balanced vs unbalanced mechanical seal manufacturer

Mechanical seals have classified several types. In this article, we will see the basic classification of mechanical seal that is the “Mechanical Seal – Balanced and Unbalanced Type”.

The pressure in any stuffing box acts equally in all directions and forces the primary ring against the mating ring. The force (F) acts only on the diameter (Do) across the seal face, it acts as a closing force on the seal faces.

To relieve the force at the seal faces, the diameter of the shoulder on a sleeve or the seal hardware is decreased. Thereby the seal face pressure can be lowered. This is called seal balancing.

A seal without a shoulder in the design is an unbalanced seal. A balanced seal is designed to operate with a shoulder. Only metal bellows seal is a balanced seal that does not require a shoulder.

Virtually all mechanical seals are available in either unbalanced ( Ref. Figure) or balanced versions. The term “unbalanced” is used when the stuffing box pressure times the area exposed to the pumped fluid (closing force), acting to close the seal faces, is greater than the average pressure between the seal faces (pressure gradient)times the area of contact between the faces. In other words, unbalanced mechanical seal exhibit net hydraulic closing forces which are generated by the actual pressures to be sealed.

For example, if there were a stuffing box pressure of 50 psig (3.4barg), the spring load would have to be added. Hence, the “face load” or closing force on the faces would be even higher than 50 psig times the face area. This, of course, limits the pressure sealing capacity of an unbalanced seal.

Unbalanced seals are often more stable than balanced seals when subjected to vibration, misalignment and cavitation. The disadvantage is their relatively low-pressure limit. If the closing force exerted on the seal faces exceeds the pressure limit, the lubricating film between the faces is squeezed out and the highly loaded dry running seal fails.

The balanced seal has the same opening (face) area as the unbalanced seal, but the closing area has been reduced about the face area. Because force equals pressure times area, reducing the closing area reduces the closing force. Consequently, less heat is generated and the seal generally has a longer life.

To simplify the explanation, balancing mechanical seal involves a small design change which reduces the hydraulic forces acting to close the seal faces. Balanced seals have higher pressure limits, lower seal face loading, and generate less heat. They are better able to handle liquids with low lubricity and high vapour pressures. This would include light hydrocarbons. Because seal designs vary from manufacturer to manufacturer and from application to application, it is not possible to standardize on either configurations or materials that cover all conceivable services. Available basic designs have variations that were often developed to meet specific applications. Each seal design has its own strengths and weaknesses.

Nowadays most of the seal manufactures are used only balanced mechanical seal. In some special mechanical seals (ie., engineered seals) are designed with unbalanced mechanical seal.

Balanced mechanical seals are more preferred than unbalanced mechanical seals. Seal balance can range from 0.65 to 1.35, depending on operating conditions.

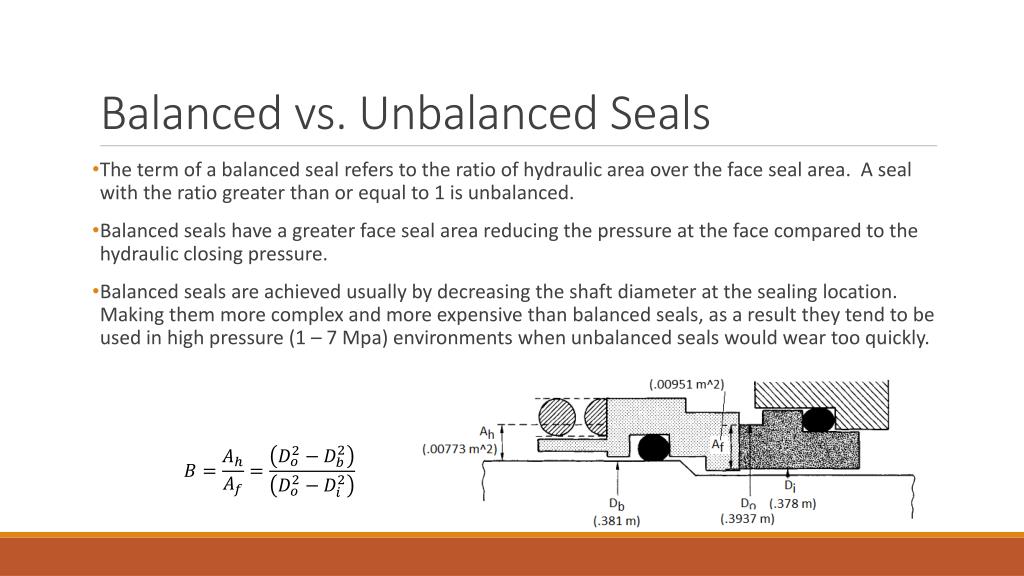

A. A balanced seal is a mechanical seal configuration in which the fluid closing forces on the seal faces have been modified through seal design. Seal balance, or balance ratio of a mechanical seal, is simply the ratio of two geometric areas. These areas are called the closing area (Ac) and the opening area (Ao). The closing area is different when pressure is on the outer diameter of the seal than when the pressure is on the inner diameter. When the pressure is on the outer diameter, the closing area is from the seal face outer diameter down to the lowest point, where the secondary seal rests against the shaft or sleeve. When the pressure is on the inner diameter, the closing area is from the highest point, where the secondary seal rests against the primary ring counter bore, down to the sleeve diameter.

The opening force is always the area of the sealing faces. The balance ratio is then Ac/Ao. A seal with a balance ratio less than 100 percent is called a balanced seal. A seal with a balance ratio greater than 100 percent is called an unbalanced seal. Most balanced seals have a balance ratio between 60 and 90 percent. Most unbalanced seals have a balance ratio between 110 and 160 percent.

Pusher seals normally require a step in the shaft/sleeve or internal hardware to achieve a balanced design. Metal bellows seals do not require this step. The balance diameter, or mean effective diameter (MED), of metal bellows seals is located near the middle of the convolution. When pressure is applied to the outer diameter of the seal, the MED shifts downward, lowering seal balance. The opposite is true when the seal is subject to internal pressure. The rate of change in the balance depends on the face width and the bellows leaflet design.

Pusher seals can be designed to withstand pressure from either direction. This is accomplished by trapping the O-ring between two diameters as shown in Figure 4.1. The cavity must be long enough to allow the O-ring to move, allowing pressure to act on the primary ring. These designs allow the seal to withstand system upsets.

The balance of a seal refers to the distribution of load across the seal faces. If there is too much load on the seal faces, it can lead to a leakage of fluids from within the seal which essentially renders the seal useless. Moreover, the liquid film in between the seal rings runs the risk of vaporising.

This can result in higher wear and tear off the seal, shortening its life span. Seal balancing is therefore necessary to avoid disasters and to also elongate the life of a seal.

A balanced seal has a higher pressure limit. This means that they have a larger capacity for pressure and they also produce less heat. They can handle liquids that have a low lubricity better than unbalanced seals.

On the other hand, unbalanced seals are typically much more stable than their balanced counterparts as far as vibration, cavitation and misalignment are concerned.

The only major drawback that an unbalanced seal presents is a low pressure limit. If they are put under even slightly more pressure than they can take, the liquid film will quickly vaporise and will cause the running seal to run dry and thus fail.

Many early mechanical seal designs placed the spring inside the process fluid. Most products (process fluids) that are sealed are not very clean. When the spring mechanism of the mechanical seal is immersed in this unclean fluid, dirt collects between the springs. This situation eventually impacts the spring’s ability to respond to movements and vibrations, and the ability to keep the seal faces closed. Over time, clogging of the springs will cause premature seal failure.

The ideal design offers springs on the atmospheric side of the mechanical seals. The springs will be protected from the process fluid and their ability to work will not be impeded.

The pressure from both the seal springs (Ps) and the hydraulic pressure of the liquid in the pump (Pp) provide a compression force that keeps the seal faces closed. Balanced seals reduce the seal ring area (Ah) on which the hydraulic pressure of the liquid in the pump (Pp) acts.

By reducing the area, the net closing force is reduced. This allows for better lubrication that results in lower heat generation, face wear, and power consumption. Balanced seals typically have higher pressure ratings than unbalanced seals.

Mechanical seals can be designed with inserted seal faces or with monolithic seal faces. In both cases, the sacrificial seal face is often made from carbon/graphite. This material offers good running properties but is relatively weaker from a mechanical standpoint than other options. Inserted face designs use a metal rotary holder to transmit the shaft torque to the seal face.

The disadvantage of this inserted face design is that the face and holder material have different coefficients of thermal expansion. This changes the net interference force between both parts when they are exposed to heat from the process fluid or face friction. The seal face deforms, which results in leakage and accelerated wear.

More modern seals are equipped with monolithic seal faces that are made out of only the seal face material itself. The torque transmission is applied directly to the seal face. This is possible if the geometry of the seal face is designed in a particular shape to give it the strength to handle the torque through its geometric design. These monolithic seal face designs have been made possible through the use of Finite Element Analysis (computer modeling).

Monolithic seal faces provide a more stable fluid film between the faces, and they do not deform in operation compared to inserted faces (or to a much lesser degree). Therefore, they are more commonly used nowadays when reliability and low emissions are vital.

All mechanical seal designs have at least one secondary seal that interacts with the dynamic movement of theflexible mounted face. This secondary seal moves with the springs to keep the seal faces closed and is defined as thedynamic secondary seal. During operation of a rotary design, springs will keep the seal faces closed. They adjust with each rotation for any misalignment from installation and parts tolerances. As the springs compensate, the dynamic secondary seal moves back and forth, twice per revolution. This rapid movement prevents the protective chrome oxide layer (the layer that protects the metal) from forming. Erosion of this unprotected area under the dynamic secondary seal will cause a groove to develop. Eventually this groove becomes so deep that O-Ring compression is lost and the seal leaks. In most cases, fretted shafts must be replaced to achieve an effective seal.

With rotary mechanical seals, it is important that the stuffing box face is perpendicular to the shaft for the faces to stay closed. There will always be some resulting misalignment from installation and parts tolerances. The springs must adjust with each rotation to keep the seal faces closed. This adjustment becomes more difficult at higher speeds.

In contrast, a stationary seal is a mechanical seal designed in such a way that the springs do not rotate with the pump shaft; they remain stationary. Because the springs do not rotate, they are unaffected by rotational speed. The springs do not need to correct or adjust with each rotation; they adjust for misalignment only once when installed.

Rotary seals are simple in design which makes them inexpensive. They are suitable for lower speeds only. Stationary seals are more complicated to design but are suitable for all speed ranges. Because of design complexity, stationary seals are more commonly configured as cartridge seals rather than component seals.

Marco Hanzon is Vice President of Global Marketing for A.W. Chesterton Company. He has been an active member and past chairman of the Mechanical Seal Committee of the European Sealing Association. Marco"s experience includes working as an In-Field Support Engineer for mechanical seals.

The balance ratio of a mechanical seal is an area ratio and is related to the seal face load. Balance ratio is defined as the ratio of the closing area to the opening area. Seals with a balance ratio > 1 are "unbalanced"; ratios of < 1 are considered "balanced". Seals are balanced to decrease friction and wear, so you will usually move to a balanced seal at pressures of 250 psid and above (although you can use them at lower pressures as well). Unbalanced seals will be used up to 250 psid. The theory becomes more complex when you talk about metal bellows style mechanical seals; in those designs the balance ratio will increase at higher pressures primarily due to the bellows plate geometry. Visually if you were to look at the primary face of an unbalanced pusher style seal vs. a balanced pusher style seal you would notice a "step" in the face geometry (reducing the closing area and changing the balance ratio).

In theory, the lower the balance ratio, the lower the fluid film temperature, the longer the seal life. In practice, leakage control can sometimes be sacrificed and the faces may become unstable depending on if the fluid is volatile (vaporizing), or if any other face distortions occur. In general, review of the application with your seal vendor is always recommended. If you are adhering to API 682; then balanced seals are your only options due to the nature of the services. The attached is a very rough representation of what I just said. It depicts a single set of seal faces pressurized from the OD: the balance ratio calculations will become more complicated when you discuss OD vs. ID pressurizations particularly in dual pressurized seals. Hope this helps.

Centrifugal pumps are one of the most extensively used pumps in municipal and complex industrial applications. However, a proper sealing arrangement is imperative for these pumps to prevent fluid leakage and protect the pump’s inside from contaminants in the atmosphere. Mechanical seals are preferred for sealing the pump as they require less maintenance and are much more durable than packing seals.

There are a variety of options in the market when it comes to mechanical seal systems. Before illustrating the types of mechanical seals for centrifugal pumps, here are four key considerations when choosing the appropriate seal system.

Consider the type of fluid that will be pumped and how it will affect the seal system design—factors such as lubricity, volatility, corrosive properties, and cleanliness matter the most.

Make a choice depending on the pressure exerted on the seal face. For instance, unbalanced seals are suitable for low-pressure applications, while balanced seals are appropriate in high-pressure conditions.

Temperature considerations will help determine whether you need to choose a pump with heat-sensitive components. For example, balanced seals sustain high temperatures better than their unbalanced counterparts.

These types of mechanical seals are typically low in cost and used for more generalized purposes. However, installing and adjusting standard component seals is time-consuming and requires a fair amount of operational skills. In addition, as they are composed of separate dynamic and stationary components, incorrect installation remains the major cause of errors.

Cartridge type mechanical seals are easy to install and ensure high performance. They are a one-piece unit incorporating all sealing components into a single assembly. Cartridge seals provide substantial maintenance advantages compared to other seal types while reducing installation time and the risk of assembly errors.

Pusher seals rotate along the shaft or sleeve to maintain contact with the faces of the seal to reduce wearing and wobbling caused by any misalignment. They are less expensive and come in different sizes and designs. The only drawback is that the elastomer is subject to wear.Non-pusher type seals maintain contact with the faces without rotating axially. They function under low temperatures and high pressures. However, the bellows used in these seals must be replaced frequently to work in corrosive environments.

Balanced mechanical seals work at high operational pressures while generating lesser heat. They are suitable for handling low lubrication liquids and high vapor pressure. Balanced seals increase seal life by reducing the closing force.Unbalanced mechanical seals are a more economical alternative that works for low/medium pressure applications. They are highly stable and still work in conditions where there are vibrations, shaft misalignments, or fluid cavitations.

There are various types and arrangement of the mechanical seals being used for the centrifugal pumps. Some of the commonly used ones are described below:

The pusher type of mechanical seals move axially along the rotating shaft or the sleeve to maintain the contact with the faces of the seal. This feature of these seals helps compensate for the wearing that may occur at the seal face, and wobbling due to misalignment. The pusher types of mechanical seals are used commonly, are less expensive and are easily available in the market in wide range of sizes and designs. The only disadvantage of these seals is that they tend to hang up and sometimes there is fretting of the shaft.

The unbalanced types of mechanical seals are used under drastic conditions where there are vibrations, misalignment of the shaft, and the problem of the cavitation of the fluid. These mechanical seals are inexpensive, allow lesser leakage of the fluid and are highly stable. However, these seals can operate only under low pressure range and if the force of the fluid exceeds certain limits the lubricating film between the faces squeezes out and the seal fails.

As the name suggests, the non-pusher or bellow type of mechanical seals don’t have to be moved axially to maintain their contact with the faces. These seals can work under low temperature and high pressure applications. The bellows used in these seals should be upgraded so that they can work under the corrosive environments.

The balanced mechanical seals have the ability to sustain higher pressures across the faces and they generate lesser heat thus they are suitable for handling liquids that have low lubricating capacity and hydrocarbons that have high vapor pressure.

The major advantage of the cartridge seals is that they don’t require complicated setting during the installation as required by the conventional seal. This helps reducing errors associated with seal setting and eventually also reduces the maintenance required.

There are various types and arrangements of the mechanical seals available in the market. It is very important to use appropriate mechanical seal for the required application. If the incorrect mechanical seal is selected there are chances that the fluid would start leaking from the pump and the very purpose of installing the expensive mechanical seal will be destroyed. In addition there would be loss of time, manpower, resources and also some safety hazards.

1) Liquid or fluid to be pumped: The first and the most important factor to consider while selecting the mechanical seal for the centrifugal pump is the liquid or the fluid to be pumped. If ordinary liquid like water is to be pumped, then conventional mechanical seal with ordinary materials can be selected. In fact in many water pumps ordinary glands are used as the sealants since any leakage of water to the external atmosphere is not dangerous. But you can always see the water dripping from the pumps using ordinary glands.

If the pump has to handle corrosive liquids like acids, it is very important to select corrosion resistant materials for the mechanical seals. Some of these materials can be stainless steel, bronze or hastelloy. The mechanical seals also comprise of the mating surfaces and these should also be made up of corrosion and wear resistant materials like ceramic, silicon or tungsten carbide, carbon etc. For the corrosive environments the materials for the stationary parts of the mechanical seal can be Teflon, Buna, EPR or Viton.

2) Pressure of the liquid: The liquid enters the pump at certain pressure and the pump has to increase its pressure to certain level so that it reaches certain height. The total pressure on the seal decides whether one should opt for the balanced seal or the unbalanced type of seal.

3) Temperature of the liquid: Some pumps handle liquids at high temperatures and others handle the liquids at low temperature. The materials and mating surfaces used in mechanical seals should be able to sustain the temperature of the fluid.

4) Nature of fluid: The liquids to be handled by the pump may be having ordinary flow, but there can also be chemical solutions that have high viscosity and slow flow, there can be precipitates, there can be abrasive liquids and so on. These types of fluids usually cause more wear and tear of the parts of the mechanical seals and in such cases it is advisable to use double seals.

5) Safety and Environmental concerns: The safety of human being handling the pump is of prime importance so are the permissible emission standards. To be on the safer side it is always better to used double seals that work as the better sealants and are more reliable.

Balanced and unbalanced type The specific pressure (the force per unit area) of the end face of the friction pair and the pressure of the medium to be sealed can be divided into balanced and unbalanced types.

Non-equilibrium type: The effective area of the medium acting on the moving ring (the area where the offset pressure cancels each other) is equal to or greater than the contact area of the moving and static ring. The specific pressure of the end face increases or decreases proportionally with the pressure of the sealing medium, so that when the medium pressure is high, a large specific pressure is generated on the end surface, which accelerates the wear of the friction surface, generates heat, and destroys the liquid film on the end surface to form dry friction. Generally, the unbalanced medium pressure does not exceed 686 KPA.

Balanced type: When the medium pressure is high, it is necessary to try to eliminate the effect of a part of the pressure on the friction surface from the sealing structure. This type of seal is called a balanced mechanical seal. In this seal, the effective area B of the medium acting on the dynamic damage is smaller than the contact area A of the end face of the dynamic static ring. The specific pressure on the sealing end face can be controlled by itself, and the increase or decrease of the medium pressure has little effect on the specific pressure of the end face.

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

Depending on the pump type and the process variables, there are various mechanical seal types to choose from. Each seal variant has its unique design and characteristics which make it suitable for a specific application. MES has years of experience with industrial mechanical seals and support systems, making us an authority in this area.

Mechanical seal types vary in design, arrangement, and how they disperse the hydraulic forces acting at their faces. The most common seal types include the following:

Balanced mechanical seal arrangements refer to a system where the forces acting at the seal faces are balanced. As a result of the lower face loading, there is more even lubrication of the seal faces and longer seal life. Learn about our mechanical seal lubrication systems today.

Balanced mechanical seals are particularly suited to higher operating pressures, typically above 200 PSIG. They are also a good choice when handling liquids with low lubricity and higher volatility.

Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result can exhibit much lower mean time between failure. Unbalanced seals are not recommended for high pressure or most hydrocarbon applications.

Pusher seals utilize one or multiple springs to maintain seal closing forces. The springs can be in the rotating or stationary element of the mechanical seal. Pusher type seals can provide sealing at very high pressures but have a drawback due to the elastomer under the primary seal face that can be subjected to wear as the face moves along the shaft/sleeve during operation.

Non-pusher seals utilize a metal or elastomeric bellows to maintain seal closing forces. These seals are ideally suited to dirty and high temperature applications. Bellows seals are limited to medium/lower pressure applications.

Conventional seals are typically lower cost and often installed on general service equipment. These seals require higher operator skill to service as they installed as individual components.

Cartridge type mechanical seals incorporate all of the seal elements into a single assembly. This dramatically reduces the potential for assembly error and the time require for seal replacements. Learn more about the difference between cartridge and non-cartridge mechanical seals today.

When deciding on the type of seal system for a centrifugal pump, operators must choose according to their unique application. Failure to select the proper seal type can lead to loss of pump integrity, breakdowns and costly repairs. To avoid these undesirable results, all operators must consider the following factors before deciding.

The amount of pressure exerted at a mechanical seal’s faces has a significant effect on its performance. If a pump is to be operated at low pressures, an unbalanced mechanical seal will be suitable. However, in conditions where higher pressures are anticipated, balanced seals will prove a more reliable solution.

Balanced mechanical seals perform better than their unbalanced counterparts in conditions where the operating temperatures are higher than normal. Heat sensitive components are better preserved in balanced mechanical seals compared to other seal types.

As it goes for all types of machinery, operator safety is the top priority. The use of double mechanical seals in centrifugal pumps provides additional protection as they have increased sealing capacity and are generally more reliable.

Single Spring Balanced & Unbalanced SealOwing to our industrial expertise, we are able to manufacture, export and wholesale premium quality Single Spring Balanced & Unbalanced Seal. With an aim to ensure that offered unbalance seals are able to stand tall on the expectations of patrons, we manufacture these using best grade material. Along with this, we keep in mind industry set quality standards while manufacturing these unbalance seals. Prior to dispatch, we make these unbalance seals pass a quality check so as to ensure their flawlessness.

We are a prominent Industrial Balanced and Unbalanced Single Spring Seal. Clogging type applications. Torque Transmission from Retainer Shell to Dynamic Ring is done through Drive Lugs. GLOBE STAR Make Balance and Unbalance Single Spring Seals are Single Helical Coil Spring Seals Developed for clogging type applications.

Secondary Seal: U71 & B71 : Viton, EPDM, Silicon, Aflas, EPR, Kalrez, TCV, U76 & B76 : GFT, PTFE, FEP, Grafoil, Hardware : SS 316, SS 304, Hast - C, Monel, Alloy -20

Our organization is one of the prominent names in the market engaged in providing Inside Mounted Balanced and Unbalanced Single Spring Seal. These seals are of U71 &U76, B71 & B76 series and are Single Helical Coil Spring Seals. Provided seals are suitable for dirty media & clogging type applications. Drive lugs help torque transmission from retainer shell to dynamic ring. In these seals all the parts are fasten together through a snap ring that aid convenient installation & removal. All the parts can be changed from U71 to U76 & B71 to B76 by interchanging only the dynamic ring and the secondary seal.

We manufacturer U71 &U76 and B71 & B76 series of Slurry Seal. Contact with us to get the best deal of Slurry Seal. We also provide Slurry Seal on customized base.

We manufacture, supply and export the finest quality of single spring unbalance seals, for various industrial applications. The single spring unbalance seals are used mainly in dirty and congealing application. The seals are highly demanded for the anti abrasive applications. These seals are easy to install and operate for different application being used in various industries. These seals are compact in design for handling liquids of varying contamination including Slurries Sludge, sewage, Viscous and crystallizing Solution. These Seals are designed in both balanced and unbalanced version based on pressure parameters. Spring clogging does not occur in single spring seals. We are the manufacturer of pusher seal.

We are a highly esteemed General Purpose Multi Spring Unbalanced Seal. Their Compact Design permits their use in all types of Centrifugal Pumps. All Components are held together by a Snap Ring that helps in easier installation & removal. this kind is widely used in various industries for different applications such as rotating equipment, pumps, mixers, agitators and compressors.

8613371530291

8613371530291