mud pump fluid end parts made in china

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

Production and quality inspection are separated, different process have different people to responsible, inspection methods are advanced, and have high-end inspection laboratories and detectors.

F500、F800 、F1000、F1300、 F1600、F-1600HL 、F-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

HHF-1300、HHF-1600 、HH3NB-1600H、HH3NB-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

7P-50、8P-80、9P-100、10P-130、12P-160、14P-220Hydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

PZ-7、 PZ-8、 PZ-9 、PZ-10、PZ-11Hydraulic end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

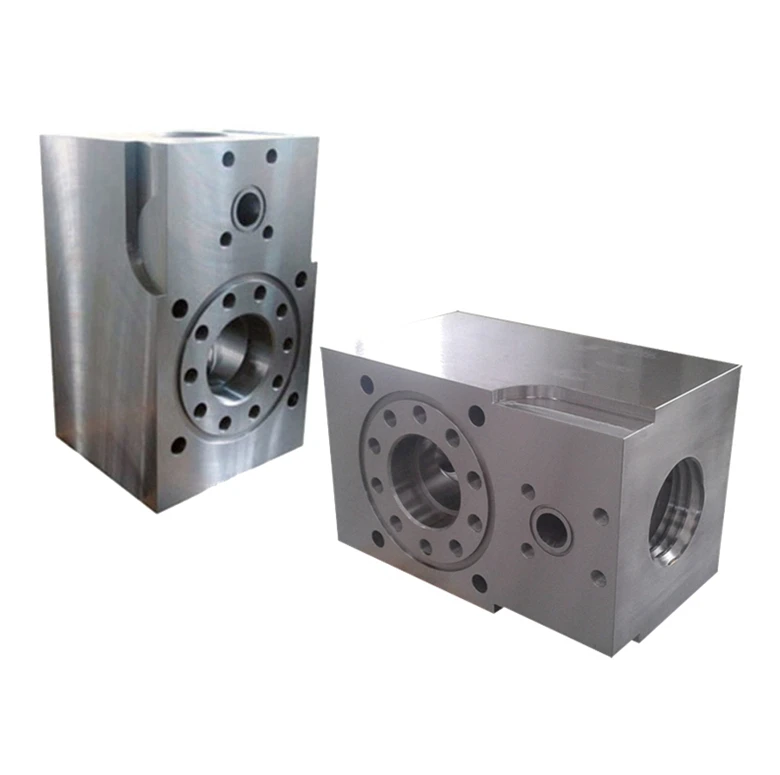

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

8613371530291

8613371530291