mars opportunity mission parts supplier

To accomplish its missions, NASA relies on the support of hundreds of contractors and suppliers. Here"s a look at some of the companies that contributed to the Mars Science Laboratory and the future success of Curiosity’s mission on the Red Planet.

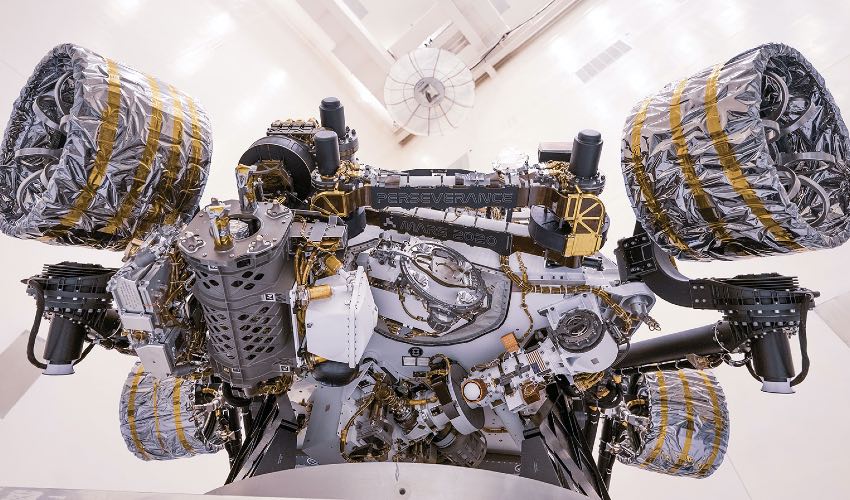

Employees at Windings, Inc., manufacturer of stators and electric motor components, watched the Mars rover landing with special interest this week. They made some of the parts on the Perseverance rover that will be exploring the surface of Mars.

NEW ULM — Many different types of parts and products are manufactured in New Ulm and these parts are sent all over the world. In some cases, they are sent out of this world.

Windings have manufactured several items for NASA over the years. The parts built for Perseverance were not the first from Windings to end up in space.

The Windings webpage lists some of the space missions that have including components and assemblies produced by the company. The mission list includes space vehicles, satellites, Parker Solar Probe, Curiosity Mars Rover and Perseverance Rover.

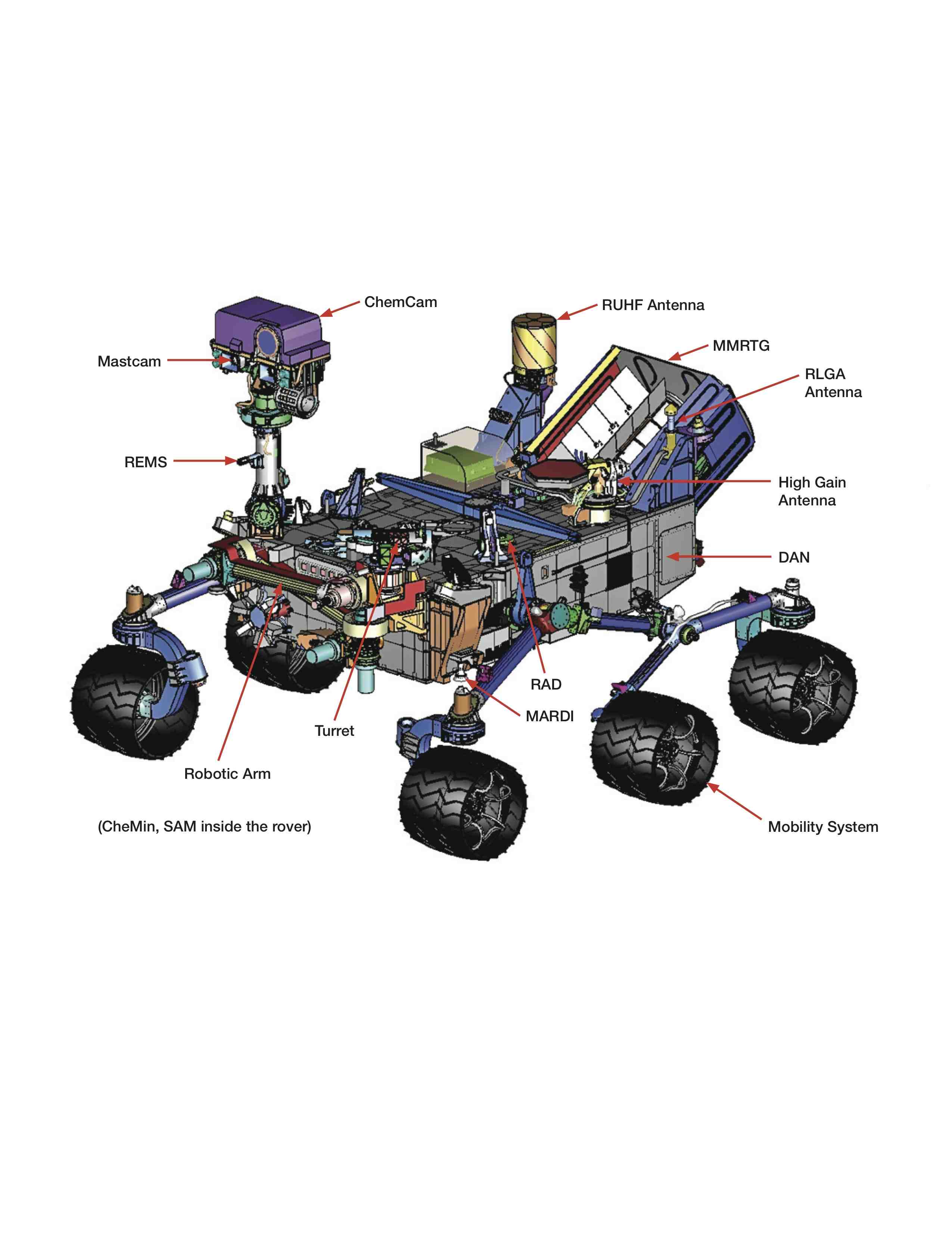

The exact parts Windings manufactured for the Perseverance Rover are a secret, but Windings Director of Marketing David Hansen was able to share that Windings provided components for the rover’s robotic arm and coring turret drill.

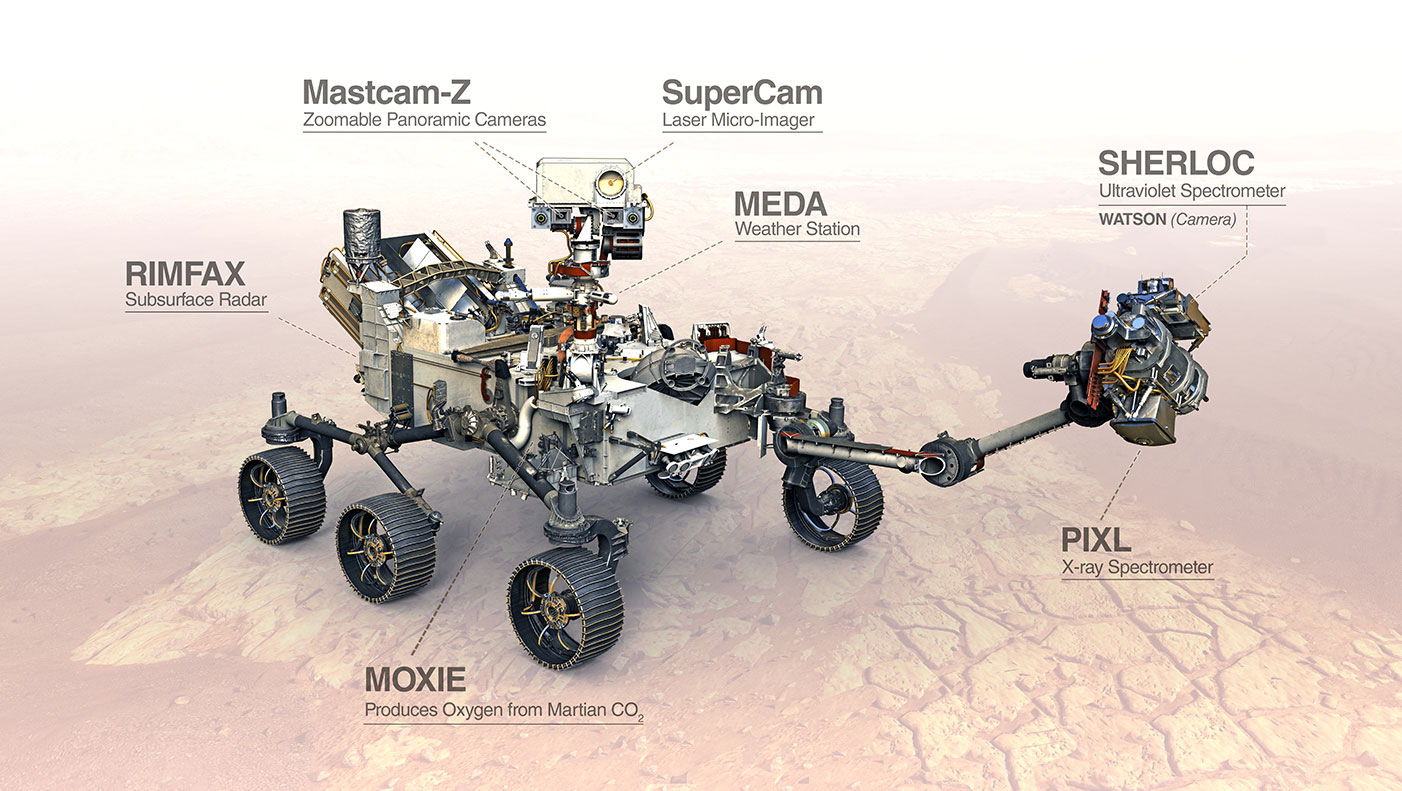

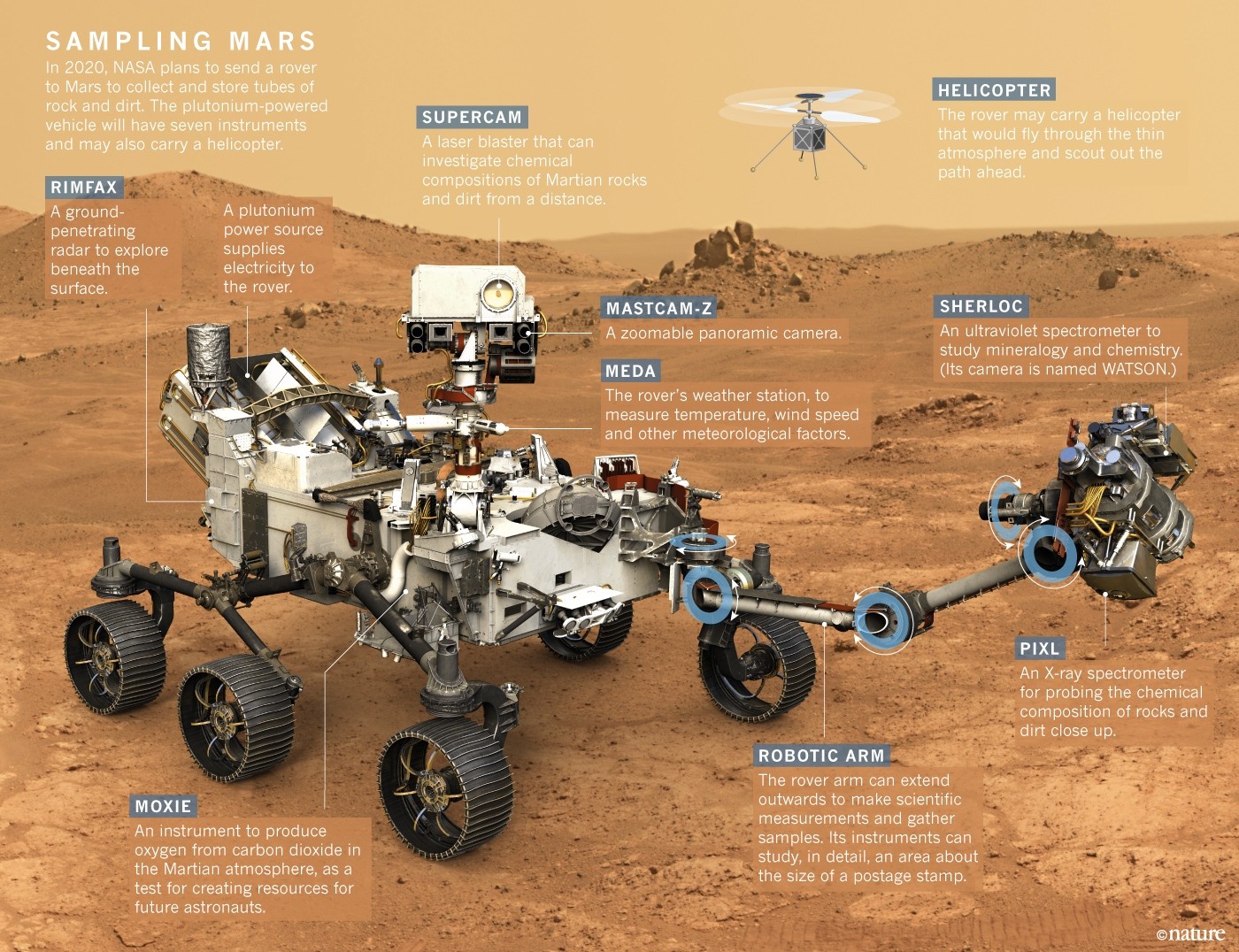

The Perseverance Rover’s main task on Mars will be to seek signs of ancient life and collect samples of rock and regolith for a possible return to Earth.

Perseverance was launched July 30, 2020 and after six months landed at Jezero Crater of Mars. Hitching a ride on the Perseverance rover is a helicopter named Ingenuity. This will be the first aircraft to attempt a powered, controlled flight on another planet.

CHICAGO (WLS) --NASA"s Perseverance rover has landed on Mars, and will now search for signs of ancient life on the red planet with the help of parts made in Roscoe, Ill.

This latest, boldest mission to Mars seeks to unlock the secrets of the universe. Perseverance is now in the Jezero crater, where scientists believe water once flowed more than 3 billion years ago.

If you want to see science fiction at work, visit a modern machine shop, where 3D printers create materials in just about any shape you can imagine. NASA is exploring the technique – known as additive manufacturing when used by specialized engineers – to build rocket engines as well as potential outposts on the Moon and Mars. Nearer in the future is a different milestone: NASA"s Perseverance rover, which lands on the Red Planet on Feb. 18, 2021, carries 11 metal parts made with 3D printing.

Curiosity, Perseverance"s predecessor, was the first mission to take 3D printing to the Red Planet. It landed in 2012 with a 3D-printed ceramic part inside the rover"s ovenlike Sample Analysis at Mars (SAM) instrument. NASA has since continued to test 3D printing for use in spacecraft to make sure the reliability of the parts is well understood.

As "secondary structures," Perseverance"s printed parts wouldn"t jeopardize the mission if they didn"t work as planned, but as Pate said, "Flying these parts to Mars is a huge milestone that opens the door a little more for additive manufacturing in the space industry."

Of the 11 printed parts going to Mars, five are in Perseverance"s PIXL instrument. Short for the Planetary Instrument for X-ray Lithochemistry, the lunchbox-size device will help the rover seek out signs of fossilized microbial life by shooting X-ray beams at rock surfaces to analyze them.

PIXL shares space with other tools in the 88-pound (40-kilogram) rotating turret at the end of the rover"s 7-foot-long (2-meter-long) robotic arm. To make the instrument as light as possible, the JPL team designed PIXL"s two-piece titanium shell, a mounting frame, and two support struts that secure the shell to the end of the arm to be hollow and extremely thin. In fact, the parts, which were 3D printed by a vendor called Carpenter Additive, have three or four times less mass than if they"d been produced conventionally.

Perseverance"s six other 3D-printed parts can be found in an instrument called the Mars Oxygen In-Situ Resource Utilization Experiment, or MOXIE. This device will test technology that, in the future, could produce industrial quantities of oxygen to create rocket propellant on Mars, helping astronauts launch back to Earth.

To create oxygen, MOXIE heats Martian air up to nearly 1,500 degrees Fahrenheit (800 degrees Celsius). Within the device are six heat exchangers – palm-size nickel-alloy plates that protect key parts of the instrument from the effects of high temperatures.

X-ray Image of 3D-Printed MOXIE Part:This X-ray image shows the interior of a 3D-printed heat exchanger in Perseverance"s MOXIE instrument. X-ray images like these are used to check for defects within parts.Credit: NASA/JPL-Caltech.Full image and caption ›

While a conventionally machined heat exchanger would need to be made out of two parts and welded together, MOXIE"s were each 3D-printed as a single piece at nearby Caltech, which manages JPL for NASA.

"These kinds of nickel parts are called superalloys because they maintain their strength even at very high temperatures," said Samad Firdosy, a material engineer at JPL who helped develop the heat exchangers. "Superalloys are typically found in jet engines or power-generating turbines. They"re really good at resisting corrosion, even while really hot."

"I really love microstructures," Firdosy said. "For me to see that kind of detail as material is printed, and how it evolves to make this functional part that"s flying to Mars – that"s very cool."

A key objective of Perseverance"s mission on Mars is astrobiology, including the search for signs of ancient microbial life. The rover will characterize the planet"s geology and past climate, pave the way for human exploration of the Red Planet, and be the first mission to collect and cache Martian rock and regolith (broken rock and dust).

Subsequent missions, currently under consideration by NASA in cooperation with ESA (the European Space Agency), would send spacecraft to Mars to collect these cached samples from the surface and return them to Earth for in-depth analysis.

The Mars 2020 mission is part of a larger program that includes missions to the Moon as a way to prepare for human exploration of the Red Planet. Charged with returning astronauts to the Moon by 2024, NASA will establish a sustained human presence on and around the Moon by 2028 through NASA"s Artemis lunar exploration plans.

The parts include voltage regulators, voltage references, synchronous buck regulators, LDOs, PWM controllers, mosfet drivers, a 16-channel multiplexer, a SPST switch, RS-422 transmitters, RS-422 receivers and MPU supervisors.

“Renesas’ Intersil rad-hard ICs are deployed throughout the rover and its seven instruments,” according to the company. They support subsystems for mission power management and distribution, inertial measurement unit, data handling and processing, and navigation and flight entry, descent, and landing control.”

“Deep space is a challenging environment for spaceflight and Mars rover systems, particularly due to the intense radiation environment encountered in nearly all mission profiles,” said Renesas. “Design, layout, certain process technologies, and manufacturing steps like burn-in and total dose testing of ICs ensures predictable performance and prevents system failure while in flight and on long duration robotic and crewed missions to other planets.”

CHICAGO (WLS)—NASA"s Perseverance rover has landed on Mars, and will now search for signs of ancient life on the red planet with the help of parts made in Roscoe, Ill.

This latest, boldest mission to Mars seeks to unlock the secrets of the universe. Perseverance is now in the Jezero crater, where scientists believe water once flowed more than 3 billion years ago.

On Tuesday night, engineers at the Space Flight Operations Facility of Jet Propulsion Laboratory in Pasadena, California, sent their final commands to the rover Opportunity on Mars. With no signal received in reply from the dormant rover, NASA formally announcedtheend ofthe mission today.

“I declare the Opportunity mission as complete, and with it, the Mars Exploration Rover mission as complete,” said Thomas Zurbuchen, associate administrator of NASA. “I have to tell you, this is an emotional time.”

The rover lost contact with Earth on June 10, 2018. A Mars-wide dust storm darkened the otherwise apricot skies of the fourth planet from the sun, starving the rover’s solar panels of needed sunlight. The agency maintained a vigil in hope that once the storm subsided, the rover might reawaken. During the intervening months, NASA blasted a fusillade of commands at the rover—835 in all—in case some signal might be received and operations resumed. After eight months of silence, the agency made the decision to pronounce the time of death and bid the robot farewell.

Opportunity is one-half of a two-rover mission called Mars Exploration Rovers (MER). The rovers landed separately on Mars in January 2004. Opportunity landed in Meridiani Planum near the Martian equator. Spirit, its twin, landed halfway around the planet, at the crater Gusev. The rovers primary missions were to last 90 Mars days, or sols (about 24 hours and 40 minutes). Two thousand sols later, Spirit was still sending science back to Earth, losing contact at last in 2010. Opportunity survived on Mars for over 15 years.

Today there are eight spacecraft from the world’s space agencies on or orbiting Mars, with a handful set to launch next year including NASA’s Mars 2020 rover. A frontier subdued by robotic explorers, Mars bears little resemblance to the planet we knew in 2000, when the MER mission was conceived. At the time, a single spacecraft circled the red planet: the lonely Mars Global Surveyor. NASA’s two previous, high-profile missions to Mars had both failed. Mars Polar Lander crashed into the planet, and Mars Climate Orbiter vanished, either burned up in the Martian atmosphere or deflected off into space.

MER came in the aftermath of failed mission proposals by Ray Arvidson, a professor at Washington University in St. Louis; Larry Soderblom of the U.S. Geological Survey; and Steve Squyres, a professor at Cornell University. Each of the three had been beaten by David Paige of University of California, Los Angeles, whose ill-fated Mars Polar Lander was selected for flight by NASA.

“Before Spirit and Opportunity, there was a feeling of longing to get onto the surface so that we could understand what the orbital data were telling us,” Arvidson says. “Seeing Mars from four hundred kilometers above the surface is different than looking at the rock textures and cross bedding and particle sizes and details of mineralogy and picking apart the rocks. That’s how we do geology on Earth. It would be very difficult to understand Earth the way we do just from orbital data—maybe impossible.”

It took five tries to land a mission proposal, evolving finally into a single Mars Exploration Rover. Squyres, the principal investigator of the mission, eventually convinced Dan Goldin, then-administrator of NASA, to send two rovers in case one failed.

The two robotic explorers were built by NASA’s Jet Propulsion Laboratory (JPL), which had previously landed the Mars Pathfinder spacecraft and its companion rover, Sojourner, in 1997. Pathfinder, which lasted 85 days, was wildly successful in the public imagination. Its little Sojourner rover traveled a whopping one hundred meters—which was one hundred meters farther than anything had ever roved on Mars before. The mission came in at $150 million dollars, and “faster, better, cheaper” became the agency mantra. After the failures of Mars Polar Lander and Mars Climate Orbiter, engineers grimly added to the mantra: “…pick two.”

MER would become an $820 million mission for both rovers—construction through prime mission—which was an unbelievable bargain, particularly considering the unexpected longevity of the spacecraft. (For comparison, Vikings 1 and 2, launched in 1975, were multi-billion-dollar landers when adjusted for inflation.)

“When I was in high school, these rovers landed,” says Heather Justice, the lead rover driver for Opportunity at JPL. “That was the first big NASA thing that I saw that really got me thinking about working in space or robotics. And I remember thinking at that time, maybe someday I’ll do something like that. I didn’t think it was going to bethatmission. They were only supposed to last 90 days!”

Each rover landed using supersonic parachutes to slow down and then airbags which burst outward from all sides before the spacecraft collided with the planet. The rovers hit Mars as the world’s least-destructive meteorites, bouncing and bounding across the planet’s surface like a couple of dice in some giant"s game. Opportunity eventually settled in Eagle crater on Meridiani Planum.

NASA"s Mars Exploration Rover Opportunity gained this view of its own heat shield during the rover"s 325th martian day (December 22, 2004). The main structure from the successfully used shield is to the far left. Additional fragments of the heat shield lie in the upper center of the image. The heat shield"s impact mark is visible just above and to the right of the foreground shadow of Opportunity"s camera mast. This view is a mosaic of three images taken with the rover"s navigation camera.

Before the mission, she explains, planetary scientists had certain ideas about Mars, how it operated as a planet, and how it looked from the surface. “The first images down from the Opportunity landing site were really amazing because it was such a different looking planet,” she says. “I gave talks to the general public before the landing and said not to be surprised if it looked like the Sojourner landing site or the Viking landing site. But the Opportunity landing site was really, really different. And that was really cool.”

The science team chose to land at Meridiani because Mars Global Surveyor found spectral evidence of crystalline hematite at that location. “There was a lot of debate at the time of what was the cause of that,” Calvin says. “Was it rock-water interaction? Was it volcanic? I don’t think we understood Mars’s history and water cycle at all. There was so much more detail in the geologic history than we anticipated before the mission.”

The small spherules on the Martian surface in this close-up image are near Fram Crater, visited by NASA"s Mars Exploration Rover Opportunity during April 2004. These are examples of the mineral concretions nicknamed "blueberries." Opportunity"s investigation of the hematite-rich concretions during the rover"s three-month prime mission in early 2004 provided evidence of a watery ancient environment.

“To me,” Calvin says, “the two big discoveries are that the hematite signature discovered from orbit is in these spherules, and that we found, with Spirit, places that were basically volcanic vents with nearly pure silica.” The latter find, involving hot water interacting with rock, would have been conducive to habitability—a possible life-supporting ecosystem on Mars millions and millions of years ago, the shadow of which remains today as scars and subtle clues embedded in the rock.

The silica was discovered by accident, a serendipitous side effect of a faulty wheel on the rover Spirit. The wheel jammed, and as the other five wheels dragged it along, an odd, white trench was carved in the Martian dirt. Both rovers had problems with the same wheel, either in rotation or in steering, according to Bill Nelson, the engineering manager for the MER project. “On Spirit, the right front wheel wouldn’t turn, but it would steer. On Opportunity, it would turn but it wouldn’t steer. So we submitted a NASA Lessons Learned that said that we should start leaving off the bad sixth wheel and only make five-wheeled rovers in the future.”

A self-portrait of NASA"s Mars Exploration Rover Spirit shows the solar panels still gleaming in the Martian sunlight and carrying only a thin veneer of dust two years after the rover landed and began exploring the red planet.

Opportunity casts a long shadow over all subsequent Mars rovers, setting a gold standard of JPL engineering. Customized versions of its mobility software are used on the rovers Curiosity and upcoming Mars 2020. Fifteen years of meticulous measurements of Martian dust and its effects will be invaluable for future missions. And then there’s the rover’s durability.

“We have set the off-world record for distance,” Nelson says. “We’ve gone over 45 kilometers. Almost two years ago, we were the winners of the first Mars marathon, and I expect we will hold that record for quite some time to come. I honestly don’t think Curiosity has much hope of traveling nearly as far as we have, and it’s not really clear that Mars 2020 will, either.”

The distance traveled has been a scientific multiplier. “This was a rover that lasted a long time,” says John Callas, the MER project manager at JPL. “NASA had a requirement that to get to full mission success, you had to go at least 600 meters. So we designed this rovering system to go a kilometer—and we were totally over the moon to have that kind of capability at Mars. We never imagined we would be able to go over 45 kilometers. We’ve driven so far.

This scene from the panoramic camera (Pancam) on NASA"s Mars Exploration Rover Opportunity looks back toward part of the west rim of Endeavour Crater that the rover drove along, heading southward, during the summer of 2014.

Eagle Crater, where Opportunity landed, is geologically in the Hesperian Period—the middle period of Mars history, roughly concurrent with the Archean Eon on Earth. In 2011, the Opportunity rover reached the Endeavor crater, which is Noachian Period rock, where the oldest geology on Mars can be studied. The last eight years have been like a bonus mission, practically a third vehicle in the MER fleet. “In a sense,” says Callas, “by driving this rover so far, we were able to drive back in time and study much older geology.”

One of the greatest contributions of this mission, Callas says, is an intangible. Every day, scientists and engineers wake up and go to work on Mars. Every day, something new is learned and Mars becomes a little more part of our world. “Until January 2004, we had these occasional visits to Mars. The Viking landers in the seventies. Pathfinder in 1997. We attempted to return in 1999 with Polar Lander. With MER, not only did we visit the surface of Mars, but we stayed there. Every day, new information about the surface of the Mars is coming in from some surface asset. We have entered the era of sustained, daily exploration of the surface of Mars.”

Fifteen years of operation with no service station in sight would be an astonishing, successful stretch for any vehicle, let alone one rolling in the inhospitable climes of Mars. The tawny, frozen, dead world that greeted Opportunity has been wholly changed in the eyes of the earthbound. What once was the inert moon, but red, is now a planet where water once flowed freely and in abundance. The question is no longer: Was Mars wet? The rover Opportunity enabled scientists to ask instead: Did something swim in those waters, and how do we find it?

David W. Brown is the author of One Inch From Earth (Custom House, 2020), about a group of scientists who studied Europa, needed to know more, and spent twenty years convincing NASA to mount a flagship mission there. His work also appears in the New York Times, Scientific American and the Atlantic.

SPARKS, Nev.,July 28, 2020 –Sierra Nevada Corporation (SNC), the global aerospace and national security leader owned by Eren and Fatih Ozmen, has contributed eight unique components being used on NASA’s Mars 2020 Perseverance rover, including parts that enable the rover’s safe and stable descent onto the Martian surface. This is the 14th Mars mission that SNC has supported through its critical parts and components.

“These applications are the heart of the Mars 2020 mission,” said SNC CEO Fatih Ozmen. “We are so excited that SNC’s custom-designed engineering is facilitating the groundbreaking work NASA wants to accomplish, in collecting samples from the Mars surface and preparing them to send back to Earth for analysis. We’re so proud to once again be part of the team.”

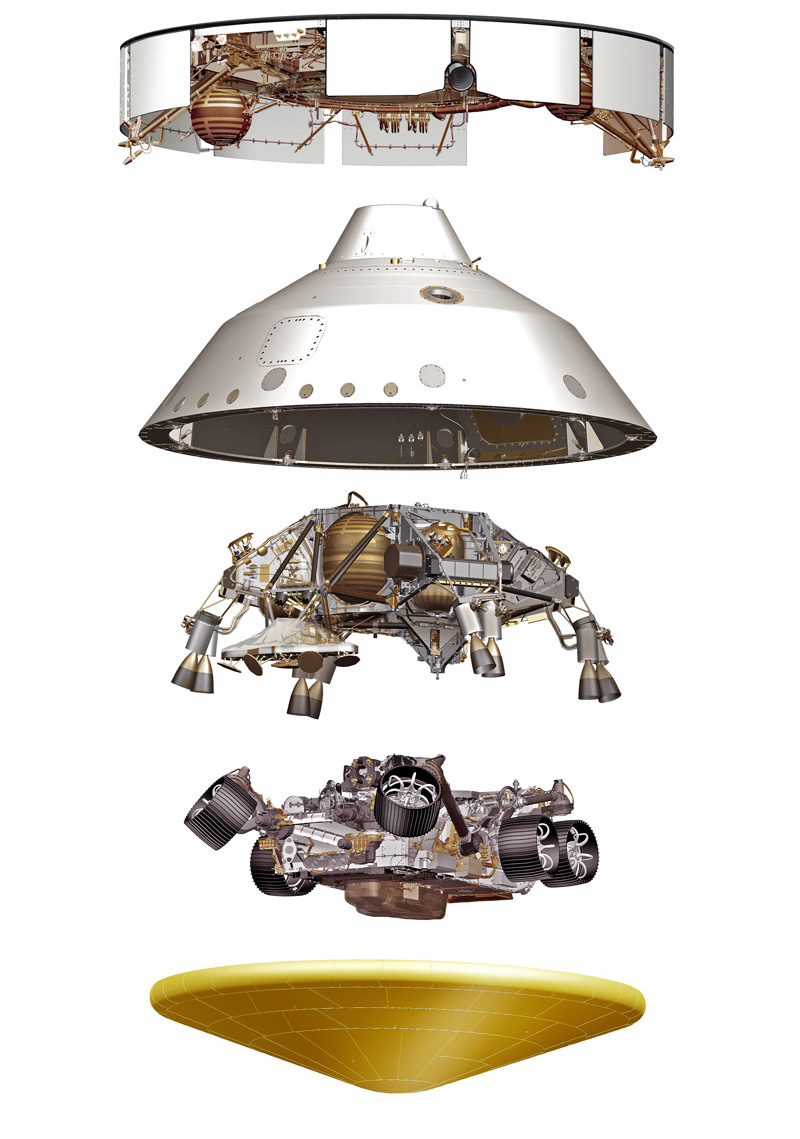

SNC engineering will be front and center when Perseverance makes it descent onto the red planet using the sky crane maneuver. Without the SNC-engineered descent brake mechanism, which has been utilized on prior Mars missions as well, the rover could not safely land on the surface of Mars. The descent brake ensures the rover lowers to Mars in a controlled manner. If the rover is lowered too slowly, the sky crane could run out of fuel and crash before getting the rover to the Mars surface.

Perseverance is also making history by carrying Ingenuity, the first helicopter to fly on another planet. SNC will play a crucial part in getting Ingenuity airborne, having developed the mechanism that assists in its deployment. Once in flight, Ingenuity will study Mars from above, scouting locations for Perseverance to explore.

SNC has supplied more than 4,000 subsystems and components to the U.S. government, prime contractors and international customers since 1987, on over 400 space missions, with 100% mission success.

About Sierra Nevada Corporation (SNC)Owned by Chairwoman and President Eren Ozmen and CEO Fatih Ozmen, SNC is a trusted leader in solving the world’s toughest challenges through best-of-breed, open architecture engineering in Space Systems, Commercial Solutions, and National Security and Defense. SNC is recognized among The Top 10 Most Innovative Companies in Space, as a Tier One Superior Supplier for the U.S. Air Force and is the only aerospace and defense firm selected as a 2020 US Best Managed Company. For nearly 60 years, SNC has delivered state-of-the-art civil, military and commercial solutions including more than 4,000 space systems, subsystems and components to customers worldwide, and participation in more than 450 missions to space, including to Mars.

An instrument system that is part of NASA’s Mars Perseverance Rover, scheduled to land on Mars this month, uses components 3D printed through electron beam melting (EBM) by Carpenter Additive. The titanium parts were challenging to produce because of a design relying on internal lattices and other delicate features to achieve high strength despite minimal material use in accordance with a strict mass budget. As this episode of The Cool Parts Show describes, NASA engineers had to design these components without considering how they might be made. The resulting manufacturing process demands not just 3D printing, but also a sequence of postprocessing steps including chemical milling.

See replicas of the Perseverance additive manufactured parts in this episode, which we filmed while Perseverance itself was in the final days of its approach to Mars.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

That"s right, and we have parts that are on their way to Mars. We have replicas of parts headed to Mars. These are components of NASA"s Perseverance rover, scheduled to land on the surface of Mars, February 18th.

That"s right, these parts are cool, because they are on their way to another planet. But they were also very difficult to manufacture. 3D printing played a big part, but it doesn"t tell the whole story, and we"re going to take you through that process today.

Yeah, among other things, these parts are examples of extreme lightweighting. They had to fulfill their function within a very strict budget of the amount of mass they"re allowed to have. That ultimately shaped a lot of the manufacturing considerations and the number of steps that were involved. These replica parts haven"t undergone all of those steps, so these are unfinished compared to what"s on their way to Mars, they don"t look exactly like them. But they"re plenty to let us talk about all the challenges that went into making these special parts. There are four components here — they all go together. Stephanie, could you describe the system that these components are a part of?

Yeah, so these are all part of the PIXL. It"s the Planetary Instrument for X-ray Lithochemistry. So part of the Perseverance Rover"s mission is to assess the potential for life on Mars and this instrument is going to be part of that mission. So the PIXL is going to be used to look at rock and soil samples on the planet"s surface, look for those signs of life. And the other interesting thing to note about it is that it"s going to be on the end of this cantilever arm, basically on top of a hammer drill. So not only do these components, this instrument, have to survive the launch, the spaceflight, the crash landing on Mars — they"re also going to be in a really challenging location on the rover when it"s actually in use.

The parts are titanium, Ti64, they are made through electron beam melting. These components were designed by NASA engineers and produced through additive manufacturing by Carpenter Additive.

And we should say you may have seen Carpenter Additive as a sponsor on other episodes of The Cool Parts Show. This is not sponsored content, we just really think these parts are cool.

Right, and we think you"ll agree. So, Stephanie, you mentioned how 3D printing is not the whole story here. That"s pretty crucial, and we"re going to draw that out. 3D printing was essential for producing these complex parts — more complex than they seem to be, we"ll get to that — but 3D printing was not sufficient for producing them. There were a variety of postprocessing operations necessary to complete these parts to the design requirements that NASA had. Carpenter oversaw that, they put together that sequence of steps and delivered that process, 3D printing through post processing. If you think about it, what the NASA engineers were tasked with — so yeah, that PIXL device, it has to perform its duty at the end of that drill. And let"s not minimize: it"s got to survive a trip through space, it"s got to survive landing on the surface of Mars, it"s got to do everything it needs to do within very constrained limitations of how heavy it can be. In the end, the designers didn"t have bandwidth to think about, “Could these parts even be made?” And it turns out, they"re pretty difficult to produce.

Right, so if you step back and you look at these components, it"s like, they"re simple parts or simple in what they do. These are brackets, this is a housing component, right? Seemingly, these are the mundane parts of the instrument. But if you"re not careful, these components could eat up all of your mass budget and you need that mass, you need it for the sensors and the electronics that let this instrument do the work it needs to do. So how do you get weight out of parts like these? It comes down to design consideration, it comes down to aspects of the design you wouldn"t even have to worry about if this was being used on Earth. For example, in places and angles where two surfaces come together, not allowing the fillet there, or the web of material to be as large in diameter as you might otherwise allow it to be, because that"s just a little bit too much metal in there and it eats up mass unnecessarily. Or components like these, which look like they could have been made out of, say, bent sheet metal. What parts like these actually are, are very, very thin wall structures that are hollow inside and have delicate lattices that provide the strength at minimal weight. I think this is a good moment to hear from Carpenter Additive, let"s bring in Ken Davis, who is director of Additive Technology.

Yeah, and that"s an important distinction. Like these are sort of similar processes, they"re both powder bed fusion — you have your bed of powder, you have a recoater, and then you have an energy source, either that laser or the electron beam that"s melting the powder together to form your parts. But with laser sintering, the unused powder kind of stays loose in the bed. And with electron beam melting, you"re printing at a really high temperature, the whole machine is at a really high temperature. So you"re basically heat treating at the same time you"re printing. You don"t end up with solid parts in loose powder, you end up with solid parts in this kind of like semi-sintered cake of powder. Like you"re saying, you get some trade-offs with that. You may lose some of the detail and resolution that you could get out of a laser process, but you"re also able to avoid some of the challenges with support structures and the thermal stresses that you might get from that other process.

Thermal stresses are what was really key in what drove the choice in this case. Electron beam melting uses a coarser powder, so even though it is a fine-detail process, at its finest it still produces thicker, heavier forms and features than a laser-based process does. But electron beam melting offers that opportunity to reduce and control thermal stresses, and that was really critical here because the Carpenter engineers just didn"t have the opportunity to add extra material here and there to provide a little bit of bolstering and support against the warping that might happen due to thermal stresses as the parts were being built. That lower thermal stress environment was what was essential for producing these really fine-detail forms for maintaining the geometric fidelity of these fine-detail parts and features.

Okay, so electron beam melting becomes the manufacturing solution here. But there"s still trade-offs, like this introduces some really interesting postprocessing challenges, because a lot of these pieces are hollow. If you"re 3D printing with electron beam melting, and you end up with this like semi-sintered cake of powder inside your parts, you can"t just pour it out. So, let"s talk postprocessing. How did they get that powder out?

Normally, we use manual tools and agitation to clear this powder and break it apart. But we couldn"t get into these small box beams through small access holes that are only about five millimeters in diameter. So we use a technique called ultrasonic powder removal where a transducer is attached to the part, you manually tune the transducer to a frequency that meets the natural frequency of that powder inside and causes it to break apart. But then as it breaks apart, that structure changes its natural frequency, so you have to keep manually retuning. A very small part that would fit in the palm of my hand was so complex, that it took, in some cases, two days of labor to manually adjust this tuning process to get all that powder extracted. But without the ultrasonic powder extraction, we would have never gotten all that powder out of the parts.

So, that"s how they got the powder out. But after that, these components are still too big. They"re the right shape, they"re accurately the right shape, but the features of these components still have too much material, too much mass. Electron beam melting, for all its precision, is still too coarse for some of the delicacy that these features required. For metal 3D-printed parts, machining is pretty typical as an operation after the 3D printing. But machining as we usually think of it — a tool cutting metal — wasn"t sufficient for the needs of parts like these.

As we always say, it"s never just additive manufacturing, there"s subtractive and other processes that are involved. Additive is just one of the tools you bring to bear on this project, or on any project. And never does a project demonstrate that more than this one. So we couldn"t print these thin walls, some were down as thin as 15 thousandths of an inch with a ±one-thousandths tolerance, and then in that same component, it would thicken up to 45 or 60 thousandths in other areas, and then there would be some very heavy features where a bolt was added to the part. What we ended up doing was printing the parts much thicker in general, to a wall thickness that we could guarantee that we could maintain and reproduce print over print with a very narrow tolerance. Then we used chemical milling selectively around the part to bring various wall thicknesses not just into size, but also to achieve the surface finish we desired.

Okay, so we"ve heard electron beam melting, we"ve heard ultrasonic vibration for powder removal, we"ve heard chemical milling, there"s a longer list of operations than that. Can you give us a more thorough sequence of the operations that went into making these parts?

So, there"s a lot. I have a cheat sheet here because I don"t want to forget anything. Taking us all the way back to the printing process, electron beam melting to make the parts; everything went through HIPing, hot isostatic pressing, to eliminate any kind of porosity; then there was breakout, so pulling the parts out of that cake of powder; support removal, some of these parts had sacrificial supports that were attached that had to be removed; ultrasonic powder removal, like we"ve talked about; deburring and grit blasting; chemical milling also, which we just talked about; they used microtek finishing, which is sort of like a polishing process with an abrasive slurry; and then there was some conventional final machining on these parts as well. But one more thing, in between every single one of those steps I just mentioned, there was also inspection. So they used laser scanning, they used X-ray inspection, they weighed the parts in different stages. These are really complicated components and Carpenter wanted to be sure that if anything was going awry, they could catch it really quickly and start over. They didn"t want to put a bad part through all of these different processes. And then at the very end, everything went through CMM inspection before it got shipped off to NASA.

It"s worth saying, additive manufacturing usually is not this difficult. These were distinctive parts, special demands called for special processing considerations.

So we hope for and anticipate a successful landing of NASA"s Perseverance rover on Mars on February 18th. When that happens, when it"s in the news, look for the PIXL device on the rover. Look for these components made through additive manufacturing, look for these cool parts on the surface of Mars.

All right, I think we got this. I"ll start. So these are components of the PIXL instrument for the Perseverance rover currently on its way to Mars. They were 3D printed with electron beam melting out of titanium by Carpenter Additive, who was very limited in the kinds of design changes that it could make. It had to really adhere to NASA"s mass budget and stick to the original design.

Electron beam melting was just the beginning, it accurately produced parts to the right form, but the parts were far from complete at that stage. Getting the powder out was a postprocessing step that came next. A special ultrasonic vibration process was necessary to accomplish that, get the unfused powder out of the parts. Next came a sequence of postprocessing steps necessary to complete these components, one of which was chemical milling for removing unneeded material, getting a little bit more mass out to get it to that mass budget. NASA engineers did not design these components, thinking about how they would be made — there was too many other things to think about. Ultimately, Carpenter Additive took on the challenge of manufacturing these parts and saw them through to an additive manufacturing process complete with postprocessing that was able to deliver these parts effectively.

Speaking of additive manufacturing wins, if you are interested in seeing the kinds of things that additive manufacturing is accomplishing on Earth check out our previous episodes. We have done more than 20 episodes now of The Cool Parts Show. Each one focused on a transformative 3D-printed part, all kinds of applications, many different products and industries. Go to TheCoolPartsShow.com.

If you like the show, we hope you"ll subscribe. If you"re on YouTube, go ahead and click the bell icon to get notified about any new episodes coming out. And if you have a cool part you"d like to tell us about, you can email us at cool parts at AdditiveManufacturing.media.

It takes years of preparation to create the rover, which is made up of many moving parts, including the gears in the arm, which were made by Forest City Gear.

“I think the first one… there were three vehicles, Spirit and Opportunity, and then the next one was Curiosity. This later one is Perseverance,” Young said.

The small parts are a big deal for Forest City Gear: it takes up to eight months to make. NASA needs all the parts finalized one year prior to the big launch.

“It’s fun for folks to learn that their gears are going well beyond the Earth. What’s Mars? Thirty-seven million miles, I think. That’s beyond the imagination of most people,” said Young.

:focal(643x502:644x503)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/31/00/31002851-cfd5-447f-800f-3f64a16d3356/pia08814.jpg)

Perseverance, nicknamed Percy,car-sized Mars rover designed to explore the Jezero crater on Mars as part of NASA"s Mars 2020 mission. It was manufactured by the Jet Propulsion Laboratory and launched on July 30, 2020, at 11:50 UTC.Perseverance has been active on Mars for 721 sols (741 Earth days, or 2 years and 11 days) since its landing. Following the rover"s arrival, NASA named the landing site Octavia E. Butler Landing.

The rover"s goals include identifying ancient Martian environments capable of supporting life, seeking out evidence of former microbial life existing in those environments, collecting rock and soil samples to store on the Martian surface, and testing oxygen production from the Martian atmosphere to prepare for future crewed missions.

Despite the high-profile success of the Curiosity rover landing in August 2012, NASA"s Mars Exploration Program was in a state of uncertainty in the early 2010s. Budget cuts forced NASA to pull out of a planned collaboration with the European Space Agency which included a rover mission.

In 2011, the Planetary Science Decadal Survey, a report from the National Academies of Sciences, Engineering, and Medicine containing an influential set of recommendations made by the planetary science community, stated that the top priority of NASA"s planetary exploration program in the decade between 2013 and 2022 should be to begin a NASA-ESA Mars Sample Return campaign, a four-mission project to cache, retrieve, launch, and safely return samples of the Martian surface to Earth. The report stated that NASA should invest in a sample-caching rover as the first step in this effort, with the goal of keeping costs under US$2.5 billion.

After the success of the Curiosity rover and in response to the recommendations of the decadal survey, NASA announced its intent to launch a new Mars rover mission by 2020 at the American Geophysical Union conference in December 2012.

Though initially hesitant to commit to an ambitious sample-caching capability (and subsequent follow-on missions), a NASA-convened science definition team for the Mars 2020 project released a report in July 2013 that the mission should "select and store a compelling suite of samples in a returnable cache."

The rover"s computer uses the BAE Systems RAD750 radiation-hardened single board computer based on a ruggedized PowerPC G3 microprocessor (PowerPC 750). The computer contains 128 megabytes of volatile DRAM, and runs at 133 MHz. The flight software runs on the VxWorks Operating System, is written in C and is able to access 4 gigabytes of NAND non-volatile memory on a separate card.Perseverance relies on three antennas for telemetry, all of which are relayed through craft currently in orbit around Mars. The primary UHF antenna can send data from the rover at a maximum rate of two megabits per second.X-band antennas provide communications redundancy.

JPL built a copy of the Perseverance; a twin rover used for testing and problem solving, OPTIMISM (Operational Perseverance Twin for Integration of Mechanisms and Instruments Sent to Mars), a vehicle system test bed (VSTB). It is housed at the JPL Mars Yard and is used to test operational procedures and to aid in problem solving should any issues arise with Perseverance.

The Ingenuity helicopter, powered by solar-charged batteries, was sent to Mars in the same bundle with Perseverance. With a mass of 1.8 kg (4.0 lb), it demonstrated the reality of flight in the rarefied Martian atmosphere and the potential usefulness of aerial scouting for rover missions. Its pre-launch experimental test plan was 3 flights in 45 days. As of August 31, 2022, it has made 30 successful flights.Ingenuity"s 25th successful flight, which occurred on April 8, 2022, saw the helicopter set new records for highest speed and distance traveled during a single flight.Perseverance.livestreaming three hours later at 10:15 UTC confirming the flight.Ingenuity made additional incrementally more ambitious flights, several of which were recorded by Perseverance"s cameras.

Associate Administrator of NASA"s Science Mission Directorate, Thomas Zurbuchen selected the name Perseverance following a nationwide K-12 student "name the rover" contest that attracted more than 28,000 proposals. A seventh-grade student, Alexander Mather from Lake Braddock Secondary School in Burke, Virginia, submitted the winning entry at the Jet Propulsion Laboratory. In addition to the honor of naming the rover, Mather and his family were invited to NASA"s Kennedy Space Center to watch the rover"s July 2020 launch from Cape Canaveral Air Force Station (CCAFS) in Florida.

Mather wrote in his winning essay:Curiosity. InSight. Spirit. Opportunity. If you think about it, all of these names of past Mars rovers are qualities we possess as humans. We are always curious, and seek opportunity. We have the spirit and insight to explore the Moon, Mars, and beyond. But, if rovers are to be the qualities of us as a race, we missed the most important thing. Perseverance. We as humans evolved as creatures who could learn to adapt to any situation, no matter how harsh. We are a species of explorers, and we will meet many setbacks on the way to Mars. However, we can persevere. We, not as a nation but as humans, will not give up. The human race will always persevere into the future.

After May 17, 2022, the rover will move uphill examine rocks on the surface for evidence of past life on Mars. On its return downhill, it will collect sample rocks to be retrieved and examined by future expeditions.

One such new technology is Terrain Relative Navigation (TRN), a technique in which the rover compares images of the surface taken during its descent with reference maps, allowing it to make last minute adjustments to its course. The rover also uses the images to select a safe landing site at the last minute, allowing it to land in relatively unhazardous terrain. This enables it to land much closer to its science objectives than previous missions, which all had to use a landing ellipse devoid of hazards.

The landing occurred in the late afternoon, with the first images taken at 15:53:58 on the mission clock (local mean solar time).northern vernal equinox (Ls = 5.2°), at the start of the astronomical spring, the equivalent of the end of March on Earth.

Jezero Crater is a paleolake basin.perchlorates.Dr. Kennda Lynch"s work in analog environments on Earth suggests that the composition of the crater, including the bottomset deposits accumulated from three different sources in the area, is a likely place to discover evidence of perchlorates-reducing microbes, if such bacteria are living or were formerly living on Mars.

During its travels on Mars, NASA scientists had observed around Sol 341 (February 4, 2022) that a small rock had dropped into one of its wheels while the rover was studying the Máaz rock formation. The rock was visible from one of the hazard avoidance cameras, and was determined not to be harmful to the rover"s mission. The rock has since stayed on Perseverance"s wheels for at least 123 sols (126 days) as the rover traveled over 5 miles (8.0 km) on the surface. NASA deemed that Perseverance had adopted a pet rock for its journey.

Mars Oxygen ISRU Experiment (MOXIE), an exploration technology investigation to produce a small amount of oxygen (O2) from Martian atmospheric carbon dioxide (CO2). On April 20, 2021, 5.37 grams of oxygen were produced in an hour, with nine more extractions planned over the course of two Earth years to further investigate the instrument.

Radar Imager for Mars" subsurface experiment (RIMFAX), a ground-penetrating radar to image different ground densities, structural layers, buried rocks, meteorites, and detect underground water ice and salty brine at 10 m (33 ft) depth. The RIMFAX is being provided by the Norwegian Defence Research Establishment (FFI).

Mars Environmental Dynamics Analyzer (MEDA), a set of sensors that measure temperature, wind speed and direction, pressure, relative humidity, radiation, and dust particle size and shape. It is provided by Spain"s Centro de Astrobiología.

There are additional cameras and two audio microphones (the first working microphones on Mars), that will be used for engineering support during landing,Perseverance"s components see Learn About the Rover.

It is planned for Perseverance to visit the bottom and upper parts of the 3.4 to 3.8 billion-year-old Neretva Vallis delta, the smooth and etched parts of the Jezero Crater floor deposits interpreted as volcanic ash or aeolian airfall deposits, emplaced before the formation of the delta; the ancient shoreline covered with Transverse Aeolian Ridges (dunes) and mass wasting deposits, and finally, it is planned to climb onto the Jezero Crater rim.

In its progressive commissioning and tests, Perseverance made its first test drive on Mars on March 4, 2021. NASA released photographs of the rover"s first wheel tracks on the Martian soil.

In support of the NASA-ESA Mars Sample Return, rock, regolith (Martian soil), and atmosphere samples are being cached by Perseverance. Currently, out of 43 sample tubes, rock sample tubes cached: 15,

NASA plans to invest roughly US$2.75 billion in the project over 11 years, including US$2.2 billion for the development and building of the hardware, US$243 million for launch services, and US$291 million for 2.5 years of mission operations.

Adjusted for inflation, Perseverance is NASA"s sixth-most expensive robotic planetary mission, though it is cheaper than its predecessor, Curiosity.Perseverance benefited from spare hardware and "build-to print" designs from the Curiosity mission, which helped reduce development costs and saved "probably tens of millions, if not 100 million dollars" according to Mars 2020 Deputy Chief Engineer Keith Comeaux.

NASA"s "Send Your Name to Mars" campaign invited people from around the world to submit their names to travel aboard the agency"s next rover to Mars. 10,932,295 names were submitted. The names were etched by an electron beam onto three fingernail-sized silicon chips, along with the essays of the 155 finalists in NASA"s "Name the Rover" contest. The three chips share space on an anodized plate with a laser engraved graphic representing Earth, Mars, and the Sun. The rays emanating from the Sun contain the phrase "Explore As One" written in Morse code.

A sample of a souvenir boarding pass for those who registered their names to be flown aboard the Perseverance rover as part of the "Send Your Name to Mars" campaign.

In 2016, NASA SHERLOC co-investigator Dr. Marc Fries — with help from his son Wyatt — was inspired by Geocaching"s 2008 placement of a cache on the International Space Station to set out and try something similar with the rover mission. After floating the idea around mission management, it eventually reached NASA scientist Francis McCubbin, who would join the SHERLOC instrument team as a collaborator to move the project forward. The Geocaching inclusion was scaled-down to a trackable item that players could search for from NASA camera views and then log on to the site.Jet Propulsion Laboratory (JPL), NASA Public Affairs, and NASA HQ, in addition to Groundspeak Geocaching HQ.

Perseverance launched during the COVID-19 pandemic, which began to affect the mission planning in March 2020. To show appreciation for healthcare workers who helped during the pandemic, an 8 cm × 13 cm (3.1 in × 5.1 in) plate with a staff-and-serpent symbol (a Greek symbol of medicine) was placed on the rover. The project manager, Matt Wallace, said he hoped that future generations going to Mars would be able to appreciate healthcare workers during 2020.

One of the external plates of Perseverance includes a simplified representation of all previous NASA Martian rovers, Sojourner, Spirit, Opportunity, Curiosity, as well as Perseverance and Ingenuity, similar to the trend of automobile window decals used to show a family"s makeup.

In December 2021, the NASA team announced a program to students who have persevered with academic challenges. Those nominated will be rewarded with a personal message beamed back from Mars by the Perseverance rover.

The orange-and-white parachute used to land the rover on Mars contained a coded message that was deciphered by Twitter users. NASA"s systems engineer Ian Clark used binary code to hide the message "dare mighty things" in the parachute color pattern. The 70-foot-wide (21 m) parachute consisted of 80 strips of fabric that form a hemisphere-shape canopy, and each strip consisted of four pieces. Dr. Clark thus had 320 pieces with which to encode the message. He also included the GPS coordinates for the Jet Propulsion Laboratory"s headquarters in Pasadena, California (34°11’58” N 118°10’31” W). Clark said that only six people knew about the message before landing. The code was deciphered a few hours after the image was presented by Perseverance"s team.

Landers, Rob (February 17, 2021). "It"s landing day! What you need to know about Perseverance Rover"s landing on Mars". Florida Today. Archived from the original on February 19, 2021. Retrieved February 19, 2021.

mars.nasa.gov. "Touchdown! NASA"s Mars Perseverance Rover Safely Lands on Red Planet". NASA. Archived from the original on February 20, 2021. Retrieved February 18, 2021.

"Mars Perseverance Landing Press Kit" (PDF). Jet Propulsion Laboratory. NASA. Archived (PDF) from the original on February 18, 2021. Retrieved February 17, 2021.

Kremer, Ken (February 11, 2012). "Budget Axe to Gore America"s Future Exploration of Mars and Search for Martian Life". Universe Today. Archived from the original on November 29, 2020. Retrieved February 17, 2021.

Wall, Mike (December 4, 2012). "NASA to Launch New Mars Rover in 2020". SPACE.com. Archived from the original on November 11, 2017. Retrieved December 5, 2012.

Mustard, J.F.; Adler, M.; Allwood, A.; et al. (July 1, 2013). "Report of the Mars 2020 Science Definition Team" (PDF). Mars Exploration Program Anal. Gr. NASA. Archived (PDF) from the original on October 20, 2020. Retrieved February 17, 2021.

"Mars 2020 Rover"s 7-Foot-Long Robotic Arm Installed". mars.nasa.gov. June 28, 2019. Archived from the original on December 5, 2020. Retrieved July 1, 2019. The main arm includes five electrical motors and five joints (known as the shoulder azimuth joint, shoulder elevation joint, elbow joint, wrist joint and turret joint). Measuring 7 feet (2.1 meters) long, the arm will allow the rover to work as a human geologist would: by holding and using science tools with its turret, which is essentially its hand.

"Prototyping an Onboard Scheduler for the Mars 2020 Rover" (PDF). NASA. Archived (PDF) from the original on February 18, 2021. Retrieved July 30, 2020.

Amanda Kooser (September 5, 2020). "NASA"s Perseverance Mars rover has an Earth twin named Optimism". C/Net. Archived from the original on November 28, 2020. Retrieved February 25, 2021.

"Mars mission readies tiny chopper for Red Planet flight". BBC News. August 29, 2019. Archived from the original on December 5, 2020. Retrieved March 14, 2020.

Chang, Kenneth. "A Helicopter on Mars? NASA Wants to Try". The New York Times. Archived from the original on December 17, 2020. Retrieved May 12, 2018.

Drake, Nadia (July 30, 2020). "NASA"s newest Mars rover begins its journey to hunt for alien life". nationalgeographic.com. National Geographic. Archived from the original on July 30, 2020. Retrieved July 30, 2020.

Mehta, Jatan (February 17, 2021). "How NASA Aims to Achieve Perseverance"s High-Stakes Mars Landing". Scientific American. Archived from the original on February 26, 2021. Retrieved February 25, 2021.

Al Chen (26:11) (February 22, 2021). "NASA Press Conference Transcript February 22: Perseverance Rover Searches for Life on Mars". Rev. Archived from the original on March 2, 2021. Retrieved February 27, 2021.

"HiRISE Captured Perseverance During Descent to Mars". NASA. February 19, 2021. Archived from the original on February 22, 2021. Retrieved February 25, 2021.

"Sounds of Perseverance Mars Rover Driving – Sol 16 (16 minutes)". nasa.gov. National Aeronautics and Space Administration. Archived from the original on March 20, 2021. Retrieved October 1, 2021.

Webster, Guy; Brown, Dwayne (January 21, 2014). "NASA Receives Mars 2020 Rover Instrument Proposals for Evaluation". NASA. Archived from the original on November 12, 2020. Retrieved January 21, 2014.

Timmer, John (July 31, 2014). "NASA announces the instruments for the next Mars rover". Ars Technica. Archived from the original on January 20, 2015. Retrieved March 7, 2015.

Brown, Dwayne (July 31, 2014). "NASA Announces Mars 2020 Rover Payload to Explore the Red Planet as Never Before". NASA. Archived from the original on March 5, 2016. Retrieved July 31, 2014.

Jet Propulsion Laboratory (JPL). "Mars Oxygen In-Situ Resource Utilization Experiment (MOXIE)". techport.nasa.gov. NASA. Archived from the original on October 17, 2020. Retrieved December 28, 2019.

Hecht, M.; Hoffman, J.; Rapp, D.; McClean, J.; SooHoo, J.; Schaefer, R.; Aboobaker, A.; Mellstrom, J.; Hartvigsen, J.; Meyen, F.; Hinterman, E. (2021). "Mars Oxygen ISRU Experiment (MOXIE)". Space Science Reviews. 217 (1): 9. Bibcode:2021SSRv..217....9H. doi:10.1007/s11214-020-00782-8. hdl:ISSN 0038-6308. S2CID 106398698. Retrieved March 9, 2021.

Webster, Guy (July 31, 2014). "Mars 2020 Rover"s PIXL to Focus X-Rays on Tiny Targets". NASA. Archived from the original on June 22, 2020. Retrieved July 31, 2014.

"RIMFAX, The Radar Imager for Mars" Subsurface Experiment". NASA. July 2016. Archived from the original on December 22, 2019. Retrieved July 19, 2016.

Chung, Emily (August 19, 2014). "Mars 2020 rover"s RIMFAX radar will "see" deep underground". cbc.ca. Canadian Broadcasting Corp. Archived from the original on September 25, 2020. Retrieved August 19, 2014.

Hamran, Svein-Erik; Paige, David A.; Amundsen, Hans E. F.; Berger, Tor; Brovoll, Sverre; Carter, Lynn; Damsgård, Leif; Dypvik, Henning; Eide, Jo; Eide, Sigurd; Ghent, Rebecca (2020). "Radar Imager for Mars" Subsurface Experiment—RIMFAX". Space Science Reviews. 216 (8): 128. Bibcode:2020SSRv..216..128H. doi:ISSN 0038-6308.

"NASA Administrator Signs Agreements to Advance Agency"s Journey to Mars". NASA. June 16, 2015. Archived from the original on November 8, 2020. Retrieved March 14, 2020.

Kinch, K. M.; Madsen, M. B.; Bell, J. F.; Maki, J. N.; Bailey, Z. J.; Hayes, A. G.; Jensen, O. B.; Merusi, M.; Bernt, M. H.; Sørensen, A. N.; Hilverda, M. (2020). "Radiometric Calibration Targets for the Mastcam-Z Camera on the Mars 2020 Rover Mission". Space Science Reviews. 216 (8): 141. Bibcode:2020SSRv..216..141K. doi:ISSN 0038-6308.

Bell, J. F.; Maki, J. N.; Mehall, G. L.; Ravine, M. A.; Caplinger, M. A.; Bailey, Z. J.; Brylow, S.; Schaffner, J. A.; Kinch, K. M.; Madsen, M. B.; Winhold, A. (2021). "The Mars 2020 Perseverance Rover Mast Camera Zoom (Mastcam-Z) Multispectral, Stereoscopic Imaging Investigation". Space Science Reviews. 217 (1): 24. Bibcode:2021SSRv..217...24B. doi:10.1007/s11214-020-00755-x. ISSN 0038-6308. PMC PMID 33612866.

Webster, Guy (July 31, 2014). "SHERLOC to Micro-Map Mars Minerals and Carbon Rings". NASA. Archived from the original on June 26, 2020. Retrieved July 31, 2014.

Strickland, Ashley (July 15, 2016). "New Mars 2020 rover will be able to "hear" the Red Planet". cnn.com. CNN News. Archived from the original on October 16, 2020. Retrieved March 14, 2020.

mars.nasa.gov (March 5, 2021). "Perseverance Is Roving on Mars – NASA"s Mars Exploration Program". NASA’s Mars Exploration Program. Archived from the original on March 6, 2021. Retrieved March 6, 2021.

"10.9 Million Names Now Aboard NASA"s Perseverance Mars Rover". Mars Exploration Program. NASA. March 26, 2020. Archived from the original on December 9, 2020. Retrieved July 30, 2020.

"Geocaching on Mars: An Interview with NASA"s Dr. Francis McCubbin". Geocaching Official Blog. February 9, 2021. Archived from the original on February 21, 2021. Retrieved February 16, 2021.

"Geocaching and NASA head to Mars with the Perseverance Rover". Geocaching Official Blog. July 28, 2020. Archived from the original on February 16, 2021. Retrieved February 16, 2021.

"NASA"s Perseverance rover to test future spacesuit materials on Mars". collectSpace. Archived from the original on February 18, 2021. Retrieved February 16, 2021.

Wall, Mike (June 17, 2020). "NASA"s next Mars rover carries tribute to healthcare workers fighting coronavirus". space.com. SPACE.com. Archived from the original on December 16, 2020. Retrieved July 31, 2020.

Belam, Martin (February 23, 2021). ""Dare mighty things": hidden message found on Nasa Mars rover parachute". The Guardian. Archived from the original on February 26, 2021. Retrieved February 26, 2021.

Chang, Kenneth (February 24, 2021). "NASA Sent a Secret Message to Mars. Meet the People Who Decoded It". The New York Times. Archived from the original on February 25, 2021. Retrieved February 26, 2021.

NASA"s Mars Exploration Rover (MER) mission was a robotic space mission involving two Mars rovers, Mars. It began in 2003 with the launch of the two rovers to explore the Martian surface and geology; both landed on Mars at separate locations in January 2004. Both rovers far outlived their planned missions of 90 Martian solar days: MER-A Spirit was active until March 22, 2010,Opportunity was active until June 10, 2018.

The mission"s scientific objective was to search for and characterize a wide range of rocks and soils that hold clues to past water activity on Mars. The mission is part of NASA"s Mars Exploration Program, which includes three previous successful landers: the two Viking program landers in 1976 and Mars Pathfinder probe in 1997.

In July 2007, during the fourth mission extension, Martian dust storms blocked sunlight to the rovers and threatened the ability of the craft to gather energy through their solar panels, causing engineers to fear that one or both of them might be permanently disabled. However, the dust storms lifted, allowing them to resume operations.

On May 1, 2009, during its fifth mission extension, Spirit became stuck in soft soil.Spirit was being retasked as a stationary science platform. This mode would enable Spirit to assist scientists in ways that a mobile platform could not, such as detecting "wobbles" in the planet"s rotation that would indicate a liquid core.Jet Propulsion Laboratory (JPL) lost contact with Spirit after last hearing from the rover on March 22, 2010, and continued attempts to regain communications lasted until May 25, 2011, bringing the elapsed mission time to 6 years 2 months 19 days, or over 25 times the original planned mission duration.

In recognition of the vast amount of scientific information amassed by both rovers, two asteroids have been named in their honor: 37452 Spirit and 39382 Opportunity. The mission is managed for NASA by the JPL, which designed, built, and is operating the rovers.

On January 24, 2014, NASA reported that then-current studies by the remaining rover, Opportunity, as well as by the newer Mars Science Laboratory rover Curiosity would now be searching for evidence of ancient life, including a biosphere based on autotrophic, chemotrophic and/or chemolithoautotrophic microorganisms, as well as ancient water, including fluvio-lacustrine environments (plains related to ancient rivers or lakes) that may have been habitable.habitability, taphonomy (related to fossils), and organic carbon on the planet Mars was then switched to a primary NASA objective.

Perform calibration and validation of surface observations made by Mars Reconnaissance Orbiter (MRO) instruments. This will help determine the accuracy and effectiveness of various instruments that survey Martian geology from orbit.

The MER-A and MER-B probes were launched on June 10, 2003 and July 7, 2003, respectively. Though both probes launched on Boeing Delta II 7925-9.5 rockets from Cape Canaveral Space Launch Complex 17 (CCAFS SLC-17), MER-B was on the heavy version of that launch vehicle, needing the extra energy for Trans-Mars injection. The launch vehicles were integrated onto pads right next to each other,Launch Services Program managed the launch of both spacecraft.

On January 21, 2004, the Deep Space Network lost contact with Spirit, for reasons originally thought to be related to a flare shower over Australia. The rover transmitted a message with no data, but later that day missed another communications session with the Mars Global Surveyor. The next day, JPL received a beep from the rover, indicating that it was in fault mode. On

8613371530291

8613371530291