mud agitator calculator brands

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

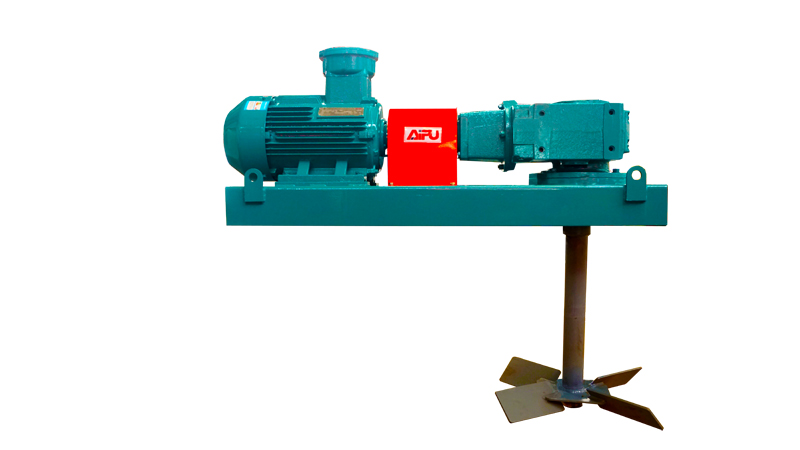

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

The major technological facilities for Alumina Refinery comprises of various types of stationery and rotating process equipment like crushers, conveyors, ball mills, tanks, pumps, piping, agitators, evaporators, heat exchangers, causticizers, filters and calciners. Majority of the process equipment in the Alumina refinery are tailor-made suiting the plant capacity requirement.

In the opinion of equipment designers and process experts, the design of agitators for mixing the slurry with the desired degree of agitation is considered to be complicated and tricky issue.

In view of requirement of suitable agitators for Alumina refinery, it was felt essential to briefly outline the mixing process and elaborate the basic guidelines with associated parameters required for drive rating calculations for slurry mixing agitators suiting various process conditions in Alumina refinery.

Agitator components mainly include impeller, shaft, gear box and drive motor suitably designed for meeting the process requirement. The mixing process for keeping the solids in suspension is known as off-bottom suspension. This process keeps the solid particles moving just above the bottom of the vessel preventing the settling of solids.

The other process used for homogeneity of slurry is popularly known as Full tank suspension. In case of full tank suspension, the degree of agitation is close to 10. Hence the agitator always moves the tank bottom solids to the top level allowing its transfer to next tank connected in series.

Due to the actual characteristics of alumina hydrate or sizes of tanks with very large useful capacity, following are additional challenges for the designer while designing the agitators to be used in the white area of the Alumina Refinery -

Hence adequate precautions must be taken by Agitator manufacturers while selecting / designing the impellers considering above critical aspects as power number and flow number depend on the type of impeller.

Dimensionless numbers often correlate with some performance parameter and greatly aid engineering analysis and design. Main dimensionless numbers used for arriving at drive rating for agitators are Reynolds number, Flow number and Power number.

While designing the mixing agitators for process industries like Alumina refinery, illogical Reynolds number is used comprising of impeller diameter of mixer, RPM of agitator, density of fluid and kinematic viscosity of fluid.

The most common type of washer is the top-load, belt-driven washing machine. This variety of washing machine uses an agitator to spin the clothes through the water and remove dirt. Agitator washing machines are the least expensive to purchase; however, they require the most water to operate, increasing the cost of utilities. These washers typically have the shortest wash time, but do not extract as much water as their high efficiency counterparts; resulting in an increased amount of time required for drying.

Notably, agitator-style washing machines require less maintenance than high efficiency washers and subsequently tend to last longer than high efficiency washers (Consumer Affairs). Traditional agitator washing machines range from $300 to $900, depending on brand, features, and capacity.

High efficiency top-load washers use an impeller motion and spin faster than traditional agitating machines. They clean clothes better, using less water, and extract water better than standard agitating washing machines, thereby reducing required drying time. A high efficiency washer takes longer to complete a cycle than the agitator variety, but is typically more gentle on clothes.

High efficiency top-load models are more expensive than agitator machines, but less expensive than front-load washers. These models typically range from $650-$1000 (Consumer Reports). High efficiency models require more maintenance than the traditional agitator variety and have a shorter lifespan, averaging around 11 years (The Spruce).

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

8613371530291

8613371530291