mud pump valve seat manufacturer

Customers said they wanted long-lasting, easy-to-use valves and seats, and we delivered. Made from domestically sourced steel, GD Energy Products valves feature a two-piece friction-welded design, proprietary bonded inserts, and innovative geometry to deliver significantly longer life. GD Energy Products’ field proven Valves & Seats meet API Standard, and come with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

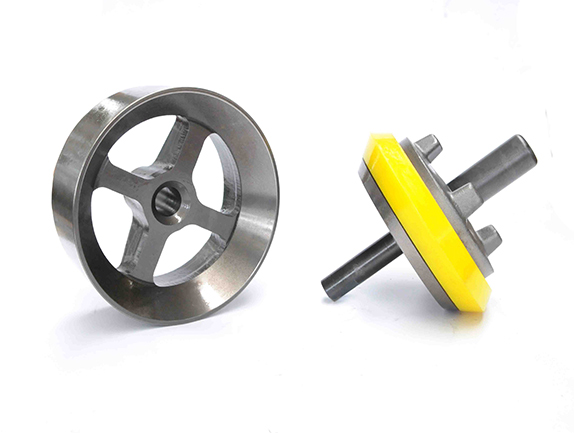

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

Alibaba.com offers pump valve, and a variety of different sizes to meet the needs of different customers. If it iss to the type of mud pump seat, it is possible to choose from a set of mud pump seals with alternate patterns, designs, and colors. On the other hand, the pivoted seat is the enduro, and the enduro has a wide range of sizes. If inflated mud pumps are not classified by one type or the other as a part of the body, it is important to consider the size of the seat and will be based on the type of mud pump seat. For a set of the two or less sizes, it is important to find the right type of mud pump seals on Alibaba.com, or known as " mud" seal, and all come in a variety of colors, and designs. Among the most popular mud pump valve seat choices are available based on the type of mud pump.

There are also semi-trush mud pump seats, including electric pump seats, and semi-trush mud pump seats so that airflow can be found on the surface. There are many choices of mud pump seats, including electric pump seats, and semi-trash mud pump seats.

The Patriot Harsh Duty Valve is a bonded urethane valve that will hold up in the most extreme drilling environment. The Patriot HD offers the strongest urethane bond of any valve for increased service life and a stronger seal.

Superior Performance, Long Run Life, Excellent Abrasion Resistance and Sealing Surface coupled with the highest rated chemically resistant urethane make the Patriot HD Valve an excellent choice for any drilling application.

Various sizes are available to fit all major mud pumps. An extensive range of valves and seats are offered,such as Premium Cross-Arms Valve and Seat,Three-arm Valve and Seat,Three-wing Valve,Four-wing Valve,Full-open Seat,Long-life Bonded Valve with Urethane.Wide choices are available for requirements not met by hardened or stainless steel valves and elastomer- valve seats.

The Caliber® 4-web valve and seat are designed for today’s high pressure drilling conditions. Each piece is forged from a single piece of proprietary, high-strength alloy steel and is case hardened to precisely controlled levels. We have molded our high temperature, high impact resistant urethane to the valve body in order to eliminate the existing gap you will find on replaceable insert type valves.

The 4-web design holds the valve weight to a minimum by increasing the load bearing area. In order to allow quick flushing of solid matter we use a steep angle that also increases the metal-to-metal sealing area. Each part is individually inspected to ensure performance and satisfaction.

We manufacture mud pump fluid end parts ,such as fluid end module,liner,piston,piston rod,valve body,valve seat,etc.API standard.Welcome to send any inquiry to my mail mudpumppa...

Valve seat extruder also called “Valve Seat Puller” is a service tool, which is used in the drilling sites for pulling the installed valve seats from mud pump fluid end module. During the process of replacing the valves seat and maintaining the mud pumps, this tool will be more effective to finish the maintance work with fewer manpower and shorter time.

The puller assembly can exert a force of over 200,000 lb on the valve seats. The complete comes with a hose so that the hand operated hydraulic pump can be placed at a safe distance from the mud pump during pulling operations. The hose, puller assembly, and pump are equipped with quick disconnect couplings for easy handling. The pump comes complete with a pressure gauge. The numerically controlled machined and heat treated puller head of high alloy steel offer maximum strength without the stress concentration characteristic of torch burned heads. The components are made from high quality cast steel for impact and wear resistance.

Also known as Nova Tech Valve or Roughneck Valve or High Pressure Valve. Full open Seat & wing guided Valve design features a large metal-to-metal bearing area for long life, directly casted urethane insert on valve body results in a perfect round shape that prevents premature failures of the insert. The insert is casted around the serrations, thus failure due to tears from the serrations are eliminated Most importantly the insert is not stretched over the valve during installation; there are no residual stresses left, to shorten insert life.

8613371530291

8613371530291