how does a mud pump work made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Find W series mud pump from pressure grouting pump manufacturer - Saigao gruop in China. The W series mud pump can be widely used in all kinds of works in oil field, which is su...

BW Piston pump mud pump for drilling rig for grouting cement With factory price on Sale is mainly used to grout cement, slurry, paste and mud into holes to support and anchor in geology, mining, construction, metallurgy, railway, chemical engineering, water conservancy, petroleum exploration, etc. It can also be used to inject fluids while drilling holes to lower the temperature and clean the broken stone and soil.

Henan Yugong Machinery Co., Ltd. is a large machinery manufacturing enterprise which focuses on research and development, production and sales of mining, tunnel construction, road and bridge construction equipments and so on.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

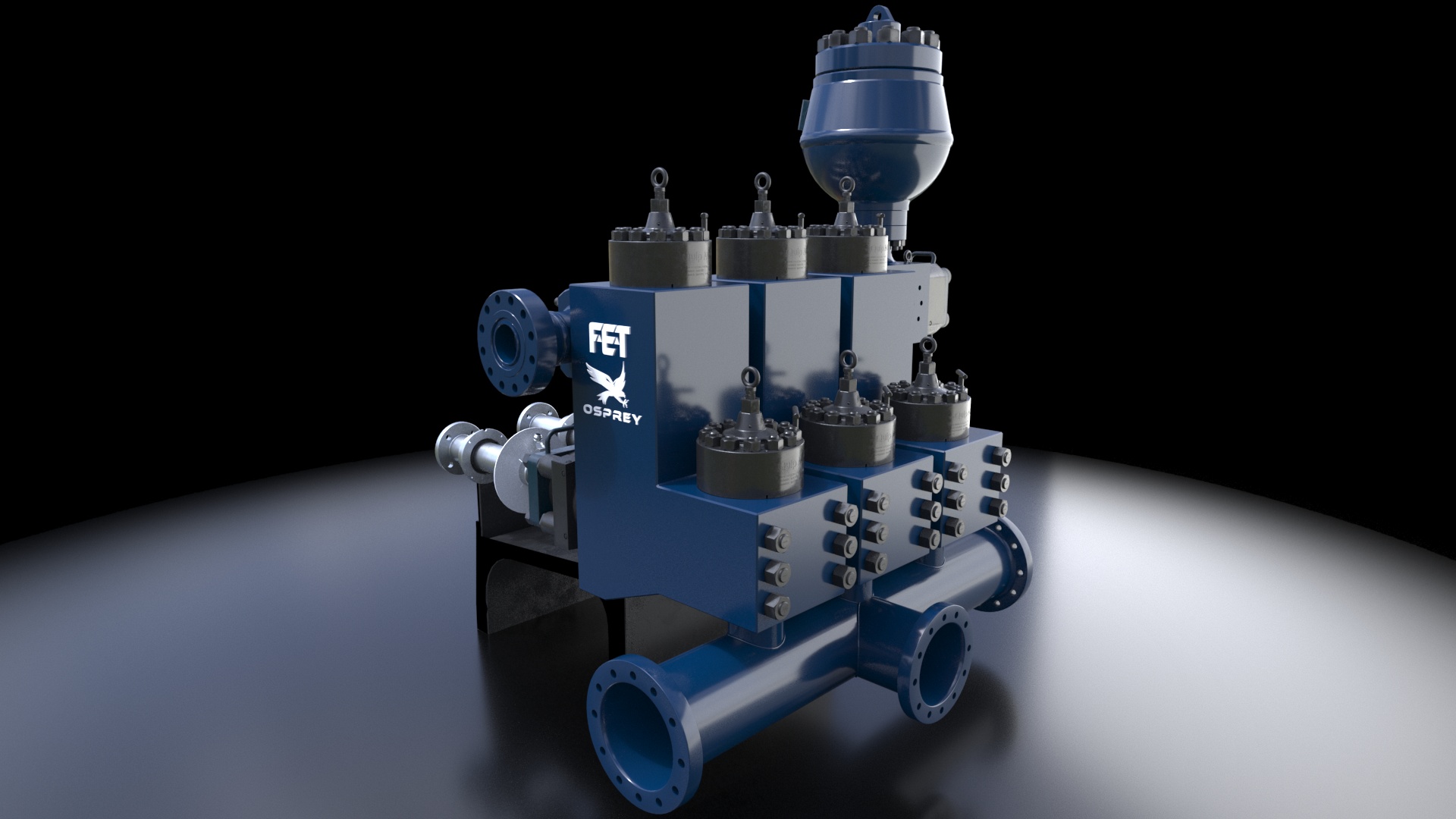

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

AH000003030700 triplex mud pump liner 170 180, AH1301010402 cross head guide lower and upper, AH36001-05.16A wear plateAH1301010513, AH33002-03.00 KB-45 KB-75pulsation dampener, 380202052250006020 for BOMCO and YK-150F pressure gauge suppliers

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

In 1996, Phillips China, Inc. (PCI) based in Shekou, People"s Republic of China, was faced with the decision to either submit a development plan for the Xijiang 24-1 Field in the 15/11 Contract Area of the South China Sea or to relinquish their rights to the field. The remote location of the field and the relative small size of the reservoir made this decision difficult. Several studies conducted over a number of years on various development scenarios indicated that any type of stand alone development, such as a small platform or subsea wells, would be uneconomical. It was, therefore, concluded that the only way of developing the 24-1 was to drill an extended reach well (ERW) from PCI"s Xijiang 24-3 Platform, over 8-km away. Such a well would have a world record horizontal reach.

One of the biggest concerns for the success of an ERW was whether the platform rig, which was designed for a 4573-m measured depth (MD) (3049-m true vertical depth (TVD)) development wells, could be upgraded sufficiently. Also of concern were the relatively remote location of the Xijiang operation, the lack of experience in ERW drilling in the area, the transitional step from drilling relatively shallow development wells to drilling a world record ERW, hole stability, torque and drag, directional control, logistics and weather.

This paper will describe the upgrade process performed on the drilling rig to enable it to drill and complete this record breaking well. It will include a post-well evaluation of the upgrades. In addition, it will describe the drilling and completion of the well and how PCI addressed all the concerns listed above.

HW-440/446 Pump can be widely used in all kinds of works in oil field. When the cylinder liner specification is 6”-3 1/2”, piston structure is recommended and it is suitable for Oil-Well Repair and shallow-well drilling, etc. When the cylinder liner specification is 3 1/4”-2”, axial piston structure is recommended and it is suitable for high-pressure work.

In oil drilling, high-pressure mud pump is the heart of drilling platform, and wear resistant cylinder liner is the main vulnerable part of mud pump. It need to withstand working conditions of high pressure, high wear and strong corrosion. At present, the mud pump cylinder liners are mainly bimetal cylinder liners and ceramic cylinder liners. The lining of the bimetal cylinder liner is made of high-chromium cast iron metal materials, the lining of the ceramic cylinder liner is made of alumina or zirconia structural ceramic material.

The pumps are mainly design for solids control circulating system of oilfield drill rig. It can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer, to assure these equipments work efficiently.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We have been focusing on producing triplex single-action mud pump and its accessories since we built our company. So far, we can offer two series products that are respectively the F-series and 3NB-series. Our F-series drilling pumps including models of RLF-500, RLF-800, RLF-1000, RLF-1300, RLF-1600 and RLF-2200 are designed and manufactured strictly in accordance with the API 7K specification (Certificate No.: 7K-0130) based on the American Emsco F-series drilling pump. Our products of the 3NB-series cover models of 3NB-350, 3NB-500, 3NB-600, 3NB-800, 3NB-1000A/D, 3NB-1300A/D and 3NB-1600. They are designed and produced following the standard formulated by Ministry of Petroleum Industry of China and can meet the needs of different customers.

Our F-series triplex mud pumps are designed and manufactured based on the American Emsco F-series mud pump strictly in accordance with API 7K specification. All of the expendable parts are interchangeable with any other similar spare parts produced according to API specification.

The optimized design helps to improve the suction performance of our products and extend the service life of the expendable parts. Triplex mud pumps of the RL3NB series are produced and tested strictly in accordance with the SY5138 standard formulated by Ministry of Petroleum Industry of China.

Customized Mud PumpWe can design and manufacture customized pump used for mud drilling according to customer"s requirement. We provide not only the mud pump itself, but also the power system and transmission system to make a pump package. After being assembled on the well site, the pump package is ready to work.

Since all the expendable parts are compatible with other similar parts made in accordance with the API specification, F-series mud pumps are easy to maintain all over the world.

Due to compact solid structure and small size, the F-series products have excellent performance to meet the drilling technological requirements of high pumping pressure and high displacement. Designed with longer stroke for lower working stroke rate, these products have fine water filling performance and buffering performance in suction pipelines. Meanwhile, the service life of the expendable parts in the fluid end will be extended as well. The power end of this series product is durable since its lubricating system combines forced lubrication and splash lubrication together.

Because of limited parts supply, the 3NB-series mud pumps mainly sell domestically. In resent years, due to cheaper price, they become more and more popular in oversea countries, especially in Kazakhstan and Russia.

We can also design mud pump package mainly composed of the power system, transmission system and the pump itself, according to customer’s environment. Other facilities like filling system, manifolds and control system are also available. Diesel engine driving and electric motor (DC/AC variable frequency motor) driving are optional. As to transmission mode, we provide gear reducer, hydraulic coupler and hydraulic torque converter for your selection. After being assembled on the well site, the pump package will go into operation.

Our F-series triplex mud pumps are designed and manufactured based on the American Emsco F-series mud pump strictly in accordance with API 7K specification. All of the expendable parts are interchangeable with any other similar spare parts produced according to API specification.

The optimized design helps to improve the suction performance of our products and extend the service life of the expendable parts. Triplex mud pumps of the RL3NB series are produced and tested strictly in accordance with the SY5138 standard formulated by Ministry of Petroleum Industry of China.

Customized Mud PumpWe can design and manufacture customized pump used for mud drilling according to customer"s requirement. We provide not only the mud pump itself, but also the power system and transmission system to make a pump package. After being assembled on the well site, the pump package is ready to work.

8613371530291

8613371530291