api 682 mechanical seal data sheet excel pricelist

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

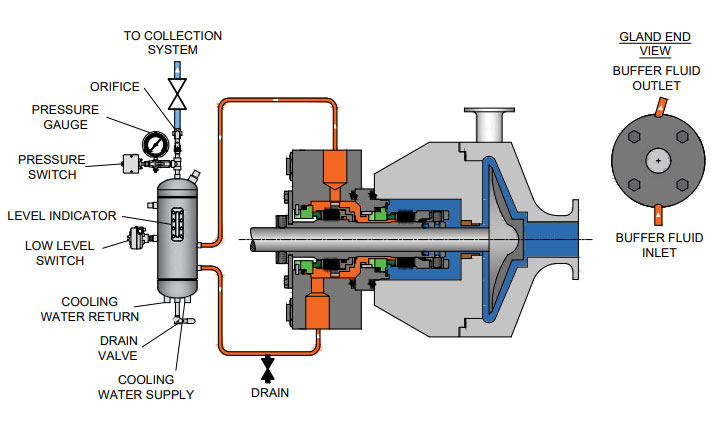

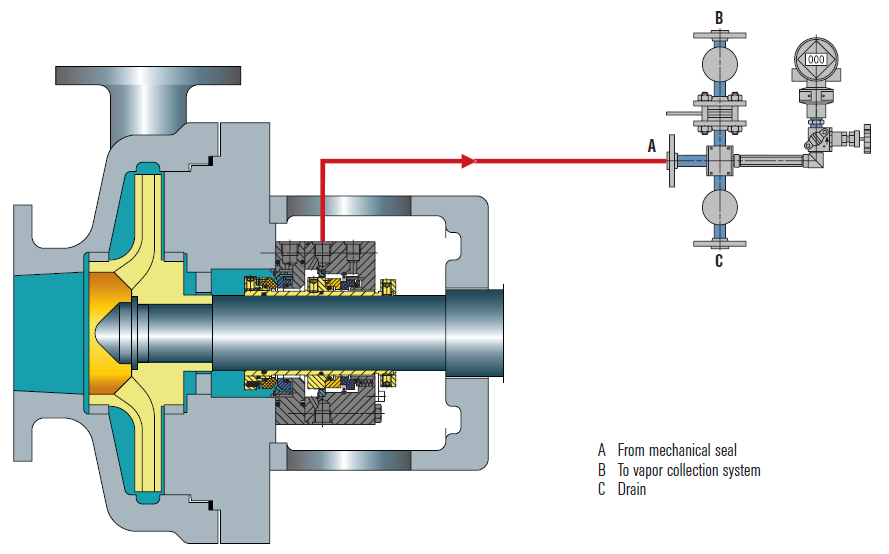

API 682 Seal. Viking’s seal chamber will accept almost any customer-specified brands and types of API 682-compliant Category 1, 2 or 3 cartridge mechanical seals, and can provide API seal plans to meet application requirements. Standard seal is a category 2 single mechanical seal. Carbon vs. silicon carbide with API Plan 13.

3mm corrosion allowance above Maximum Allowable Working Pressure (MAWP). The XPD 676 has an additional 3mm corrosion allowance built into all pressure containing components over and above our standard steel Universal Seal series pumps.

Casing drain and seal chamber vent. XPD 676 has cast-in casing drain with ANSI Class 300 RF flange and seal chamber vent to completely drain the casing before maintenance.

Certified performance testing in accordance with Section 3.6 of the Hydraulic Institute pump standards, at the specified viscosity (from 28 to 25,000 SSU), with data including speed, discharge pressure, suction pressure, power, and capacity. Viking XPD 676 pumps carry a five year limited warranty.

Data sheets applicable to proposals, purchase & as-built • Installation manual • Operation & Maintenance manual • Spare parts recommendations & price list • List of drawings & submittals

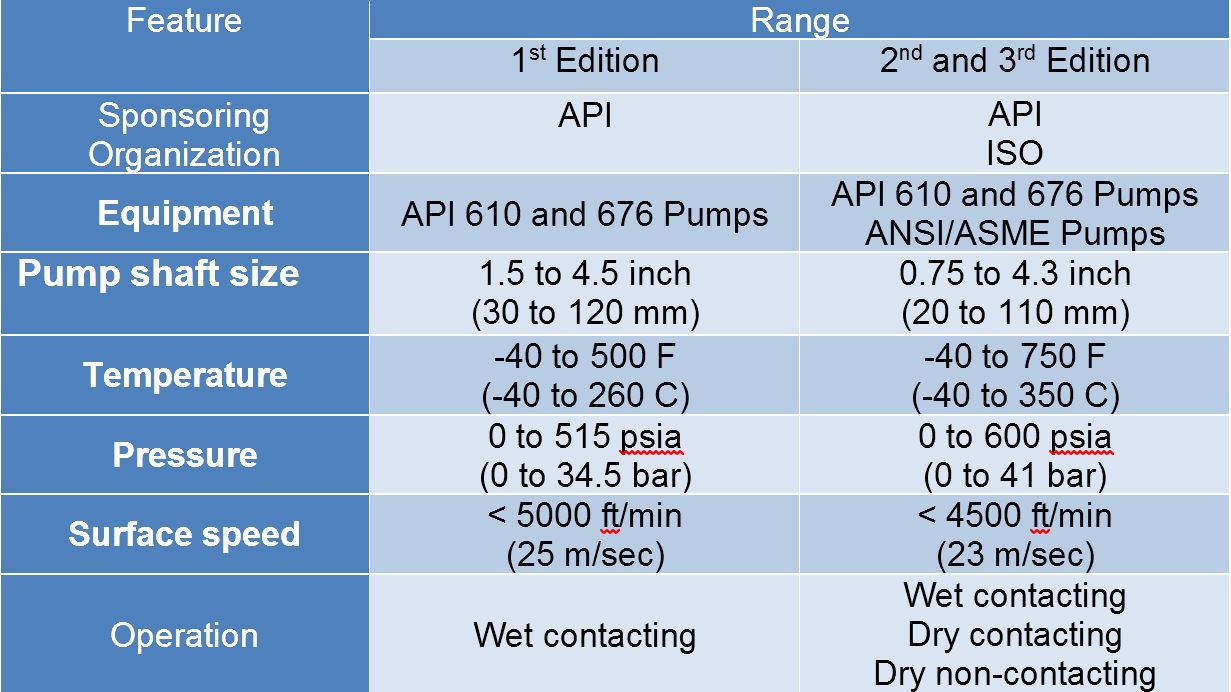

The APILITE (R) mechanical seal is a new addition to the API 682 RDT cartridge seal family. It is designed for sealing heavy and light hydrocarbons, including VOCs, and other hazardous fluids at oil refineries and petrochemical plants, gas plants, and chemical plants. APILITE RDT seal is an o-ring dual seal to be used with API Plan 52, 53, or 54.

Minimized bending of seal rings allows for stable operation under higher pressures and for longer MTBR (mean time between repair) because of less wear;

Interchangeability of many parts and design solutions with the SD APITERM seal reduces inventory of spare parts, lets the seal survive under pump dry-running, and decreases prices by encreasing parts production volume;

8613371530291

8613371530291