mobile mud pump repair in stock

Explore a wide variety of mobile mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mobile mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mobile mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mobile mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mobile mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

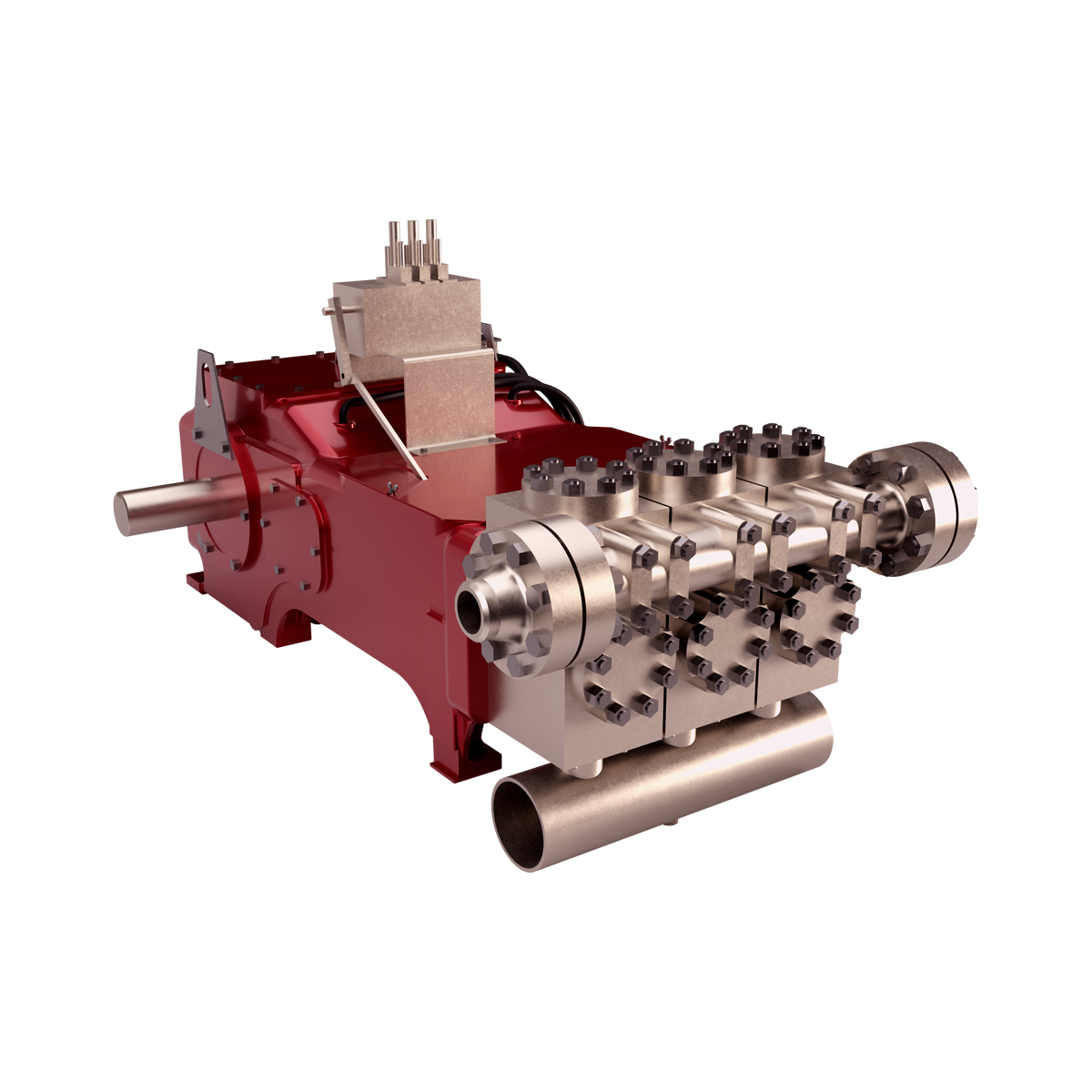

Repairing your pumps quickly and efficiently to get your operations back up and running is GD Energy Products’ top priority. If your pump requires immediate attention, our field engineers and service technicians can be deployed to your job site or facility. Our experienced technicians are trained to identify and inspect your pumping issue and conduct as-needed service, repairs and preventative maintenance at your preferred location.

GDEP offers a full range of 24/7 on-site pump maintenance and repair offerings tailored to your individual needs. We offer comprehensive repairs for fracking pumps, drilling pumps, well service pumps, fluid ends and modules. Additionally, our customers have access to 24/7 service, ongoing parts support and product maintenance.

GDEP’s inspection program offers a comprehensive and proactive approach to solving your pump issues. Our field service technicians can utilize advanced troubleshooting procedures to uncover various underlining issues with the capability of performing onsite repairs using genuine, high-quality OEM replacement parts to guarantee maximum performance

If you have a large fleet or pumps that simply require more attention, we can provide you with a dedicated field service technician with either half-day or full 24/7 coverage.

Our state-of-the-art repair facilities operate in a constant state of readiness to provide your pumps with the most comprehensive and cutting-edge repair and maintenance services. With facilities strategically located in all major shale plays throughout the United States, we are able to provide our customers with efficient service on a local level.

If you have a large-scale repair that cannot be completed in the field, bring your pump to any one of our repair facilities and expect the same level of service and expertise. A highly trained and experienced team of field engineers, service technicians and repair mechanics possess all the necessary skills and insights required to overhaul any pump, all under one roof. Backed by our satisfaction guarantee, you can have the confidence your pumps will operate at peak performance after it leaves our facility.

Our dedicated customer support team ensures the whole process is transparent and efficient, from the initial call and throughout the entire repair process.

Our team of experts is available 24/7 to service and repair any brand of pump. Whatever your repair needs, GDEP will bring the proper experience, tools and equipment needed to get the job done.

If your Ampco Pump is experiencing issues or is not operating and outputting the way its designed to please feel free to give our Repair Coordinators a call here National Gear Repair by calling (909) 460-0101. National Gear Repair is a comprehensive remanufacturing center specializing in the repair and remanufacturing industrial machinery such as Industrial Gearboxes and Pumps. We have been working with many industries throughout the continental US and Canada including the pharmaceutical industry, the chemical industries and food and beverage industries. National Gear Repair Technicians Are Timken Bearing CErtified and Falk School Trained meaning we dont just change out bearings and seals here we install them via utilizing a liquid nitrogen solution to shrink the shafts allowing us to place a super heated bearing into place, locking it via gravity and thermal expansion.

National Gear Repair Technicians are the best choice for Ampco Pump Repair due to our expertise and experience working with SS316L and Alloy Materials as well as all types of centrifugal pumps, gravity fed pumps, industrial pumps and more.We maintain a large inventory of critical spare parts for Ampco Pumps assuring that we do everything we can to finish your Industrial Pump Repair as fast as possible without reducing the quality and care for the repair process.

Once we receive your Ampco Pump We begin the inspection process by taking apart the pump and placing it in an industrial parts washer to remove all the grime and gunk too allow us to see the faults in the pumps. We then send out a quote and once the repair is approved we begin by repairing any damage to the housing and replacing and repairing all bearing and seal areas before replacing all internal gearing and components. National Gear Repair has the ability to Manufacture all internal components for all Ampco Pumps.

National Gear Repair offers 24 Hour Emergency Rush Repair Services due in part to our large critical stock of all Ampco Pump Inventory as well as our ability to manufacture internal components on site. This premium service is utilized by our larger clients and smaller clients as well who cant afford to wait even 5 days for a standard Ampco Pump Repair and as such we have their pump repaired and delivered within 24 to 48 hours.

Once we repair all damage and rebuild your pump with new bearings and seal areas as well as new components we then place your pump on a test bench for 15 minutes to perform a load test to check overheating, vibration and proper vacuum for no air leaks. Once your Ampco Pump Passes this test it is certified with out 24 Month Warranty Which goes into effect when you put the pump into production.

National Gear Repair specializes in the repair and remanufacturing of all industrial equipment. We offer free freight and free quotes nationwide and a 24 month warranty for all Ampco Pumps. If your Ampco Pump is having issues do not hesitate to call us now to speak with a repair coordinator or email me directly at Tony@NationalGearRepair.com

National Gear Repair has been repairing Gardner Denver Pumps for decades and as such we consider ourselves experts on Gardner Denver Pump Repair and Ingersoll Rand Pump Repair. If you call our Vacuum Pump Repair Coordinators Directly By Calling (909) 460-0101 you will be connected with a Repair Coordinator who has years of experience working with Gardner Denver Vacuum Pumps. All National Gear Repair Pump Repair Coordinators have experience working as mechanics and technicians for National Gear Repair in the Past often times we can diagnose the fault in your pump before we actually get it in our shop. We always recommend that you let us pick up the pump for a free quote as National Gear Repair offers Free Freight and Free Quotes Nationwide.

All National Gear Repair Technicians are Timken Bearing Certified and Falk School trained. We don’t just change out bearings and seals here at National Gear Repair we don’t install bearings with press instead we prefer to shrink the shafts with liquid nitrogen and then place super heated bearings allowing gravity to do the work for us and locking in with thermal expansion and physics.

National Gear Repair has Gardner Denver Critical Spare Parts and Components in stock at all times to ensure our repair lead times are the shortest in the industry (something we pride ourselves on). We also offer 24 Hour Emergency Rush Repair for your Gardner Denver Pump. We have the ability to Manufacture all gearing and critical components allowing us to keep lead times down and if needed for emergency rush repair we can have gears set to the exact same rockwell and brinell hardness as the OEMS.

Once your Pump Repair is complete we mount the pump on a custom test bench inside of our Quality Assurance Department to run a 6 hour test on a low load to test for vibrations, overheating, Seal leaking or other abnormalities. Once your Gardner Denver Pump has passed it is then certified with our 24 Month Warranty which goes into effect the day you put the pump into production. If it sits in your facility for a year and then you chose to install it the 2 year warranty starts Right There.

If your Gardner Denver Pump is in need of repair Call now At (909) 460-0101 to be connected to a Gardner Denver Pump Repair Specialist. If you have any questions regarding our emergency rush repair service Email Me Directly at Tony@NationalGearRepair.com

National Gear Repair offers Free Freight and Free Quotes Nationwide as well as a 24 Month Warranty. We Also offer 24 Hour Emergency Rush Repair Service.

All CategoriesAir compressors (2)Air compressor (1)Screw air (1)Attachments (2)Bucket (1)Screen (1)Backhoes (1)Excavators (1)Compactors (2)Compactor (1)Roller (1)Drill Rigs (1)Drilling (20)Brakes (1)Cat walk (1)Drilling Rig (1)Equipment (5)Mud Mixing Tank (3)Mud Pits (2)Pipe wrangler (1)Pumps (3)Solids separation (3)Electrical Equipment (4)Circuit Breaker (1)Cutler Hammer (1)Eaton (1)Switchgear (1)Engines (22)Cores (2)Diesel (5)Drilling (2)Drilling Rig (1)Engine (5)Equipment (2)Natural Gas (2)Oilfield (1)Pump drive (1)Pumps (1)Generators (13)Cat (2)Diesel (5)Generator (5)John Deere (1)Heaters (3)Air heater (1)Blower (1)Indirect fired heater (1)Iron (2)Pipe (1)Sucker Rod (1)Man Camps (3)Man Camp (2)Rig House (1)Mud Pumps (24)1000hp (4)Cat (1)Diesel (2)Emsco (3)Engine (1)Mud pump (7)Pump (6)Natural Gas Compression (10)Compressor Station (3)Engine (1)Frick (2)Natural Gas (3)Waukesha (1)Oil Field (4)Bathroom (1)Shipping container (1)Support Equipment (1)Tanks (1)Production (3)Injection (1)Pump (1)Pumping Unit (1)Road Graders (3)Blade (1)Road Grader (1)Service Trucks (1)Service Truck (1)Silos (2)Sand silos (1)Tanks (1)Support Equipment (17)Accumulator (4)Closing Unit (3)Drilling Rig (2)HPU (1)Koomey (3)Mud pump (1)Oilfield (1)Power Swivel (1)Tanks (1)Trailer (4)Flatbed (1)Gooseneck (1)Step deck (1)Trailer (1)Trucks (1)Water Truck (1)Valves (82)

1. BW-160/10 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1000 meter.

2. BW-160/10 mud pump is a horizontal, triplex, single acting reciprocation piston pump. It is function is to supply the drilling hole with flushing liquor in order to carry bit. It is used matching drill rigs. It is applied to geological and engineering prospecting such as the railway, the water conservancy, the met-allurgy, the build and the geology etc industry whose hole deep is within 1000m. Also it can be used to deliver water to high mountains or in the execution domain of middle and low pressure grouting and non excavating matching. This pump ha advantages such as small cubage, light mass, long life, simple operation and reliable per-formance, etc

A: Normally mud pump products will take about 3-15 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 15 days.

8613371530291

8613371530291