mud pump components manufacturer

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

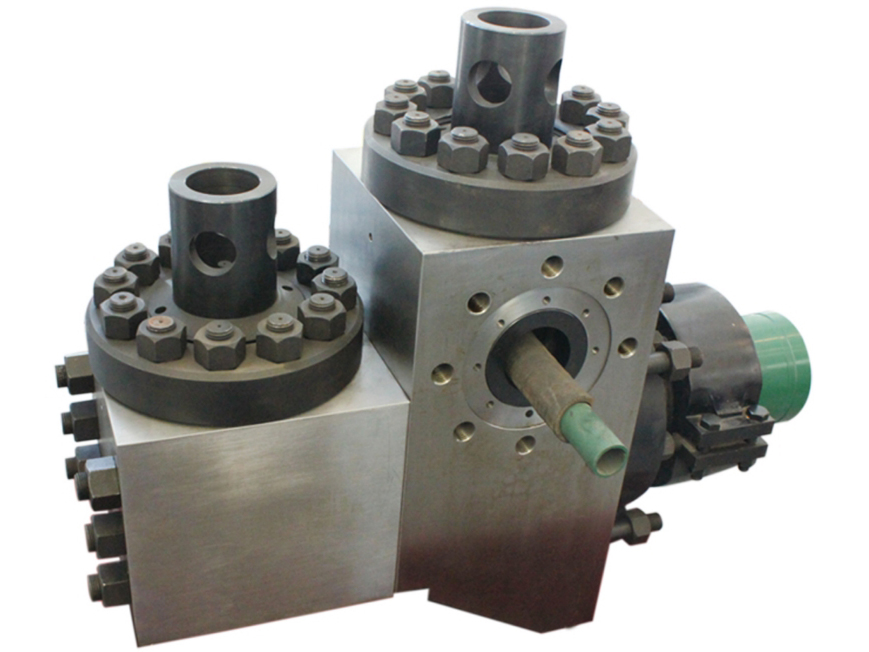

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

American Mfg Company is a quality manufacturer of replacement parts for the wide variety of mud pumps, centrifugal pumps, rig parts, and swivel parts found on the World market today.

American Mfg Company Pumps And Parts carry over $5,000,000 of interchangeable mud pumps parts, centrifugal pump parts, rig parts and swivel parts in stock for all major manufacturers such as Gardner Denver, Failing, Wheatley, National, Emsco, Ideco and Opi, as well as OE AM pumps.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Fluid End Module As an important component on the fluid end of mud pump, our Rundong value module is made premium 8620 or 4135 alloy steel with forging, normalizing, rough machining and then quenching and tempering processes. In this way, the interior of the fluid end module will have hardness in the range of HB285 to HB330.

Pump Liner Rundong’s mono-metal liner has its inner bore quenched with the carburized layer thickness as 1.5 to 1.8mm to achieve hardness of 58 to 60 HRC. The liner features high hardness, great corrosion resistance, no deformation and high surface finish.

Piston Assembly Piston is one of the wear parts consumed the most in mud pump for drilling system. Rundong manufactures pistons of various specifications, which can be applied on different drilling pumps, such as F series, 3NB series, P series, PZ series and UNB series.

Piston Rod Our company provides piston rods and extension rods for different mud pumps including F series, 3NB series, QZ series, PZ series, P series, etc.

Pulsation Dampener Rundong provides discharge pulsation dampener assembly, discharge pulsation dampener capsule and suction pulsation dampener capsule and related accessories, which all could be applied on different types of mud pumps such as F series, PZ series and P series, etc.

Safety Valve Our shear safety valve is able to ensure normal operation of the mud pump in conditions with working pressure less than rated value. It comes in flange type and thread type. It features great flexibility in toggling on and off, small pressure-bearing area of the piston attached, easy resetting, good compatibility with most types of mud pumps.

Flanges and Cylinder Parts Rundong provides different flanges and cylinder parts, which include cylinder head, cylinder liner, valve cover, cylinder head flange and cylinder liner flange, etc. Those parts could be applied on various mud pumps, such as F series, 3NB series, PZ series and P series.

Rubber Pump Parts Rundong provides varieties of rubber pump parts including piston rubber cup, valve rubber, seal ring, O-ring, gasket, etc. These rubber parts could be applied on different mud pumps, such as F series, 3NB series, PZ series and P series.

Crosshead and Parts Rundong manufactures crossheads, crosshead pins and crosshead slides for different mud pumps including F series, 3NB series, PZ series and P series. Our crosshead pins are made of premium structural alloy steel through one-piece forging process, while crossheads and crosshead slides are made...

Other Mud Pump Parts Rundong offers drilling rig mud pumps and pump components. There are wide ranges of mud pump parts like bearings, manifolds, cross fittings, pump housings, clamps and others.

8613371530291

8613371530291