schumacher mission parts factory

Buying a used Schumacher Mission Electric Touring Car, or any used RC Model, has a number of advantages. It is generally cheaper than new, ready built and may come with a variety of expensive hop-ups already installed. Cheap, pre-loved bargains are always becoming available. However, depending on the age of your purchase, it may need a little tender loving care before you can take it out on the road.

The one thing you will always need is an instruction manual. If not supplied with your purchase, they can often be downloaded from the Schumacher website, or purchased separately on eBay. With an instruction manual, any problems with your model Touring Car you may discover, can easily be fixed.

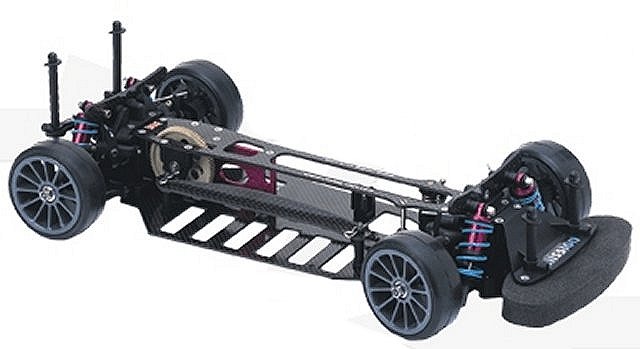

When you receive your used Schumacher Touring Car, make a general visual inspection of the chassis, front and rear wishbones, suspension shock towers etc, for any broken parts that may need to be replaced. Then, take a screwdriver and box spanner and check each self tapping screw and nut for security, taking care not to over tighten.

Next, for those Schumacher models with oil filled shock absorbers, remove them from the chassis and dismantle the coil springs. The damper shafts should push in and pull out with a smooth action. If you feel a jolt as you change direction, this means the oil has leaked out and must be topped up. At the same time, change the O-Ring seals to prevent more leakage. Also check the damper shafts for damage. If they are scratched, change them as soon as possible.

If the body shell of your Schumacher Mission is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your Mission model, fit an under guard to stop dirt and gravel entering the chassis.

If you intend to race your Mission Touring Car model at a competitive level, I would also recommend you obtain and fit titanium pivot shafts, turnbuckles, tie rods and steering rods.

The Mission steering servo is also prone to damage. In high speed crash situations, the fragile gear teeth of the servo can be broken off, rendering your expensive servo useless, so be sure to obtain a good quality "Servo Saver". Check out my Servo Information article.

If body roll on your Schumacher Mission is a problem, handling can be improved with the use of stabilizers, anti roll or sway bars, stiffer tuning springs and, or, thicker silicone oil in the dampers.

If your used Schumacher Touring Car comes with plastic and sintered brass bushings (ring type bearings), check the shafts that run in them for wear. Dust and grit can get into these bearings and abrade the shafts. Therefore, you should replace them all with shielded ball bearings. If the model has been run with ring type bearings, you may have to change all the axles and driveshafts. For more information, take a look at my article, How to get the best from your Bearings.

This FWD variant features a motor-forward design for maximum front grip, fully-adjustable suspension, heavy duty front driveshafts, alloy parts and a large-volume fluid-filled front differential.

Notice: Some of our articles, videos and descriptions may contain affiliate links, which means that if you click on one of the product links, we may receive a small commission. This helps support the website and social media channels and allows us to continue to produce content. Thank you for the support!

After more than 15 years of outfitting race teams with high-performance parts, Don Schumacher Motorsports Precision Manufacturing (DSM) has announced it is expanding into the automotive, defense, equipment/manufacturing, and aerospace industries.

DSM was founded in 2005 as a specialty parts manufacturer and R&D center for Don Schumacher Racing’s (DSR) fleet of championship-winning NHRA race cars, and has since grown to become one of the leading parts suppliers for race teams competing across multiple motorsports industries. Among its most high-profile projects are the DSM engine block and cylinder head assembly, utilized across the DSR teams, and a collaboration with Mopar, SRT, and BES Racing Engines to offer a variety of parts and components for the Mopar Dodge Challenger Drag Pak race car.

DSM is also heavily involved in the NHRA’s Factory Stock Showdown Series, offering on-site parts support to Drag Pak owners, and was instrumental in Leah Pruett’s 2018 Factory Stock Showdown Series title campaign.

“We originally launched DSM as the manufacturing arm of DSR so we could guarantee quality-control by producing key engine components in-house. Other teams took notice and before long, we were producing parts for them, too. We’re thrilled to now be able to offer that same level of high-precision manufacturing and customer service to organizations that operate outside of the motorsports realm,” DSM Vice President Chad Osier said.

The Mission FT is based on Schumacher’s fast, durable, and race proven Mission platform. It features a forward motor position for maximum traction and fully adjustable suspension with alloy threaded shocks to handle the toughest carpetor asphalt tracks.

Should you want try your hand at 4WD the Mission FT can easily be converted into a great handling 4WD touring car. In either 2WD or 4WD configuration the Mission FT is fun to drive, and awesome to race.

BROWNSBURG, Ind. (January 23, 2020) – Rahal Letterman Lanigan Racing (RLL) announced today that Factory Motor Parts (FMP), a multi-generational, family-owned company that provides premium, original equipment and name brand automotive parts, has joined the team as a sponsor of the No. 15 NTT INDYCAR SERIES entry for Graham Rahal in 2020. FVP will be the primary sponsor of Rahal’s Honda-powered entry at World Wide Technology Raceway on August 22 and the company will also be an associate sponsor for the 2020 season.

“Factory Motor Parts (FMP) and the FVP brand are excited to team up with Rahal Letterman Lanigan Racing for the 2020 season,” said Dave Schumacher, Director of Marketing, Factory Motor Parts. “The FMP mission is to be the best independent aftermarket auto supplier in the industry, so teaming up with one of the best race teams, and their partners, is a great fit for FMP and the FVP brand.”

“It’s exciting for us to bring a new partner into the sport and also an exciting time to be in the IndyCar Series,” said Bobby Rahal, co-owner of Rahal Letterman Lanigan Racing with David Letterman and Mike Lanigan. “As a family-owned business there are a lot of synergies between our companies. Factory Motor Parts has built a solid business model over the past 75 years and we look forward to working together to further grow both of our organizations.”

Founded in Minneapolis in 1945, Factory Motor Parts (FMP) is a multi-generational, family-owned company providing premium, original equipment and name brand automotive parts. FMP is a dedicated partner for professional service centers, dealerships, fleets and wholesale customers. FMP is committed to building business-to-business relationships, focusing on the automotive professional.

After more than 15 years of outfitting race teams with high-performance parts, Don Schumacher Motorsports Precision Manufacturing (DSM) has announced it is expanding into the automotive, defense, equipment/manufacturing, and aerospace industries.

DSM was founded in 2005 as a specialty parts manufacturer and R&D center for Don Schumacher Racing’s (DSR) fleet of championship-winning NHRA race cars, and has since grown to become one of the leading parts suppliers for race teams competing across multiple motorsports industries. Among its most high-profile projects are the DSM engine block and cylinder head assembly, utilized across the DSR teams, and a collaboration with Mopar, SRT, and BES Racing Engines to offer a variety of parts and components for the Mopar Dodge Challenger Drag Pak race car.

DSM is also heavily involved in the NHRA’s Factory Stock Showdown Series, offering on-site parts support to Drag Pak owners, and was instrumental in Leah Pruett’s 2018 Factory Stock Showdown Series title campaign.

“We originally launched DSM as the manufacturing arm of DSR so we could guarantee quality-control by producing key engine components in-house. Other teams took notice and before long, we were producing parts for them, too. We’re thrilled to now be able to offer that same level of high-precision manufacturing and customer service to organizations that operate outside of the motorsports realm,” DSM Vice President Chad Osier said.

8613371530291

8613371530291