api plan 52 mechanical seal for sale

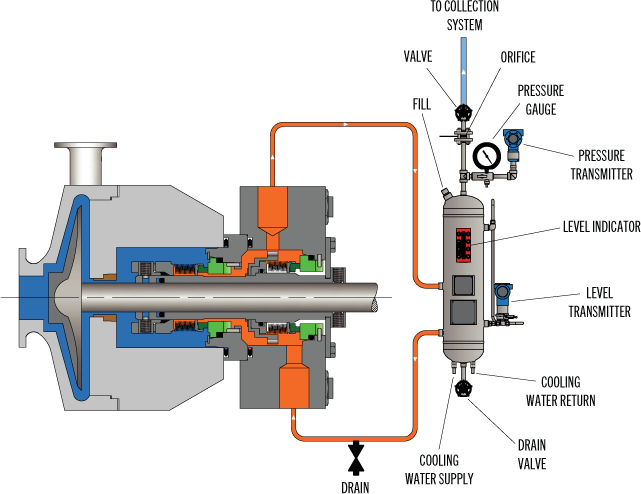

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

1. Keep the sealant vessel vent continuously open, which is necessary to maintain buffer fluid pressure close to atmospheric pressure and vent the vapors to flare.

API Seal Plan 52 utilizes a reservoir and circulates an unpressurized buffer fluid between the inboard and outboard seals. To provide positive circulation through the support system and into the seal, a pumping ring is employed. Frictional losses in the buffer fluid inlet and outlet lines should be minimized by selecting the proper tube size, using large radius and/or 45 degree bends, and reducing the length of tubing runs. Seal Plan 52 is commonly used with light hydrocarbons or fluids with a high vapor pressure. The buffer fluid must be compatible with process fluid as inboard seal leakage will eventually mix with the buffer fluid.

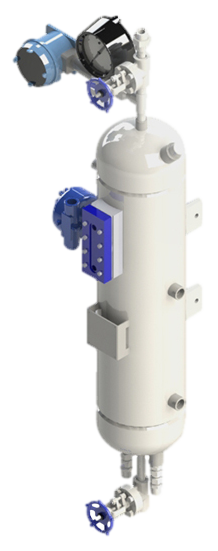

Plan 52 is available as a seal pot assembly. The associated field installation kit for use in connecting the seal pot assembly to your system is also available. Assembly components may include:

See page 31 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.

Circulation of buffer liquid to and from the reservoir is dependent on thermal siphoning and/or an internal circulating device (pumping ring) inside the seal.

The MP52 series aligns with API 682 Plans 52 and 53A. The Plan 52 is designed to support liquid buffer fluid for a containment seal chamber that is below the seal chamber pressure. The Plan 53A is a pressurized system designed to isolate the seal from the process completely by providing liquid barrier fluid at a pressure higher than the seal chamber.

Our seal reservoirs are built to ASME Section VIII standards and are available with ASME U code stamps. Flexaseal Engineered Seals and Systems, LLC provides standard and custom buffer fluid reservoirs that meet API 682 Standards. As an industrial seal pot manufacturer for the chemical, petrochemical, and industrial industries, our seal pot systems help protect the environment and your workers from hazardous materials.

These reservoir-based seal support systems are designed for both API Plan 52 and 53A applications to support unpressurized and pressurized dual seals. Circulation of buffer/barrier fluid is normally achieved with a pumping ring (or optional circulating pump), and a range of heat exchangers can be packaged with the system — selection dependent on available plant utilities.

Flowway Teknik design and manufactures seals and associated products mainly for the oil and gas, chemical, pharmaceutical, pulp and paper, power, mining and many more industrial applications. Today, it provides the most complete selection of engineered mechanical seals and sealing support systems. Our products are recognized as a trusted brand in a process industry.

In this plan external reservoir provides buffer fluid for the outer seal of an un-pressurized dual seal arrangement (Arrangement 2). During operation an internal pumping ring provides circulation. The reservoir is connected to a vapour recovery system and is maintained at a pressure less than the pressure in the seal chamber. It is normally used for the applications where process fluid leakage to atmosphere must be minimised and contained. Plan 52 works best with clean, non-polymerising pure products that have vapour pressure more than the buffer system pressure. Leakage of higher vapour pressure process liquid into buffer system will flash in the seal pot and escape into the vent system.

The operating principle of this seal plan accepts a certain product leakage. So inevitably, the inboard seals will pass pump product – mind the seal faces – and may transform the buffer fluid into (hazardous) chemical waste.

Also, contrary to expectations, the low operating pressure of a plan 52 will not buy an inexpensive low-pressure design. It is common practice – and API 682 specified – to have the plan 52 seal support systems designed for the same pressure and temperature ratings as the pump. So the non-pressurized dual seal plan 52 solution will not save (much) compared to the pressurized plan 53 solutions. That is why for dual seal applications we would generally recommend the pressurized plan 53(B) solution as it has quite some advantages – explained elsewhere.

The non-pressurized plan 52 solutions should be considered though, for high purity applications where the pumped product accepts no contamination or when high sealing pressures would result in excessive heat loads.

Non-pressurized dual seal plan 52 solutions work best for clean, solids-free and non-polymerizing products with a vapour pressure that is higher than 1.1 bar-a at lowest ambient. It is better not used for products with a low(er) vapour pressure, nor products that are highly dangerous or lethal, like H2S gas.

![]()

Cyclone separators are typically used in an API Plan 31 arrangement and incorporated in the seal flush line (API Plan 11 ) from the discharge of the pump.

53B accumulator-based seal support systems utilize a bladder to maintain system pressure to pressurized dual seals and absorb barrier fluid thermal expansion while separating the pressurizing gas and barrier fluid.

53C accumulator-based seal support systems utilize a piston to maintain system pressure to pressurized dual seals and absorb barrier fluid thermal expansion while separating the pressurizing gas and barrier fluid.

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans 65 and 75) or gas leakage (API Plan 76), or a mixture of gas and liquid leakage (API Plan 75).

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans 65 and 75) or gas leakage (API Plan 76), or a mixture of gas and liquid leakage (API Plan 75).

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans 65 and 75) or gas leakage (API Plan 76), or a mixture of gas and liquid leakage (API Plan 75).

A PG 72 (API Plan 72) system is used to provide a clean, regulated gas supply to a dual unpressurized seal arrangement where the containment seal is dry running.

A PG 74 (API Plan 74) system provides a clean, dry, regulated supply of pressurized barrier gas (usually nitrogen) to dual pressurized, non-contacting seals.

These reservoir-based seal support systems are designed for both API Plan 52 and 53A applications to support unpressurized and pressurized dual seals.

Plant seal water filtration system, maintaining clean water supply to improve the reliability mechanical seals and gland packing and also flow control and pressure-regulating devices.

SafeJet is an automatic seal water filter. Its operation is based on “flow-through” filter technology, which utilizes reliable laminar filtering method.

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support systems when additional cooling is required.

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support systems when additional cooling is required.

Most centrifugal compressors today use dry gas seals to contain high-pressure gas, whether on a high-pressure reinjection duty or a low-pressure pipeline machine.

8613371530291

8613371530291