how does a mud pump work price

Mud pumps are essential equipment for any oil or gas well. They are used to move drilling mud and other fluids needed during the drilling process. To select the right mud pump for your well, you need to understand the different types available and what each one can do.

In this article, we will take a comprehensive look at mud pumps and provide you with all the information you need to make an informed purchase. We will also discuss how mud pumps are used in drilling operations and highlight some of their key features. By the end of this article, you will clearly understand what mud pumps are and what they can do for your well.

A mud pump is a type of reciprocating positive displacement pump that is specifically designed for use in drilling operations. It helps to circulate the drilling fluid (or “mud”) through the drill bit and back up to the surface. The mud pump also provides pressure to keep the drill bit from becoming plugged.

The pump creates suction that pulls the drilling fluid from the pit and then uses its piston to push the fluid back up the well. This action not only circulates the fluid but also helps to remove any cuttings or debris that may have been generated during the drilling process. Mud pumps are an essential part of the drilling process and are typically used in conjunction with other pumps, such as centrifugal pumps, to create a complete pumping system. Without a mud pump, drilling would not be possible.

There are many different types of mud pumps, each with its own advantages and disadvantages. However, pump experts generally understand the requirement and then suggest which type of pump design would be more efficient. Here are five of the most popular types:

Piston mud pumps are the most common type of mud pump. They use a piston to draw mud from the pit and then force it to the drill bit through the hose. Piston mud pumps are very durable and can handle a lot of pressure. However, they are also very loud and can be challenging to operate.

Plunger mud pumps work similarly to piston mud pumps, but they use a plunger instead of a piston. As a result, plunger mud pumps are quieter than piston mud pumps and are easier to operate. However, plunger mud pumps are not as durable and can only handle a limited amount of pressure.

Hydraulic mud pumps use hydraulic power to draw mud from the pit. They are very powerful and can handle a lot of pressure. However, these types of pumps are generally costly and can be challenging to operate.

Diaphragm mud pumps use a diaphragm to draw mud from the pit. They are less powerful than hydraulic mud pumps but are much cheaper. They are also easier to operate. These merits make such pumps more used in small scale operations.

Peristaltic mud pumps use peristaltic action to draw mud from the pit. They are the most expensive type of mud pump but are also the most powerful. Unfortunately, they are also the most difficult to operate. But given their operational power, they are used in large-scale mining and drilling operations.

Even though mud pumps are very lucrative for mining and drilling purposes, they exhibit many more merits, making them useful in other industries. Following are some of the main advantages of mud pumps:

Mud pumps help to increase the efficiency of drilling operations by allowing for fluid circulation and cooling of the drill bit. This results in faster drilling and less wear on the equipment.

Mud pumps also help to improve safety during drilling operations by providing a means to circulate and cool the drill bit, which reduces the risk of overheating and fire.

Mud pumps can also help to improve the accuracy of drilling operations by preventing the drill bit from wandering off course due to excessive heat build-up.

The use of mud pumps can also help to reduce the costs associated with drilling operations by reducing the need for frequent replacement of drill bits and other worn items.

The use of mud pumps can also help to increase the productivity of drilling operations by reducing the downtime associated with the frequent replacement of drill bits and other worn items.

Mud pumps are an essential part of the oil and gas industry, as they are used to pump drilling fluid (mud) into the drill hole. There are many different mud pumps, each with its own unique set of features and applications. A reliable pump expert will help you choose which pump to use where. Here are 10 of the most common applications for mud pumps:

Mud pumps are extensively used to circulate drilling fluid during the drilling process. This helps to cool and lubricate the drill bit and remove cuttings from the hole.

Mud pumps are also used in hydraulic fracturing operations, where high-pressure fluid is injected into the rock formation to create fractures. The pump helps to circulate the fracturing fluid and keep the pressure at the desired level.

Mud pumps are sometimes used in geothermal operations to circulate water or other fluids through the drilled well. This helps extract heat from the rock and bring it to the surface.

In coal seam gas extraction, mud pumps are used to circulate water and chemicals through the coal seam to dissolve the methane gas and make it easier to extract.

In potash mining, mud pumps are used to circulate brine solution through the ore body to dissolve the potassium chloride (potash) and pump it out of the mine.

Mud pumps are often used in water well drilling operations to circulate water through the drill hole and help flush out any cuttings or debris. Pump experts can customize mud pumps to suit this application.

In tunnelling operations, mud pumps can circulate a slurry of water and clay through the drilling area. This helps to stabilize the walls of the tunnel and prevent collapse.

Mud pumps are sometimes used in pipeline operations to help clean and inspect the inside of the pipe. The pump circulates water or other fluids through the pipe to remove any build-up or debris.

In environmental remediation projects, mud pumps can circulate water or chemicals through contaminated soil or groundwater. This helps to break down contaminants and make them easier to remove.

Mud pumps can also be used in construction projects to help remove water from the site or stabilize the ground. For this application, they are extensively used in large construction sites.

Mud pumps are an essential part of many different industries and have various applications. If you need a mud pump for your next project, be sure to consult with a pump expert to find the right pump for your needs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes drilling mud pump price wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A drilling mud pump price comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the drilling mud pump price of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of drilling mud pump price for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of dr drill mud pump prices, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

Mud pumps can be divided into single-acting pump and double-acting pump according to the completion times of the suction and drainage acting in one cycle of the piston"s reciprocating motion.

Mud pumps come in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is used. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplexes with five horizontal piston/plungers. The advantages that these new pumps have over convention triplex pumps is a lower mud noise which assists with better measurement while drilling (MWD) and logging while drilling (LWD) decoding.

The fluid end produces the pumping process with valves, pistons, and liners. Because these components are high-wear items, modern pumps are designed to allow quick replacement of these parts.

To reduce severe vibration caused by the pumping process, these pumps incorporate both a suction and discharge pulsation dampener. These are connected to the inlet and outlet of the fluid end.

The power end converts the rotation of the drive shaft to the reciprocating motion of the pistons. In most cases a crosshead crank gear is used for this.

Displacement is calculated as discharged liters per minute. It is related to the drilling hole diameter and the return speed of drilling fluid from the bottom of the hole, i.e. the larger the diameter of drilling hole, the larger the desired displacement. The return speed of drilling fluid should wash away the debris and rock powder cut by the drill from the bottom of the hole in a timely manner, and reliably carry them to the earth"s surface. When drilling geological core, the speed is generally in range of 0.4 to 1.0 m^3/min.

The pressure of the pump depends on the depth of the drilling hole, the resistance of flushing fluid (drilling fluid) through the channel, as well as the nature of the conveying drilling fluid. The deeper the drilling hole and the greater the pipeline resistance, the higher the pressure needed.

With the changes of drilling hole diameter and depth, the displacement of the pump can be adjusted accordingly. In the mud pump mechanism, the gearbox or hydraulic motor is equipped to adjust its speed and displacement. In order to accurately measure the changes in pressure and displacement, a flow meter and pressure gauge are installed in the mud pump.

The construction department should have a special maintenance worker that is responsible for the maintenance and repair of the machine. Mud pumps and other mechanical equipment should be inspected and maintained on a scheduled and timely basis to find and address problems ahead of time, in order to avoid unscheduled shutdown. The worker should attend to the size of the sediment particles; if large particles are found, the mud pump parts should be checked frequently for wear, to see if they need to be repaired or replaced. The wearing parts for mud pumps include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be adopted to increase the service life of the wearing parts, which can reduce the investment cost of the project, and improve production efficiency. At the same time, wearing parts and other mud pump parts should be repaired rather than replaced when possible.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

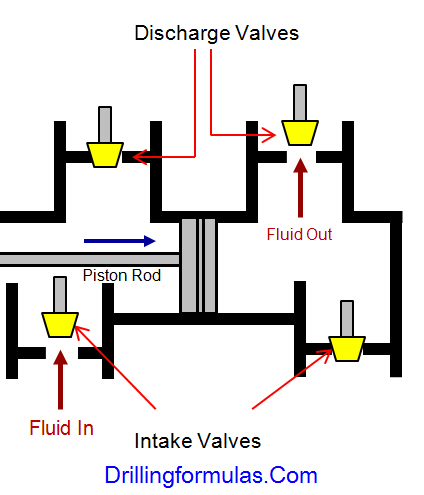

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

When the piston rods are moved forward, the intake valves are in close position and the discharge valves are in open position allowing fluid to discharge (Figure 5).

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

Mud pump is one of the most critical equipment on the rig; therefore personnel on the rig must have good understanding about it. We’ve tried to find the good training about it but it is very difficult to find until we’ve seen this VDO training and it is a fantastic VDO training about the basic of mud pumps used in the oilfield. Total length of this VDO is about thirteen minutes and it is worth to watch it. You will learn about it so quickly. Additionally, we also add the full detailed transcripts which will acceleate the learning curve of learners.

Powerful mud pumps pick up mud from the suction tank and circulate the mud down hole, out the bit and back to the surface. Although rigs usually have two mud pumps and sometimes three or four, normally they use only one at a time. The others are mainly used as backup just in case one fails. Sometimes however the rig crew may compound the pumps, that is, they may use three or four pumps at the same time to move large volumes of mud when required.

Rigs use one of two types of mud pumps, Triplex pumps or Duplex pumps. Triplex pumps have three pistons that move back-and-forth in liners. Duplex pumps have two pistons move back and forth in liners.

Triplex pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;

• One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

Triplex pumps are gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. Input horsepower ranges from 220 to 2200 or 164 to 1641 kW. Large pumps can pump over 1100 gallons per minute, over 4000 L per minute. Some big pumps have a maximum rated pressure of over 7000 psi over 50,000 kPa with 5 inch/127 mm liners.

Here is a schematic of a triplex pump. It has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Look at the piston at left, it has just completed pushing mud out of the liner through the open discharge valve. The piston is at its maximum point of forward travel. The other two pistons are at other positions in their travel and are also pumping mud. But for now, concentrate on the left one to understand how the pump works. The left piston has completed its backstroke drawing in mud through the open intake valve. As the piston moved back it instead of the intake valve off its seat and drew mud in. A strong spring holds the discharge above closed. The left piston has moved forward pushing mud through the now open discharge valve. A strong spring holds the intake valve closed. They left piston has completed its forward stroke they form the length of the liner completely discharging the mud from it. All three pistons work together to keep a continuous flow of mud coming into and out of the pump.

Crewmembers can change the liners and pistons. Not only can they replace worn out ones, they can also install different sizes. Generally they use large liners and pistons when the pump needs to move large volumes of mud at relatively low pressure. They use a small liners and pistons when the pump needs to move smaller volumes of mud at a relatively high pressure.

In a duplex pump, pistons discharge mud on one side of the piston and at the same time, take in mud on the other side. Notice the top piston and the liner. As the piston moves forward, it discharges mud on one side as it draws in mud on the other then as it moves back, it discharges mud on the other side and draws in mud on the side it at had earlier discharge it. Duplex pumps are therefore double acting.

Double acting pumps move more mud on a single stroke than a triplex. However, because of they are double acting they have a seal around the piston rod. This seal keeps them from moving as fast as a triplex. Input horsepower ranges from 190 to 1790 hp or from 142 to 1335 kW. The largest pumps maximum rated working pressure is about 5000 psi, almost 35,000 kPa with 6 inch/152 mm linings.

A mud pump has a fluid end, our end and intake and the discharge valves. The fluid end of the pump contains the pistons with liners which take in or discharge the fluid or mud. The pump pistons draw in mud through the intake valves and push mud out through the discharge valves.

The power end houses the large crankshaft and gear assembly that moves the piston assemblies on the fluid end. Pumps are powered by a pump motor. Large modern diesel/electric rigs use powerful electric motors to drive the pump. Mechanical rigs use chain drives or power bands (belts) from the rig’s engines and compounds to drive the pump.

A pulsation dampener connected to the pump’s discharge line smooths out surges created by the pistons as they discharge mud. This is a standard bladder type dampener. The bladder and the dampener body, separates pressurized nitrogen gas above from mud below. The bladder is made from synthetic rubber and is flexible. When mud discharge pressure presses against the bottom of the bladder, nitrogen pressure above the bladder resists it. This resistance smoothes out the surges of mud leaving the pump.

Here is the latest type of pulsation dampener, it does not have a bladder. It is a sphere about 4 feet or 1.2 m in diameter. It is built into the mud pump’s discharge line. The large chamber is form of mud. It has no moving parts so it does not need maintenance. The mud in the large volume sphere, absorbs this surges of mud leaving the pump.

A suction dampener smooths out the flow of mud entering into the pump. Crewmembers mount it on the triplex mud pump’s suction line. Inside the steel chamber is a air charged rubber bladder or diaphragm. The crew charges of the bladder about 10 to 15 psi/50 to 100 kPa. The suction dampener absorbs surges in the mud pump’s suction line caused by the fast-moving pump pistons. The pistons, constantly starts and stops the mud’s flow through the pump. At the other end of the charging line a suction pumps sends a smooth flow of mud to the pump’s intake. When the smooth flow meets the surging flow, the impact is absorbed by the dampener.

Workers always install a discharge pressure relief valve. They install it on the pump’s discharge side in or near the discharge line. If for some reason too much pressure builds up in the discharge line, perhaps the drill bit or annulus gets plugged, the relief valve opens. That opened above protects the mud pump and system damage from over pressure.

Some rig owners install a suction line relief valve. They install it on top of the suction line near the suction dampener. They mount it on top so that it won’t clog up with mud when the system is shut down. A suction relief valve protects the charging pump and the suction line dampener. A suction relief valve usually has a 2 inch or 50 mm seat opening. The installer normally adjusts it to 70 psi or 500 kPa relieving pressure. If both the suction and the discharged valves failed on the same side of the pump, high back flow or a pressure surge would occur. The high backflow could damage the charging pump or the suction line dampener. The discharge line is a high-pressure line through which the pump moves mud. From the discharge line, the mud goes through the stand pipe and rotary hose to the drill string equipment.

The policy set forth below outlines the personal data that Power Zone Equipment may collect, how Power Zone Equipment uses and safeguards that data, and with whom we may share it. This policy is intended to provide notice to individuals regarding personal data in an effort to be compliant with the data privacy laws and regulations of the jurisdictions in which Power Zone Equipment operates.

Power Zone Equipment encourages our employees, independent contractors, customers, suppliers, commercial visitors, business associates, and other interested parties to read this policy. By using our website or submitting personal data to Power Zone Equipment by any other means, you acknowledge that you understand and agree to be bound by this policy, and agree that Power Zone Equipment may collect, process, transfer, use and disclose your personal data as described in this policy.

Power Zone Equipment is committed to maintaining all reasonable precautions to ensure the privacy and security of personal data gathered by Power Zone Equipment. During your use of our website or through other communications with Power Zone Equipment, personal data may be collected and processed by Power Zone Equipment. In general, Power Zone Equipment collects personal contact information (e.g. name, company, address, telephone number and e-mail address), which you knowingly provide either by registration, requesting quotes, answering questions or otherwise for use in our commercial relationship. At times we may collect additional personal data that you voluntarily provide, including, but not limited to, job title, additional contact information, date of birth, hobbies, areas of interest, and professional affiliations.

Power Zone Equipment’s website is intended to be used by Power Zone Equipment customers, commercial visitors, business associates, and other interested parties for business purposes. Personal data collected by Power Zone Equipment through its website or by other means is used in support of our commercial relationship with you, including, but not limited to, the processing of customer orders, orders from vendors, managing accounts, learning about customers’ needs, responding to inquiries, and providing access to information. Also, in compliance with the laws and regulations of the relevant jurisdiction to support our relationship with you:

we may use third party service providers to assist us in collecting, assembling or processing personal data in connection with services related to our business relationship;

we (or a third party on our behalf) may use personal data to contact you about a Power Zone Equipment offer in support of your business needs or to conduct online surveys to understand better our customers’ needs; and

If you choose not to have your personal data used to support our customer relationship (especially direct marketing or market research), we will respect your choice. We do not sell your personal data to third parties, nor share it with third parties except as set forth in this policy. Power Zone Equipment will retain your personal data as long as you maintain a customer relationship with Power Zone Equipment and/or if you have registered to receive marketing or other communication from Power Zone Equipment, until such time as you request that we delete such personal data.

Power Zone Equipment is the commercial operator of its website and uses service providers to assist in hosting or otherwise acting as data processors, to provide software and content for our sites and to provide other services. Power Zone Equipment may disclose personal data supplied by you to these third parties who provide such services under contract to protect your personal data. In addition, where consistent with the laws and regulations of the relevant jurisdiction, Power Zone Equipment may disclose personal data if such disclosure:

For our customers in Switzerland and the European Union (EU), please note that Power Zone Equipment is a US based company. If you use our websites or web portals or, all information, including personal information, may be transferred to Power Zone Equipment (including subcontractors that may be maintaining and/or operating our website) in the United States and elsewhere and may be transferred to third parties that may be located anywhere in the world. Although this may include recipients of information located in countries where there may be a lower level of legal protection for your personal information than in your location country, we will protect your information in accordance with requirements applicable to your information and/or location. Specifically, for data transfers out of the EU, Power Zone Equipment will utilize data transfer agreements containing the Standard Contractual Clauses. By using our websites or web portals, you unambiguously consent to the transfer of your personal information and other information to the United States and elsewhere for the purposes and uses described herein.

When you access Power Zone Equipment’s websites or web portals, we may automatically (i.e., not by registration) collect non-personal data (e.g. type of Internet browser and operating system used, domain name of the website from which you came, number of visits, average time spent on the site, pages viewed). We may use this data and share it with our worldwide affiliates and related service providers to monitor the attractiveness of our websites and improve their performance or content. In this case, processing is performed on an anonymous basis and at Power Zone Equipment’s discretion.

In addition, certain online technical applications or other interactions you have with Power Zone Equipment may require the entry of business and technical data. By providing the requested information, you are consenting to the processing and storage of such information by Power Zone Equipment. Unless Power Zone Equipment is advised that you want this information removed from Power Zone Equipment’s server, such information may be retained by Power Zone Equipment and used for future commercial communications. A request for removal of this information can be made at the contact information provided below. Power Zone Equipment will take all reasonable precautions to assure that no such information will be provided or divulged to other third parties, except, if applicable, those third parties performing site hosting, maintenance, and related site service activities.

Cookies are information stored automatically on a website user’s computer. When a user views Power Zone Equipment’s website(s), Power Zone Equipment may store some data on the user’s computer in the form of a “cookie” to automatically recognize the user upon future visits to Power Zone Equipment’s website(s). Power Zone Equipment will make reasonable efforts to ensure compliance with the laws and regulations of relevant jurisdictions with regard to cookies.

Power Zone Equipment will not knowingly collect personal data from children under the age of 18. Power Zone Equipment’s website(s) is not intended for individuals under 18 years of age

Power Zone Equipment will take reasonable precautions to protect personal data in its possession secure against the risk of loss, misuse, unauthorized access, disclosure, alteration and destruction. Power Zone Equipment periodically reviews its security measures in an effort to ensure the privacy of personal data.

Power Zone Equipment will use personal data only in ways that are compatible with the purposes for which it was collected or subsequently authorized by you. While Power Zone Equipment will take reasonable steps to ensure that personal data is relevant to its intended use, accurate, complete, and current, Power Zone Equipment is also relying upon each individual to assist in providing accurate updates of his or her personal data.

Power Zone Equipment website(s) may contain “links” to websites owned and operated by third parties. By accessing these links, which are provided for your convenience, you will leave our site and will be subject to the privacy practices of the other website. This policy does not apply to any personal information you provide to unrelated third parties.

In general, Power Zone Equipment will only retain personal data for as long as needed for the specific purpose of processing and in accordance with Power Zone Equipment’s records management policy, or as otherwise required by the laws and regulations of a particular jurisdiction. For example, data will be retained during the time period that you are authorized to use Power Zone Equipment website(s), including any Power Zone Equipment tools accessible through our website(s). Upon termination of such authorization, your personal data related to use of Power Zone Equipment website(s) will be removed.

Upon request, Power Zone Equipment will grant individuals reasonable access to personal data that it holds about them. In addition, Power Zone Equipment will take reasonable steps to permit individuals to correct, amend, or delete information that is demonstrated to be inaccurate or incomplete. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact the following:

If your personal data is processed in the EU or you are a resident of the EU, the EU General data Protection Regulation grants you certain rights under the law. In particular, the right to access, correct, or delete the personal data Power Zone Equipment holds about you.

To the extent required by applicable law, Power Zone Equipment will grant individuals reasonable access to personal data that Power Zone Equipment holds about them and will take reasonable steps to permit such individuals to correct, amend, or delete information that Power Zone Equipment holds about them. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact his or her Power Zone Equipment commercial contact or contact us at the following email address:sales@powerzone.com.

If you have a comment, question, or complaint about how Power Zone Equipment is handling your personal data, we invite you to contact us in order to allow us to resolve the matter. In addition, individuals located in the EU may submit a complaint regarding the processing of their personal data to the EU data protection authorities (DPAs). The following link may assist you in finding the appropriate DPA:http://ec.europa.eu/justice/data-protection/bodies/authorities/index_en.htm.

Power Zone Equipment reserves the right to modify this policy from time to time in order that it accurately reflects the legal and regulatory environment and our data collection principles. When material changes are made to this policy, Power Zone Equipment will post the revised policy on our website.

If you have any questions or comments about this policy (e.g. to review and update, or remove your personal data from our database) please contact +1-719-754-1981 orsales@powerzone.com

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

OPI 700 HDL TRIPLEX PUMP(Ref#7719T) 700 hp at 150 rpm, fully rebuilt, Cat 3408 engines (approx. 15000 hours and run very well) Two available Price: $275,000 CDN each

NATIONAL 12P-160 TRIPLEX MUD PUMP(Ref#5586T) 3 available in India. 1600 HP, rated pump speed 140 strokes per minute, maximum fluid cylinder liner bore 6¾”, stroke 10", 10,000 PSI hydrostatic pressure of standard cylinder. 2.853 ratio of gears. 10" suction connection, 6" discharge connection. Valve pot mod .7., steel fluid ends, 5,000 psi pulsation dampener. Oilfield skid mounted. Performance Data: at 120 strokes per minute with 6¾” liners, pump will produce 4305 PSI and 574gpm. Set up for electric power. Dimensions and weight: 84,700lbs, 209"L x 113"W x 75"H. Built 1976. Located India, removed from offshore drilling rig.

NATIONAL 12P-160 TRIPLEX PUMPS(Ref#2355R) 3 available, driven by GE752 traction motor, 1600 hp, 12” stroke, 5000 psi, surge chamber, skid mounted, located Middle East Price: $310,000

NATIONAL 12P-160 TRIPLEX PUMPS(Ref#8938R) 3 available, overhauled by National Oilwell (ready in 2-3 weeks after purchase), 1600 hp @ 120 stroke per minute, 12” stroke, 5000 psi, skid mounted, GE Amerimex 752 traction motors, new liners, seats, valves and pistons Price: $295,000 each

NATIONAL 12P-160 MUD PUMP(Ref#2062Re) Refurbished, complete with South West fluid ends and DC traction motors, located Middle East, 3 available Price: $720,000 each

NATIONAL 8P80 TRIPLEX MUD PUMP(Ref#9073R) 800 hp, 6-1/2” x 8-1/2”, FS, FS FE w/QC caps and cylinder head caps, Oteco 3” shear relief valve, suction screen, 5 x 6” centrifugal charging pump, powered by Cat 3412 diesel engine, rod cooling pump, Oteco type D pressure gauge, mud valves, bull wheel, master skidded, complete, good condition Price: $275,000

NATIONAL OILWELL 850 HP MUD PUMP(Ref#15442T) Mattco API-9 fluid end rebuilt, very little use after rebuild, pulsation dampener, no engine, skid mounted Price:$22,000

NATIONAL 7-P-50(Ref#6302R) 750 hp, 8” stroke, 6” suction inlet, 4” discharge outlet, piston size 4-1/2” – 7”, max rod load 85,000#, approx. weight 11,500#, lubrication force fed, steel pump power end, double helical gears, 4.95:1 gear ratio, rod bearings sheel type replaceable, main bearings straight roler, pinion bearings spherical roller, crankshaft 1pc forged alloy steel, connecting rod knuckle joint, crosshead guide bronze replaceable, piston type fluid end Monoblock design, from high strength alloy steel, treated and sonic tested, Cat D379 diesel engine, 500 HP max linear bore size 3-1/2 – 6-1/4 x 7-3/4” stroke, test pressure 10,000 psi, gear ratio 2.742.8” suction line to 4 discharge stroke, location South America Price: $110,000

NATIONAL JWS 165 WELL SERVICE TRIPLEX PUMP WITH 140 BARREL WORK TANK(Ref#2633Tb) 5 x 6, Detroit 8V71 engine, standard transmission, skid mounted Price:$87,500

NOV JWS 340 TRIPEX MUD PUMPS(Ref#2345T) Two available, Skidded, Detroit Series 60 diesel engine DDEC V (475 hp), Allison 750 (6-speed) transmission with lock up control pane, Mission 4 x 5 centrifugal suction pump, 4” plungers, pulsation dampener, pressure gauge, safety valve, 10,000 psi fluid end, 5000 psi working pressure, NOV plug valve control manifold (4-valve) configured for 15k operation. Can be configured to kill wells, acidize, cement, reverse circulate, drill out frac plugs or run in tandem. Self-contained with fuel and fluid tanks and controls. Steel canopy over skids, covered battery boxes, new batteries and disconnect switches. Well maintained and in excellent condition. Low hours on pumps and motors. Ready to work. Price: $154,500 each

NATIONAL JWS300 MUD PUMP(Ref#2767R) Series 60 Detroit diesel, 14 liter engine w/Allison transmission, mounted on oilfield skid, major overhaul, completely unitized with fuel tank, fluid end rebuilt by Matco Price: $195,000

NATIONAL OILWELL VARCO 308T-7(Ref#3358T) 4” Ceramic plungers, external drip lubricated, pulsation dampeners, John Deere 400hp engine, bypass oil filter, electric start, 200 gal fuel tank, well maintained, Hansen gear 7.25:1, Cobra with cooler Price:$225,000

(2) NATIONAL C350 MUD PUMPS(Ref#3077N) Standby – not pump in 15 years. Pumped chalk continuously at 600 psi in a cement factory. Complete with electrics and electric motor, complete, bull wheels and guards, complete, fluid end, pistons, liners, and valves. Low hours. Located Europe. Price for both: $105,000 loaded in a 40’ container

NATIONAL G700 14” STROKE DUPLEX MUD PUMP(Ref#8312Ta) 700 HP, 14” stroke, cast iron fluid end, surge chamber, 285 gpm @ 3550 psi with 5” pistons or 805 gpm @ 1265 psi with 8” pistons, mounted on skid 10’ x 23’ with enclosure, sold as is Price: $27,500

NATIONAL 5-1/2 X 10” MUD PUMP(Ref#14556Ta) skid mounted with fuel tank, 471 Detroit diesel engine, 4 speed transmission, all new injectors Price: $16,500

NATIONAL C-100 DUPLEX MUD PUMP SYSTEM(Ref#10047R) National C100 duplex mud pump (currently has 5-1/2” liners), gear end and mud end is in good shape, powered by 671 Detroit engine, 1000 gallon fuel tank capacity, tndem trailer mounted (air brakes), fully winterized enclosure with heater unit, locking doors and parts shelves, stairways and rails, 8” steel suction line/hose/sand screen pot/pole winch for adjustment of suction depth, Price: $50,000

IDEAL 5 X 10 DUPLEX MUD PUMP(Ref#9068T)453 Detroit engine (tall, not short), mounted on 5th wheel trailer, new bearings in crane case Price: $18,500

PERONI PTO/C TRIPLEX MUD PUMP(Ref#6306R) 110mm (4.331”) bore x 190mm (7.480”) stroke, 5000 psig, 125 rpm, 151.6 gpm, 350 psig, stainless steel flud end, Cummins Big Cam, Model NTC-350, built 1980, Eaton 23-speed manual transmission, Philadelphia Model 13HP-2 gear reducer rated 496 hp ratio 14:1, input 1760 rpm, output 126 rpm, pressurized lubricant system, fuel tank 300 gal, trailer mounted, 11’7”H x 41’4”L x 8’1”W double frame triple axle, king pin to 5th wheel, air brakes and lights, approx. 68,700#, located South America Price: $90,000

HHF 500 TRIPLEX MUD PUMP(Ref#2565Tb) (Hongua International), year 2012, KTA 1150C (19-P750) engine, 6-3/4” cylinder diameter, 7-1/2” stroke, lots of spares Price: $150,000

NF-500 (CHINESE MANUFACTURED0 500 hp MUD PUMP(Ref#13723R) Manufactured 2011, 550 gpm@3000 psi, Cat C15 diesel engine, pulsation dampener, mounted on Galvanized jack-up base, located Australia Price: $280,000

SKYTOP BREWSTER 7-1/4 X 14” MUD PUMP(Ref#13399Rb) 379 Cat didsel engine, Matco hi pressure forged steel fluid end, quick change valve heads, Hydril dampener, brand new expendables sill in box Price: $59,500

OILWELL 14PDH(ref#3813R) 7-1/4 x 14, Matco fluid end with screw type valve, covers and cylinder heads, Detroit 8V71 diesel engine, surge chamber, pip-off valve, 10 groove pully, 5-1/2” liners, mounted on oilfield skid, 1 year warranty on motor, Price: $90,000

OILWELL DUPLEX MUD PUMP(Ref#1190N) Rebuilt with all new fluid end parts and rebuilt gear end, Detroit 8V71 diesel engine, mounted on oilfield skid, hand clutch, belt drive, belt guard, pulsation dampener, pressure gauge, pressure relief valve, cleaned and painted, factory specs:

OILWELL 4 X 6 MUD PUMP(Ref#8578T) New belts, diesel power, new mud end parts, mounted on skid on 8’ x 16’ gooseneck trailer, ready to work Price: $28,000

DRESSER OMEGA TRIPLEX PLUNGER PUMP MODEL JL3000(Ref#362T) 3000 hp, built 1999, unmounted, rebuilt, freshly painted, and not used since Price: $165,000

EWS 440 UNITIZED MUD PUMP PACKAGE(Ref#599N) refurbished Detroit Series 60 engine, refurbished Allison transmission, input horsepower rating 440 max, 320 max pump speed rating, 6” stroke length, 4-1/2” maximum piston size, 3000 psi fluid end working pressure rating, 3” (as required) discharge connection size, 6” (as required) suction connection size, 2” NPT accessory connection size, API#4 valve size, API#S-2 piston rod end, 35 gallon cancase oil capacity, 24 gallons liner wash capacity, internal gear ratio: 4.58:1, 6.517:1. Price: $200,000

DRAGON W-440 TRIPLEX 6” MUD PUMP(Ref#7756Ta) skid mounted on 8’ x 28’ skid, Detroit 60 Series 8 cyl Turbo diesel power plant with 440 hp, on board fuel tank, M310 Series control panel Price: $132,500

L & L SMC T135-5 TRIPLEX 6” MUD PUMP(Ref#7756Tc) mounted on 7’ x 21’ skid, Cat 6 cyl turbo diesel engine, in-line style system, hyd tanks Price: $29,500

MCFARLAND P38 PUMP(Ref#3917Ta) low hours, 1”, 10,000 psi set up, pump can be configured for 18,000 or 25,000 psi, 60 hp electric motor, skidded Price: $27,500

FAMMCO TRIPLEX PUMP(Ref#2760T) 2 x SPM 600 HP 10K, 3-1/2 x 6’ stroke plunger, powered by (2) Cat C12 400 hp diesel engines, (2) Allison HT750 trans., (2) 4 x 5 cent pumps, (2) 5 x 6 slurry mixing pumps, 6 bbl mixing tub, 14 bbl averaging tub, mounted on 2002 tandem axle 8’6”W x 50’ step deck trailer Price on Request

GARDNER DENVER PZ-11(Ref#10748R) approx. 7000 hours, Cat 3512C (1476 hp), 5000 psi fluid end cylinder, 5-1/2” piston cylinder, antifreeze heaters, WPT W21-CG-300 Type 1 PTO clutch, 16 groove drive sheave, 16 groove bullwheel, 16 groove Kevlar belt with necessary guards, 5 x 6 x 11 charge pump c/w 50 hp@1200 rpm electric motor. Discharge plumbing: 2” 5M XXH B/W Oteco gate valve, 4” 5M XXH b/w Oteco gate valve, 3” 5M Oteco popoff valve w/1502 connection, 2” 5M type D Oteco mud gauge with 1502 connection, Hydril 20 gal 5M pulsation damper. Mounted on oilfield skid with separate, with expendables cabinet, knowledge box and removable engine skid for breaking the engine and pump into separate smaller loads. Winterization package, oilfield lighting, explosion proof starters for charge pump, rod oiler pump and liner wash pumps. Price: $695,000 - Make Offer

GARDNER DENVER PZ9 TRIPLEX MUD PUMPS(Ref#7062T) Two Available, each complete with Cat 3508 diesel engines, pulsation dampener, and mud tanks with desander, desilter, etc. Price for Package: $110,000

GARDNER DENVER PZ9 TRIPLEX MUD PUMP(Ref#14850R)2 units available, no power, fully serviced to OEM specs in July 2008 and stored since then Price for both: $430,000

GARDNER DENVER PZ8(Ref#862T) Rebuilt, complete, 8” stroke, 750 hp, alloy steel modular flud cylinders, 6-1/2” liners, liner wash system, API 7 valve pots, gear reducer, steel billet fluid end, pulsation dampener, suction connection, FF discharge connection, 4.5 gear ratio, skid mounted, 130”L x 88”W x 54”H POR

GARDNERDENVER PZ7(Ref#8588N) US manufactured, freshly rebuilt, new Detroit Series 60 engine, Allison transmission, pulsation dampener, complete and ready to go. Price: $375,000

GARDNER DENVER PZ7 STYLE TRIPLEX MUD PUMP(Ref#1245Nb) Reconditioned, inspected and tested. 550 hp input, Cat D379PCTA diesel engine (reconditioned), air start, muffler, standard instrument gauge panel, mounted on Cat rails, new 20CB500 air clutch, reconditioned radiator. Belt drive assembly consisting of pump drive sheave, pump drive belts with belt guard, engine drive sheave, engine drive belts with belt guard, pillow block bearings. Reconditioned Continental Emsco PD-45 12 gallon 5000 psi WP pulsation dampener. New O’Drill/MCM ORV 21050 2” 1,000 – 5,000 psi WP shear relief valve. New O’Drill/MCM 2” 0 – 6,000 psi WP type D mud pressure gauge. PZ7 fluid modules complete with suction manifold and discharge strainer cross. New CA-122 liner wash pump, pinion driven with spary nozzle system, water tank and hoses. New fluid end expendables with 6” liners. (3) runner oilfield type master skid with loading hitches. New 5 x 6” R.H. centrifugal 178 series charge pump, 1-7/8 shaft, 10” impeller size, belt driven off pinion shaft, drive belts with belt guard. New 6” fgure 400 hammer union. New 4” 5000 psi WP gate valve, new 200 gallon air receiver tank, new air controls. Price: $455,000

Fitted with 5" Liner and pistons, bare pump, no extras, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED.

Fitted with 5” liners and pistons with washing and lubricating system, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with a rebuilt Detroit Diesel V1271 w/ Twin Turbo, 550 HP, with a chain case and a manual transmission

Fitted with liner & pistons, with rod washing & lubrication system, bare pump no extra"s, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with New CAT C13 (440 HP) diesel power unit, w/hand clutch, belt drive, belt guard, fuel tank.

Fitted with 5" Liner and pistons, w/washing & lubricating system, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with New CAT C15 (540 HP) diesel power unit, with manual transmission with 4 to 1 gear case, fuel tank.

GARDNER DENVER PAH(Ref#10664Rc) rebuilt, Detroit 8V92 diesel engine, Allison 5960 transmission, new pistons, liners, valves, rebuilt engine Price: $210,000

Manufactured 2008, Cat C-9 new genset, 10 bbl tank, shaker, charging pump, Allison HT750 transmission, 1600 hours, mounted on mobile 52’ trailer Price: $290,000

GARDNER DENVER PAH MUD PUMP(Ref#7546T) 8V92 Detroit diesel engine, Allison transmission, choke manifold on unit and charge pump, pistons and liners, Price on Request

MUD KING PAH MUD PUMP(Ref#12669T) Detroit Series 60 engine, Allison 750 transmission, 3” centrifugal pump, 90 bbl 2-compartment circulating tank Price: $290,000

GARDNER DENVER TRIPLEX MUD PUMP(Ref#8245Rb) Completely rebuilt, new paint, skid mounted, new Detroit 671 engine 165 hp @ 1800 rpm, new fuel tank, lines and fluid end, multi speed transmission and clutch, 12 volt DC starting and operating system, 5” suction, 1742 to 10,000 psi discharge pressure, 8 – 138 gpm capacity, full functional control panel, mounted on oilfield skid, dims 240”L x 90”W x 60”H 12,000# Price: $39,500

KERR 2200 AND 3500 OR FMC M1214 TRIPLEX MIST PUMPS(Ref#7999T) Cat engines, 4 speed transmissions, rigged up with secondary containment, onboard lighting, winterization canvas for cold weather operations, Also available with Cummins or John Deere engines Priced from $77,500 to $97,500

GARDNER DENVER PQ172 TRIPLEX MIST PUMP(Ref#7827Ta) Deutz F3L914 45hp 3 cyl air cooled diesel engine with electric start, manual transmission, gauges, 4’H x 4’W x 7.5’ long, 3” hardline, 22 bbl mixing tank, skid mounted Price: $17,500

GARDNER DENVER GXP TRIPLEX 6 X 16 MUD PUMP(Ref#11010T) Skid mounted, twin Detroit 671 diesel engines, 30 ton, dimensions: 28’L x 11’W x 8’H Price: $32,500

GARDNER DENVER GXR 800 HP DUPLEX MUD PUMP(Ref#12423Rb) Matco steel fluid end, pulsation dampener, fuel tank, gauges, controls, starter, mounted on oilfield skid, completely rebuilt engine and fluid end Price: $125,000

GARDNER DENVER FXN 7-1/4 X 14 MUD PUMP(Ref#1403T) Cat 3408 engine air start with pump drive and belt guard, PD55 Hydril dampener, 750 gallon fuel tank, mounted on heavy duty drop deck tandem trailer, low hours Price: $87,500

GARDNER DENVER FXN 7-1/2” X 14” DUPLEX MUD PUMP(Ref#8312Tb) 500 hp, on skid with Cat D343 engine, capable of 200 gpm @ 3000 psi with 4” pistons or 775 gpm @ 940 psi with 7-1/2” pistons, sold as is Price: $27,500

GARDNER DENVER FXN 7” X 14” DUPLEX MUD PUMP(Ref#6637Ta)Forged steel fluid end, quick change caps, Cat 3412 diesel engine, Hydril K20 3000 pulsation dampener, Demco 2” relief valve, belt drive, type F3000# pressure gauge, rod oiler pump, speed sensor, electric start, air clutch, skidded with roof, 3-1/2” x 20’L vibrating hose Price: $76,000

GARDNER DENVER FZ-FXZ MUD PUMP(Ref#4087Tb) 7-1/2 x 12, Tier 1 Detroit diesel 60 Series, 12.7L 500 hp, good gear and fluid ends, same-trailer mounted, 500 gal fuel capacity Price: $90,000

GARDNER DENVER FXZ 6-1/2” X 12” MUD PUMP(Ref#10287Tb) Detroit 8V71 engine, hauled on 3 axle skid trailer with 1989 TTRAC International truck Price: $69,500

GARDNER DENVER FXN DUPLEX MUD PUMPS(Ref#8214R) Two available, 14” stroke, 2” rod size, 400 hp, 75 strokes per minute, cast fluid ends, unitized on oilfield skid with Cat 3406 diesel engines, air start, new filters, oil and coolant, air receiver on deck, fluorescent lighting, drive belts with air clutch. Gone over and in good operating condition, ready to be put into service. Pumps currently have new 6” liners with production being 480 gpm @ 1000 psi. All fluid end parts are brand new and never used, including the valves, gears, liners, pistons, rods, head gasket, and rod packing, equipped with pulsation dampener. 32’ long x 11’ wide x 7’ high 50,000# weight Price: $72,500 each

GARDNER DENVER FXZ 7-1/4 x 12”(Ref#8810R) Trailer mounted, suction rod, suction strainer, twin GMC 150 hp engines, flywheel, belt guards, totally rebuilt 2011 Price: $100,000

GARDNER DENVER FXZ 7 X 12 MUD PUMP(Ref#6602RD) only 1300 hours on new 12 Liter Volvo engine, air clutches, skid mounted, 20’L x 9’7”W x 8.4”H, 40,000# Price: $45,000

GARDNER DENVER 5-1/2 X 8 FXN DUPLEX MUD PUMP(Ref#6678T) Cast fluid end, 671 Detroit, Spicer 6853-C transmission, hydraulic pump, air controls, 1” hyd hoses, skidded Price: $44,500

GARDNER DENVER 5 1/2 X 10 MUD PUMP(Ref#3261Rb) 6 cylinder Cummins diesel engine, hand clutch, 5 speed transmission, 5-1/2” liners, skid mounted, 10” stroke, ready to work Price on Request

GARDNER DENVER 5 X 10 MUD PUMP(Ref#1480Tb) air driven, used with cement for grouting wells, sitting 3-4 years, valves will need rebuilding, trailer mounted, air over hydraulic brakes, includes 28 joints of 21’ pipe Price: $39,500

GARDNER DENVER 5 X 10 MUD PUMP(Ref#5882Tb) 453 Detroit engine, battery start, mounted on oilfield skid with axles, starts and runs Price: $14,500

GARDNER DENVER FDFXDH MUD PUMP(Ref#14457T) 4” inlet, 3” outlet, pulsation dampern, new piston and rods, engine has been removed Price: $40,000

5-1/2 x 8” GARDNER DENVER MUD PUMP(Ref#4523N) Manufactured 1960’s, rebuilt a couple years ago, skid mounted, 4 cylinder Detroit engine, used Supercharger, 637 hours on it, runs good, needs cosmetic work Price: $32,500

GARDNER DENVER 5 X 6 MUD PUMP(Ref#302Tb) 2 available, unmounted, rebuilt pumps, need normal expendables (neoprene is old in the valves etc) Price: $17,500

GARDNER DENVER FG-FXG 5 X 6 MUD PUMP(Ref#3510R) Detroit diesel engine, mounted on tandem axle trailer, one suction and one discharge hose included Price: $39,500

GARDNER DENVER 5 X 6 MUD PUMP(Ref#13203T) electric drive, in custom skid, fully rebuilt gear end and fluid end, excellent condition Price: $22,500

GARDNER DENVER FXF-DE8 4 X 5 MUD PUMP(Ref#10148T) Manufactured 1996, new condition of gear and fluid ends, no engine, new 4” liners, new pistons, new chrome rods, new valves, new liner studs in head, new suction flange and gasket, new 2” steel discharge flange Price: $13,500

4 x 5 GARDNER DENVER PISTON MUD PUMP(Ref#7097Rb) bull wheel or can be connected to hydraulic motor, 75% condition, needs some work Price: $5,500

GARDNER DENVER 5 X 6 HYDRAULICALLY DRIVEN MUD PUMP(Ref#2505T) approx. 2500 hours, unmounted, (taken off a rig), fluid ends have not been rebuilt POR

GARDNER DENVER PE5U 4X5 TRIPLEX MUD PUMP(Ref#11077c) powered by Cat 3306 diesel engine, Eaton 5-speed transmission, manifold, enclosed building Price: $72,500

GARDNER DENVER PE5 TRIPLEX MUD PUMP(Ref#4692Ta) Detroit 6V71 engine, electric start, radiator, 2” Shear relief valve, Spicer manual transmission, skidded Price: $25,000

GARDNER DENVER TEE PUMP(Ref#1654T) Manufactured 1998, 1602 hours, 4" plungers with hydraulic charge pump, Detroit Series 50 (rebuilt), 5 speed, Skid mounted with fuel tank, Rebuilt expendables with seals, valves, seats, packings and gaskets. Price: $72,500

GARDNER DENVER TEE MUD PUMP(Ref#6440T) New, unused, manufactured 2014, 4 available, bare pumps Price: $39,500 each New Cat C7 engines available at additional cost

GARDNER DENVER TEE 4 X 5 TRIPLEX MUD PUMP **NEW**(Ref#9115R) 4” piston and liners, well servicing valve and seats, bare pump, extras a extra cost, 2 available (1 plunger and 1 piston) Price bare pump: $64,000

(1) NATIONAL C250 DUPLEX MUD PUMP7-1/4 x 15”, New fluid end parts, bolt on valve cover, Rebuilt gear end, Pulsation dampener, new Cat C15 diesel or 12V71 diesel engine, Electric start, Controls, gauges, safety shut off, Master skid Price with Cat engine: $135,000 Price with Detroit engine: $120,000

GARDNER DENVER FXK 7 1/4 x 14” DUPLEX MUD PUMP New fluid end part, Rebuilt gear end, Detroit 12V71 diesel engine, Electric starter, Controls, gauges, Safety shut off Price:$80,000

(2) NATIONAL C-150 DUPLEX MUD PUMP 6 ¾ x 12” 250 gpm / 550 PSI, New fluid end part, Rebuilt gear end, Pulsation dampener, Detroit diesel engine, Electric start, Controls, safety shut down, Master skid Price:$80,000 6 weeks delivery

7” x 12” WHEATLEY DUPLEX MUD PUMP (rebuilt), Model 27-12, powered by rebuilt 671 Detroit diesel engine, rebuilt gear end and fluid end, with all new fluid end parts, hand clutch, pulsation dampener, rod lubricating gland, pressure gauge, pressure relief valve, belt drive, belt guard, fuel tank, battery start, mounted on oilfield skid, cleaned and painted, guaranteed for 6 months, delivery 12 weeks after order Price: $42,000 Delivery 12 weeks

CENTERLINE 7-1/2 X 10 MUD PUMP(Ref#14556Tb) high pressure, no engine, needs retaining liner cage and (1) side suction manifold needs replacing, unmounted Price: $39,500

WHEATLEY 5 X 10 MUD PUMP AND KING SWIVEL(Ref#1557Nm) 20 bbl tank, mounted on gooseneck double axle dual tires trailer, 1995 International single axle tractor, hoses, hydraulic valves and hoses Price: $95,000

CONTINENTAL EMSCO D500 DUPLEX MUD PUMP(Ref#5074Tb) Trailer mounted, Detroit Series 60 diesel engine 14L, 40’ tandem axle trailer with hydraulic leveling jacks, currently working Price: $87,500

EMSCO D500 DUPLEX MUD PUMP(Ref#6329T) 16” stroke, 500 hp, ductile iron fluid end, Cat D353 diesel engine with radiator, 640 hp, 1300 rpm, inline 6 cylinder, 4 stroke, 6-1/4” bore x 8” stroke, (1473 in3) displacement, turbo charged (air to air aftercooled) aspiration, capable of 268 gpm @ 2720 psi with 4-3/4” pistons or 751 gpm @ 970 psi with 7-1/2” pistons. Price: $37,500

EMSCO D500 DUPLEX MUD PUMP(Ref#6118Rh) Emsco D500 duplex mud pump with steel fluid end, Hydril K-20-3000 pulsation dampener, belt driv with Cat D379 diesel engine, air starter, radiator, air clutch, mounted in 12’ x 29’L mud pump house with parts bin, controls Price on Request

EMSCO D500 DUPLEX PUMPS(Ref#8722R) Two available, Cat 3406C diesel engine, Cotta gear box, mounted in enclosed building 11’6” x 30’ Price: $70,000

EMSCO D500 4-3/4 – 7-1/2” X 16” DUPLEX MUD PUMP(Ref#8312Tc) 500 hp, Mounted on skid with Cat D353 engine, capable of 268 gpm @ 2720 psi with 4-3/4” pistons or 751 gpm @ 970 psi with 7-1/2” pistons, sold as is Price: $27,500

EMSCO D500 4-3/4 – 7-1/2” X 16” DUPLEX MUD PUMP(Ref#83

8613371530291

8613371530291