumen production. Laundries: Heating of dryers, hot mangles, automatic ironing machines.

Delivery With the sizes according to DIN EN 733, the delivery considerably exceeds the standard nominal capacity. With further sizes, the performance range was extended in both directions, viz greater and smaller deliveries, for the economic operation of smaller heat-transfer plants. Shaft sealing By means of uncooled, maintenance-free mechanical seal of the unbalanced type. A safety stuffing box with a following throttling area is arranged in front of the mechanical seal. Even in case of failure of the mechanical seal, these additional safety elements prevent seepage from the emerging in a hazardous quantity and manner. The requirements according to DIN 4754 are thus exceeded. It is ensured that any heat-transfer seepages emerging from the shaft sealing are safely drained through leakage outlet LO, and completely collected. Owing to a special design of the built-in unit, the temperature is reduced to such an extent that proper functioning of the bearing and shaft sealing is ensured. Shaft sealing

Type and series construction Horizontal, single- and two-stage, single-flow volute casing centrifugal pumps with axial inlet. The pump dimensions are according to DIN EN 733. The series contains additional sizes with dimensions exceeding to the standard.

Series design according to unit assembly system. Shaft bearing in a bearing bracket equipped with a support foot. Volute casing with cast-on feet. Sizes NTT 2/25-200/01, 2/32-200/01, 2/40-200/01 and 2/50200/01 are double-stage, but in their outer dimensions, they correspond to the respective single-stage sizes. Owing to the two-stage design, relatively small delivery flows are achieved with the great delivery heads, good efficiencies and low NPSH values.

Series NTT All coupling types and base plate designs can be combined with each other. With our interactive system ALL2CAD, you will get the aggregate dimensions. Drive Surface-cooled, three-phase squirrel cage induction motors, IM B3 type of construction, enclosure IP 55 according to IEC Standard, class F insulation, capacities and main dimensions according to DIN 42673. Materials Inlet pressure (ps ) plus maximum delivery head must not exceed the curve values for the final pump pressure (pd ).

Bearing and lubrication By means of two grooved ball bearings C4 DIN 625 with the one on the pump side being lubricated by the fluid to be pumped, the one on the driving side by special grease.

* According to DIN 4754 for the safe draining of the heat transfer seepage quantities emerging from the shaft sealing. Shaft coupling and accidental contact protection Flexible shaft coupling according to DIN 740 without or with spacer. A coupling guard as protection against accidental contact according to DIN 31001 is supplied as soon as the scope of supply includes pump, base plate and shaft coupling. Two coupling types are available: single flexible and double cardanic coupling. The pump sizes with bearing bracket size 470, nominal impeller diameter 315 and 400 and the pump sizes with bearing bracket sizes 530 and 650 will be equipped with double cardanic couplings.

Explosion protection The pump fulfils the requirements according to EC Explosion Protection Directive 94/9EG (ATEX 100a) for equipment and equipment group II, category 2 G. Categorisation into temperature classes according to EN 13463-1 depends on the temperature of the pumped medium. The max. permissible temperature of the pumped medium for the respective temperature classes are shown in the order specific data sheet. Note: In case of the operation of a category 2 pump, the unacceptable heating of the pump surfaces caused by a possible operational fault must be prevented by a control mechanism. In case of an operation with know parameters (Q, H, υ, ρ = const.), a pump performance controller can be supplied with the pump to detect any operational faults.

Hydraulic No. Actual impeller diameter Shaft sealing Material design The abbreviation is displayed on the nameplate. With the two-stage sizes, the actual impeller diameter relates to the second stage. " With the two-stage sizes, the number of stages is placed with an oblique stroke in front of the nominal width of suction branch, e.g. 2/32-200/01/...

Denomination Mechanical seal Gland packing Intermediate ring Threaded ring Nilos ring Spacer sleeve Tension sleeve Disc Disc spacer Disc spacer Disc spacer Rivet Rivet Pipe Hexagonal screw Hexagonal screw Hexagonal screw Hexagonal screw Stud bolt Screwed plug Screwed plug Screwed plug

ALLWEILER solutions Successful in important branches Decades of experience and branch-specific know-how ensure solutions that are practical and dependable. In addition to individual units with a motor or with a free shaft end, you can get complete systems and customer-specific cast parts from ALLWEILER AG. You are not just investing in machines with ALLWEILER AG. You are also profiting from decades of know-how about applications and processes in your branch. You will find pumps and systems by ALLWEILER AG in the following sectors:

Stainless steel pumps with CIP and SIP design, EHEDG and FDA certified. Especially for the careful delivery and proportioning of even sticky, paste-like and solids-rich media.

! Tool Machinery ! Water and Wastewater Pumps for water treatment; share of dry solids content up to 45 percent; macerators, which make is possible to pump delivery media that are high in fibre and solids.

! Pulp and Paper ! Process Engineering and Chemical Industry (ATEXconformity) Shaft bearing, shaft seal and material designs in accordance with the chemical characteristics of the delivery media. Magnetic coupling for hermetically sealed pumps.

Pumps with extremely high availability (24 hours; 365 days) and many sizes, starting with small proportioning pumps and ranging to large Kaolin feeding pumps.

ALLWEILER AG Postfach 1140 " 78301 Radolfzell Allweilerstr. 1 " 78315 Radolfzell Germany Tel. +49 (0)7732 86-0 Fax. + 49 (0)7732 86-436 E-Mail: [email protected] Internet: http://www.allweiler.com VM 500 GB/09.04 – Ident No. 795 277

The order was for eight pumps for PET production, 140 glycol pumps, and 20 thermal oil pumps for the plant s primary and secondary loops. The pumps delivered to Wujiang will be used to expand a polyester production plant. According to Stefan Kleinmann, Vice-President of the Industry business segment and member of the Allweiler AG executive board: "Allweiler AG won this contract because the operator of the plant has been using our pumps with great success since 2003. The long-term and very effective support provided by our subsidiary in Shanghai was another reason."

The pumped liquid can reach temperatures as high as 280° C during production of synthetic yarns. For this reason, the pumps are manufactured from 1.4581-grade stainless steel, a highly heat-resistant material. The special metal bellows-type seals are also designed to handle these high temperatures. The CNH-B series pumps are equipped with supplemental heating because liquid polyester begins to solidify below 250° C. Capacity is 400 m³ per hour at a pressure of approximately 14 bar; drive power is 180 kW.

Allweiler s largest chemical-standard pumps from the CNH-B series in size 200-500 are used to move thermal oil in the primary loop. This series reaches a capacity of 1200 m³ per hour at a maximum pressure of 25 bar and a maximum delivery head of 147 m. Liquid temperature can be as high as 350° C. Pumps of types NTT and NTWH are used in the secondary loop, depending on the liquid properties. In this application, the "Therminol" heat transfer oil reaches temperatures of 330° C and higher.

8613371530291

8613371530291