balanced mechanical seal for sale

Optimal performance is attained by selecting from three standard seal face balances; the BXQ seal is high balanced for flashing hydrocarbon applications

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• ...

Cartridge seals for critical, toxic and emission control applications, where single seals are notaccepted;• Built-in pumping device improves barrier fl uid cooling;• Springs locations prevents contact ...

... corrosion;• Monolithic rotating unit virtually eliminates clogging in the seal area;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge ...

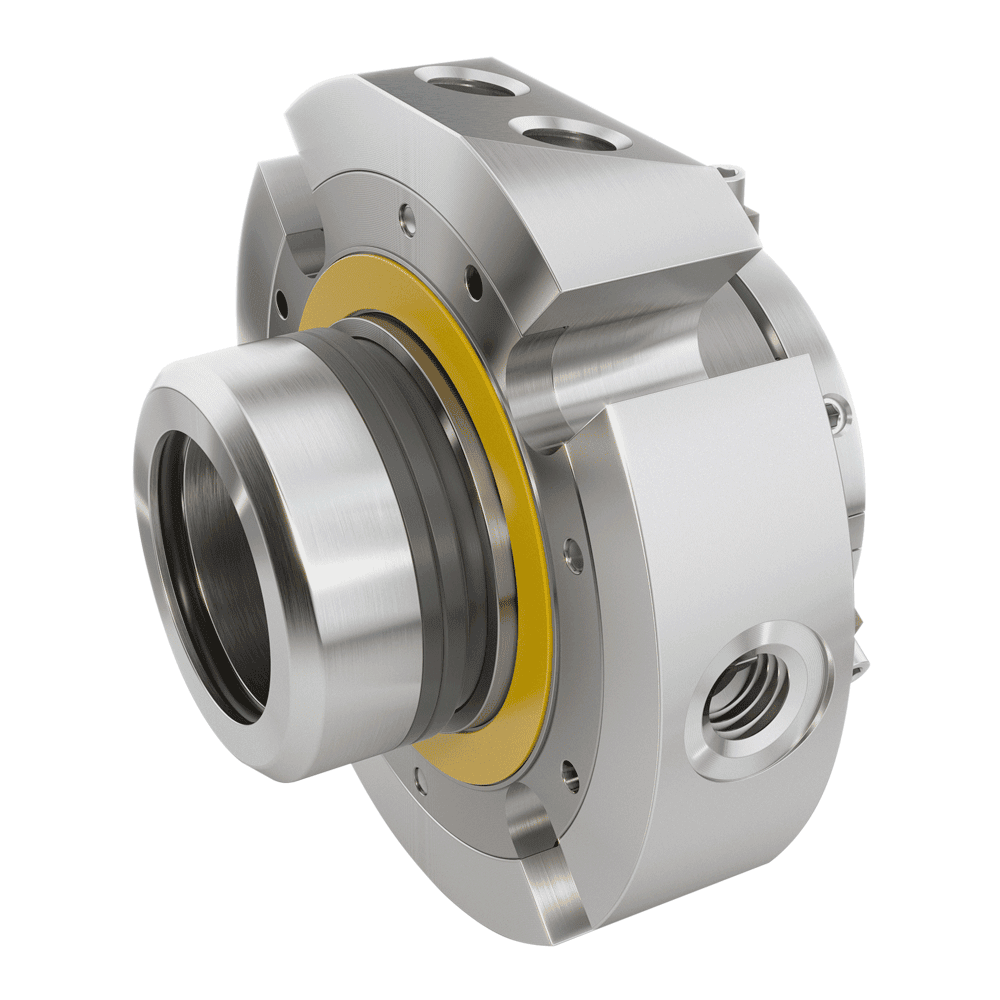

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal ...

Single mechanical seal, balanced, external, independent of the direction of rotation with multi-spring configuration. The MTM190 Series represents the mechanical seal ...

Single echanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The springs are never in contact with the fluid. The MTM190 Series represents the mechanical ...

... dual unpressurized arrangement, without outboard seals also incorporating the same non-pusher technology, the seal can be configured to suit both the operator and pipeline needs.

Flexible seal, suitable for the narrower seal housing and suitingcommon European seal housing standards. STK A1 has a longworking length and is fitted with a seal head ...

we are engaged in offering an assortment of Multi Spring Reverse Balanced Mechanical Seals. The offered range find its applications in various industries such as chemical, refinery, petrochemical and pharmaceutical. These seal can be easily assemble or dismantled through cir-clip provided and can be change to balance version.Witch can be provided with single, double or tandem arrangement with external seal support system & devices.

"Multiple spring Revesed Balance Mechanical Seals" are externally mounted internally balanced multiple spring seals. the unique feature of this type of seals is that, it eleminated the shaft step or sleeves for balancing. these seals are externally mounted and hence the metal parts including the spring do not come in contact with the surculating media and therefor can be used for corrosive or abrasive media sealing. the compact design eleminates the requirement of extra radial and axial space for its installation.

Since failure of the mechanical seal on the shaft is the number one cause of pump shutting down, it is important to know the standard terms of the world of mechanical seals.

Mechanical seals are comparable to precision instruments. These seals use margins with many decimal places. The mechanical seal life depends on many factors, and it can vary from a few intense minutes to many trouble-free years. In general it can be stated that: the more attention paid to the mechanical seal and related equipment, the longer they will last.

Years ago, packing materials such as stuffing box packing were used for most shaft seals. These types of shaft seals required a fair amount of leakage to keep the packing properly lubricated and cooled. Until 1915 the mechanical seal was invented. This shaft seal managed to keep the fluid in by using two incredibly flat surfaces (one that rotates with the shaft, and one stationary in the housing). Despite the fact that these treads also need a little bit of ‘leakage’ to create a hydrodynamic layer, this is often not noticeable as this liquid evaporates. Most pumps today have mechanical seals. However, because the parts and surfaces are so delicate, it is also the number one cause of pump failure. This requires a better understanding of this type of seal and its application.

A set of (very flat lapped) treads as primary seal: the minimum distance between these treads, which are perpendicular to the shaft, minimizes the leakage. Often two different materials are used as the tread, a harder and a softer material, to prevent the materials from sticking together. One of the treads is often anti-friction corrosion material such as carbon graphite. A relatively hard material such as silicon carbide (SiC) or ceramic alumina is often used for the other tread. However, when processing abrasive substances, two hard surfaces are normally used.A tread is mounted stationary in a house.

Mechanical seals require a fluid to maintain lubrication. The running surfaces are usually lubricated by a very thin layer of liquid (or gas) between the two running surfaces. Lubrication can also come from another fluid other than the product, depending on the seal requirements.

Pusher seals use a secondary seal that moves axially along the shaft or shaft sleeve to maintain pressure on the running surfaces. This allows the seal to compensate for wear and any less accurate shaft alignment. The advantage is that this seal type is the cheapest. The main disadvantage of this configuration is that the secondary seal can gall on the shaft or shaft sleeve, especially when processing abrasive product.

This is the category in which the bellow seals fall. These seals do not use a secondary seal that must be able to move along the shaft or shaft sleeve to maintain contact. The secondary seals do not move with this type of seal under any circumstances, not even during use. The tread wear is compensated for by an elastomer or metal bellows. A disadvantage of this type of seal is the higher cost price of the seal and that a larger seal must be used in a corrosive environment because the material of the bellows is otherwise too thin.

We speak of a balanced seal if the pressure on the running surfaces caused by the pressure in the system is taken into account. It may sound crazy if the goal is to achieve shaft seal, but a mechanical seal must leak! After all, the running surfaces of the primary seal must be lubricated with the pumped product. When the pressure on the product side exceeds approximately 250 psid, the pressure on the treads can increase to such an extent that no liquid film can form between the surfaces. The lack of lubricating film will cause the seals to wear out very quickly.

To overcome this problem, the balanced seal was introduced in 1938. With a balanced mechanical seal, high pressure is taken into account by adjusting the surface of the tread, which distributes the stuffing box pressure over a larger surface. Balanced seals are easy to recognize, there is a step in the shaft sleeve and/or the running surface. Incidentally, this works a bit more complicated with a metal bellow, but the principle remains the same. Mechanical seals can also be designed to balance for overpressure on both sides of the tread assembly.

Cartridge seals consist of a pre-mounted mechanical seal on a shaft sleeve that can be installed as a whole over the shaft or shaft sleeve. Cartridge seals are very easy to install and the chance of short service life due to suboptimal installation is less probable. It should come as no surprise that cartridge seals are a lot more expensive than the previously discussed seals. On the other hand, there are lower maintenance costs. Incidentally, it is not always possible to apply a cartridge seal if, for example, there is no space in the house.

Excellent axial movementThe seal can move ± 2,0 mm independent of the compression of the springs. The seal follows the movement of the shaft without influencing the compression of the springs. This feature is essential when sealing equipment with flexible bearing units.

Patented protected spring packageThe springs are located outside both the product and the flush. Minimizing the risk for clogging, which is one of the most common causes for seal failure. Patent No: 900912-2

Safe drive of rotating surface at the atmospheric sideThe rotating face on the atmospheric side is driven by three big drive pins machined into the sealing face. The pins are not in contact with the quench liquid, eliminating the risk of them being blocked axially by residues from the quench.

Hygienic applicationsSmooth surfaces without cavities or closed spaces make the seal suitable for food and drug applications. If required, the gasket may be replaced with O-rings according to EHEDG in order to achieve a hygienic designed seal suitable for CIP (Cleaning in Place).

H4 designThe rotating sealing face on the product side has the new “H4-design”. This means that the seal face is O-ring mounted and the outer diameter of the seal face is the same as of the holder. This prevents the forming of turbulent flows, which cause heavy wear in abrasive liquids.

Hygienic solutionsSmooth surfaces without cavities or closed spaces make the seal suitable for food and drug application. If required the gasket may be replaced with O-rings in execution according to EHEDG to achieve a hygienic designed seal suitable for CIP (Cleaning in Place).

H4 designThe rotating sealing face on the product side has the new “H4-design”. This means that the seal is O- ring mounted and the outer diameter of the seal face is the same as of the holder. This prevents the forming of turbulent flows, which cause heavy wear in abrasive liquids.

Optional additional flange for flushingThe seal may be equipped with an extra flange when flushing into the media is needed. The standard design is without flange since the chamber with a small gap given by the flushing flange may encourage material build-up if flush is not connected.

We are well known as a reliable Single Spring Seal Manufacturers and Exporters. Our Seals are produced using superb crude material that guarantees fantastic toughness.With our experts, we provide clients a high quality Single Coil Spring Balanced Seal which are obtained by basically changing the carbon face assembled through circlip provided. These balanced seals are manufactured as for ‘O’ Ring & PTFE wedge type Secondary Seals. The offered Single Coil Spring Balanced Seal are appreciated for its premium quality, high efficiency and durability. We are giving these spring balanced seals at industry leading rates within stipulated periods of time.

The globe star engineers (India) are the major mechanical seal providing company of India. We are considered as the trustworthy manufacturer, supplier and exporter of the MULTI SPRING REVERSED BALANCED SEALS. These seals are designed to handle corrosive or abrasive media, as the metal components of this seal do not come in contact with the media to be sealed. Due to its compact design, neither radial nor axial extra space is required for installation.

The Type RT-50B is Reverse Balance Mechanical Seals. It is multiple springs externally mounted reverse balanced seal with O-ring as secondary sealing member. This seal can also be used for corrosive services as the metallic components do not come in contact with liquid to be sealed. This seal can also install indouble back to back arrangement as an internal seal. Sealing member can also be changed as per chemical compatibility. All metal components including spring are isolated from aggressive media Sealing. Even if barrier fluid pressure goes down this seal will not allow process fluid to mix with barrier fluid.

We also manufacture and supply Single Spring Mechanical Seals, Multi Spring Mechanical Seals, Teflon Bellow Seals, Elastomer Bellow Mechanical Seals, and Metal Bellow Seals as being top most mechanical seal manufacturers in Mumbai as well as known as one of the most precise mechanical seal manufacturing companies in India.

The balance of a seal refers to the distribution of load across the seal faces. If there is too much load on the seal faces, it can lead to a leakage of fluids from within the seal which essentially renders the seal useless. Moreover, the liquid film in between the seal rings runs the risk of vaporising.

This can result in higher wear and tear off the seal, shortening its life span. Seal balancing is therefore necessary to avoid disasters and to also elongate the life of a seal.

A balanced seal has a higher pressure limit. This means that they have a larger capacity for pressure and they also produce less heat. They can handle liquids that have a low lubricity better than unbalanced seals.

On the other hand, unbalanced seals are typically much more stable than their balanced counterparts as far as vibration, cavitation and misalignment are concerned.

The only major drawback that an unbalanced seal presents is a low pressure limit. If they are put under even slightly more pressure than they can take, the liquid film will quickly vaporise and will cause the running seal to run dry and thus fail.

8613371530291

8613371530291