ce certification mud agitator supplier

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

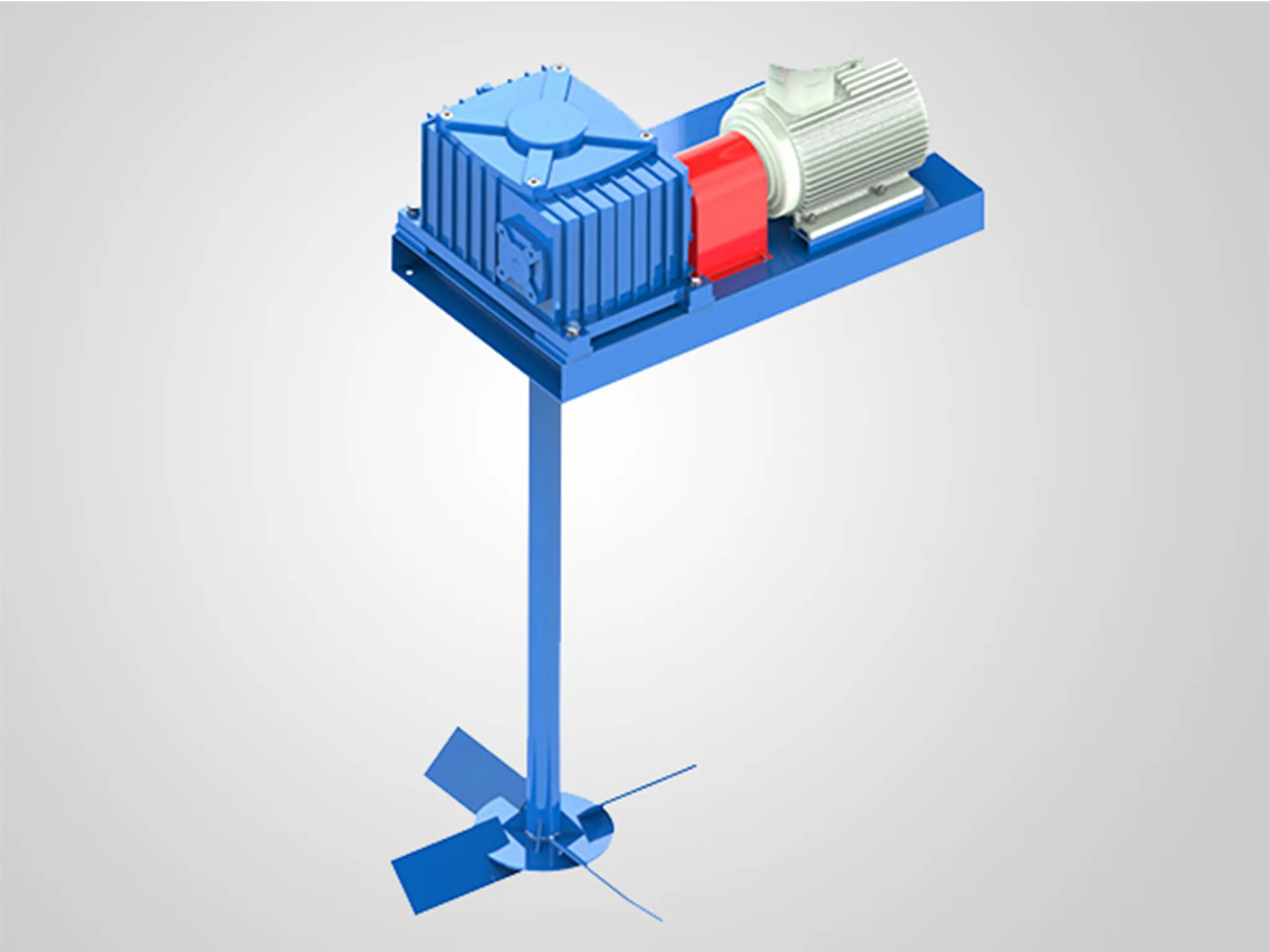

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

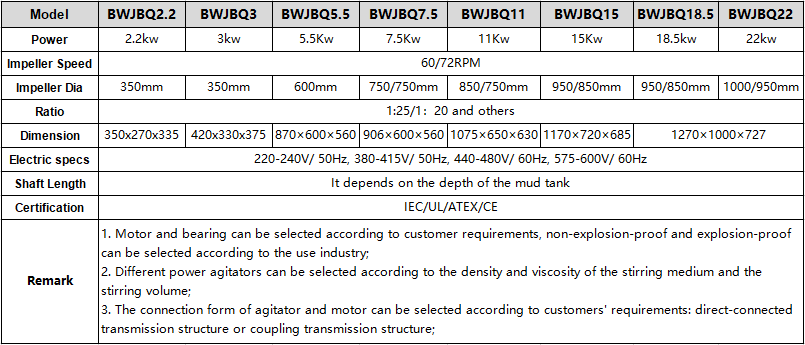

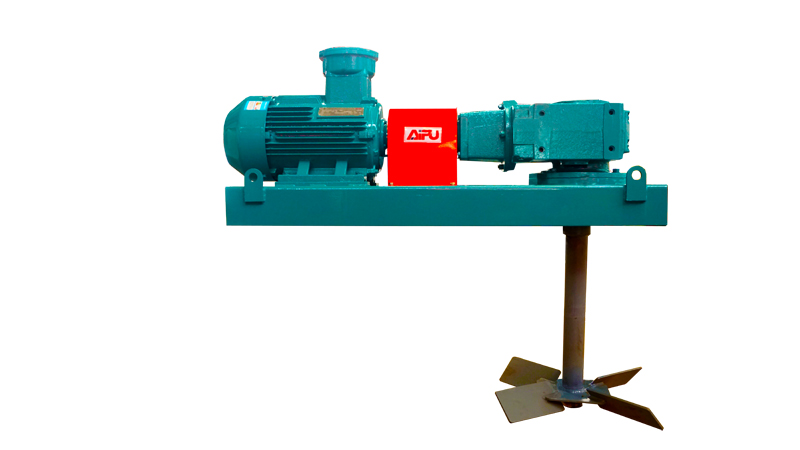

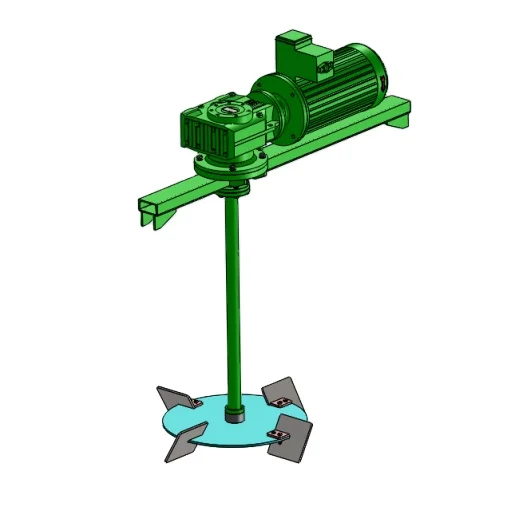

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

After years of development, Brightway Solids Control Co., Ltd. has been recognized by many authoritative organizations in the industry and won many awards, including: the honor of drilling solids control equipment technology center; the honor of high-tech enterprise; the honor of AAA credit company; independent innovation enterprise; independent research and development company; quality service integrity company; police equipment alliance companies; CCTV recommended brand company; Alibaba gold supplier,etc.

The quality management system certifications obtained by Brightway Solids Control Co., Ltd. include: API certification, ISO9001-2015 quality management system certification; environmental management system certification; environmental occupational health and safety management system certification, etc.; industry qualification certifications obtained include: IADC drilling contractor qualification certification; product qualification certifications are: mud shaker CE certification by EU; mud cleaner CE certification by EU; drill cuttings dryer CE certification by EU; drilling fluid centrifuge CE certification by EU, etc.; mud agitator CE certification by EU; drilling fluid sand pump CE certification by EU, etc.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole.

The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Distributor of mixers in varieties including laboratory, drum, tank & more. Uses include welding, power transmission, welding, power tools, painting, security, adhesives, sealants, material handling & pneumatics. Storage/material handling equipment services are also available and include surveying, product selection, layout, product removal and installation. Additional services include 24-hour emergency response services, inventory management services, safety services, repair and replacement programs & hazardous recycling services. 1 year warranty. Services include 24-hour emergency order response services, inventory management services, safety services, repair and replacement programs, hazardous recycling services and storage/material handling equipment services. 1 year warranty.

we are offering mud mixer and mud agitator.colin jet mud mixer is used to concoct the drilling fluids and to change its density and viscosity. This device can satisfy the fluid weighting & mixing of solids control system used for 1500m-9000m drilling. Jet mud mixer is special equipment to prepare and increase the drilling fluids weight by adding and mixing bentonite, change the fluid density, change the mud density, viscosity, and dehydration. The effect is more prominent matching with shear pump. Jet mud mixer is a unit used together with the solids control system for petroleum drilling and horizontal directional drilling (hdd). The unit includes one sand pump, one jet mixing hopper and one jet mixer that are installed in a base with pipe valves. It is safe and stable and can be moved conveniently. At the same time�we can make twin-jet mud mixer according to the user requirements. Jet mud mixer features & benefits: 1. Mud mixer is a single jet mixer combined with 45 kw (or 55 kw) sand pump and a jet mud hopper or a double jet mixer of two pumps and two hoppers. 2. The weighting hopper can be combined with a pump or be used independently with pump connected together by manifold valve. 3. Put the drilling fluids materials (bentonites, barite powder) and the corresponding chemical additives (polymer) into circulation tank for increasing the total.

Drill-Quest Engineering is a family-owned business founded in 2002 in Zug Switzerland by the late William (Bill) Schluneger. Bill was first introduced to the oilfield business early in life by his grandfather while growing up in Oklahoma and began to buy and sell drilling equipment as a young adult.

Kapwell supply customised CE/UKCA/NORSOK, ATEX Zone 1 certified centrifugal degasser to suit the client requirements. All our components are NACE certified and manufactured to the highest quality.

Kapwell degasser ensures the best mud recovery and stabilises mud viscosity. Our Cenrifugal degassers consist of ASME certified degasser vessel, vacuum pump, motor and control cabinet. The drilling mud from the shaker mud tank gets sucked into the vacuum degasser by a vacuum created by a regenerative vacuum/blower. The vacuum degasser then bursts the mud bubbles, causing a release of harmful gasses such as methane, H₂S, and CO₂ from the mud to the surface. The toxic gases then discharged away from the rig at a safe distance to a flare line or other point of disposal

8613371530291

8613371530291