mud agitator parts factory

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

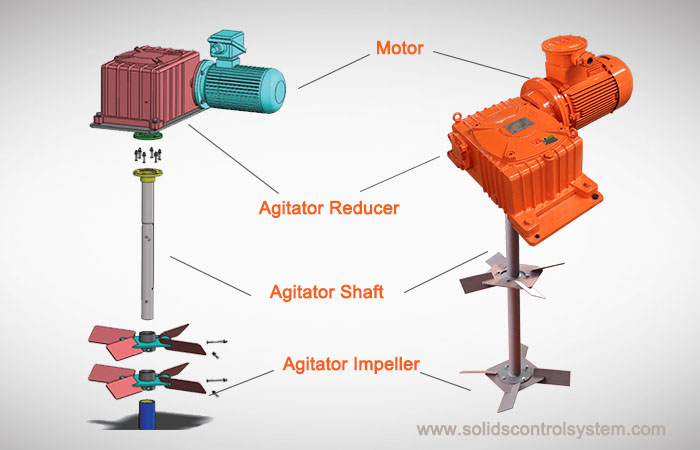

The mud agitator parts includes motor, reducer, base, stirring rod, impeller and other spare parts. Among them, the motor and the reducer, and the reducer and the pulsator shaft are all connected by a rigid coupling, and the pulsator is assembled by welding four blades. The mud agitator is generally installed on the surface of the mixing tank, and the mixing medium is mainly solid and liquid, including mud, muddy water, oil and water and other media.

In the actual use of mud agitator, often due to the quality of the motor, reducer, base, stirring rod, impeller and other spare parts will fail or be damaged, so the quality of the mud agitator parts thedirectly determines the effect and life of the agitator. When we choose a mud agitator, we need to know the daily maintenance and troubleshooting methods of the mud agitators spare parts.

The failures caused by the mud agitator parts include drive failure, transmission failure and mechanical failure. The failure of the explosion-proof motor parts of the mud agitator will cause the drive failure of the motor unable to rotate. The failure of the reducer spare parts will cause the motor torque to be unable to be transmitted to the stirring rod through the reducer, and transmission failure occurs. If the maintenance is improper, for example, the reducer is not often lubricated, it is indeed easy to malfunction; the impeller of the agitator, The material of the extension bar spare parts or improper installation may cause other mechanical failures. Therefore, the two important parts of the motor and reducer need to be specially maintained during the use of the agitator.

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission、 the revolution is steady、it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW 、JBQ7.5kW 、JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for GN Solids Control drilling fluids processing system.

GN Solids Control as a professional manufacturer for soilds control equipments, we have designed lots of high-quality products, and JBQ series Agitator is one of them. To keep both the mud uniformity and the suspension of solids, the mud agitator is used to agitate the mud consecutively and reliably.This agitator agitates the mud to make cuttings, silt and sand pass the solids control system without being precipitated onto the tank bottom. Due to the simplex turbine decelerator, this product is featured by compact construction, light weight, balanced transmission, low noise, high efficiency of transmission and strong agitating power. Therefore, it is a reliable product in the solids control system.

China manufacturer GN Solids Control offer the world with drilling mud agitator equipments.We are an exporter of drilling fluid mud agitator for Indian, Russian,middle east.etc..Our factory and company are Quality Management System ISO 9001-2000 certified.GN Solids Control operate international oil gas drilling mud separation system sales,service,manufacturing,distribution serivce.Buy drilling fluid mud agitatorfrom China manufacturer.Your best mud agitator for drilling mud circulation system.

We know just how critical downtime can be to your operations. And we’ve responded by developing an inventory system that assures ready availability of critical parts, and a delivery network that speeds those parts right to your door. ProQuip’s standard delivery system can often ship stock parts the same day as ordered. Extremely large stock orders or those requiring additional manufacturing may take longer.

Sometimes old machinery can no longer satisfy current application requirements. But with genuine ProQuip parts, your worn agitators or outdated drive systems can often be retrofitted with new, more efficient components. The end result for you: a cost-effective solution that gets your proven performer back in top operating condition to handle today’s demanding service conditions.

Nearly every agitator is customized to some extent. Shaft extensions are manufactured to fit into each customer’s specific vessel or tank and impellers are sized to specifically fit the application. There are also numerous other components of an agitator which, due to customer request or design requirements, were originally custom made. ProQuip maintains records on every ProQuip agitator shipped with complete design details.

These customized components must be manufactured to the application specifications to replace the original component. Delivery of these custom components is dependent on component complexity and material availability. Shafts and impellers can often be turned around in 2 weeks or less. ProQuip offers competitive prices and assurance that replacement parts are made to the same demanding standards as the original equipment

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

ProQuip doesn’t just make industrial tank agitators, we deliver comprehensive mixing technology and solutions that will help you meet your specific process objectives. Whether you’re in chemical processing or a wide variety of other industries, our stock and custom tank agitator designs are engineered to provide reliable, efficient, long-term performance that will help maintain product quality, maximize productivity, and reduce downtime.

Contact us today at 1-330-468-1850 or applications@proquipinc.com for help determining the right tank agitator and mixing solution for your application.

Mud agitators are indispensable in drilling fluid configuration. The mud agitator adopts the circular arc cylindrical worm reducer, the shaft section is a circular arc cylindrical worm, and the worm gear tooth shape is a circle that is conjugative to the worm. Therefore, the convex-concave meshing performance is reliable, the benefit is high, and the structure is compact.

The circular arc tooth of themud agitator reducerin the mud agitator is a kind of mud agitator part that can often be seen. It has great advantages in structure and transmission, especially in special environments. It has the function of automatic locking, so it is liked by many solid control manufacturers.

1: Heat and oil leakage of the arc reducer. The arc gear worm gear reducer is designed for the purpose of improving the operation efficiency. The worm gears used are all made of non-ferrous metals, and the worms are mostly made of hard steel. Therefore, during the operation of the sliding friction drive, the worm gears are reduced. The machine will generate a large amount of heat and increase the temperature of the reducer. The temperature increase of the worm gear reducer will cause the various parts in the reducer to have differences in the fit due to the different coefficients of thermal expansion, resulting in a gap between the mating surfaces. The oil such as lubricating oil used in the reducer will also become thinner or deteriorated under the action of high temperature, resulting in leakage or lubrication failure. The way to prevent the temperature rise of the worm gear reducer is to reasonably match the material of the worm gear and worm to avoid excessive friction. At the same time, pay attention to the surface quality of the meshing friction surface and select suitable lubricants. Another direct way to cool the reducer is to install a cooling device or reduce the temperature of the operating environment.

KOSUN mud agitator is part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solids particles from depositing in the circulating tank and to stabilize the performance of drilling fluids. The motor and speed reducer, speed reducer and impeller shaft are connected by steel coupling.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

8613371530291

8613371530291