mud pump parts pdf pricelist

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Headquartered in Mansfield, Ohio, Pumper Parts is a global supplier of quality replacement parts that fit Wilden®, ARO®, and Yamada® air-operated double diaphragm pumps. The company was formed to meet the demands for faster delivery of replacement parts at competitive prices.

Pumper Parts serves customers all over the world in a variety of markets, including chemical, paints & coatings, food processing, pharmaceutical, construction, mining, utilities, pulp & paper, metal finishing, and general industrial. A worldwide network of fully-stocked distributors and an extensive staff of qualified professionals are committed to supporting these customers. Pumper Parts is housed in a state-of-the-art facility to ensure that proper stock levels are maintained.

This mud pump will deliver the consistent flow of drilling fluid that is vital to HDD pipeline drilling projects. Suction inlet valve suspends charged flow during drill rod makeup and breakout process, keeping excess drilling fluid from escaping as drill pipes separate. The lubrication pump is driven off the auxiliary pad on the engine. It provides 55 psi (3.8 bar) of continuous crankshaft lubrication. The internal hydraulic reservoir has a capacity of 49 gal (185.5 L). Clutch with continuous duty throw-out bearing allows for longer pump disengagement during drill rod makeup/breakout....

A triplex piston pump produces up to 435.3 gpm (1647.8 L/min), providing a continuous flow of drilling fluid during drill operations. An electric centrifugal pump provides constant flow, keeping the pump running cool and leading to a longer life for both pistons and liners. Remote pendant control allows operator to mount controls where it makes sense for them. The remote pendant control monitors mud rate and eliminates the need for stroke counter. The integrated liner wash tank eliminates the need for additional water containers or electricity when running the pump. An engine-mounted air...

14-P-220 Triplex Mud Pump Specifications LINER SIZE (INCHES) 9 8 7½ 7 6½ 6 5½ 5 MAX DISCH. PRESSURE, PSI OF 14-P-220 WITH HIGH PRESSURE FLUID END 2795 3535 4025 4615 5360 6285 7475 7500 SPEED (SPM) INPUT (HP) **HYD (HP) GALLONS PER MINUTE *105 *2200 1980 1215 960 843 735 633 540 454 375 80 1676 1509 925 731 643 560 483 411 346 286 60 1257 1131 694 548 482 420 362 308 259 214 40 838 754 462 366 321 280 241 206 173 143 VOLUME/STROKE (GALLONS) 11.57 9.14 8.03 7 6.03 5.14 4.32 3.57

10000 Richmond AvenueHouston, Texas 77042 NATIONAL OILWELL VARCOUnited StatesPhone: 713 346 7500Fax: 713 435 219514-P-220 Triplex Mud Pump

Small foot print with high horse power to weight ratio. Bearings and gearing designed for a minimum L10 life of 30,000 hours at rated load. Rigid, fabricated oilfield style frame and skid that will provide a stable platform for the pump operation. Fabricated crank shaft with a forged core to minimize vibration and insure longevity. High strength steel used in all drive components. Cast cross heads and guides to maximize longevity. 1HP – 230/460 VAC - 3 Ph lubrication pump 1HP – 230/460 VAC - 3 Ph liner wash pump One 5 gallon pulsation dampener with strainer cross. Index able gear assembly that can be mounted on ether side. Pressure relief valve. Pressure gauge. PAH compatible fluid end

Options Charge pump. Custom skids. Motor starter(s) in explosion proof enclosure Mechanically driven lubrication / liner wash pumps Dual lubrication pumps Dual liner wash pumps Custom unitization

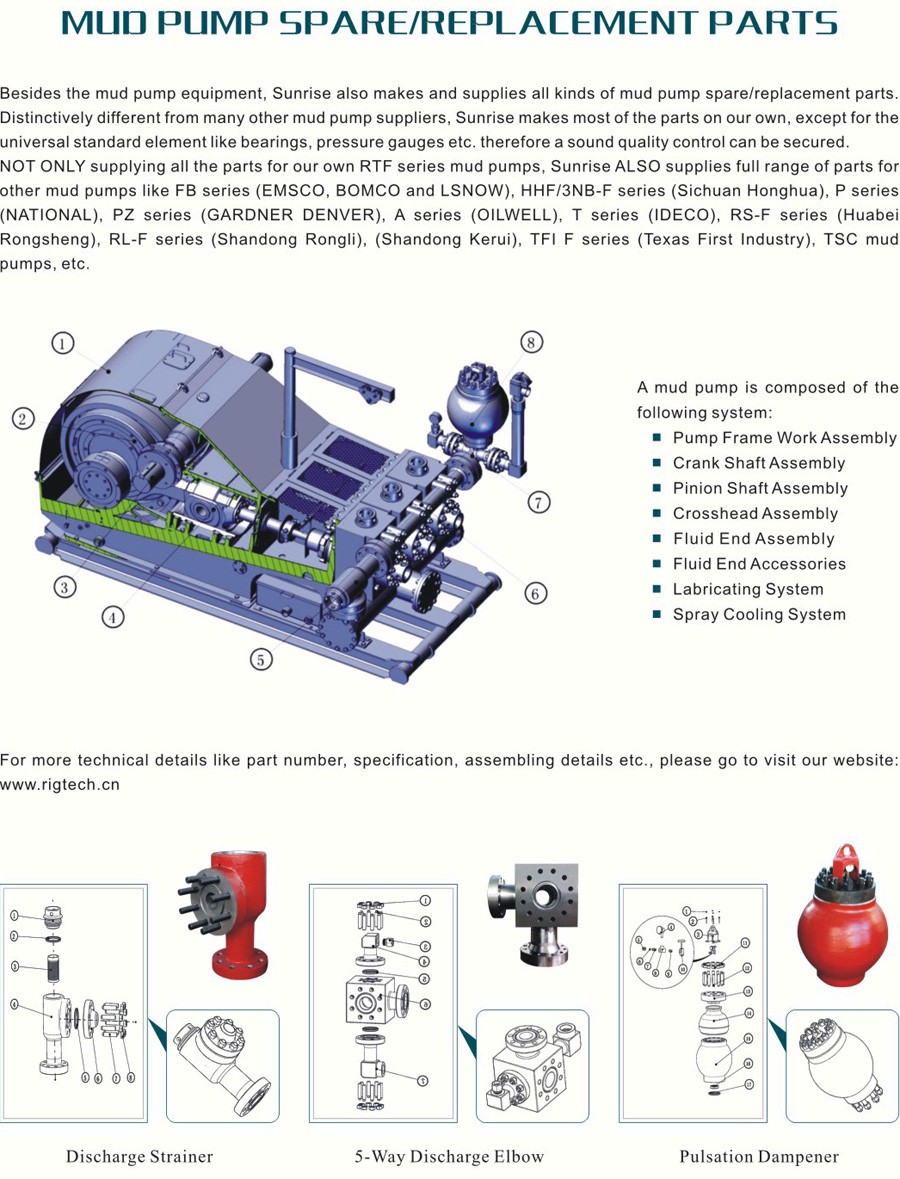

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

8613371530291

8613371530291