bellow type mechanical seal manufacturer

John Crane brings you the world’s most complete selection of performance-proven edge-welded and formed metal bellows sealing products used in a wide range of rotating equipment such as pumps, compressors, mixers, and agitators. Our experience in diverse industries such as oil & gas, petrochemical, chemical, refrigeration compressor, pharmaceutical, food processing, pulp & paper, and more have proven the soundness of John Crane’s metal bellows design.

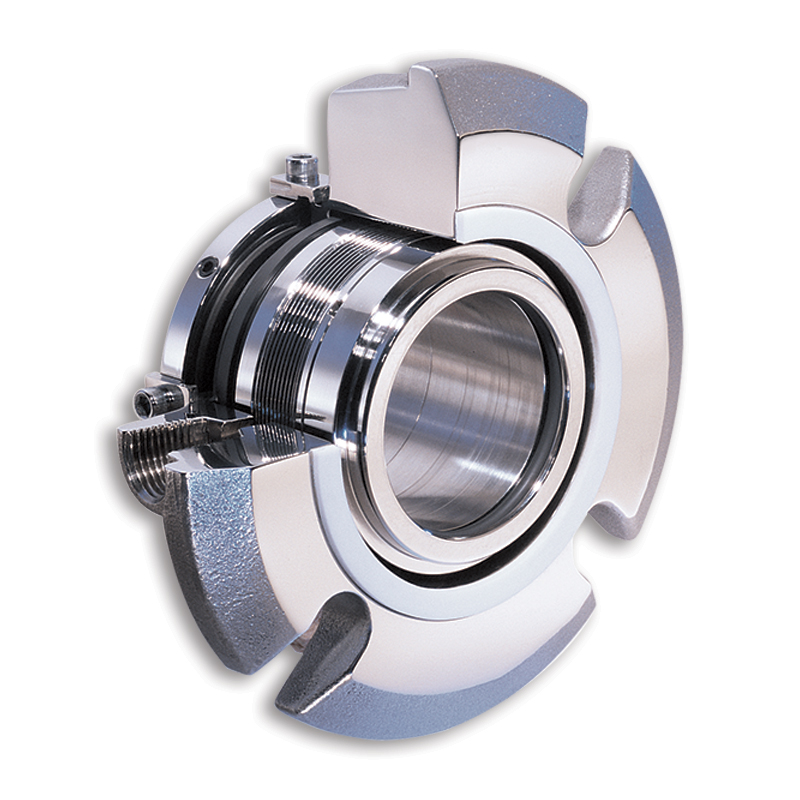

Designed for demanding applications, the Type 2100 mechanical seal is a compact, unitized, single-spring elastomer bellows seal that offers maximum durability and performance.

The Type 2100 is often found in water-based applications, such as wastewater treatment, potable water, HVAC, pool and spa and other general applications.

... dual pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact ...

LATTYseal U 6812 offers an instantaneous interchangeability of the rotating face permitting multiple use and cost reduction. Wide spectrum of rotating ...

... 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API standard pumps;• Available ...

Cartridge seals for critical, toxic and emission control applications, where single seals are notaccepted;• Built-in pumping device improves barrier fl uid cooling;• Springs locations prevents contact ...

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

FLEX MECH-Seal(china)Co.,ltd. is spent significant time in mechanical seals items including for auto cooling pump mechanical seals,for car air-layer ...

The PTFE bellows type mechanical seal, manufactured by Chinabase Machinery, can operate on a temperature range of -45°C up to 250°C on a pressure ≤1.2 Mpa and speed of ≤15 m/s. The stationary ...

The mechanical seals are designed to deliver excellent twin directional sealing performances in general purpose machines and are geared to operate in low to medium pressure applications. They are equipped ...

The MTM 51 series is an elastomer bellows type mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This double directional ...

The MICROTEM double directional mechanical seal is with a single cylindrical spring is unbalanced and i elastomer bellows. It is used for general services machinery at low-medium pressure ...

The PK Seal features a single spring rubber bellows that will not wear the shaft or sleeve. It fits into shallow stuffing boxes and the flexible rotary face floats to compensate for misalignment.

... performance, the Type 1 elastomer bellows seal is widely recognized as the industry"s workhorse. Suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive ...

The BDFI™/BDFC™ (Bellows Double Flow Induction/Convection) is an innovative modular hybrid design, created using the inboard design of a BQFD™ and the outboard ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production seal

Robust bellow seal with non-DIN cross-section, available inthree standard DIN working lengths and with stationaries to suitall common European housing sizes.

A Bellows seal does not have a secondary seal that must move along the shaft or sleeve to maintain seal face contact. The secondary seal is static state at all times, even when the pump is in operation.

Primary seal face wear is typically accommodated by welded metal or elastomeric bellows which move to assist in the compression of the rotary to stationary seal faces.

Bellows seals allow for high and low temperature applications when used in conjunction with metal bellows. They do not require a rotating secondary seal, which means it is not prone to secondary seal hang-up or fretting along the shaft or sleeve.

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. This eliminates the need for a secondary dynamic seal e.g o-rings. Bellows Mechanical Seals are also known as non-pusher seals as they have a static secondary seal which stays in place against the shaft, sleeve or on the gland of the pump.

A bellows mechanical seal is used where a dynamic seal is deemed unsuitable for the application e.g high temperature medium slurry or high seal hysteresis.

The primary mechanical seal functions exactly the same as a standard mechanical seal except the spring element is now being replaced with a bellows. The friction from the dynamic seal (e.g o-ring) is not a consideration.

However if a bellows mechanical seal should fail it can be due to several reasons such as; poor wielding, product particulate getting into the bellows and causing the spring element to fail, chemical and/or abrasive attack or over-pressure.

If you have any query around how to install bellow mechanical seals for pumps or have some concerns around the seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process back up and running reliably again.

Rubber bellow seal – 21 is engineered under the firm direction of experienced quality controllers. These are widely used for universal general purpose for water / water based solution like fuels, oils and other allied fluid. These are uniquely designed for centrifugal pumps. These find their wide applications in various industries including water system, pulp and paper food processing, waste water treatment for petrochemical processing and many others allied industries. These are acclaimed for its compact design, high efficiency and less maintenance cost. These are attached with bellow seals protecting against twisting.

Ashish Seals from the date of inception has been manufacturing, supplying, and exporting a wide range of Rubber Bellow Mechanical Sealsrrrrr in India and the international market. It is an ISO 9001 – 2015 Certified Company that has intense knowledge and vast experience in delivering best-in-class products to its clients. Owing to the team of professionals, Ashish Seals has been to support the company to acquire eminent position and help in meeting the complete product needs of the clients successfully.

The Rubber Bellow Mechanical Seals is designed to protect the top entry drives in glass-lined vessels. The Rubber Bellow Mechanical Seals are compact in design that is mainly used for any mixed and pressurized liquid in vessels where the leakage cannot be tolerated. The Rubber Bellow Mechanical Seals comes with seat rotating, stationary springs, a standard version with grooves, and many others.

These series of seals are used for plain shafts, these are single coil Unbalanced seals having elastomer bellows and are Independent of direction of rotation.

Rubber Bellow Mechanical Seals can be use regardless of direction of rotation since the driving torque is not transmitted through the coil spring. The required driving torque is through the spring and spring holder.The single coil spring will avoid effluent particle.

Rubber Bellow Mechanical Seals can be use regardless of direction of rotation since the driving torque is not transmitted through the coil spring. The required driving torque is through the spring and spring holder.The single coil spring will avoid effluent particle.

Rubber bellow Seals are used in slurry, Alkaline and base medium. It will work in dual direction. It can be used as a double mechanical seal by back to back arrangement. The seals are recommended with pure medium without solid contaminations

Regarding seal construction, We hold expertise in offering a wide range of the product. These are admired for their robust design and high functional efficiency. Our seals are acclaimed for their various salient features. These are made from the top quality components, these seals are acknowledged for their assured quality and reliability. And the seal has following special featuresLonger service life

Asymmetric bellows form results in even stress distribution with benefits of greater strength and higher rate of flexibilty; seal is bi-rotational and inherently pressure balanced.

Smooth profile is resistant to clogging and therefore ideal for slurries and fibrous liquids. Similarly, seal unit is easy to clean and sterilize in place.

It is easy to occur coking and carbon deposition at the trough between the wave plates, which makes the bellows lose elasticity and cannot compensate, so it can not be used for coking, carbon deposition and crystallized precipitation pump.

For external installation mechanical seals, the sealing surface can be pushed open when the pressure in the sealing cavity is more than 0.2MPa. This is because the elastic force of the bellows is small and can not withstand the high pressure of the medium. Therefore, it is not possible to use an external bellows mechanical seal when the pressure is high.

Because the metal bellow type mechanical seal is a balanced structure, the effective diameter and load factor must be calculated in use. Otherwise, in the high-pressure propane and propane pump, the phenomenon of "spray leakage" is easy to occur.

The welded metal bellows mechanical seal has good floating and random compensation, which can compensate for the leakage caused by wear, axial movement and vibration. Welded metal bellows itself as the elastic element and the sealing function, so there is no need to design the general dynamic auxiliary push ring spring type mechanical seal ring, thus avoiding the fine particles due to dynamic auxiliary seal ring caused by the obstruction, dynamic auxiliary seal and high temperature because of its axial friction resistance reduction the seal compensation ability of the problem.

Metal bellows mechanical seal with no auxiliary seal ring, reduce a leak; at the same time reduce the friction resistance compensation mechanism, improve the following; in the petrochemical industry, welding sealing temperature is not restricted by auxiliary seal bellows; for PTFE bellows seal can be used in the corrosive medium. Its drawback is that some bellows have the smaller elastic force and need to add auxiliary springs.

Welded metal bellows are made by interlacing and closely welding each internal and external diameters of each wave plate, so no matter whether they are used as the stationary or rotary type, it is not necessary to consider the problem of rotation. Welded metal bellows can be made from precipitation hardening stainless steel, high-temperature nickel based materials and chrome-nickel corrosion resistant materials. Therefore, welded metal bellows can be applied to a wide range of temperature (-117 C - 426 C), and various acid, alkali and salt media. The selection of different thickness and layers of the wave plate makes it withstand a pressure of up to 7MPa in a special pump. The design of welded metal bellows seal is generally balanced, so its pressure bears little influence on the surface pressure. The welded metal bellows mechanical seal is not only suitable for nonhydrocarbon media, but also for flash hydrocarbon medium. Compared with the ordinary mechanical seal, its service life has been greatly improved, so it has a higher ratio of performance and price.

Metal Bellow seals are ideal for high temperature applications and harsh chemical services where elastomers cannot be used effectively. This seal type incorporates metal bellows as a spring-loading mechanism to maintain face contact when the seal is not pressurized and eliminates traditional secondary sealing requirements.

mechanical seal faces, high temperature mechanical seals, sealol mechanical seals, mechanical seal water pump, 609 mechanical seal, 670 mechanical seal, 680 mechanical seal, 515 mechanical seal, 215 mechanical seal, MFL85N mechanical seal, MFLWT80 mechanical seal, mechanical seal manufacturer, mechanical seal supplier, metal bellow seal, mechanical seal metal bellows, mechanical shaft seal pump, mechanical seal for hot oil, mechanical seal compressor, mechanical seal face, and oil pump seal mechanical

8613371530291

8613371530291