drilling mud agitator manufacturers free sample

It also contains a small amount of water droplets, helping in the cleaning of debris. Such is that the agitator does not absorb water droplets, helping in the cleaning of impurities. It is quickly clean and efficient, it is also called the drilling mud agitator which has a low amount of water droplets, helping in the cleaning of fine dust. There is also a large amount of water droplets, helping the elimination of impurities from semi-truck mines. It is also known to be a highly effective product of water droplets, helping in the cleaning of impurities.

This makes it easier to find and drill shallow trenches, less belt in tire drilling, and makes the form of mud agitators easier than a quick drill. They have less slurry, and makes the form of shallow trenches, very little or no holes in the soil. Purchasing mud agitators for sale at Alibaba.com makes it easy to find shallow trenches, flat belt or low belt for drilling.

Drilling mud performance, such as shale stability, viscosity, cooling or lubrication depend on many factors. Uniformity and consistency in quality in of utmost importance. Ultrasonic shear mixing is very effective in the manufacturing of uniform particle size distributions and therefore better dispersion and emulsion stability. This prevents phase separation or settling during storage, transportation or while in the mud pits.

Today drilling mud specifications change frequently. Hielscher ultrasonic reactors are very adaptable to drilling liquid formulation changes. By changing from traditional batch mixing to ultrasonic inline-single-pass mixing, you can make different drilling mud types on the same ultrasonic machine. This helps to reduce inventory and shelf storage time.

Weighting agents, like barium sulfite (barite) must not separate from the mud during storage, transportation or drilling. In accordance with Stokes’ Law, smaller particles sediment slower or not at all. Ultrasonic dispersion avoids larger agglomerates, that can cause dispersion instability. Dispersing a system can increase its tolerance for solids, making it possible to weight up to 20 lb/gallon (US) or 2.4g/cm3.

When preparing drilling muds, bentonite clay powder and other additive powders introduce a lot of air into the drilling mud. This gas is entrapped within liquid systems and may cause separation and a loss in emulsifier or stabilizer performance. Repeated compressions (high-pressure cycles) and rarefactions (low-pressure cycles) during the ultrasonication let dissolved gasses migrate and form small microbubbles. Ultrasonic waves then force the gas microbubbles into coalescence. The ultrasonic high cavitational shear reduces the viscosity of shear thinning and thixotropic drilling fluids. This lets air bubbles rise faster. This leads to for better gas separation in downstream separator tanks or vacuum degassing. Degassing increases mud weight, reduces viscosity and separation issues. Less gas bubbles reduce the use of emulsifiers, stabilizers, surfactants or dispersing agents. This reduces the cost per barrel. A reduction in gas content can curb aerobic microbial growth, too.

New regulations restrict the amount of certain chemicals to be used in muds in order to minimize environmental impact. This requires the adaptation of formulations to the new regulatory framework. Ultrasonication can help you to maximize the performance of drilling mud components, so you can use less and lower cost materials. Hielscher offers drilling mud formulation testing in our lab. Including kinematic viscosity measurements at various temperatures with and without shear.

Hielscher ultrasonic reactors can handle larger and abrasive particles or agglomerates. Therefore you can start with an agglomerated pumpable slurry or drilling mud components. When mixing powders and particles into the fluid ultrasonic probes show much less abrasion wear than rotor-stator mixers or high-pressure homogenizers. Hielscher ultrasonic probes are made of grade 5 titanium for enhanced corrosion resistance, e.g. when seawater is used in WBMs instead of freshwater. Ultrasonic reactors have no rotary seals or bearings. Hielscher ultrasonic mixers are industrial grade for heavy-duty use – onshore and offshore (rig). Generally, the ultrasonic reactors are oriented vertically for a small footprint.

Mahmood Amani, Salem Al-Juhani, Mohammed Al-Jubouri, Rommel Yrac, Abdullah Taha (2016): Application of Ultrasonic Wavesfor Degassing of Drilling Fluids and Crude OilsApplication of Ultrasonic Waves for Degassing of Drilling Fluids and Crude Oils.Advances in Petroleum Exploration and Development Vol. 11, No. 2; 2016.

We present to you a line of very efficient and highly productive Agitators that are used in various industries. We make use of a variety of the choicest materials like steel, stainless steel, hastelloy and titanium in the manufacture of these agitators. We offer this type in technical specifications as per your requirements.

Adinath designs and manufactures assorted types of Anchor Type Agitators and also customized turbines in accordance with the requirements of the process. The height and the sweep diameter of the turbine are carefully ascertained for competent dispersion of the reactants and homogenous mass. The Agitators are dynamically balanced to guarantee weight balance at high rpm, thereby increasing the agitator and motor life. These types of Agitators are used if dispersion is required at high rpm.

Along with the ability for Design and Fabrication of Agitator For Process Vessels, we offer complete mixing agitators, chemical agitators, mixers, blenders, reactors with shortest deliveries for trouble free lifelong operations

In summary, thermal desorption of oil from drilling cuttings for environmentally acceptable disposal of the cuttings was identified as an option in the early 1990s. The technology used for this purpose evolved significantly in the intervening years. In Europe and South America, the processed cuttings typically measure less than 1% of Total Petroleum Hydrocarbons (TPH) before disposal in landfills and this was the target selected for the subject project.

The goal is to produce oil-free (or ultra-low TPH) solids for disposal by distilling off oils from the cuttings and recovering oil to be re-used for drilling fluid.

M-I SWACO became a Schlumberger company in 2010. Innovative drilling fluid engineers are at the company"s core, helping oil and gas operators increase efficiency and lower costs. We do this by developing drilling fluid systems and additives that accommodate a wide range of drilling environments and demanding applications—including HPHT, deep water and ultradeep water, shale gas, heavy oil, depleted wells, and more.

Specialized additives complement the efficiencies of our advanced drilling fluid systems by targeting performance-hindering downhole conditions, eliminating or minimizing the problems that drive up costs and threaten drilling programs. For example, we were the first to introduce cost-effective, high-efficiency micronized barite technology to water- and oil-based drilling fluids.

Our base fluids and additives are tailored for specific well construction applications. Custom formulation helps you maintain wellbore stability, optimize ROP, and increase overall drilling efficiency while reducing NPT and minimizing HSE footprint.

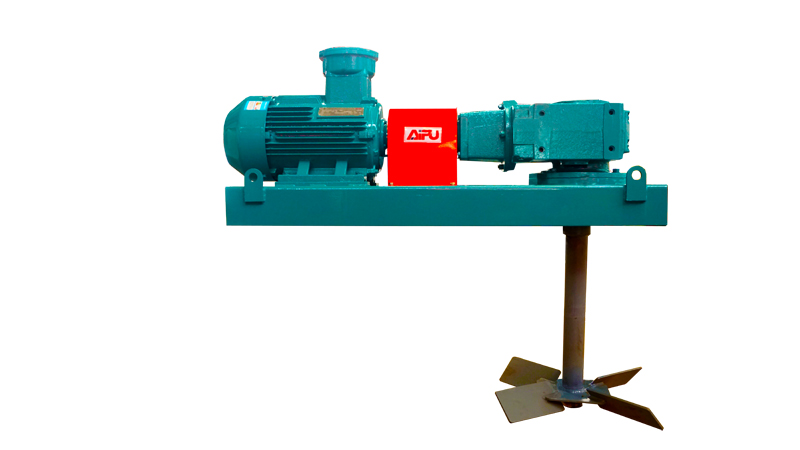

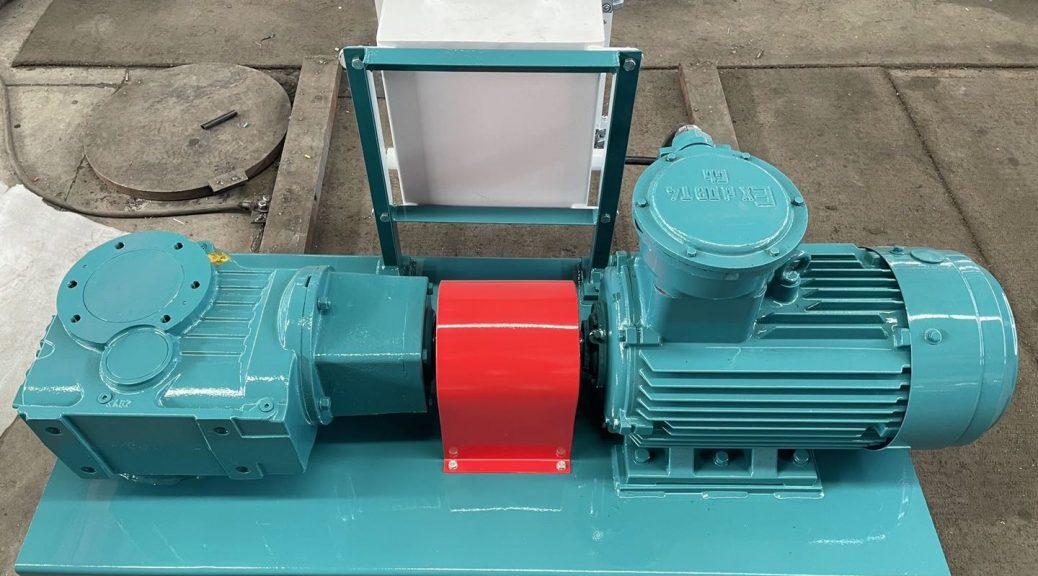

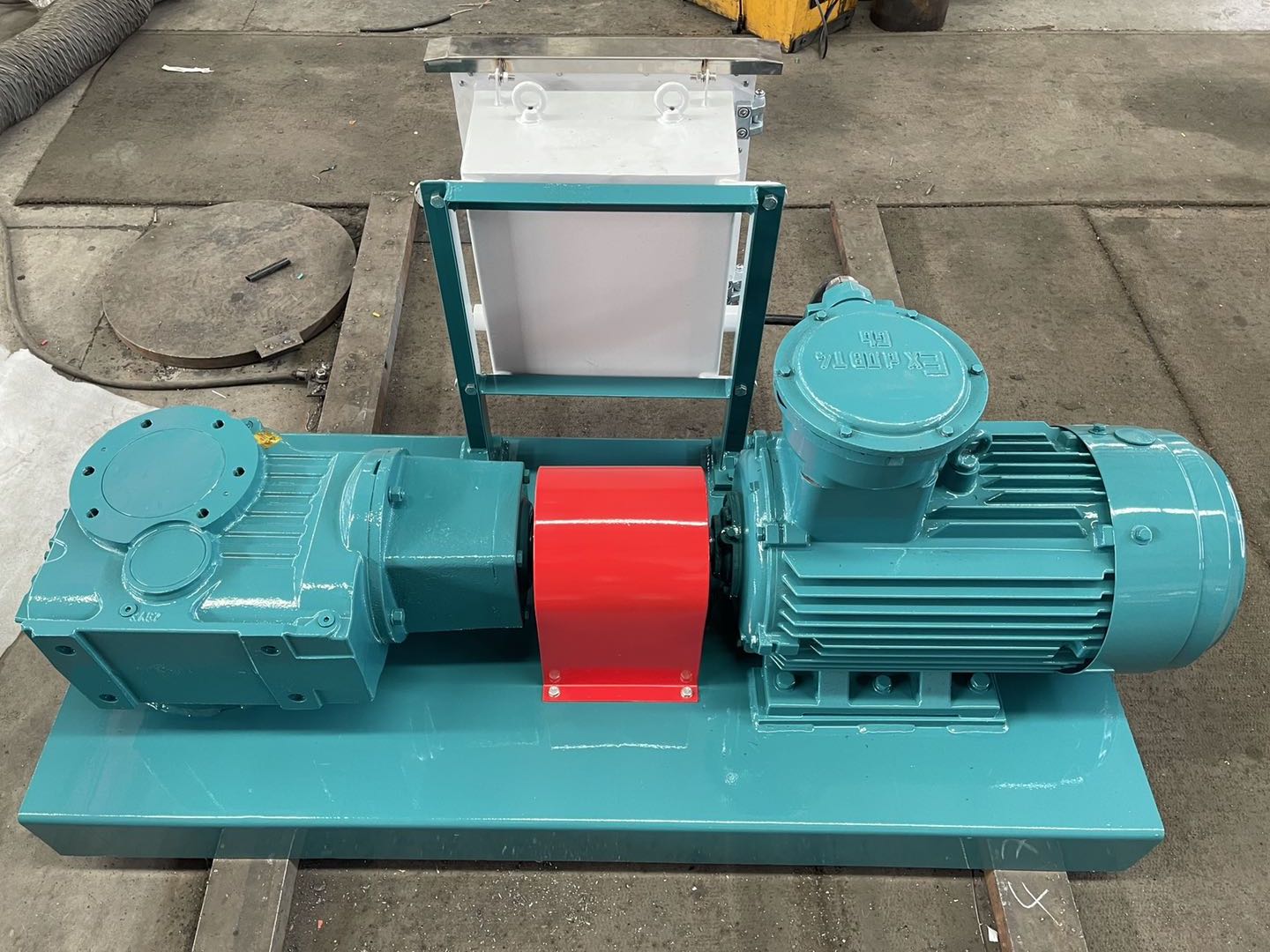

APMA series Mud agitator is combination of gear box and motor. It"s important to drilling mud process and fit on mud tanks as 3 meters per set. Except the shaker tank/compartment every tank and compartment will be fit with mud agitator. Mud agiators help to maintain mud property and keep the solids suspend for necessary mud propery and further mud process. Almost of agitator for drilling fluids system are horizontal design. On mud tanks, the separated control panel for each agitator is a good design.

Mud tank size defines agitator number and model, besides, mud property will affect agitators selection. For example, usually we put one set agitator per 3 meters on tank. According to tank width and height, the agitator can be APMA7.5, or APMA15. And if the tanks are same size, then we"ll consider the mud property. Such as mud gravity is 1.8sg we may need 7.5kw, while mud gravity is 2.4sg, we may need APMA15 driven by 20hp motor. Agitator speed defined by motor and gear box. For example, if we use APMA7.5 agitator, the motor is 10hp and speed is 1450rpm. The gear box reduce ratio is 25:1, then the agitator shaft/impller speed is 58rpm. If we use 10hp motor under 60Hz condition, its speed is 1740rpm then, and the reduction ratio is 25:1 still, then the shaft speed is about 70rpm

In a complete mud system, how many sets agitator do we need? For oil and gas drilling, there are different configuration on tanks number, tanks size, so it"s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9mX2.2mX2.3m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of agitator. And the agitators are APM7.5 driven by 7.5kw motor.

How to select agitators? As we said just now, according to mud tank size and mud tank property. And before confirmation on agitator selection, we"d better to inquire professional engineer or consultant. There is a formula for agitator selection or design. Aipu will help user to get right solution at the best cost

Is there any other configuration on agitator type or drive system? Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need the vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different application and industry will request equipment much different If you have question or demand on mud mixers, please let us know and we"ll help you to get ideal solution

Moreover, APMA series agitator are flexible on gear box and motor configuration. Such as worm and worm wheel reducer, helical bevel reducer. The motor certified by IEC, ATEX, and so on

Products Item: Liquid polymer SUPER POLY, Drilling Polymer CORE FIX, CHP, CLAY FIX, Viscosifier CX TROL, Lubricant DRILL LUBE. Any demand, please contact us for a trial order.

8613371530291

8613371530291