mud agitator sizing in stock

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

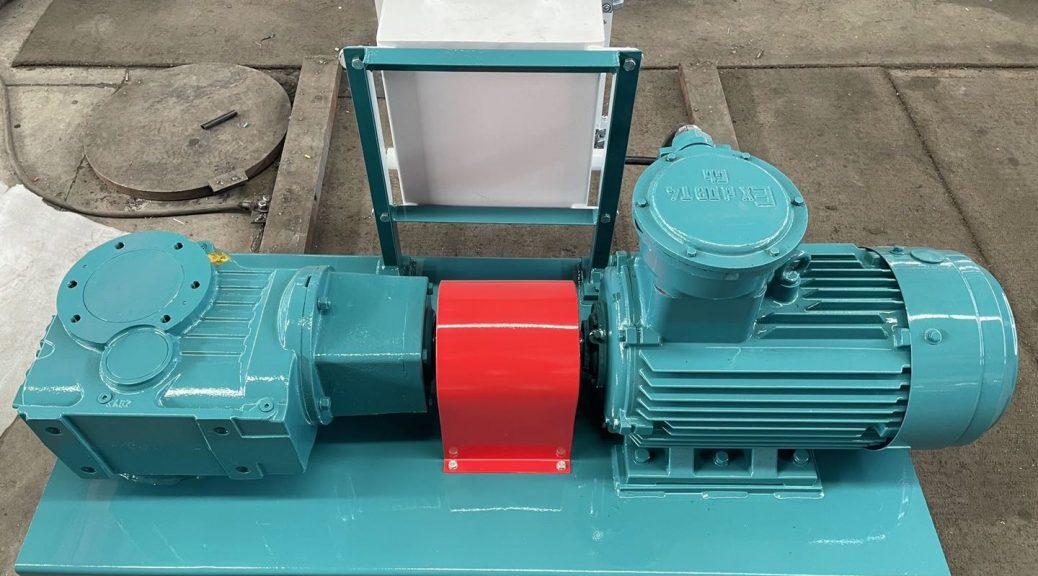

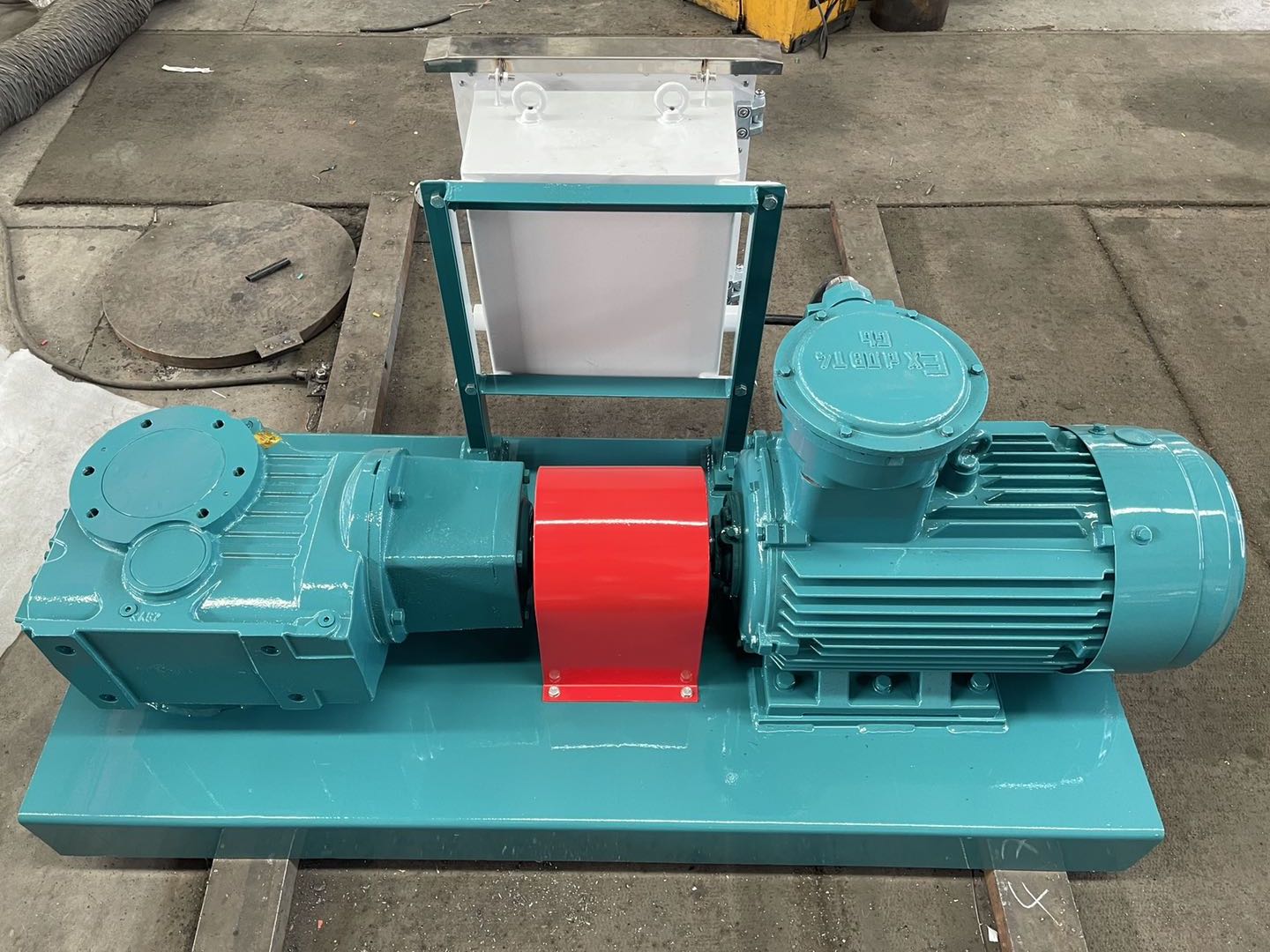

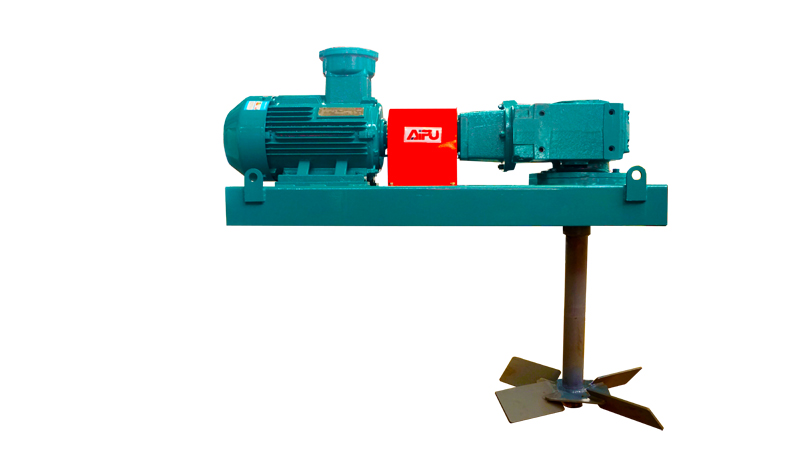

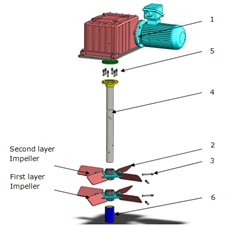

The skid mounted MA-RG agitator is compact, and its low profile reduces headroom requirements and provides more layout space on top of the tanks. The gearbox is a triple-reduction helical-bevel gear drive system that reduces the rotational speed of the motor to drive the impeller(s). Up to 95% mechanical efficiency helps reduce horsepower requirements.

Impellers are available with flat blades (radial flow), contour blades (axial flow), and canted blades (radial/axial flow). The impellers are sized according to tank volume and expected duty. Active mud system compartments—such as solids removal sections, mud mixing sections, and slug pits, which need a higher shear force to produce immediate mixing—are another consideration in impeller sizing.

A mud agitator is mainly used to agitate and mix the drilling mud to prevent solid particles from depositing in the tank. For proper mixing the mud agitator must be properly sized with respect to power requirement and impeller size.

Flow simulation (CFD) can be used to predict the rate of deposition in a tank. In many cases CFD is convenient for purposes of preliminary assessment, when the only opportunity to perform physical test is after the agitator is already installed in the field. Simulation can also be used efficiently to optimize with respect to engine power and impeller design.

The most accurate approach is to model the deposition in the tank as time passes. This is called a transient simulation. However, transient simulationis are very time consuming. A faster approach is to assume steady-state condition of the circulating fluid. For mud agitators this is usually a very good approximation to assume that the flow is not changing with time.

When the process is not verified by previous installations PG will do a CFD analysis of the tank and agitator to verify the rheology and the required installed power.

North AmericaUnited States of AmericaTel:1-847-967-2400Fax:1-847-967-3915EuropeUnited KingdomTel:44-1753-224000Fax:44-1753-224224Latin AmericaBrazilTel:55-11-3371-2500Fax:55-11-3371-2599Middle East & AfricaUnited Arab EmiratesTel:971-481-27800Fax:971-488-62830Asia PacificSingaporeTel:65-6518-1800Fax:65-6518-1803If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior totheir selection and use. In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications withoutprior notice. It is dangerous to smoke while handling products made from PTFE. Old and new PTFE products must not be incinerated. ISO 9001 andISO14001 Certified, details available on request.©2020 John CraneJC368 Revised 03/20www.johncrane.comAN-PULPPAPERAGITATORSSealing RecommendationsType 37FS Heavy-duty Split SealsThe seal most frequently used for this equipment is theJohn Crane Type 37FS non-pusher elastomer bellow splitseal or Type 3740 split seal which is often fitted with theType 73 inflatable seal. Since the equipment is large anddifficult to remove, split seals are easily used and theType 37FS effortlessly handles any shaft movements. Theaddition of the Type 73 inflatable seal allows the split sealto be serviced by holding back the product all the while thetank is full reducing downtime and eliminating lost product.However, the Type 73 inflatable seal is not split. Most oftenthe Type 37FS split seal is flushed but during shut downsthe seal water can fill the tank. Therefore, a split bushingoften made of PTFE is inserted into the stuffing box toreduce water entering the tank.Additionally, for Sulzer (Ahlstrom) Salomix SL and ST modelagitators, the Safematic Type SE2 seal is used. It is appliedin both single (SE1) and dual (SE2) seal versions dependingon the severity of the service. However, this version’sadaptive hardware differs from the pump seal design.If the shaft deflection is not an issue Standard Cartridgeseals can be used.Standard Cartridge SealsTYPE SB2/ SB2ASafematic SB2/SB2A is a dual cartridge seal. Its doublebalanced design ensures the reliability and longevity ofthe seal in the most demanding conditions. The SB2/SB2Aseal is ideal for use with environmentally hazardous andabrasive fluids, most often used in pumps in pulp mills,minerals processing and other slurry duties up to 40%solids by weight and a solids hardness of 8 Mohs.Materials: Seal faces SiC/SiC, SiC/CarbonO-rings: PTFE, EPDM, FFKMMetals parts: AISI 329 and 316 or higher a standard requirementPiping PlansThere is a growing demand for reducing seal water usageand seal-related costs. Environmental issues are aconcern, and high seal reliability is also required.Safematic Safeunit is a unit construction pressure andflow control device. These units control and monitor sealwater flow and pressure. Safeunit permits seal conditionmonitoring both visually and electronically. Low sealwater flow alarms sensors are typically used to preventseal failures and interlock agitators if flow is lost. Safeunitdetects internal seal leakage by avoiding uncontrolled sealwater leaks into the process, improving product quality andreducing energy costs.PLAN 32Type SFP for Packings or Plan 321.Inlet and outlet connections2.Check valve3.Flow gauge and valve4.Pressure gaugePLAN 54Type SFD for Dual Seals Plan 541.Inlet and outlet connections2.Connections to seal and from seal3.Check valve4.Flow gauge and valve5.Pressure gauge and valve112323445

TSC mud agitators are an important part of the mud solids control system. TSC offers a variety of motor and impeller sizes to fit specific tank configurations.

8613371530291

8613371530291