o drill mud agitator in stock

Dragon pump accessories are constructed to handle the harsh oilfield environment. Dragon stands ready to support our drilling and oilfield customers with the highest quality equipment in the industry. And, as always, Dragon backs every product it manufactures with the support you need.

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

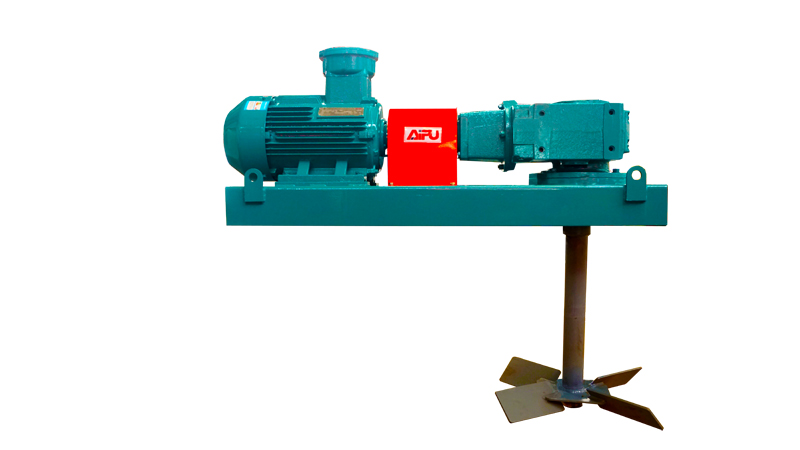

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

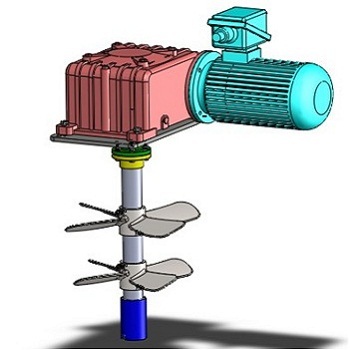

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole. The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration. Bothhorizontal / vertical drilling mud agitator available for option.

GN Solids Controlis a world famous turnkey provider of solids control equipmentfor oil and gas drilling fluids. GN Solids Control has rich experience on design, development, and manufacture solids control equipment includes but not limited to shale shaker and shaker screen, decanter centrifuge, desander, desilter, mud cleaner, mud agitator, cuttings dryer, centrifugal pump, screw conveyor and mud tank etc.

Last month, GN Solids Control finished manufacturing of one batch mud agitators for one offshore drilling rig platform. Consider the heavy duty mud, GN Solids Control provides helical bevel gerabox reducer for these mud agitators.

GN Solids Control manufactures mud agitator with single impeller, double impellers or multiple impellers. The shaft length of the mud agitator is customized based on customer’s mud tank depth.

GN mud agitator keeps the drilling mud from sediment, and plays a very important role in mud mixing, preparing and storage. GN Solids Control also provides control boxes to match the mud agitators, explosion proof includes IEC Ex, ATEX, CNEX etc.

In order to use in the offshore platform, GN Solids Control use PPG painting to cover the mud agitators with 3 layers which can keep sea moisture rusty from long time usage.

Besides the mud agitators, GN Solids Control has also been providing the other types of solids control equipment like decanter centrifuges and shale shakers for offshore drilling platforms. GN Solids Control made DNV lifting certified equipment is able to move safely and conveniently, the DNV lifting pad and supporting frame can be added optionally.

Now GN Solids Control has many solids control equipment in stock, once we received the order, we can just buy the motors and put the control boxes, tested and get it to delivery very fast. Welcome to connect with GN Solids Control for any drilling mud solids control and drilling waste management equipment inquiries.

Impeller sizes are determined by calculating the TOR (sometimes called the time of rollover) for each compartment. This is the time, in seconds, required to completely move the fluid in a compartment (Table 10.1) and can be calculated by knowing the tank volume and impeller displacement:

For flat and canted impeller applications, TOR should range between 40 and 85 seconds. As the TOR approaches 40 seconds, the chance for vortex formation and possible air entrainment increases. At values greater than 85 seconds, the proper suspension may be jeopardized and solids will begin to settle.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

When defining the area in which to mix, it is best to work with symmetrical shapes like squares or circles (as viewed in a plan drawing or overhead view of the tank layout). Rectangular tanks should be converted to nearly square compartments if possible. Maximum fluid working volumes in compartments should not be higher than 1 foot (about 3⁄10 m) from the top of the tank. This will allow for a little extra capacity in emergencies, slightly out of level installations, and/or fluid movement on floating rigs.

Working volume for square or rectangular tanks is calculated by knowing dimensional values for length (L), width (W), and height (H; in feet for gallons, in meters for liters):

For round tanks with dish or cone bottoms, calculations for working fluid volume are based on straight wall height (i.e., this height is measured from the tank top to where the tank joins the cone or dish at the bottom). This leaves adequate free space above the maximum fluid operating level. In all cases, if H<5 feet (1.5 m), a radial flow impeller should be specified.

Mud agitatoris part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solid particles from settling in circulating tank. It is composed of explosion proof motor, speed reducer,motorbaseandblade.The motor and speed reducer, speedreducer andimpeller shaft are connected by steel coupling. The impeller is welded with four blades.

We get that equipment breaks down, but that doesn’t mean you have to stop working! We manufacture and provide spare parts in our shop so that you can continue operations quickly.

Some of the parts we provide are for shale shakers, centrifugal pumps, mud pit agitators and more. Call us at281-409-0018to learn more about our spare part options and inventory. CONTACT US TODAY

A shale shaker is a vibrating device used in a rig solid control system to remove drill cuttings from mud. Shale shakers are a vital component of drilling equipment in many industries and can be costly when they break down. At Specialty Solids Control we provide spare parts for shale shakers so that you can start the first phase of your solid separation efficiently.

A centrifugal pump converts rotational energy, often from a motor, to energy in a moving fluid. Since centrifugal pumps don"t require any valves or many moving parts and maintain the aforementioned simplicity, they move at high speeds with minimal maintenance. Specialty Solids Control understands the importance of these machines and provides spare parts in case of any breakdown or need for replacement.

Mud Agitators are used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. Specialty Solids Control understands that equipment can break down from time to time which is why we provide spare parts. Schedule a call to learn more about how you can continue operations with our spare parts. Spare parts that we provide for mud pit agitators include but are not limited to: Motors & Gearboxes

Degassers are devices that remove entrained gas from drilling mud. Degassing is a crucial step after solids separation. This is an important step to reduce and eliminate the formation of gas cut mud. Learn more about how you can purchase degasser parts from Specialty Solids Control. Spare parts that we provide for degassers include but are not limited to: Compressors & Motors

A desilter is a device at the surface which removes very small particles from drilling mud. This equipment is great for removing very fine particles or silt from drilling fluid to keep the amount of solids in the fluid at the lowest possible point. We understand that these machines are important to your operations, which is why we provide desilter parts in order for you to quickly fix your desilter.

A desander is a type of mud recycling equipment designed to remove harmful solids particles ranging in size from 40 to 50 microns from your drilling mud. Specialty Solids Control provides desander parts at an affordable price. Contact us to learn how you can save.

Centrifuges are devices that rotate the mud in a bowl to generate high centrifugal forces causing solids to move toward the outside for removal. Specialty Solids provides centrifuges and centrifuge parts at an affordable price. CONTACT US TODAY

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Finemade offers a variety of motor and impeller sizes to fit specific tank configurations. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole.The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used.

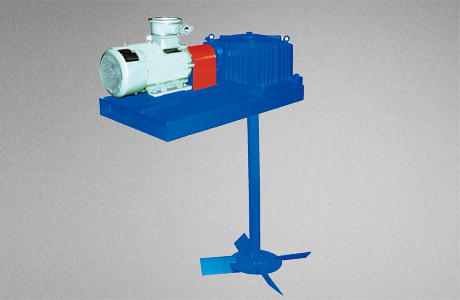

Landa mud agitators include an explosion-proof, “C” faced motor, reduction gearbox, impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

Mud Agitator is widely used in mud circulation systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft.

Mud agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation. The objective is to obtain a uniform suspension of all solids

To keep both drilling mud uniform and solid particle suspension, mud agitator is used to agitate the mud consecutively and reliably. It is furnished with an up-to-date SEW gear reducer featured by high driving efficiency, compact structure, low noise level, reliable quality and easy maintenance. Therefore, it is a reliable product of agitating the mud.

As part of the solid control system, the agitator is used to agitate the mud to make cuttings, silt and sand along with the mud pass easily the solids control system without being precipitated onto the tank bottom. The main function of the agitator is to mix the cuttings and other solids with the mud. The gear reducer uses Archimedes cylindrical worm drive, the worm is on the left side. The connection between the motor and the gear reducer as well as the reducer output shaft and the agitating shaft is made by using coupling.

The gear reducer is worm and gear single-stage reducer, so with small structural dimensions, light weight, smooth driving, low noise level, large transmitting power and powerful agitating capacity.

Aipu solids control is the professional manufactory of horizontal and vertical mud agitators. Our products are with reliable quality, good operation performance. We also provide high quality products, professional technical support, welcome to Aipu solids control to choose.

Mud agitator is an important part of the drilling-fluid solids controling system. Drilling fluids agitatorcan be installed on drilling fluid tank, with the impeller submerged into certain depth under fluid surface to stir the fluid directly.During this process, the drilling fluid can be mixed even, and the solid particles are eliminated.In this way, it can improve solid phase dispersion, and increase the viscosity and gel strength, thus to make drilling fluid keep accordant with the requirement, provide needful fluid for drilling process, and ensure the smooth going of drilling work.Drilling mud agitator is the same as mud agitator.

TR solid control provide vertical and horizontal agitator. Horizontal mud agitator is divided into coupling type and direct type agitator. If you need a horizontal mud agitator, we recommend you use a direct type agitator. drilling mud Agitator is an ideal device for stirring, mixing liquid and preventing the solid-phase precipitation in the mixture.

Drilling Fluids Agitator in the mud system used to,mixing ratio and prevent to the mud tanked.TR solid control is an exporter of centrifugal pump . We are an exporter of drilling fluids mud agitator.Our factory approval the ISO9001,drilling agitator have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese mud agitator manufacturer. We will provide the high quality drilling fluids agitator and best service.Your best drilling mud tank agitators start from TR solids control.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291