mcm mud agitator quotation

5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

Savona Equipment is your source for New, Used, and Reconditioned Industrial Agitators and Mixers for processing products in the mining, chemical, food, pharmaceutical and cosmetic industries by mixing liquids together, promoting the reactions of chemical substances, keeping homogeneous liquid bulk during storage and increase heat transfer (heating or cooling). RefurbishedIndustrial Agitators and Mixers parts will be fully repaired or replaced.

Mud mixers, mashers & pans are suitable for mixing & storing dry ingredients with liquids, paints, sealers & compounds for construction, chemical processing & painting applications. Raptor Supplies offers a wide array of Hyde, Kraft Tool Co. & Marshalltown mixers, mashers & pans. Selected models feature lightweight aluminium construction & built-in hooks for holding / hanging the mud pan on user"s belt while leaving hands free. Choose from a wide range of mixers, mashers, pans and scoop buckets on Raptor Supplies.

Shale shaker screens are important consumable parts. The screen panel is important to shale shakers. High-quality screens will help the shaker to get great performance. The accurate cut point prevents certain particles and cuttings to drop down into the mud tanks affect the further process or impact the property of the fluid.

Shaker screen life varies because of shaker conditions, mud condition, drilling condition, and the operator, etc. That means if the screens were from one batch and holding the same mesh size but life lasts different there might be the above reasons. For example, we drill an oil well in Kuwait use the OBM the extra thin screen cloth will help to get better penetration or conductance and leadless mud block or mud overflow but the life may be shorter since the fragile wire. When we use screens holding the same API size and the same configuration at some Yan"an oilfield sites use WBM, the screen life will be much longer. Since the general viscosity and mud condition is better than in Kuwait.

The mud engineers will test drilling fluids time by time. This will tell us how to do further process. They don"t check active mud property but also check the disposed of mud. They will evaluate whole mud volume and general mudflow situation. The capable mud engineers give the optimal suggestion on mud use and screen use. Finally, we"ll get the optimal solution on solids control for whole good drilling and save necessary cost

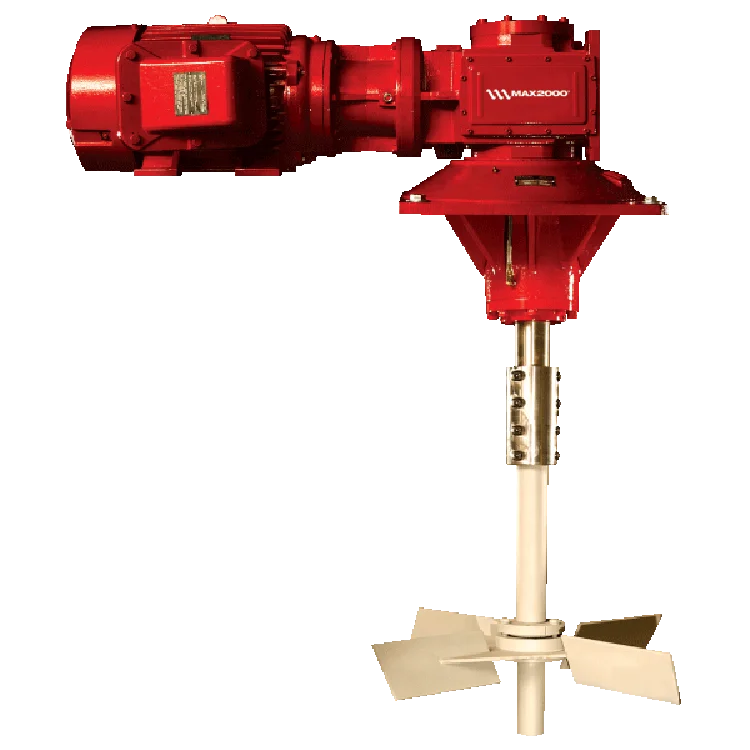

An Agitator is a equipment used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator Mud Agitator, depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitatorin API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

8613371530291

8613371530291