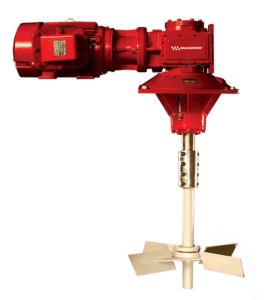

mud agitator schottel supplier

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

The MAX2000® Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high impact forces generated when the unit is energized at start-up. Each helical bevel gear stage is 98% efficient. A typical worm gear set is only 85% efficient, since it loses most of its efficiency through the generation of heat.

Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the MAX2000® Agitator is the lower bearing, which can be maintained from the top of the tank. This feature eliminates the need for in-tank inspections of the lower bearing, and also provides a barrier of grease that can be expunged out the lower seal. The lower seals are arranged to accommodate the grease pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

SCHOTTEL Industries GmbH is an industrial holding company with activities in the areas of marine propulsion systems, gearbox technology, automation technology and renewable energies. SCHOTTEL Industries is owned by the descendants of the founder of SCHOTTEL GmbH as well as by the Norwegian company Frydenbø Group AS. The Group currently comprises six companies and a total of around 1,200* employees.

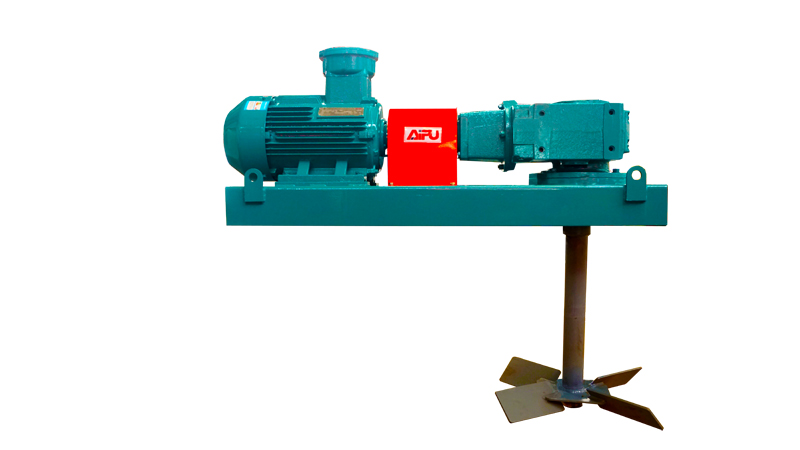

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

The direct-drive shaft assembly featured on our agitators maximizes motor efficiency which results in reduced energy consumption and greater performance. Available in vertical or horizontal configurations, all of our agitators are completely customizable and or to meet your specific tank dimensions and mud weight range.

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

8613371530291

8613371530291