psi mud agitator brands

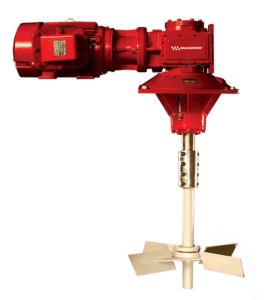

The MAX2000® Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high impact forces generated when the unit is energized at start-up. Each helical bevel gear stage is 98% efficient. A typical worm gear set is only 85% efficient, since it loses most of its efficiency through the generation of heat.

Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the MAX2000® Agitator is the lower bearing, which can be maintained from the top of the tank. This feature eliminates the need for in-tank inspections of the lower bearing, and also provides a barrier of grease that can be expunged out the lower seal. The lower seals are arranged to accommodate the grease pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

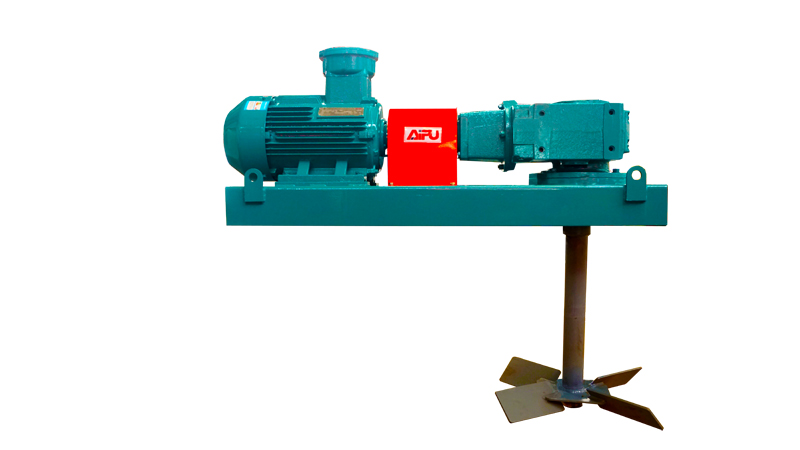

The skid mounted MA-RG agitator is compact, and its low profile reduces headroom requirements and provides more layout space on top of the tanks. The gearbox is a triple-reduction helical-bevel gear drive system that reduces the rotational speed of the motor to drive the impeller(s). Up to 95% mechanical efficiency helps reduce horsepower requirements.

Impellers are available with flat blades (radial flow), contour blades (axial flow), and canted blades (radial/axial flow). The impellers are sized according to tank volume and expected duty. Active mud system compartments—such as solids removal sections, mud mixing sections, and slug pits, which need a higher shear force to produce immediate mixing—are another consideration in impeller sizing.

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation of drilling fluid mud agitator. The objective is to obtain a uniform suspension of all solids.

Descriptions of Mud Agitator1. Mud agitator is an equipment to mix solid and fluid, mainly used in oil and gas drilling mud process, mineral working site, etc. mud system.

2. This type agitator holding simple structure, large bearing strength, low noise, more durable. It prevent solid sediment and maintain drilling fluid property. Features 1.Typical C face motor installation 2.Small footprint without skid

Mud Agitator, Drilling Solids Control,Mud Cleaning Agitator, mud agitator manufacturer Exporters, mud agitator manufacturer Suppliers, mud agitator manufacturer wholesalers, mud agitator manufacturer distributors, mud agitator manufacturer Manufacturers, mud agitator manufacturer sellers, mud agitator manufacturer

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

For many years, GN is known as a professional manufacturer of mud recycling equipment. Besides the main mud treatment equipment such as the shaker, cyclone and decanter, GN Solids Control is able to provide the mud transfer pump and mud agitators as well.

The mud transfer pump is an indispensible media for the mud flow from one place to the other. And the pump also provides the power or pressure for mud getting into the equipment for better treating result. GN has below 3 types mud transfer pump is widely in mud engineering and other industries.

Centrifugal pump - in solids control system, the centrifugal pump could be used as the feeding pump to the hydrocyclones, the pressure produces by the pump will give the mud a high speed when getting into the cyclone for better separation performance. It can also be a mixing pump connecting with venturi hopper for mud chemical supplement. GN centrifugal pump is using nodular cast iron as the material of pump case and impeller for long service life.

The mud agitator is normal equipment in mud tank for mud mixing. It can stir the mud to make the mud material dissolving and suspending evenly in the mud. According to different mud tank dimension, mud viscosity, GN solids control is able to provide the mud agitator with different size, power by selecting the suitable motor and gear box.

8613371530291

8613371530291