heavy duty mud pump brands

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Our high-head pumps are specially designed for industrial and commercial applications where high heat and high pressure are required. Whether you need to pump water, chemicals, or other liquids over long distances, our high-head pumps are up to the task.

The unique design of our high-head pumps allows them to generate high head and pressure while still maintaining a high flow rate, making them ideal for a wide range of applications including irrigation, water treatment, and industrial processing.

Our high-head pumps are also highly customizable, with a variety of options available to suit your specific needs. Whether you require a high flow rate, a high head, or a combination of both, our team of experts can work with you to create a pump that meets your requirements.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

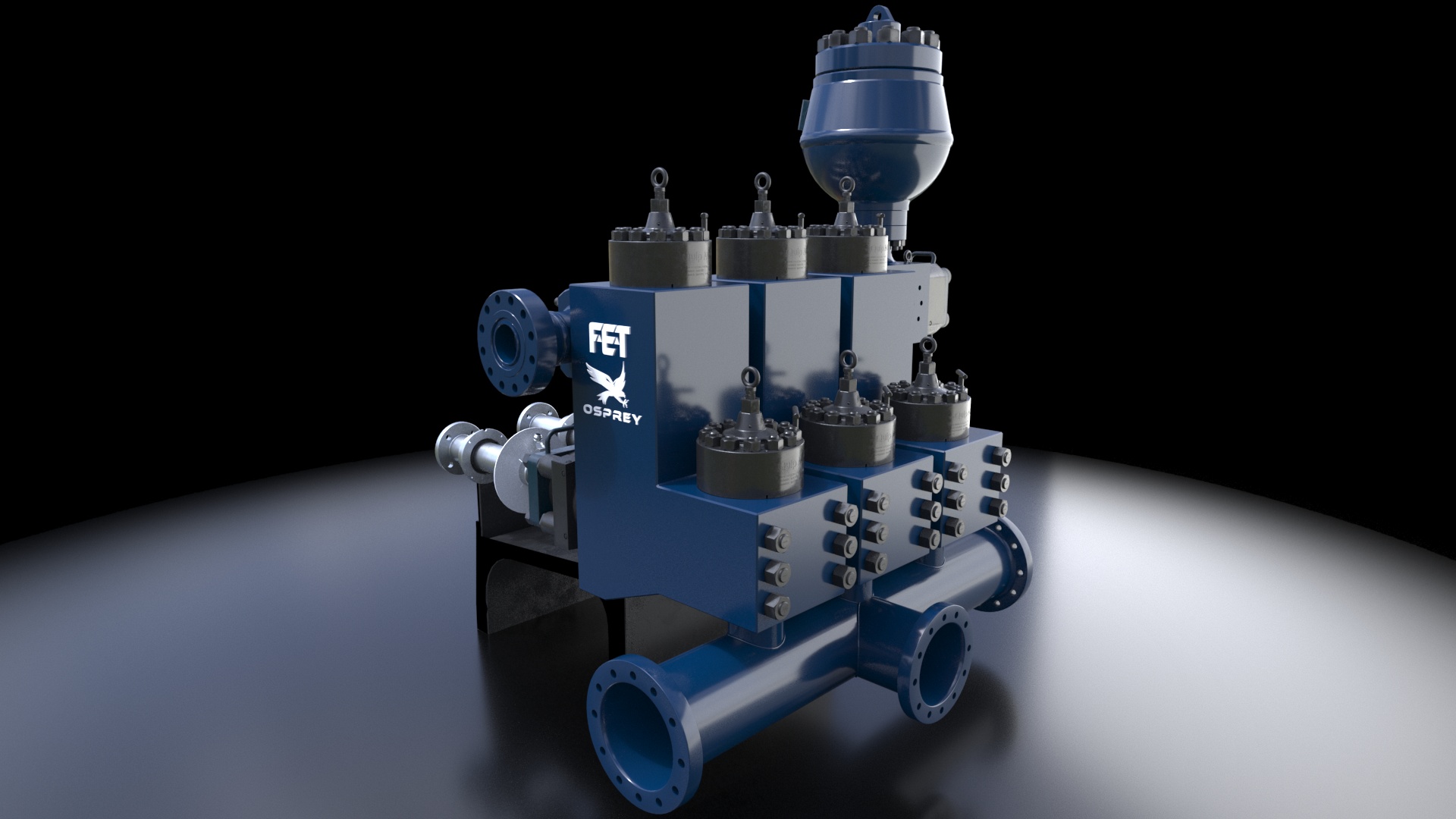

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Whether you’re transferring waste oil mixtures, bio waste, sewage, mud or lime slurries, there’s one thing you can be sure of, and that’s that you need a heavy duty, high pressure sludge pump. Capable of efficiently handling viscous fluids containing solids, Castle Pumps’ range of slurry pumps has been built up over the years to provide you with a non-clogging solution to your waste transfer applications. Not all pump designs can do the job, but that’s where we are there to help you. Our technical sales engineers are on hand to help you to select the right solution for your requirements.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

A wide variety of heavy duty mud pump options are available to you, such as 1 year, 2 years and 3 years.You can also choose from new, used heavy duty mud pump,as well as from energy & mining, construction works , and machinery repair shops heavy duty mud pump,And whether heavy duty mud pump is 1.5 years, {2}, or {3}.

The DAE Pumps Submersible Drainage Pumps support a variety of dewatering applications. Their robust design provides the highest level of performance, reliability, and ease of use. The submersible drainage pumps offer a range of sizes up to 10-inches with over 80 HP and a volume capability of pumping as much as 6100 GPM.

Submersible Sludge Pumps are peak performers in pumping thick mud, clay, and waste. These energy-efficient pumps run at low horsepower, pumping as much as 420 GPM. Available in 3-inch and 4-inch sizes, the heavy-duty DAE Pumps Submersible Sludge Pumps are capable of moving abrasive solids as large as 2-inches. Our Submersible Sludge Pumps provide the support you need for for your toughest jobs.

The DAE Pumps Submersible Slurry Pumps are the toughest and most durable submersible pump. Built for pumping the worst slurry and materials, these pumps have the highest rating in ruggedness. Our Submersible Slurry Pumps are made for dredging the most abrasive media with high solid content in quarries and mining operations. With up to 102 horsepower, these powerful unit are capable of moving 2112 GPM of solids as large as 2.5-inches, and are available in 3-inch, 4-inch, 6-inch, and 8-inch sizes.

The DAE Pumps Payload Electric Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Payload Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

The DAE Pumps Hydraulic Submersible Slurry Pumps are the industry’s best-performing hydraulic submersible pumps. Capable of pumping up to 1325 GPM our hydraulic pumps provide the reliability you need. Because these 3-inch and 4-inch pumps are compact, their lightweight design makes them necessary tools for all site operations. They are non-clogging and are also available in a high head performance of up to 350 feet

The DAE Pumps Hauler Hydraulic Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Hauler Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

DAE Pumps is committed to providing you with the highest quality of pumps at affordable prices. We build our submersible pumps with you in mind. We use the strongest material inside and out to withstand the harshest conditions for getting the job done. Over the years, we built a modular platform of submersible pump that allows us to provide the highest performing pump with the same durability and reliability from one size and power to the next. This means you get the best pump each time.

Our low-cost submersible pump lines are an extension of our commitment to affordably priced pumps. These pumps are built with the same types of metal inside and out as our modular lines, but use a different technology design that brings the performance of these pumps close to those of the other models. We offer these pumps with a lower guarantee so you can get very high-grade pumps at the best prices.

Submersible pumps are the industry’s most durable pumps for underwater operations moving solids and liquids. They can withstanding everyday use of processing water, rocks, sand, mud, sludge, slurry, and other abrasive materials. DAE Pumps provides a variety of submersible pumps for mining, dredging, minerals processing, ash pumping, wastewater, dewatering, and pumping chemicals, oil, sludge, paste, and many other applications. We offer light-duty to heavy-duty submersible drainage pumps, submersible sludge pumps, and submersible slurry pumps.

The submersible drainage pump is built for general dewatering, groundwater, raw water, and construction site use. Construction companies and various municipalities use drainage pumps for removing water from heavily flooded areas and as sump pumps when rainwater or groundwater collects in low-lying and below ground work areas.

DAE Pumps drainage pumps are designed for flexibility and ease of use. Capable of pumping solids up to .5-inches, the durable design is made to move large amounts of water. DAE Pumps drainage pumps handle clean and dirty water with the best performance and efficiency on the market. Our drainage pumps provide powerful performance with minimal maintenance, and their durable body ensures continued use in harsh environments. We offer a variety of drainage pumps in 3-inch, 4-inch, 6-inch, and 10-inch discharge outlets with a horsepower of over 80 HP, and capable of pumping up to 6100 GPM.

Made to pump thick mud and other similarly viscous mixtures of liquids and solids, submersible sludge pumps are used for moving sludge or light slurry, tank clean-outs, trench and pond cleaning, mining dewatering operations, and various other applications. The sludge pump moves the material that can clog ordinary drainage pumps.

DAE Pumps heavy-duty sludge pumps can move water, but they are made for moving solid material and are built with a high wear resistance inside and out. The high-chrome (55HRC) impellers and base of the pump ensures stability while allowing the passage of large solids. The high-quality components for the mechanical seal guarantees a watertight seal and trouble-free operation. Our submersible sludge pumps move up to 420 GPM and come in multiple sizes and power options. These sturdy sludge pumps provide the reliability you need and the performance you can trust for your dewatering, cleaning, and transferring needs.

The submersible slurry pump is the catch-all of submersibles. Capable of pumping the most abrasive media with high solids content, the slurry pump is the workhorse for quarries and settling pond operations. These ultimate pumps are used for everything from dewatering to dredging.

DAE Pumps non-clogging submersible slurry pumps provide the ultimate in toughness.They have the largest apertures to facilitate the handling of slurry with the most challenging solids and the high-efficiency high chrome agitator can lift settled solids up to 2.5-inches. The robust design uses heavy-duty bearings to withstand shocks and overloads and a double silicon carbide mechanical seal for duty application. Our slurry pumps are available in 3-inch, 4-inch, and 6-inch models, with the ability to move up to 2112 GPM.

Sand is one of the most abrasive materials for any type of pump to manage. The beating of sand on the impeller, volute, and even the hose cause extreme wear and tear on pump components. Thesubmersible sand pump is designed to minimize the effects of blasting sand. However, over a period of extended time, the submersible sand pumps will show signs of wear on these parts from the constant pounding of sand and will require replacement.

Our submersible sand pump wear components are built with a high chromium iron, an extremely strong alloy that is mainly used in mining, milling, earth-handling, and manufacturing industries which require materials with exceptional wear and corrosion resistance. The exceptional wear resistance of high chromium cast iron is due to the high volume fraction of hard chromium carbides. The toughness of the matrix also contributes to the wear resistance and makesit very suitable for pumping sand.

DAE Pumps non-clogging submersible sand pumps provide the ultimate in toughness and sand pumping capabilities. Ourpumps move up to 1664 gallons per minute of material and are available in 3-inch, 4-inch, and 6-inch models.

The rugged DAE Pumps Gulfport D540H drainage pumps move clean and dirty water with small solids up to .32-inches. These submersible drainage pumps with 4-inch discharge can move liquid at 310 GPM up to 135-feet via 8.5 horsepower. This 60Hz pump is available in 575-600V.

Offering the same high-quality, the DAE Pumps Gulfport D540S drainage pumps move clean and dirty water with small solids up to .32-inches. These durable drainage pumps with 4-inch discharge can move liquid at 310 GPM up to 135-feet via 8.5 horsepower. This 60Hz pump is available in 460V and 575-600V.

DAE Pumps Gulfport D640X drainage pumps handle clean and dirty water with small solids up to .32-inches. These rugged drainage pumps with 4-inch discharge can move liquid at 260 GPM up to 250-feet via 11.5 horsepower. This 60Hz pump is available in 575-600V.

DAE Pumps Gulfport D640H drainage pumps move clean and dirty water with small solids up to .32-inches. These reliable drainage pumps with 4-inch discharge can move liquid at 340 GPM up to 170-feet via 11.5 horsepower. This 60Hz pump is available in 575-600V.

The reliable DAE Pumps Gulfport D640S drainage pumps handle clean and dirty water with small solids up to .32-inches. These durable submersible pumps with 4-inch discharge can move liquid at 700 GPM up to 100-feet via 11.5 horsepower. This 60Hz pump is available in 460V and 575-600V.

The high-quality DAE Pumps Gulfport D740H drainage pumps move clean and dirty water with small solids up to .27-inches. These reliable drainage pumps with 4-inch discharge can move liquid at 300 GPM up to 254-feet via 15 horsepower. This 60Hz pump is available in 440-480V.

DAE Pumps Gulfport D840H drainage pumps process clean and dirty water with small solids up to .47-inches. These rugged submersible pumps with 4-inch discharge can move liquid at 760 GPM up to 240-feet via 31 horsepower. This 60Hz pump is available in 460V, 480V, and 575-600V.

DAE Pumps Gulfport D940H drainage pumps handle clean and dirty water with small solids up to .27-inches. The most powerful of our 4-inch drainage pumps come with a 4-inch discharge and move liquid at 560 GPM up to 325-feet via 36 horsepower. This 60Hz pump is available in 440-480V.

The high-performing DAE Pumps Sonora S540 Submersible Sludge Pumps handle thick, soft, wet mud and sludge with solids up to 2-inches. These heavy-duty submersible sludge pumps with 4-inch discharge can move material at 365 GPM up to 92-feet via 7 horsepower. This 60Hz pump is available in 230V and 460V options.

DAE Pumps Sonora S640 Submersible Sludge Pumps offer the ultimate performance in moving mud and sludge with solids up to 2-inches. With a 4-inch discharge, these sludge pumps transfer material at 420 GPM up to 100-feet via a 9.2 HP motor. This 60Hz pump is available in 230V and 460V options.

The rugged DAE Pumps Miramar L540 Submersible Slurry Pumps process abrasive materials with solids up to 1-inch. These durable slurry pumps with 4-inch discharge move material at 308 GPM up to 57-feet via a 7 HP motor. This 60Hz pump is available in 460V.

Offering the same high-quality, the DAE Pumps Miramar L640 Submersible Slurry Pumps move abrasive materials with solids up to 1-inch. With a 4-inch discharge, these heavy-duty slurry pumps process material at 440 GPM up to 75-feet via a 12 HP motor. This 60Hz pump is available in 460V.

The heavy-duty DAE Pumps Miramar L740 Submersible Slurry Pumps transfer abrasive materials with solids up to 1-inch. With a 4-inch discharge, the Miramar L740 slurry pumps move material at 616 GPM up to 85-feet via a 15 HP motor. This 60Hz pump is available in 460V.

DAE Pumps Miramar L840 Submersible Slurry Pumps move abrasive materials with solids up to 1-inch. With a 4-inch discharge, these reliable slurry pumps process material at 660 GPM up to 98-feet via a 20 HP motor. This 60Hz pump is available in 460V.

The high power 4-inch DAE Pumps Miramar L940 Submersible Slurry Pumps move abrasive materials with solids up to 1.5-inches. These 4-inch discharge submersible slurry pumps move liquids and solids at 880 GPM up to 171-feet via a 50 HP motor. This 60Hz pump is available in 460V.

DAE Pumps Tampa 437 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The durable DAE Pumps Tampa 437 offers an open stand or strainer, and agitator provides improved suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 437 submersible slurry pumps transfer solids and liquids at a flow rate of up to 476 GPM and with 5 HP.

DAE Pumps 455-P Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The DAE Pumps 455-P with an open stand and agitator allows for ideal suction and movement of solids up to 1-inch with a 4-inch discharge. The ergonomic 455-P submersible slurry pumps transfer solids and liquids at a flow rate of up to 594 GPM and with 7.5 HP.

DAE Pumps Tampa 455 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. DAE Pumps Tampa 455 offers an open stand or strainer, and agitator that provides greater suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 455 submersible slurry pumps transfer solids and liquids at a flow rate of up to 594 GPM and with 7.5 HP.

DAE Pumps Tampa 4110 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The efficient DAE Pumps Tampa 4110 offers an open stand or strainer, and agitator that provides enhanced suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 4110 submersible slurry pumps transfer solids and liquids at a flow rate of up to 819 GPM and with 15 HP.

The heavy-duty and reliable DAE Pumps Galveston 3304 Submersible Sludge and Slurry Pumps are the latest technology in submersible pumps for transporting slurry, sand, and a variety of other abrasive materials. DAE Pumps Galveston 3304 pumps with a combined strainer with a partially open stand and agitator allows for ideal suction and movement of solids up to 1.5-inches with a 4-inch discharge. The Galveston 3304 submersible slurry pumps transfer solids and liquids at a flow rate of up to 792 GPM and with 30 HP.

Agitator series submersible pump designed for slurry, mud & sand pumping with hard iron adjustable wear parts & bottom side discharge up to 6-inch size.

Constructed for maximum durability, our dewatering pumps are compact and lightweight, built with the contractor in mind. Trash pump with 2", 3" and 4" designs with Honda GX engine.

Constructed for maximum durability, our dewatering pumps are compact and lightweight, built with the contractor in mind. Centrifugal pump with 1", 2", 3" and 4" designs with Honda engine.

Dewatering - Direct across the line starting - Automatic series control panels are heavy duty, UL listed control panels used for dewatering applications

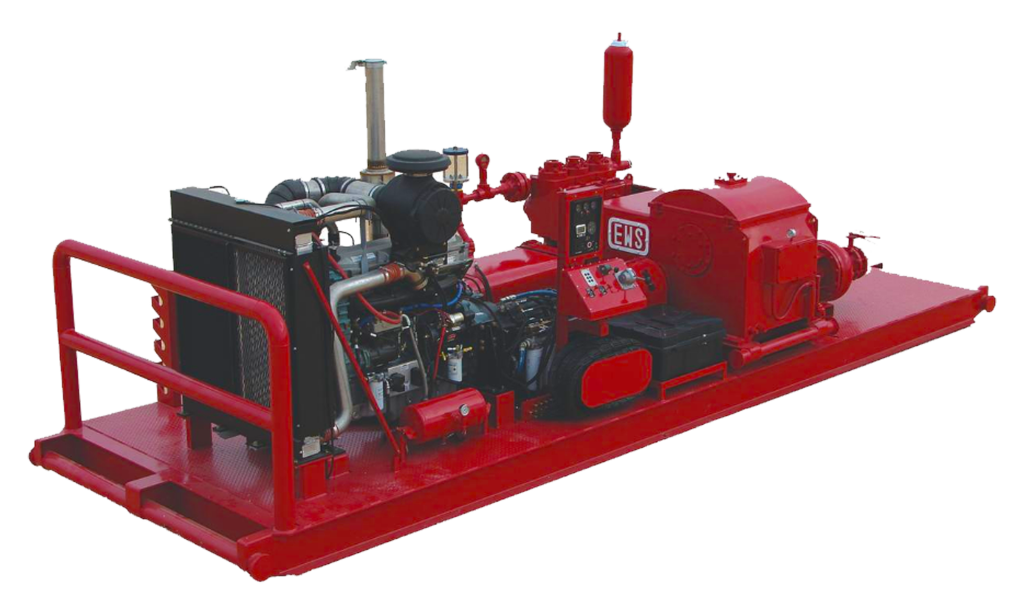

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

All equipment is rated for operating at ambient temperatures up to +120 Deg F at 1200 ft altitude. The unit is built on heavy duty oilfield skid with lift frame. The control system is mounted in a stainless steel box on the side of the unit. The digital display provides all important engine and transmission data. Unit is also equipped with emergency kill function.

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for medium to high head contractor and bypass applications

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for high head/high flow contractor and bypass applications

For industrial, mining, milling, power plant, water treatment, sewage, organic waste, or anywhere slurry solids have a tendency to accumulate, agitator pumps are the answer. Since water always flows to the path of least resistance, a pump without mechanical agitation will only pump the water, leaving the solids behind to accumulate around your pump intake, and eventually starving the pump by blocking the intake. Agitator pumps deliver kinetic energy (energy of motion) to slurry solids surrounding the pump intake, re-suspending them into a fluid state. These solids, which would have otherwise buried and starved the pump of liquid, are pulled into the pump and pushed on through the discharge keeping the intake clear and free of slurry accumulation.

Submersible pumps, which are more efficient than jet pumps, contain a hermetically sealed motor and are used for pushing fluid to the surface. We offer submersible pumps for several applications, including mines, manholes, construction sites, sewage and other areas with a high concentration of solids. Our submersible pumps come in several different varieties in order to handle the different conditions you may face in the field:

Dewatering Pumps – Heavy duty abrasion resistant pumps for dewatering: mines, power plant sumps, manholes, and construction sites. Also as water supply pumps (3/4 to 45 hp).

Corrosion Resistant Pumps – For severe corrosion: all 316 stainless-steel recessed impeller pumps. (1 to 10 hp)For moderate corrosion: Rhino Coated aluminum with stainless steel impellers, shafts, and hardware (1.5 to 45 hp).

No matter what pump you’re looking for, Piranha Pumps will deliver on your expectations, however high they may be. When it comes to the best heavy-duty submersible pumps in the business, look no further than Piranha Pumps.

If you’d like to learn more about our submersible pump systems, don’t hesitate to contact us. An experienced Piranha Pumps team member will be happy to answer any questions you have. At Piranha Pumps, you can rest assured knowing that our dredging and pumping machines are powerful, efficient, and reliable.

As a "Woman Owned" business, we have successfully developed our business from small dewatering pumps to large industrial dredges and have dotted the world with our business products. We have a strong market demand on almost every continent and a continuous demand for all of our quality products. It is our mission here at Piranha Pumps to evolve and improve our products and services to accommodate the ever-changing global market and unique needs of our diverse customer base. We aim to lead the market with our competitive pricing and industrially advanced equipment while maintaining growth and customer satisfaction.

8613371530291

8613371530291