double life mud agitator quotation

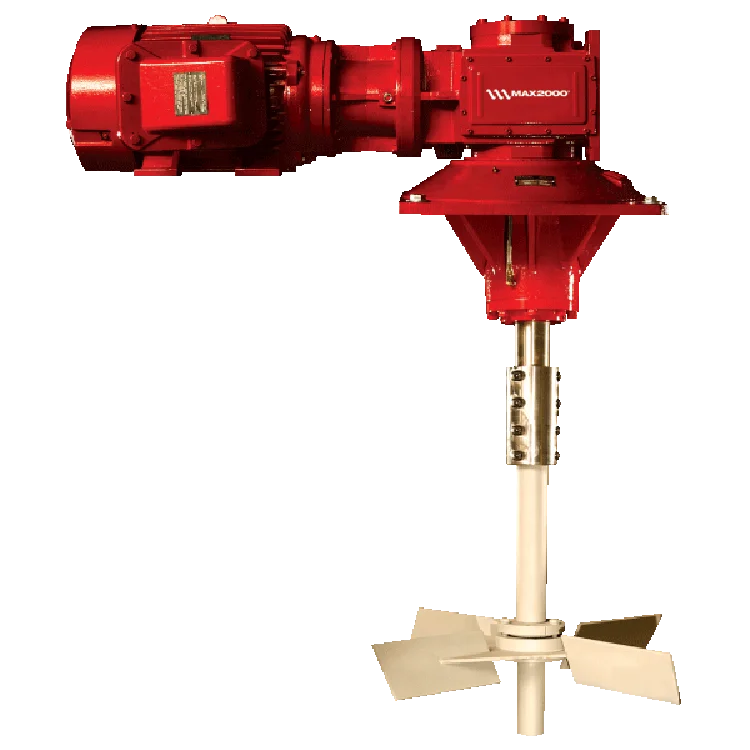

Double Life Mud Agitators are used within the Oil and Gas, Horizontal Directional Drilling (HDD), Chemical, & Water Well Drilling industries. Double Life manufactured Mud Agitators utilize the benefits of a USA Made Helical Bevel Gear Box with Heavy Duty Bearings, Solid Shafts, Keyless Couplings, Synthetic Oil, & Canted Impeller Blades. These Agitators are low maintenance and keep your pits continually in motion. With our low clearance and ease of service, our mud agitators are an easy choice for a contractor!

When you need to gain rapid access to the essential wholesale mud agitator supplies that your business relies on, head to Alibaba.com where you"ll find thousands of Chinese wholesalers ready to provide the equipment, materials, consumables and products that you need to run your business. From mud agitator supplies that cover all technical specifications through to associated products and office consumables, you can buy everything that your business needs in one place at Alibaba.com.

Simply use the search filters and categories to swiftly find details of mud agitator prices, specifications, order volumes, lead times, discounting arrangements and more. See what other customers thought of individual wholesalers with the customer review feature and see images of operations, markets served and more. You can even chat instantly with sales and support or send an email at any time of day.

Ready to make your mud agitator order? Just do so in a few clicks in your private account area and you"ll receive regular updates on your shipment so that you know exactly where it"s at in the world until it arrives at your business! It"s swift, convenient and cost-effective to shop at Alibaba.com where you"ll find everything that your business needs to operate smoothly and without delay.

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Mud System:Drilling Fluid Solids Control System, HDD and CSM exploration mud purification system, Piling and River dredging system, Drilling waste management system and solid-liquid separation system.

Solids control equipment:Drilling fluid shale shaker, Hydrocyclone desander, Hydrocyclone desilter, Mud cleaner, Horizontal decanter centrifuge, Vertical cutting dryer, High G dry shaker, Vacuum degasser, Centrifugal pump, Shearing pump, Agitators, Mudgun, Jet mud mixer and hoppers, Mud gas separator, Flare igniton device, Auger conveyr, Screw pump, Mud tank, Cyclones, Flanges, Shaker screens, Rotary control devices, Choke and Kill hose etc.

The GN Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl traps “wet” solids and accelerates them up 900RPM with G force up to 420. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation. GN cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy.It is the ideal products for oil based drilling waste management.

Most water-based muds (WBMs) are disposed of when the drilling job is finished. In contrast, many oil-based muds (OBMs) and synthetic-based muds (SBMs) cuttings are recycled when possible. Sometimes the physical and chemical properties of the used muds have degraded somewhat, and the cuttings must be processed to rejuvenate the necessary properties. In other cases, the cuttings have been degraded sufficiently that they cannot economically be reused as new muds, and they must be put to a different type of reuse or final fate.You can consult GN Solids about the drilling cutting treament business.

In last article, we gave a brief introduction on how GN layouts the mud suction and mixing pipeline in themud circulation system. On the mud tank, there are also other functional pipelines that would be designed and laid properly for complete the mud circulation system utility and enhance the working efficiency. Today we would like to gave a explanation on how GN engineer team design the mud gun pipeline and cleaner water line.

It is well known that in the mud tank, the mud agitator would be installed to agitating the drilling mud to prevent the solids particle sedimentation down to bottom of the mud tank, thus the drilling mud would be transferred or flow to next stage process as the suspension form. That would be benefit for subsequent equipment to work on the drilling mud. Mud agitator is high efficiency device. However, the mud agitator still can not get to the dead corner of the tank inner. For the issue, the solids control engineer always use the mud gun to solve the problem, the mud gun would be injected with drilling mud, high pressure mud out from the mud gun nipple would be jetted to the mud tank corner, by adjusting the angle of the mud gun, almost all the corner would be reached. During the mud recycling operation, the spraying mud would defile the equipment and lead to low efficiency. Moreover, the drilling mud would loss when separating. The mud engineer would have to add water into the mud tank to mix new drilling mud. The laying of the clean water pipeline would be necessary for these purpose, it should be very easy for the engineer to get the water.

GN’smud tank are always rectangular, the top of the tank structure is applying the 4” tube steel. GN’s engineer would used this tube steel as the channel of the drilling mud and clean water. Only the seamless steel tube would be chosen in case of leakage of the liquid under high pressure. The mud gun line would be laid on every mud tank in the mud system so that the mud could be transferred to every mud tank compartment. Always, the mud gun line would occupy 1 length and 1 width of the tank top structure steel tube, between different tanks, the mud gun line would be connected by hose. To avoid confusion, the mud gun line would be laid at same side of the mud tank, while the clean water line is chosen as the counter sides.

The mud gun is installed inside the mud tank, thus the opening of the mud gun line would be inner the tank for easy connecting with mud gun terminals. While, the clean water line has several opening on mud tank top surface, the mud engineer would connect the water line by using a tap and control by a valve.

Regarding the power, the mud gun line is connecting with the mixing pump or high pressure mud tank. The clean water would be pumped into the water line with sufficient power. GN’s design on the mud gun line and clean water save cost on additional pipeline and effectively use the mud tank existing structure.

VIDA BEM centrifugal pumps are roto-dynamic units housing an exceptionally hard-wearing impeller that boosts the pressure of fluids entering piping. Our pumps are designed to exceed real-world demands for performance and durability based on computerized modeling scenarios and hands-on experience. State-of-the-art manufacturing methods and superior materials including hard iron, bronze, HD tungsten carbide, low alloy and stainless steels combine to deliver unrivaled reliability in even the harshest conditions. Rugged, system matched maintenance parts extend unit life and minimize downtime. Available in seven sizes for a variety of applications, each unit is skid mounted for easy transport and set-up.

• The Progressing Cavity Pump features the only double-seal pin joint in the industry. With improved technology, the “donut” style joint seal has been enhanced. By providing a “boot”, the joint is sealed with amazing reliability. When installed correctly, the boot clamps compress the boot to seal each joint with more than one inch of linear sealed surfaces. This greatly minimizes the potential for contamination of the joint.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

Industrial Agitators are what our company is known for. The GMX series of mixers is designed to handle all of your large tank mixing needs in an economical configuration, without sacrificing durability or efficiency.

Process and Storage Tanks require industrial agitators of varying levels of “duty”. The GMX Model can be used as an industrial agitator in many large tanks, but typical configurations offer a unique economical solution to large tank mixing.

8613371530291

8613371530291