double life mud agitator supplier

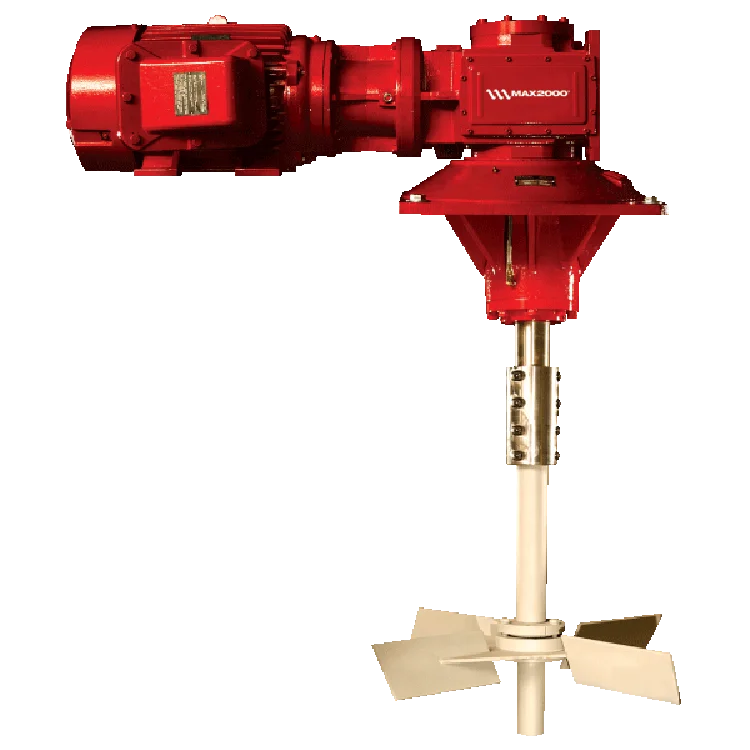

Double Life Mud Agitators are used within the Oil and Gas, Horizontal Directional Drilling (HDD), Chemical, & Water Well Drilling industries. Double Life manufactured Mud Agitators utilize the benefits of a USA Made Helical Bevel Gear Box with Heavy Duty Bearings, Solid Shafts, Keyless Couplings, Synthetic Oil, & Canted Impeller Blades. These Agitators are low maintenance and keep your pits continually in motion. With our low clearance and ease of service, our mud agitators are an easy choice for a contractor!

Centrifugal mud pumps, solids control, mud systems components, shale shakers, mud light, desander, desilter, degassers, cones, wash pipe, hoppers, agitators, shaker screens for all styles

With over 38 years of experience, Double Life 250 Series Centrifugal Pumps utilize top of the line industry technology to create one of the best, most affordable pumps in the market. Additional benefits to purchasing a Double Life pump are tungsten/viton mechanical seals. Fluid ends are made with higher grades of cast iron, producing a greater hardness than others in the industry. Every pump is assembled in the USA. www.doublelifecorp.com

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

When you need to gain rapid access to the essential wholesale mud agitator supplies that your business relies on, head to Alibaba.com where you"ll find thousands of Chinese wholesalers ready to provide the equipment, materials, consumables and products that you need to run your business. From mud agitator supplies that cover all technical specifications through to associated products and office consumables, you can buy everything that your business needs in one place at Alibaba.com.

Simply use the search filters and categories to swiftly find details of mud agitator prices, specifications, order volumes, lead times, discounting arrangements and more. See what other customers thought of individual wholesalers with the customer review feature and see images of operations, markets served and more. You can even chat instantly with sales and support or send an email at any time of day.

Ready to make your mud agitator order? Just do so in a few clicks in your private account area and you"ll receive regular updates on your shipment so that you know exactly where it"s at in the world until it arrives at your business! It"s swift, convenient and cost-effective to shop at Alibaba.com where you"ll find everything that your business needs to operate smoothly and without delay.

The Solids Removal Capabilities Of The Mud Processing System By Effectively Removing Hydrated Clays And Large Drilled Cuttings Upstream Of The Main Shakers.

Ever since 2000 BC when the Egyptians invented the shadoof, a pump used to draw water from wells, the pump has been a key component of everyday life. Here are several types of pumps invented since then, along with some of their most common applications. The wide variety of pumps for today made it impossible for us to include them all.

The GN Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl traps “wet” solids and accelerates them up 900RPM with G force up to 420. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation. GN cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy.It is the ideal products for oil based drilling waste management.

Most water-based muds (WBMs) are disposed of when the drilling job is finished. In contrast, many oil-based muds (OBMs) and synthetic-based muds (SBMs) cuttings are recycled when possible. Sometimes the physical and chemical properties of the used muds have degraded somewhat, and the cuttings must be processed to rejuvenate the necessary properties. In other cases, the cuttings have been degraded sufficiently that they cannot economically be reused as new muds, and they must be put to a different type of reuse or final fate.You can consult GN Solids about the drilling cutting treament business.

GN Solids Control high speed decanter centrifuge is widely used for low gravity drilling mud solids control (LGS). The most popular size decanter centrifuge for drilling mud solids control system is 14 inch bowl.

The high speed decanter centrifuge and low speed decanter centrifuge are fixed speed control. GN Solids Control also make variable speed control decanter centrifuge which can fix for both high gravity solids removal and low gravity solids removal. Besides drilling mud solids control, GN Solids Control decanter centrifuge can also used for drilling waste management.

The major liquid and solids separation equipment GN Solids Control can offer: shale shaker, mud cleaner, desander, desilter, decanter centrifuge, mud agitator, …

Complete mud system GN Solids Control makes: various sizes solids removal unit and mud recycling system for various kinds of drilling activities, like for HDD, CBM, piling, pipe-jacking, etc…

With a history of innovation and setting new standards, Derrick and its patented DP 600 Series shaker reassures its commitment to the drilling industry by providing long-life equipment with low maintenance requirements. This premium product includes an innovative dual concave screen frame, actuated screen compression system, optional vapor extraction covers and hood, and an optional scalping deck. The combination of these features ensures increased fluid handling capacity and provide a new standard in screening equipment.

Mud agitator is designed to agitate drilling mud in side of mud tank to stop solids building up. AIPU Solids Control delivery a number of mud agitators to India end of December through a HDD drill rig company in China. The China drill rig company is a leading rig supplier in China and well sold in India. The drill rig company choose us as a supplier because of good quality and sales service after factory inspection and agitator quality commissioning in jobsite.

2.Electrical motor. The motor will supply power to gear box to drive shaft with impeller for mud agitating. The electrical motor can be explosion proof or non explosion proof depending on drilling activities.

3.Coupler between electrical motor and gear box for steady working. There are agitators that electrical motor and gear box connect with each other directly to save cost, but AIPU build mud agitators with coupler for option for steady working and longer working life.

Mud gun is a set of equipment that for mud agitating like a mud agitator for tank corner as well as mud transfer application. The mud gun normally set at the corner of mud tank to stop solids building up at tank corner and there is a gun at trip mud tank for mud transfer. Other than mud agitating equipments, AIPU Solids Control build a series of mud equipments for solids control system, Please contact AIPU Solids Control freely for inquiry or technical support.

Anaerobic digestion requires temperature equalization and proper homogenization of the biomass to achieve a high gas production and to avoid sedimentation of organic matters. The surface crusts must be broken and prevention of foam must be managed if there are foaming tendencies. Sulzer can provide efficient and reliable Scaba agitators for digesters with high-efficiency propellers. Muffin Monster™ grinders upstream from the anaerobic digesters condition the sludge before digestion, improving the homogenization of the biomass and protecting the equipment downstream.

Whether on the surface or underground, the conditions in mines are harsh. Besides the mud, slurry, stones, and rocks, there are large volumes of water to remove in order to keep production moving.

Energy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

The sludge buffer tank can be used for a variety of purposes. The most common application is the blending and homogenization of highly concentrated primary, secondary or digested sludge. The solution used to mix the sludge itself, or to mix the sludge with the dosed thickening chemicals, depends on the design and volume of the sludge buffer tank. Submersible mixer types ABS XRW and RW, as well as the agitator type Scaba, can be used to provide highly efficient mixing. Positive displacement, progressing cavity transfer pumps and Muffin Monster™ grinders are used for solids reduction and sludge transfer from sludge feed to sludge dewatering process.

Sulzer pumps, mixers, grinders and agitators are used to condition, transfer, blend and handle sludge. Our progressing cavity, positive displacement pump range, provide a near constant flow rate with suction lift capability, for handling all types of non-Newtonian sludge and cake processes, typically demanded within the wastewater treatment plant. Maintain in place features ensure any process downtime due to the change out of wear components is kept to a minimum. The Muffin Monster™ grinders protect the equipment downstream. The sludge conditioned by grinders will not clog valves, heat exchangers, digesters, centrifuges and other equipment on the sludge line.

Water supply is vital for our daily life. To abstract the water at the source, be it the sea, river, lake or dam, water intake pumps are needed. Sulzer offers a range of pumps that are specially engineered for such applications.

Energy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

8613371530291

8613371530291