diaphragm mud pump manufacturer

Official plunger pump manufacturers page. Sludge Master Plunger Pumps are the ultimate heavy solids handling pumps for municipal and industrial fluid handling applications. Designed and manufactured by Wastecorp in North America. Parts and rebuil

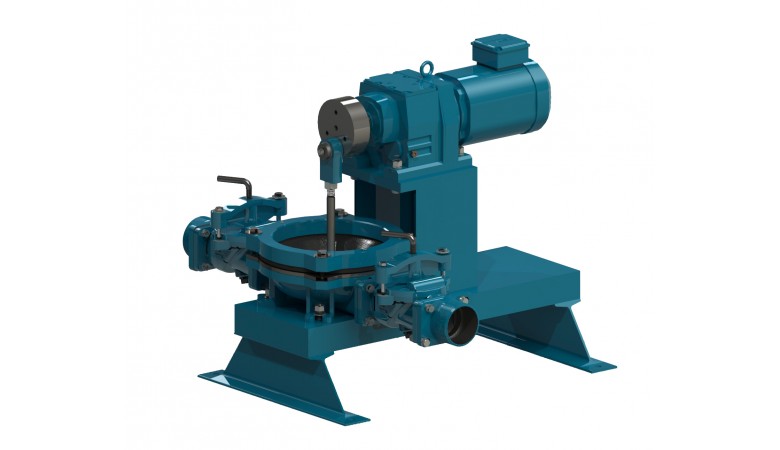

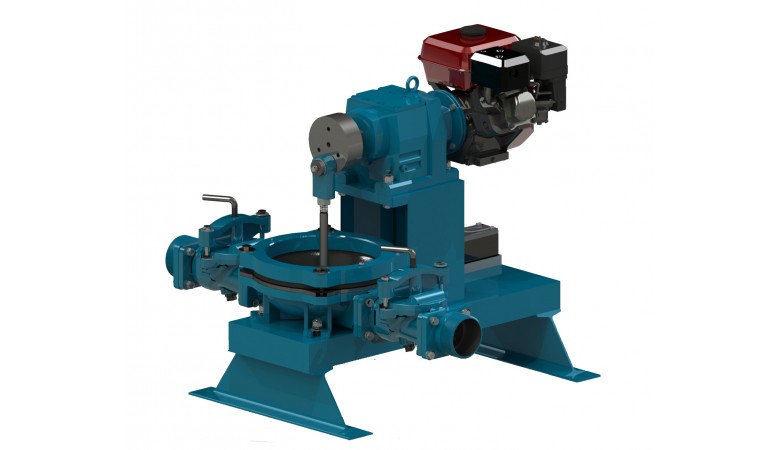

The AMT line of diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as mud or sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2 or 3 inch NPT steel suction strainer, two NPT nipples and a wheel kit for portability.

Distributor and custom manufacturer of solenoid, all-rounder, maximum process multi-layer, application piston, air operated and feeding diaphragm pumps. Aluminum, Buna-N, cast iron, polyvinyl chloride (PVC), polypropylene (PP), polyvinylidene fluoride (PVDF), stainless steel, polypropylene-fiber reinforced plastic (PP-FRP), polyvinylidene fluoride-fiber reinforced plastic (PVDF-FRP) and other materials used. Available in a variety of configurations. Features vary depending upon model, including three phase motors, actuators, positioning controllers, valves, valve balls/seals, corrosion resistance, air, liquid and hand-powered and self-priming. Serves the aerospace, architecture, automation, automotive, commercial, communication, cosmetics, dairy, electronics, government, laboratory, medical, pharmaceutical, telecommunication and other industries.

The AMT line of Diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as Mud or Sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2” or 3” NPT steel suction strainer, two NPT nipples and a wheel kit for portability. Models 338E K6, 338G-K6, 337H-K6 and 337E-K6 are kits provided less motor or engine. Suction and discharge port sizes cannot be reduced.

A Diaphragm is often referred to as Mud or Sludge pump. These heavy duty pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. Most models are designed for use with non-flammable liquids which are compatible with pump component materials.

Piston membrane pumps are our business. Our only business! We make them Robust & Tough! Josef Emmerich founded the company in 1945 and still today the company is privately owned with a manufacturing facility composed of meticulous craftsmen. Exactly as you would expect from Germany.

Emmerich Manufactured Pump Parts such as Multi-safe Membranes, diaphragms for diaphragm pulsation dampeners, valve seats, sealing rings, etc. are made from a wide variety of materials such as Perbunan (NBR), Neoprene (CR), Hypalon (CSM), Viton (FPM) and Vulkollan (AU).Since 1975, JOSEF EMMERICH PUMPENFABRIK GmbH has had its own in-house production of rubber parts.

Design and manufacture of pumps are by means of state of the art processes and certification to DIN ISO 9001 guaranteed quality. Product development is formed by innovative design and material technology utilizing individual customer requirements.

All manufactured pumps are checked on the processor controlled test stand. Automatically recorded reports of performance are provided to the customer.

The PD 3 diaphragm / mud pumps can move almost anything that flows. A 3-inch pump that can handle solids up to 1.625 inches (41 mm) and up to 88 gpm (333 l/min), these pumps are ideal for moving water with mud, slurries and in seepage areas. Built with high quality component, you will be assured of many years of top performance and durability. Large solid rubber tires provide excellent traction and smooth rolling over rough terrain.

Ductile iron crankcase provides maximum durability. Hardened forged gears extend pump life and provide efficient power transmission from the engine to the pump.

All-purpose solenoid-driven metering pump for metering liquid media in water treatment and chemical processes: Solenoid-driven metering pump Beta®. ...

The new solenoid diaphragm metering pump gamma/ X is user-friendly and has an outstandingly long service life, just like its predecessor. An ingenious solenoid control measures the back pressure and protects ...

The new solenoid-driven metering pump gamma/ XL is the enhancement to our proven gamma/ X and covers a capacity range from 8 – 80 l/h at 25 – 2 bar. The gamma/ XL also has other interfaces, for example CAN bus and Wi-Fi ...

The FLUX air-operated diaphragm pump RFM/RFML are self-priming and protected against dry running. The pumps are distinguished for its versatility and can be used for pumping low to high ...

The FLUX air-operated diaphragm pumps FDM in injection-moulded version are self-priming and protected against dry running. The pumps are distinguished for its versatility and can be used ...

... piston diaphram pump is a crankshaft driven double-acting piston diaphragm pump designed for high-pressure pumping of abrasive and corrosive slurries.

... GEHO® TZPM pump is a crankshaft driven high pressure piston diaphragm pump designed to handle abrasive mineral ores, tailings slurries and mine water.

... DX70 is a high specification, air powered, 1:1 ratio, double diaphragm pump specifically developed for the direct supply of paints and materials to spray guns. The pump features a unique ...

Available in aluminium and stainless steel this versatile 1 air operated double diaphragm pump is ideal for pumping a variety of waterborne and solvent based coatings including; Adhesives, catalyzed varnishes, ...

... air-operated diaphragm pump features a stall-free low pulsation air valve which provides a smooth and rapid changeover. The one-piece centre section eliminates leaks and reduces maintenance on Husky pumps ...

The LPM Series fixed volume dispense pumps are solenoid driven, positive displacement pumps that deliver accurate and repeatable volumes of fluid. This series is available in 10 µL and 25µL standard models, ...

The LPL Series fixed volume dispense pumps are solenoid driven, positive displacement pumps that deliver accurate and repeatable volumes of fluid. This series is available in 50 µL standard models, with ...

LPD Series variable volume dispense pumps are a new generation of stepper motor driven, positive displacement pumps designed to provide unparalleled reliability a nd performance at an economical price. ...

The ARO 1½” EXP Metallic is a diaphragm pump that is 20 to 40 percent more efficient than its competitors. Its compact, durable design with the housing constructed of aluminum, cast iron, stainless steel, ...

... set of features found in other pump technologies. You get the versatility of a diaphragm pump with the efficiency and controllability of other positive displacement technologies.

KNF diaphragm liquid pumps combine maximum performance with minimum size. The use of chemically resistant materials enables the pumps to convey virtually any type of liquid, whether neutral ...

... ecoflow diaphragm metering pumps can be configured with various pump heads and drives for almost all applications. Here, we set technological and qualitative standards: Each ecoflow diaphragm ...

... tried-and-tested modular system, ecoflow diaphragm meter pumps in sanitary/hygienic design can also be configured with various pump heads and drives for almost all applications as food ...

... of aluminum, while the diaphragms used are of high quality NBR that allow the transfer of oil with high viscosity, even with solid parts in suspension, such as used oil.

The VC 0201B assembled by Nitto, is an AC Dual Pump that features an attainable vacuum of -187 mbar. This device is powered by a 230 V or 120 V of rated voltage with a 20 l/min of rated airflow. In addition, ...

The VC0301B is a diaphragm pump with attainable vacuum pressure -213 mbar and 25 l/min rated airflow. The rated voltage of the pump is 230 V and 120 V to produce maximum ...

The DP 0102S is a pump compressor that runs continuously on a 24 V rated voltage for 5.000 h. this model weighs 0.25 kg and is capable of reaching vacuum pressures up to -267 mbar with a 7 l/min maximum ...

... performance, the stroke frequency can be adjusted manually or via an external control contact. The dosing pump is compact and, thanks to the small mounting area, can be integrated into ...

... performance, the stroke frequency can be adjusted manually or by an analogue input signal (0/4 – 20 mA). The dosing pump is compact and, thanks to the small mounting area, can be integrated ...

... metering pump, also known as the MACROY® pump, is now NSF/ANSI 61 and 372 certified for municipal compliance and safety assurance. Capable of handling pressures up to 175 psi (12 bar) and flow rates ...

Diaphragm pumps R. 1:1 for transferring, made entirely of die-cast aluminum; they ensure lasting and reliable operation with the most common automotive and industry fluids.

The RAASM pneumatic diaphragm pumps are designed with a 1:1 compression ratio and made to pump a vast range of fluids, with high viscosity and with solid parts in suspension. These models ...

The NOVADOS Family comprises leak-free diaphragm pumps as well as plunger pumps. Nearly all gear sizes in the NOVADOS series can be combined to achieve the required flow rate and pressure ...

The NOVADOS Family comprises leak-free diaphragm pumps as well as plunger pumps. Nearly all gear sizes in the NOVADOS series can be combined to achieve the required flow rate and pressure ...

... NOVAPLEX Integral pumps are powerful process diaphragm pumps for a variety of applications. They are best suited for critical high pressure installations where the capabilities of traditional ...

Why choose the MWI Double Diaphragm water pump? Its rugged design is strong enough to get through the toughest materials, including solids as large as 3.75”. Because it is portable, flexible, lightweight, and easy to set up, this pump is favored for many operations. Featuring a flex coupling, this diaphragm water pump can be completely disassembled for thorough maintenance checks and cleanings. Even the most challenging environments are no match for this double diaphragm water pump.

Double-diaphragm pumps are highly versatile and designed to handle tough jobs like pumping chemicals, slurry, concrete or barrels of water. They provide an efficient, low maintenance solution for a range of industrial applications including mining, oil & gas, wastewater treatment, pulp and paper, and pharmaceutical. Since AODD pumps use compressed air instead of electricity, they are safe to use with and around hazardous substances.

Air operated double diaphragm pumps are relatively easy to set up and relocate for different application uses throughout your plant. They are practically leak-free and can run dry since they do not contain internal seals or components that require lubrication.

For the pump function properly, the pressure of the compressed air supply must be equal to or greater than the pressure of the substance being pumped. Double diaphragm pumps are also noisier and create more vibrations than mechanical pumps. Therefore, they should not be used near sensitive machinery or devices.

Pumping Solutions is fully stocked and ready to deliver AODD pumps to meet a variety of industry-specific applications. Because the recommended uses of our specific pump models vary based on size, we have included additional information on our range of Wilden AODD pump models. Not sure where to start? Contact a Pumping Solutions expert and we can find you the right pump for your application.

The hyper-efficient ¼” air diaphragm pump design can reliably handle everything from food-grade products to highly viscous substances. The ¼: pump can handle sludges and slurries and is perfect for applications that require precise handling and efficient operating resources.

Wilden ½” air diaphragm pumps utilize reciprocating elastomer diaphragms and check valves for pumping fluid, oil, viscous fluids and slurries. The 1/2” air diaphragm pump has excellent suction characteristics for handling a high amount of grit and solids, making it a popular choice for mining applications.

Wilden’s 1 ½” air diaphragm pump is specifically designed to move, handle and transfer large volumes of viscous bulk fluid products. These pumps have optimized liquid paths to reduce friction and maximize output while transferring harsh chemicals, abrasive fluids and hard-to-transfer liquids.

The large 2” diameter can improve the transfer of sludges, slurries, abrasive fluids, oil and mineral-related products by utilizing simple diaphragm changing capabilities and a leak-free design.

Wilden’s 3” pumps are our highest capacity AODD pumps and can handle sludges, slurries and other liquids with a with high amount of grit and solid content.

Double diaphragm pumps are self-priming and typically used in low-pressure fluid transfer applications. They are compatible with dirty, contaminated, and viscous fluids and used for applications such as:

We offer a range of pumps from Wilden, a leading and trusted double diaphragm pump manufacturer. In 1955, a man named Jim Wilden invented air-operated double-diaphragm pump, and since then, the name “Wilden” has been synonymous with excellence.

Our catalog features Wilden double-diaphragm pumps ranging in sizes from ¼” to 4” with an option of Buna-N, Wil-Flex, Teflon, Saniflex, or Neoprene elastomers. Pump material and elastomer options vary depending on the pump size selected.

We’re a leading supplier of air operated double diaphragm pumps on the West Coast. With representation in Arizona, California, Idaho, Montana, Washington, and Northern Mexico, we can get you the double-diaphragm pump you need – fast. Contact us for double diaphragm pump and filtration equipment options.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm mud pump systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes diaphragm mud pump wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A diaphragm mud pump comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the diaphragm mud pump of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of diaphragm mud pump for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of diiphrag m mud pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

New York, NY /PRNewswire/ - Wastecorp Pumps, the industry leading manufacturer of mechanical Mud Sucker diaphragm pumps is excited to introduce new triplex and quadruplex diaphragm pumps for pumping effluent and wastewater. The new Mud Sucker 3 and 4 series save on spare parts costs by utilizing advanced diaphragm pump materials of construction along with the proven advantages of mechanical diaphragm technology. Mud Sucker (http://www.wastecorp.com) triplex and quadruplex pumps are capable of transferring solids laden wastewater from 50-310 GPM.

"Municipalities are facing extended budget difficulties when it comes to their wastewater treatment pump upgrade programs," said Daniel Starr Senior Vice President of Marketing and Communications at Wastecorp Pumps USA. "Our engineers responded to government need for high performance pumps without costly spare parts requirements."

He added, "Government is not the only benefactor of Mud Sucker Diaphragm Pumps; we serve the wastewater handling needs of small businesses and Multinational corporations ranging from food processing to mining applications."

Mud Sucker Triplex diaphragm pumps (http://www.wastecorp.com/mudsucker/triplex-pumps.html) feature three diaphragms for transferring wastewater, food processing waste, raw effluent and much more with fluid handling capabilities ranging from 55-310 GPM. Pump users can select from 2"-4" connection sizes. Mud Sucker triplex diaphragm pumps are available with our flapper valve design (slurries and wastewater) or our high performance, solids crushing ball valve model. Pumps are available with electric, explosion proof, gas, diesel, air operated or hydraulic drive systems. Variable frequency drives and gauges are also available as optional equipment.

For the ultimate in mechanical diaphragm pump technology, the flagship Mud Sucker 4 quadruplex diaphragm pump features four diaphragms for pumping the tough stuff. http://www.wastecorp.com/mudsucker/quadruplex-diaphragm.html

These pumps are equipped with Santoprene® diaphragms for oil and chemical transfer or select corrosive fluid pumping. Select from over six drive systems and transfer up to 310 GPM.

Mud Sucker Diaphragm Pumps are on display from November 1-4 at the global food equipment and technology show - Process Expo in Chicago. Process Expo showcases food processing equipment across all food sectors including bakery and snack, beverage, confectionary, dairy, fruit and vegetable, meat, poultry and seafood. Visit Wastecorp"s exhibit at booth 2643.

Mud Sucker diaphragm pumps are designed and manufactured by Wastecorp Pumps in the United States and Canada. Mud Sucker pumps utilize mechanical diaphragm pump technology to provide heavy duty pumping power for municipal and industrial applications including wastewater treatment plants, pump stations, food processing, waste oil, bilge, construction, mining, pulp and paper, marine pump applications and more. Mud Suckers are available in over 150 single, double diaphragm, triplex and quadruplex models with capacities ranging from 20-310 US GPM. Mud Sucker pumps are available in air operated, hydraulic, engine and single or three phase electric models. For more information on Wastecorp Mud Sucker diaphragm pumps visit http://www.wastecorp.com/diaphragm_pumps.html

Wastecorp Pumps manufactures heavy duty pumps and replacement parts for municipal, industrial, residential and commercial water and wastewater treatment applications. Wastecorp"s brands include Wastecorp Plunger Pumps, Mud Sucker Diaphragm Pumps, Trash Flow Centrifugal Pumps and Turbo Flow High Volume Pumps. The Turbo Flow pump line includes vertical sewage, horizontal split case, booster pumps and more. Wastecorp"s pump products are available worldwide. View our products online at www.wastecorp.com or contact us toll-free at 1.888.829.2783.

of diaphragm pumps (PE & PTFE, sanitary, metal, pharmaceutical, EHEDG aseptic, powder), pulsation dampeners, centrifugal pumps (industrial, hygienic, magnetic drive, vertical, self-priming, plastic), hose pumps, filter units

Tapflo pumps have become an important element of equipment for installations, especially those used for transporting hazardous liquids. Our solutions are safe and environmentally friendly and meet the high quality requirements imposed by standards and directives. Many of our products meet the requirements of the ATEX directive, which applies to the use of pumps in potentially explosive atmospheres. All our devices have the CE mark. The company has an Integrated Quality Management System compliant with the ISO standard.

8613371530291

8613371530291