mud agitator gearbox in stock

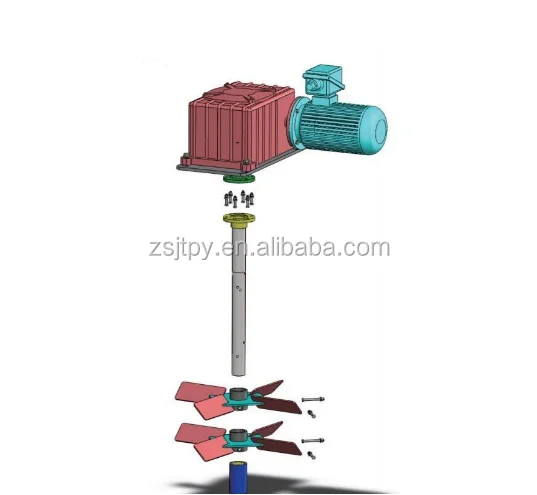

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

The Agitator provides rugged reliability along with the flexibility to meet your specific needs. Design features include a rugged cast iron gearbox housing helical bevel gearing which runs more smoothly than standard worm gears for cooler, more efficient operation and longer life. The unit’s unique lower bearing configuration allows maintenance from to top of the tank, eliminating the need for in-tank inspections. Lower bearing seals are arranged to maintain a grease pocket supplemented by four rings that ensure the gears are continually bathed in uncontaminated lubricant. Our unique shaft coupler is the strongest, most reliable in the industry. Available in vertical and horizontal configurations with a choice of canted or hydrofoil impellers in carbon or stainless steel.

• The Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high

• Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the Agitator is the lower bearing, which can

pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

• An external oil sight glass has been provided, so the oil level can be checked at a glance. Vent plugs are supplied and installed in the gearbox housing to maintain a homeostatic internal pressure, which prevents a pressure build-up that could blow out an oil seal.

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

The skid mounted MA-RG agitator is compact, and its low profile reduces headroom requirements and provides more layout space on top of the tanks. The gearbox is a triple-reduction helical-bevel gear drive system that reduces the rotational speed of the motor to drive the impeller(s). Up to 95% mechanical efficiency helps reduce horsepower requirements.

Impellers are available with flat blades (radial flow), contour blades (axial flow), and canted blades (radial/axial flow). The impellers are sized according to tank volume and expected duty. Active mud system compartments—such as solids removal sections, mud mixing sections, and slug pits, which need a higher shear force to produce immediate mixing—are another consideration in impeller sizing.

Several types of shafts are offered. Mild steel shafts are cut to length and joined to the gearbox output shaft with a rigid coupling. Solid shafts are keyed at the bottom for impeller height adjustment. Hollow pipe shafts are available for deep tanks. They are supplied in flanged sections and bolted together, making them ideal for limited lifting height.

GearBox is a crucial part of mud agitators. Mud agitators are used in surface mud system to suspend solids and maintain homogeneous mixture throughout the system.

Mud agitator was one of solids control equipment and has two main type: verticle agitator and horizontal agitator. It is very important to select optimum gearboxes for various applications of drilling project or other mud treatment.

Beacasue the gearbox which attaching the motor directly to protects correct alignment that can increase bearing life and provides high efficiency in power transfer to the impeller.

In the past, horizontal agitators mainly use worm gear unit for cost reason. But worm gear easy to broken and mantainance is difficult. you have to open shell to grease gear. Now horizontal mud agitator use helical-bevel gears ( like derrick agitator ). Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Rigid tooth flank helical gear unit are advanced of helical gears. Rigid tooth flank means more wear resistant and long life to use. So it’s trend to use rigid tooth flank gearbox.

Mud agitatoris part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solid particles from settling in circulating tank. It is composed of explosion proof motor, speed reducer,motorbaseandblade.The motor and speed reducer, speedreducer andimpeller shaft are connected by steel coupling. The impeller is welded with four blades.

GearBox is a crucial part of mud agitators. Mud agitators are used in surface mud system to suspend solids and maintain homogeneous mixture throughout the system.

Mud agitator was one of solids control equipment and has two main type: verticle agitator and horizontal agitator. It is very important to select optimum gearboxes for various applications of drilling project or other mud treatment.

Beacasue the gearbox which attaching the motor directly to protects correct alignment that can increase bearing life and provides high efficiency in power transfer to the impeller.

In the past, horizontal agitators mainly use worm gear unit for cost reason. But worm gear easy to broken and mantainance is difficult. you have to open shell to grease gear. Now horizontal mud agitator use helical-bevel gears ( like derrick agitator ). Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Rigid tooth flank helical gear unit are advanced of helical gears. Rigid tooth flank means more wear resistant and long life to use. So it’s trend to use rigid tooth flank gearbox.

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Finemade offers a variety of motor and impeller sizes to fit specific tank configurations. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole.The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used.

Landa mud agitators include an explosion-proof, “C” faced motor, reduction gearbox, impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

The direct-drive shaft assembly featured on our agitators maximizes motor efficiency which results in reduced energy consumption and greater performance. Available in vertical or horizontal configurations, all of our agitators are completely customizable and or to meet your specific tank dimensions and mud weight range.

8613371530291

8613371530291